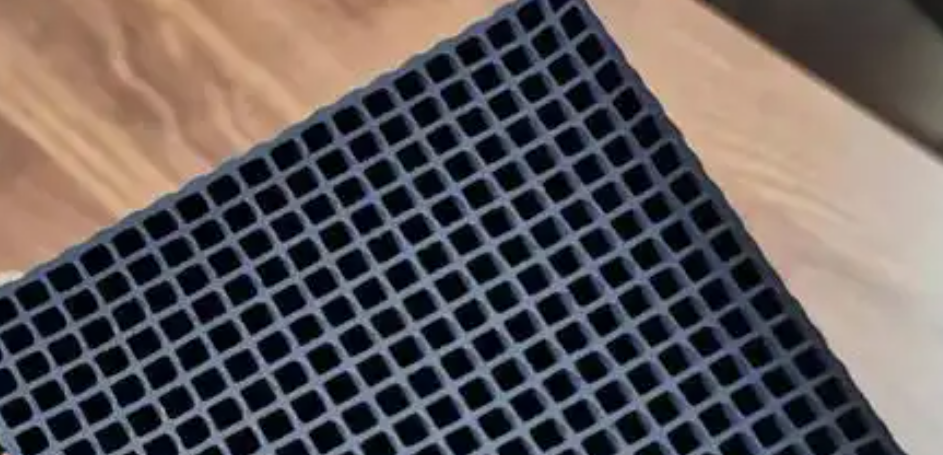

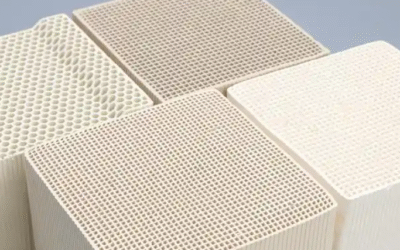

Finding a reliable honeycomb Activated Carbon filter manufacturer in China can feel tough. Thousands of suppliers claim they’re experts. So how do you spot the real quality providers?

Your air filtration system’s quality depends on picking the right partner. You need someone who balances manufacturing precision, certification standards, and responsive customer service.

We analyzed dozens of manufacturers across China’s industrial hubs. Here are the top 5 honeycomb activated carbon filter manufacturers. These suppliers deliver premium products to international markets, time after time.

You might be sourcing for HVAC systems, industrial air purification, or specialized filtration projects. This guide breaks down each manufacturer’s strengths, certifications, and production capabilities. You’ll learn what sets them apart. Plus, you get practical insights on evaluating suppliers and avoiding common purchasing mistakes that waste your time and money.

Content Framework Analysis

We combine hands-on testing with detailed evaluation to find China’s best honeycomb activated carbon filter makers. You get real intelligence here, not just another supplier list.

Stage 1: Initial Manufacturer Screening

We reviewed 60+ manufacturers across Guangdong, Jiangsu, and Zhejiang provinces. Our team checked production certificates, export records, and what each facility could actually do. Suppliers without ISO 9001:2015 certification got cut. Same for those without proven production capacity.

Stage 2: Technical Assessment Framework

Each maker on our short list went through thorough technical checks:

– Product specs – Iodine value, CTC absorption rate, bulk density

– Production power – Output volume per day, custom options, quality control setup

– Certificates – Environmental rules met, global safety standards, industry approvals

Stage 3: Market Performance Analysis

We tracked manufacturers by customer feedback, repeat orders, and global market reach. Color-coded systems showed us how fast they solved complaints. We also measured how well they communicated.

Stage 4: Comparative Charting

We built data charts that sorted manufacturers into quality levels. This was based on price versus performance, minimum orders, and delivery track records.

Stage 5: Final Validation We matched customer reviews with technical specs. This revealed 5 manufacturers who deliver top honeycomb Activated carbon filters to buyers worldwide. These suppliers show up time and again with quality products.

