ELIMINATE Metal CASTING DEFECTS & BOOST YIELDS WITH PRECISION Industrial CERAMIC FILTER Manufacturer

Intercept 10-50μm molten metal inclusions, optimize metal flow, improve casting quality, and slash production costs with our advanced ceramic foam filters. Solutions for iron, aluminum, copper, and steel metal casting. Inquire now to customize solutions for your unique needs.

Industrial Filter Types for Global supplier

FM-01 Silicon Carbide Filter

Filters for Iron Castings: Made of high-purity silicon carbide fine powder as raw material, it can withstand high temperatures up to 1500℃. It is used to filter and purify ductile iron, gray cast iron, vermicular cast iron and some alloy cast iron and non-ferrous alloys such as copper and cast aluminum.

FM-03 Zirconia Filter

Filters for Steel Castings: This porous ceramic product is made of imported stabilized zirconium oxide, which has extremely high thermal stability and can withstand high temperatures up to 1700°C. Therefore, it is particularly suitable for filtering precision castings of high melting point metals such as carbon steel, low alloy steel, and stainless steel.

FM-04 Alumina Filter

Filters for Aluminum Castings: Filter micron-level inclusions in aluminum liquid, making the aluminum liquid flow smoothly, which is conducive to filling the mold, improving the quality and yield rate of aluminum alloy castings, and is widely used in the production of aluminum alloy castings such as automobiles, aerospace, etc.

FM-10 Copper Filter

The porous ceramic filter is specially designed for copper and copper alloy casting. It has excellent thermal conductivity and affinity with copper melt, and can effectively remove impurities in copper melt without affecting the alloy composition. Widely used in the production of precision copper castings and electrical components.

FM-05 Alumina Filters

Made of high-purity alumina ceramic material, it can effectively remove non-metallic inclusions in aluminum melts. It is widely used in aluminum casting workshops such as aluminum ingots, aluminum bars, aluminum plates, aluminum strips, aluminum foils, and aluminum materials. It is used in conjunction with the filter box system to achieve continuous production.

FM-06 Ceramic Honeycomb

The honeycomb structure straight channel filter has stable size and shape. It is made of cordierite and mullite refractory materials. The precision mold molding brings strong product consistency and quality stability. The refractory ceramic filter is mainly used in gray iron, ductile iron, aluminum alloy, etc. It has strong adhesion to impurities in molten iron.

FM-08 Magnesia Filter

The high-performance filtration device is specially designed for the purification of magnesium alloy melts. It is made of high-purity magnesium oxide powder (MgO ≥ 95%). Through its unique three-dimensional mesh porous structure, it can effectively intercept oxides, slag, and non-metallic inclusions in the magnesium melt.

FM-07 Fiberglass Mesh Filter

Made of high-silica glass fiber cloth with SiO₂ content ≥96% and treated with a refractory coating. It is mainly used for the filtration and purification of molten iron, molten aluminum, molten steel, and copper solutions. We can design and meet the overall filtration solutions and series of fiber glass filter products.

