If you’re buying industrial air filters for your building, you should ask some important questions first. This ensures you get the best air quality and protect your equipment. I’ve put together the top questions to help you choose and maintain your filters.

Why Are Industrial Air Filters Important?

industrial air filters are very important. They keep the air clean which protects both your employees and your machinery. For many factories, meeting the ISO 8573.1 Air Quality Class Guidelines is a must. From my experience, using filters that meet these standards helps you get the pure air needed for your specific work.

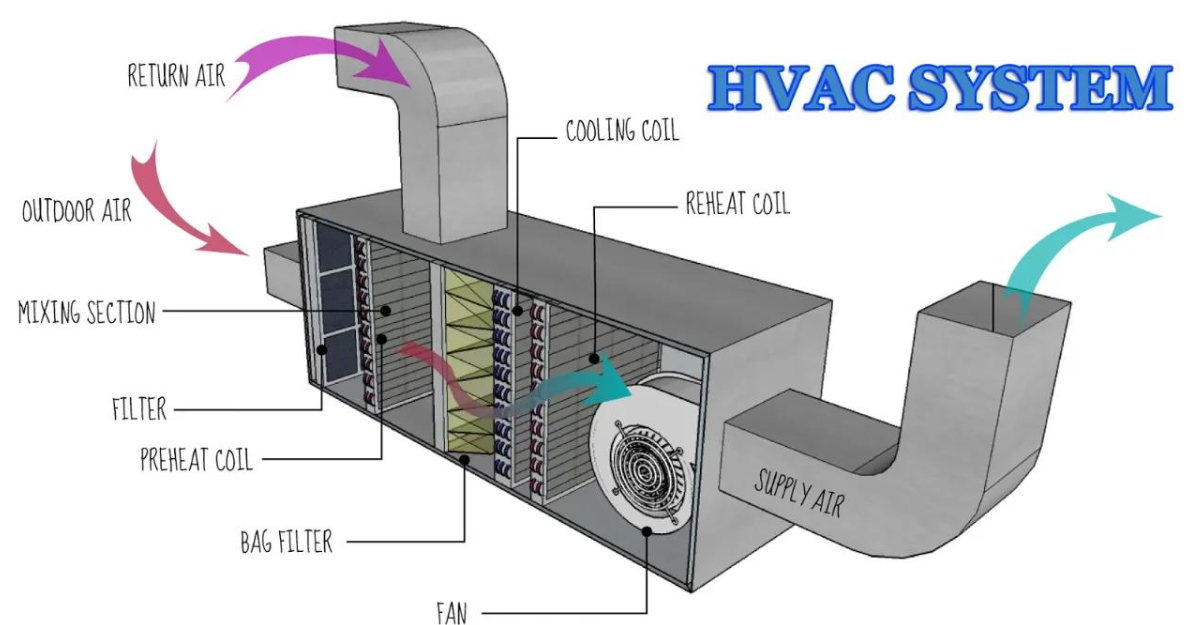

How Do You Select the Proper Filter Type and Size?

There are over 30 standard air filter sizes. I suggest you always confirm the right dimensions. You can check the label on your current filter, but you should also measure its length, width, and depth yourself. If your HVAC vents are a custom size, I recommend ordering custom filters. This gives you a perfect fit and helps your system work its best.

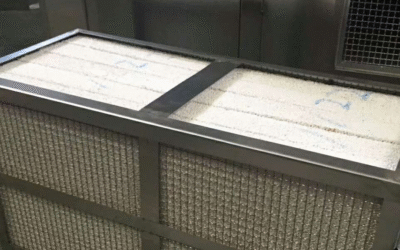

What Is the Recommended Maintenance and Replacement Frequency?

I recommend replacing most panel or pleated industrial air filters every 2–3 months. The real timing depends on how often you run your system, the local air quality, and the humidity. You can also watch the static pressure. This measurement helps you know the right time for a change. Some places use this number to know when the filter is too clogged to work well.

How Do You Choose the Right MERV Rating?

The MERV rating tells you how well the filter traps particles. A higher number means it traps more. But not all systems can use high-MERV filters. I suggest you check your HVAC manual or ask an authorized technician. The filter manufacturer can also tell you what works. This makes certain the filter is right for your system and meets your air quality needs.

Why Is Proper Filter Sizing and Installation Crucial?