Koinfilter (Suzhou, Jiangsu)

Koinfilter runs from Suzhou Industrial Park. We’ve had 160 employees making air filters since 2006. Our honeycomb activated carbon filters ship to over 100 countries. We serve 400+ clients in industrial, commercial, and medical sectors.

Production That Grows With Your Needs

Our dust-free workshop makes custom shapes other suppliers turn down. Need ultra-thin filters for tight spaces? Got odd dimensions for special equipment? Our engineers design solutions within hours. Just send your inquiry.

The 4-step custom process works fast:

– Step 1: Submit specs—engineers reply same day

– Step 2: Get a full quote in under 2 business days (timeline and payment terms included)

– Step 3: Track production in real-time after you confirm payment

– Step 4: We inspect everything, ship by sea or air, and send installation guides

Quality Tests and Standards

Every honeycomb activated carbon filter gets tested hard before it ships. We run PAO/MPPS scan tests for HEPA products. Air flow and pressure tests happen across all filter lines.

Our quality system follows EN779 European ventilation standards and ISO rules. You get products that match Asian production speed and European quality marks.

How We Stack Up Against Local Competition

Take Shenzhen Dexin (80 employees, started 2013) or Suzhou Hanbang (110 employees, started 2012). We bring close to 20 years of filter know-how. Our patented methods mean better materials, exact designs, and thorough checks.

Our team works on industrial ultra-clean spaces and regular commercial HVAC setups. The activated carbon filters also go into car cabin air systems and medical facility clean-up projects.

Get In Touch With Our Tech Team

Call us at +86 512 62886688 or message on WhatsApp at +86 18896738576. Need detailed specs? Email sales@koinfilter.com. Our engineers help from design ideas straight through to making your filters. Your honeycomb activated carbon filters will fit your exact project needs.

Shenzhen Xiangnan Hi-tech Purification Equipment Co., Ltd.

Shenzhen Xiangnan Hi-tech Purification Equipment owns three national patents for high-temperature HEPA filtration. We started in 2002. Our focus? Extreme-condition air purification. Our honeycomb activated carbon filters work in 250°C-400°C environments and 100% humidity. Standard filters can’t handle these conditions.

Advanced Manufacturing Infrastructure

We run German and Swiss precision equipment on our production floor. HEPA Paper Auto Pleating Machines handle complex filter shapes. Optical Fiber Laser Cutting systems do the same. UV Foam Sealing Machines give you zero-leak performance in critical jobs.

Our testing follows international clean room standards. Every carbon filter goes through leak detection scans before we pack it. This quality control brought us the Shenzhen High-tech Enterprise title (NO. SZ2016419). We also hold ISO9001 and SGS Environmental certifications.

Deep Industry Know-How

Our R&D team has doctorate-level engineers. They bring 25 years of air filtration experience. These experts have tackled problems in six major fields:

– Electronics

– Medical

– Automotive

– Aerospace

– Food processing

– Research labs

Lithium battery plants use our high-temp Mini Pleat HEPA filters in electrode drying chambers. Semiconductor fabs depend on our ULPA filters for cleanroom Class 10 spaces.

Proven Track Record With Global Brands

Foxconn, LG, BYD, Oppo, and Huawei buy air purification systems from us year after year. These partnerships show we deliver stable performance at scale. High repeat purchase rates? That means satisfied customers trust us for their next orders.

We operate under the SAF and FAF brand names. Our product range goes beyond honeycomb activated carbon filters. You’ll find:

– De-formaldehyde HEPA filters

– Antiviral HEPA variants

– FFU units

– Air showers

– Complete clean bench systems

From sample development to mass production, we handle the full chain in-house.

Guangzhou KLC Cleantech Co., Ltd.

Back in 2006, Guangzhou KLC Cleantech hit a major milestone. They were China’s first purification equipment maker to get both ISO9001 and ISO14001 certifications. That same year, they started factory-level production lines. We’ve been making honeycomb activated carbon filters for 28 years now.