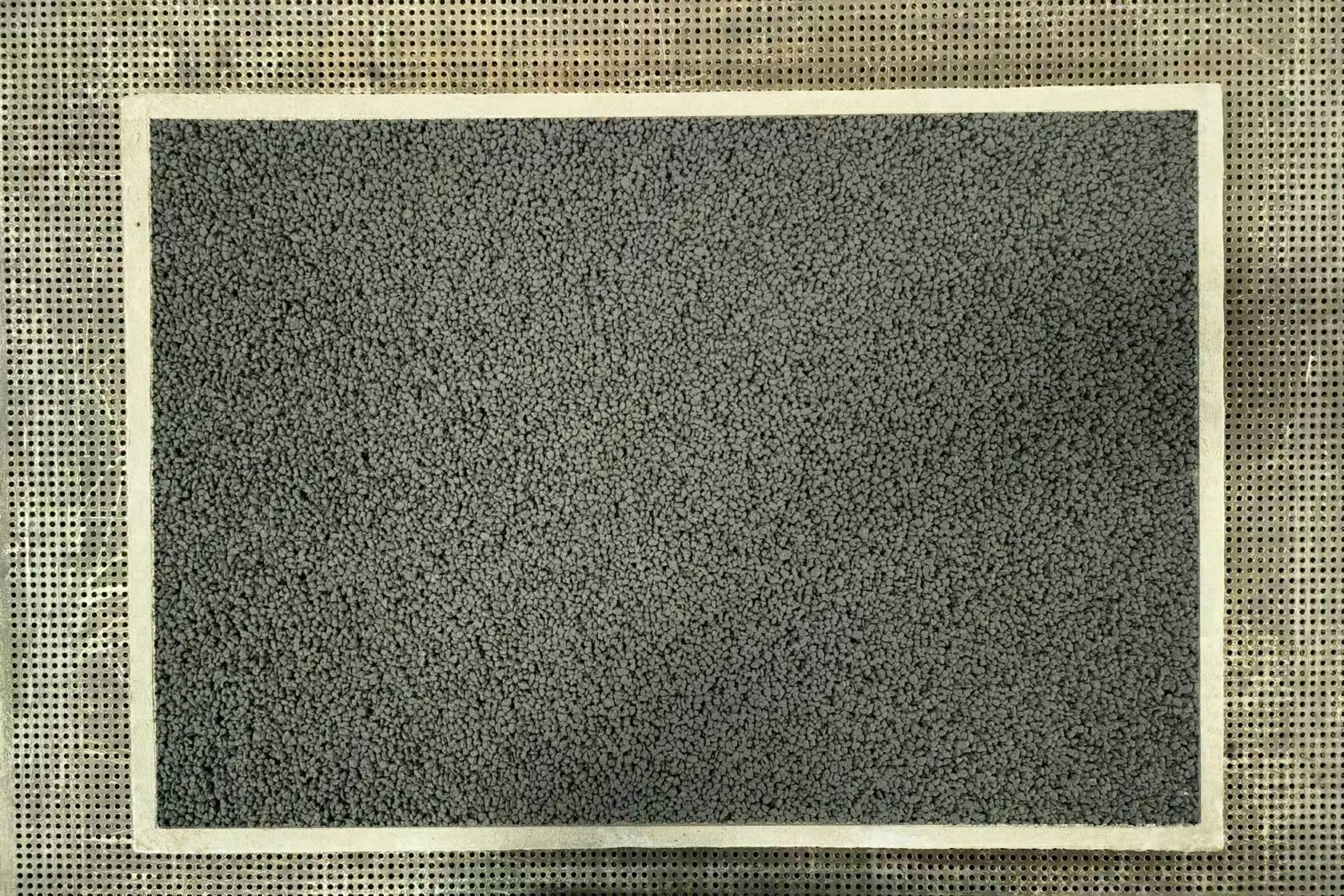

FM-09 SIC Filters

Using high-purity silicon carbide particles as raw materials, it has excellent strength, chemical stability and long service life. It is a high-temperature metal filtration solution designed for aluminum and aluminum alloy casting processes, suitable for gravity casting, die casting, squeeze casting and sand casting.

Whether you’re in manufacturing automotive, aerospace, wind power, or custom production, we have the right industrial filter solutions tailored for your needs.

Casting Processes

Filter Application: Foundry Industry

Industrial filters for foundry are widely used in various casting processes due to their excellent high-temperature resistance, filtering effect, and strong adaptability, especially in the production of castings with high precision and high-quality requirements.

Sand Casting

In the pouring system of sand casting, ceramic filters and mesh filters are often used, placed in the sprue or cross runner position, to filter non-metallic inclusions in the molten metal.

Lost Foam Casting

Ceramic filters can be used in the pouring system of lost foam casting to prevent the residues produced by the gasification of the foam model from entering the casting.

Investment Casting

In investment casting, foundry filters are usually installed at the front end of the pouring cup or the pouring system for metal liquid purification of high-precision castings.

Gravity Casting

In metal mold casting, the porous ceramic filter can be installed in the gate or runner, suitable for the casting of aluminum alloys, copper alloys, etc.

Centrifugal Casting

In the centrifugal casting process, ceramic filters can be used to purify the molten metal before entering the mold to reduce the impact of impurities on the casting.

Die Casting

Although high-pressure casting process usually adopts high-speed filling, foam ceramic filters can still be used for metal liquid pretreatment in some special cases.

Leading Filter Manufacturer

In automotive and aerospace industries, even tiny casting flaws can cause major problems—weak parts, porosity defects, and costly reputation damage. As a leading industrial filter manufacturer, FoundryMax provide reliable filtration solutions trusted by top foundries worldwide. Their strict quality control ensures every filter performs flawlessly, helping customers achieve “zero-defect casting.”

Trusted Expertise

A top ceramic filter manufacturer with ISO 9001:2015 certification, serving elite foundries in 35 countries.

Strict Quality Control

Every filter manufacturing process—material selection, sintering, pore sizing, and testing—is optimized for reliability.

Guaranteed Performance

Filters work consistently in harsh conditions, delivering clean, defect-free castings.

Years of Expertise

Annual Output

Patents

- More than 1 billion ceramic filters have been produced since founding

- Serving more than 1,200 casting foundries in 35 countries around the world

- Complete 5 generations of product iterations and upgrades

- Establish a full-process quality traceability system

- Fully automated production lines

- Daily production capacity of more than 200,000 pieces

- Mature flexible production system

- Equipped with imported testing equipment, 100% full inspection to ensure zero defects before leaving the factory

Our engineering team has achieved breakthroughs in filter technology by targeting the core pain points of the foundry industry:

- Revolutionary innovation in production process

- Breakthrough control of dimensional accuracy

- Continuous leadership in new product development

Our Services

Pre-Sales

Precision Filtration Starts with Deep Casting Analysis

Alloy-Specific Filter Optimization

Controlled Porosity for Optimized Filtration

Seamless Integration with Your Gating System

Data-Driven Iterative Filter Design

Complex Geometries for Optimized Casting

In-Sales

Reliable and Efficient Delivery

Quality Control Throughout Entire Production Process

Stable Foundry Filter Delivery Time

Cost-Effective Logistics Solutions

Proactive Shipping Notifications

Multi-layer Protective Packaging Prevents Damage

After-Sales

12-Hour Fast Response and Detailed Technical Support

Our engineering team will answer your questions about foundry filters within 12 hours. We promise to provide an initial solution within 2 hours of receiving customer feedback and detailed technical support within 12 hours.