Using an industrial filter with the correct size is key to good airflow. It also keeps your system from working too hard. If the size or installation is wrong, the system will not work as well. This can lead to higher energy bills and even damage your HVAC parts. I always recommend you double-check measurements and follow the installation instructions closely.

What Are the Advantages of Bulk Purchasing Industrial Air Filters?

In my opinion, buying in bulk is a smart move. It makes maintenance easier and lowers the price of each filter. This is a great idea if you have many HVAC units or do maintenance by season. Having a stock of filters on hand makes swapping them quick and keeps your business running without interruption.

What Should You Do If Performance Drops After a Filter Change?

What if your HVAC system works worse after a filter change? I suggest you first check that you used the right size and type. Make sure you installed it correctly, with no gaps or anything blocking the air. If problems continue, you may need a professional look to avoid more issues.

Pro Tip: Based on my experience, you should always talk to an expert filter distributor or a certified HVAC pro. They can give you advice on filter choice, size, and what works with your system. This will help your equipment last longer and keep your business running smoothly.

Core List-Based Information

Standard Industrial Air Filter Sizes and Types

You can find over 30 standard air filter sizes (examples: 10x20x1, 14x20x1, 16x24x1, 18x30x1).

Industrial systems have different needs. Based on my experience, filter capacities range from 9 l/s (19 cfm) to over 1100 l/s (2300+ cfm) to fit the building.

Sometimes, you may need custom filter sizes. I see this with unusual vent slots or unique setups.

Filter types:

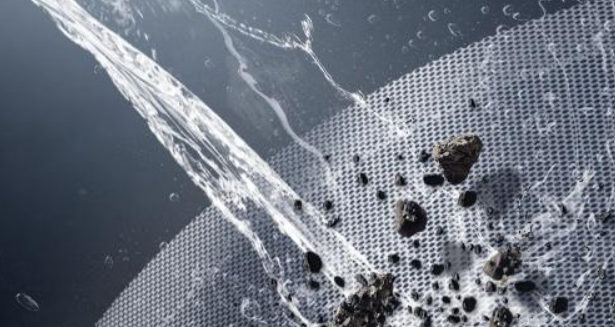

- Fiberglass/Synthetic (MERV 1–4): I find this is a low-cost option. It gives basic protection from dust and debris.

- Panel Filters: These are flat and disposable. I recommend them for general use.

- Pleated Filters (MERV 8–15): These have a high surface area. They are better at catching mold spores, dust mites, and pollen.

How to Measure and Choose Filter Dimensions

- The size is shown as length × width × depth (thickness). This nominal size (rounded up) is printed on the frame.

- The filter’s actual size is about 0.25–0.5 inches smaller than the nominal size.

- I strongly recommend you measure your vent slot—length, width, and thickness—before ordering. This is critical for bulk purchases.

- Choosing the right size stops air from bypassing the filter. It also helps your system run well.

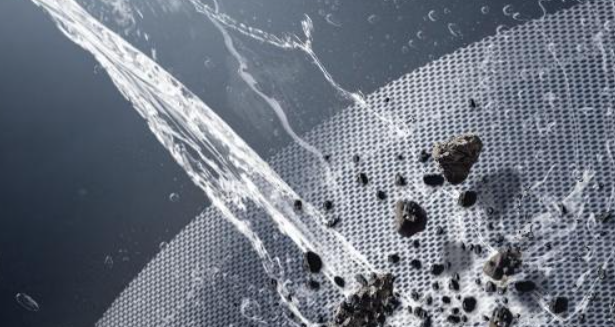

Key Industrial Air Filter Maintenance Guidelines

I suggest you change filters every 1–3 months. This depends on the filter type and your air quality.

From what I’ve seen, pleated filters last longer than fiberglass filters because they have more surface area. If you have high airflow or use the system a lot, you’ll need to replace them more often.

You should watch for reduced airflow or an increased energy load. These are signs that it’s time for a new filter.

In dusty or humid places, you will have to change filters more often. The same applies if your system runs constantly.

I suggest you track replacement schedules and pressure readings. This is a good way to maintain efficiency and stay compliant.

Tips for Bulk Purchasing and Routine Management

- If a filter’s size isn’t labeled, I recommend using a tape measure. Be sure to check both the nominal and actual sizes.

- You should estimate your annual filter needs. You can base this on your maintenance schedule.