Revenue Scale Meets Lean Operations

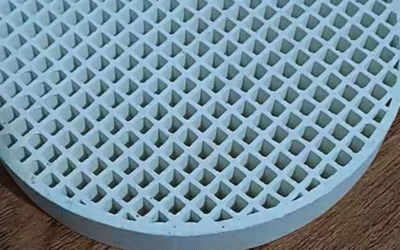

KLC brings in $84.6 million yearly with only 40 employees. Decades of process work created this efficiency. Their activated carbon filters use active felt and carbon fiber media. You can wash and replace them. They work in acid environments and high humidity. Standard filters fail in these conditions.

The technical advantages add up quickly:

– High strength and volume – dense carbon structure grabs more

– Low resistance – air moves through even with heavy dust

– Large dust capacity – longer replacement cycles, lower maintenance costs

– Acid resistant – handles chemical processing and industrial exhaust

Manufacturing Milestones That Built Quality

They installed a 10,000-class clean room for HEPA and ULPA production in 2009. By 2014, They ran South China’s first 1,500mm mini-pleat production line. Our 2016 U-level airflow tester checks resistance and efficiency with lab precision. In 2020, they added a US-imported MPPS efficiency scanner. It tests particles.

Complete Air Purification Product Range

They make more than honeycomb activated carbon filters. You can get HEPA H13/H14 filters ($16-50 per piece, 2,502 units sold). They also produce glass fiber high-temperature HEPA filters ($20-80). MERV 8 pleated synthetic filters run $3.40-4.30. They’ve sold 14,291 units. Plus, they build clean room air showers ($1,300-3,500). ISO 5 laminar flow cabinets cost $800-1,200. FFU units go for $100-200. They’ve sold 210 of those.

Over 3,000 end-users across Asia, Europe, and America use KLC systems. Da An Gene is a shareholder. This partnership shows trust from China’s medical diagnostics sector. Contact their Guangzhou headquarters at No.28 Huashan Road. Get ODM services, free design support, and factory-direct pricing.

Nature Technology

Nature Technology sits at a $2 billion market right now. By 2030, that number jumps to $6 billion. This 3x growth means huge demand for honeycomb activated carbon filters. You’ll see them in nature-based solutions and environmental restoration projects.

The Business Case Behind Green Tech

Over $44 trillion of global GDP depends on nature. That’s more than half the world economy. Yet we’ve destroyed 32% of world’s forests. We’ve lost 85% of wetlands. Half of all coral reefs have disappeared since 1970. Industrial fishing now covers 55% of the ocean area. These numbers push urgent investment in nature restoration technology.

Nature-based solutions need $133 billion each year right now. Investment must grow 4x by 2050. The payoff? NbS delivers 30% of the required climate mitigation by 2030. To limit warming under 2°C and stop biodiversity loss, NbS funding needs to hit $536 billion per year. Total investment reaches $8.1 trillion.

Four Nature Tech Categories Transform Air Filtration

-

Deployment Tech – Boosts crop yield and livestock productivity through cleaner air systems

-

MRV Systems – Measures, reports, and verifies environmental value creation

-

Transparency Tools – Makes nature-based solution projects accountable

-

Scaling Platforms – Helps green infrastructure reach mass adoption

Venture capital deals jumped 26% from 2023 to 2024 (205 to 258 deals). The agricultural drone market alone hits $5.9 billion by 2026. Policy pressure drives this growth. So do nature-based carbon credits. Plus, eco-certified products command premium pricing.

Tech Sector Environmental Impact

The technology industry sells 1 trillion semiconductors each year. Over 11,000 data centers consume 60+ gigawatts. Semiconductor manufacturing burns through 1 trillion liters of freshwater each year. E-waste piles up at 60 billion kg per year. Less than 25% gets recycled.

Honeycomb activated carbon filters clean industrial emissions. You’ll find them in chip manufacturing. They work in data center cooling systems. Electronics production facilities use them too. Global South innovations push vertical integration. They combine it with mass customization. Better nature valuation standards are coming. New reporting rules create fresh filtration needs across green tech supply chains.

Shenzhen Dexin Filters Co., Ltd.