Proactive Follow-up on Filter Usage

We track filter usage and provide improvement solutions based on your questions to ensure that the filtration effect continues to meet your casting production needs. We conduct customer return visits every quarter to promptly understand customer needs and potential problems.

Professional Technical Guidance

For problems and difficulties encountered during the use of industrial filters, we can provide customers with comprehensive technical service support, including on-site guidance, remote assistance, and video tutorials.

Guaranteed Technical Consultation

We offer consulting services for other issues encountered during the casting process. Our team of experienced casting experts can provide comprehensive technical advice and solutions, including alloy selection and process optimization.

Iterative Filtration Process Optimization

We provide customized recommendations based on your evolving production needs to continuously optimize your filtration performance. We can customize filtration solutions based on your production data and experimental results, and provide recommendations for continuous improvement.

Continuously Updated Documentation

Filters and other refractory ceramic casting material resources are updated promptly to reflect any process changes or improvements. Our online knowledge base provides the latest product information, technical documentation, and FAQs for your convenience.

Why Choose us?

We have been focusing on the export of foundry consumables for more than 20 years, and our global customers have witnessed our professionalism and quality.

Expertise and Knowledge

Decades of expertise in filtration tech & refractory casting materials. Our metallurgists average 18+ years’ casting experience, blending hands-on skills with academic rigor. We pinpoint and solve inclusion root causes, not just symptoms. Tap into knowledge from global casting successes.

Innovation and Technology Advantages

Dedicated R&D team goes beyond standard filtration products, forging ahead with top university research partnerships. Invest in cutting-edge tech+tomorrow’s breakthroughs in filtration breakthroughs, that enhance foundtry factory high eficiency!

Custom Solutions for Your Specific Needs

Tailored filtration starts by diving deep to analysize specifics and goals. We consider metal composition & quality aims, and our engineers craft solutions: ceramic formulations, filter dimensions, pore configurations & mounting tips.

Quality Assurance and Reliability

From raw material selection to final inspection, quality is infused!. Our multi-stage quality system goes beyond that, and gives 100% traceability. Validations from top automotive & aerospace firms back the high standards that we provide.

Partnership Beyond Products

Our filter support never ends from any issues. You get foundry engineers that are accessible 24/7. Our customer portal delivers tech docs with training guides. That’s why we have a 70% customer retention rate within 15 years of relationship!

Value Beyond Price

Our industrial ceramic filters may not be the cheapest, but provides low cost with high casting quality. Value that gets documented with low scrap, rework, tool life, and high metal casting quality.

Support Fast Industrial Filter Sampling for Your Casting Production Testing

R&D Capabilities

Innovation

Driving innovation in foam ceramic filtration technology

We invest 8% of our revenue each year in R&D, focusing on next-generation industrial ceramic materials and filter designs to improve casting results.

By investing in cutting-edge technologies and promoting collaboration among experts, we continue to push the boundaries of industrial ceramic filtration, provide innovative solutions, and are certified as an upgraded R&D institution and a technology-based innovative enterprise.

Collaborative Expertise

Teams of university industrial ceramic engineers and our company work together with metallurgical experts to jointly address emerging casting challenges and promote innovation in filtration technology.

Advanced Coating Technology

Using advanced coating technology to enhance metal/ceramic interaction, improve filter performance and extend service life.

Intellectual Property Portfolio

We have 8 patents covering ceramic formulas and manufacturing processes, and another 5 patents are pending for advanced industrial filtration technology.

Predictive Simulation Software

Use simulation software to predict filtration performance in specific applications to provide customized solutions and optimize casting results.

Invention Patents

Deep Experience

Country of sale

Customers

Trusted by

Top Industry Leaders

Trusted by 500+ Global Filter Distributors

With over 20 years serving in the casting industry across 50 countries, our filters process over 500,000 tons of molten metal annually for customers ranging from boutique foundries to global automotive suppliers. Our customer base ranges from boutique automotive foundries to global foundry material suppliers. Our client retention rate exceeds 70%, with an average relationship duration of 15 years. Industry recognition includes Technology-Based Enterprise, Innovative Enterprise, Quality Management System Certification, and preferred supplier status with the top five automotive manufacturers. Our expertise spans a wide range of foundry applications, from precision investment casting to high-volume automotive production, millions of dollars in annual savings for our clients. Contact us today to learn more and receive a customized solution!

SGS

ISO 9001: 2015

ISO 45001: 2018

ISO 14001: 2015

Certified Filter Manufacturer

Double Guarantee of Quality and Responsibility

Actively Implement Environmental Protection Commitments

Ensure Each Test Data is Authentic and Reliable

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China