- I think it’s a good idea to keep a stock of filters on site. This helps avoid downtime when a replacement is needed.

- You can consult pros for advice on the best MERV ratings and filter types for your space.

Buyer’s Checklist for Industrial Air Filters

- First, I’d confirm your filter slot dimensions. Check if they can fit thicker, higher-performance filters.

- You need to balance a higher MERV rating with your system’s airflow capacity. I suggest checking the manufacturer’s limits.

- In dusty or high-use settings, I recommend scheduling a change each month. For standard conditions, every three months should be fine.

- I recommend you log replacement dates and check system data. This leads to the best long-term savings and ensures compliance.

What to Check Before You Buy

From my experience, when you buy industrial air filters, you should look closely at a few key things. Pay attention to the filter size, if it will fit your system, its MERV rating, and how often you’ll need to change it. If you’re placing a large order, you need to check these specifications carefully. These factors affect your air quality, how long your unit lasts, and help you meet regulations.

Getting the Filter Size Right

I suggest you always look at the filter’s label. It will show you three important numbers: length, width, and thickness. Industrial filters usually come in standard sizes from 24” x 24” to 48” x 48”. Their thickness can be between 4” and 12”. Filters for commercial HVAC systems are often smaller, ranging from 12” x 12” to 36” x 36”. A filter’s actual size can be about half an inch smaller than the size printed on the box. If you can’t find a label, I recommend you measure the filter slot yourself to be sure.

Making Sure the Filter Fits Your System

You need to confirm that the new filter’s size and type will work with your equipment. Check your system’s filter slot and airflow needs. Thicker filters, like 4–5 inch models, create a better seal. This stops dirty air from leaking past the filter. Your filter housing must be deep enough to handle the extra thickness. I advise against using a filter with a smaller connection size than your HVAC unit. This can strain your system and make it less efficient. For the best results, I recommend using a filter that matches or is larger than your system’s required connection size.

Choosing the Correct MERV Rating

In my opinion, most industrial and commercial spaces need filters with a MERV 8 to MERV 15 rating. I suggest you use MERV 8-10 for common dust, pollen, and mold. You should upgrade to MERV 13-15 to catch finer particles. This is a good choice for sensitive places like hospitals or clean rooms. If you have a special area like a clean room or paint booth, you should follow the ANSI/ASHRAE Standard 52.2. This will help you pick the right filter material and performance.

How Often to Replace Filters & Plan Maintenance

I believe you should schedule replacements based on how much you use the system and your area’s air quality:

- In a standard office or commercial building, change them every 3–6 months.

- For industrial zones or places with a lot of dust, I recommend changing them every month, or even more frequently.

Filters with a high MERV rating usually need to be checked and replaced more often. You can track the pressure difference across the filter and watch your environment. This helps you find the best time to replace them and keeps your indoor air clean.

Smart Bulk Buying and Stock Management

Before you finalize an order, I suggest you confirm the dimensions, filter material, and MERV rating for every filter. This is very important for large or seasonal orders. Look at your average use and maintenance plan to figure out how much stock you need. For example, if you replace filters every month because of heavy use, you should plan your bulk orders around that. You can avoid expensive downtime by making sure your inventory meets your daily needs and any industry rules.

My Recommended Action Steps

- If you can’t find a label, measure your filter slot to confirm the size.

- I strongly suggest you double-check that the filter will fit your system before you order. This is vital for upgrades or large purchases.

- Set up a schedule for pressure checks and regular filter changes.

- If your HVAC system is complicated or uses special filters, I recommend talking to an expert or reading the manufacturer’s guide.

Examples:

– Common industrial filter sizes include 24″x24″x4″, 36″x36″x6″, and 48″x24″x12″.

– Based on my experience, MERV 8 works well for standard dust. You’ll need MERV 13 for clean rooms or hospital areas.

– If you need to filter 5-micron particles with 99% efficiency, I recommend choosing filters specifically made for heavy-duty industrial work.

summary

I’ve worked with countless industrial facilities. My experience shows that investing in the right air filters goes beyond simple compliance. It’s about protecting your people and equipment for years. Take time to ask these questions before you buy. You will see the benefits later. Your systems will run without problems, your energy bills will be manageable, and your workplace will stay healthy. I believe good air quality is an investment that provides value every single day.