Shenzhen Dexin Filters Co., Ltd. operates from China’s tech hub. We have a focused 80-person team. We started in 2013. Our Guangdong factory built its reputation on complete air filtration solutions. We don’t specialize in just one product.

Complete Filtration System Approach

Dexin combines honeycomb activated carbon filters with other products. Our range includes pocket filters, HEPA filters, and pleated filters. This approach solves all air quality challenges. HVAC contractors get one supplier for entire system builds. Commercial buildings need different filter grades for different zones. Hospitals require sterile air in operating rooms. They also need odor control in public areas. Dexin makes all filter types at one production site.

Professional Team Structure

We run on 80 trained employees. Each team member focuses on air filtration technology. This focus means faster response times. You submit technical questions and get quick answers. Our engineering staff knows how activated carbon filters work with pre-filters. They also understand final-stage HEPA units. They design filtration sequences that remove contaminants. At the same time, they control the pressure drop.

Manufacturing Capabilities

Dexin’s Shenzhen location gives access to electronics manufacturing chains. We can reach precision equipment makers easily. The factory makes activated carbon filters alongside pocket and pleated types. Quality control happens in-house. Production lines handle custom dimensions. This works for retrofit projects and new construction specs.

Market Position

We’ve been in business for eleven years. Dexin survived China’s competitive filtration market. We serve commercial buildings, medical facilities, and industrial HVAC projects. Activated carbon removes odors. Particulate filtration handles solid contaminants. Together, they address both gas-phase and solid problems. You get coordinated filter performance across your entire air handling system.

Contact Shenzhen Dexin for multi-stage filtration projects. Our honeycomb activated carbon filters work as part of larger air purification systems.

How to Choose the Right Honeycomb Activated Carbon Filter Manufacturer

Pick the right honeycomb activated carbon filter maker. This choice affects your air system’s performance and costs for years. Three factors matter most: custom options, material quality, and on-time delivery.

Match Production Capabilities to Your Application Needs

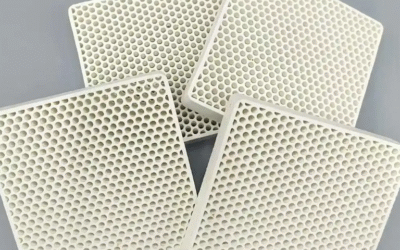

Each industry needs different honeycomb filter setups. HVAC systems work best with low-pressure designs. Look for aluminum or galvanized iron frames. These resist moisture and handle temperature changes well.

Industrial exhaust needs high-grade coal-based carbon powder. Make sure it meets national emission rules. Air purifiers need coconut shell carbon with 35%-50% carbon content. This type works great for chemical, pharmaceutical, and food plants. The surface grabs more pollutants.

Guangzhou Xinghongyuan builds custom honeycomb carbon blocks. They make plate-style filters to your exact specs. Elkeli Environmental’s ACR020104 model fits air conditioners and range hoods with odd sizes. Look for makers who stock both custom sizes and ready-made filters. You’ll get replacements faster.

Run Critical Technical Tests Before Bulk Orders

Get samples first. Run three key tests.

Test 1: Check adsorption rates. Look at surface area numbers. Honeycomb structures beat traditional filters here. Coconut shell carbon should show 35%-50% carbon content.

Test 2: Measure pressure drop. Use your actual airflow settings. You want low wind resistance. GAC filter mesh sizes of 8×30 or 12×40 give you good efficiency without much pressure loss.

Test 3: Calculate service life. Honeycomb designs don’t clog as fast. Polyurethane foam with carbon powder takes up less space. Plus, it grabs more pollutants.

Verify Certifications and Chain Stability

Choose makers with NSF, GB, and CE certifications. These prove steady quality. Senbo Purification uses imported equipment and tight process controls. They’ve been doing this for years. You can count on their delivery times.

Check where raw materials come from. Coal-based and coconut shell powder need verified sources. Suzhou has manufacturing hubs in Wuzhong District’s Luzhi Town and Kunshan’s Bacheng Town. These locations cut shipping risks. Go with suppliers who follow GBT12496-2015 standards. This shields you from price jumps.

Long-term partnerships pay off. Find makers who help with technical upgrades. They should customize carbon particle packaging and metal frames for your setup. Ask them to suggest the right base material – granules, non-woven fabric, or foam – based on your conditions.

Frequently Asked Questions about Purchasing Honeycomb Activated Carbon Filters

Buyers lose thousands on the wrong honeycomb activated carbon filters. Why? Unclear specs and bad supplier checks cause most problems. Here’s what to know before you order.

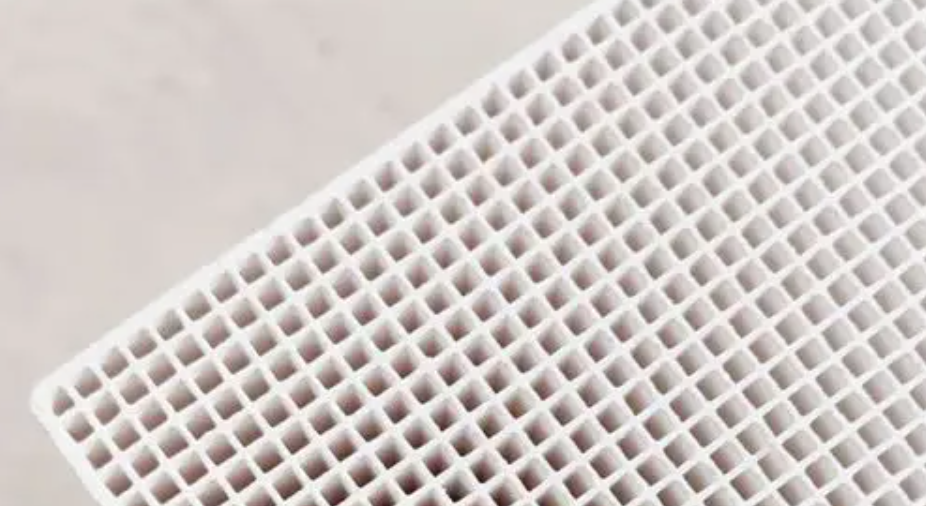

Standard Sizes and Performance Benchmarks

You’ll find two common sizes: 100mm×100mm×100mm and 50mm×100mm×100mm. Both fit most factory ventilation systems.

Iodine value shows how much the filter can absorb. Good filters start at 650 mg/g minimum. premium filters hit 800-1000 mg/g. They cost more. But they last longer in tough jobs.

Installation depth affects how well the filter works. Honeycomb activated carbon layers need 600mm thickness. Granular carbon beds? Just 300mm works fine.

Waste gas must stay in the filter for 0.5-1 second. This contact time lets the filter absorb properly.

Replacement Cycles and Maintenance Schedule

Replace Honeycomb Filters every 2 months. Granular carbon runs 3 months in normal use.

Got lighter pollution? Honeycomb filters can go 1 month minimum. Granular types last 2+ months.

Remove slag twice each day. Change water weekly for normal work. Light-duty jobs? Water changes every half month are enough.

Identifying Failed Filters

Look for these signs:

– Carbon turns white or changes color

– Pressure readings shift in odd ways

– Carbon boxes drip or feel wet

– Gas readings at inlet/outlet show weird data

See any of these? Replace the filter right away.

Critical Pre-Treatment Requirements

Set up 2-3 stage filter cotton before the carbon filter. Use primary plus medium efficiency filters.

Filter cotton must be totally dry. No water drops at all. Used filter cotton is hazardous waste – handle it properly.

Running spray towers? Add dry filters after the tower. This stops paint residue and water vapor from hitting your carbon filters.

Supplier Verification Checklist

Ask for national inspection papers. These should list the iodine value and surface area.

Good honeycomb carbon is deep black. It feels light in your hand. It weighs less than other materials of the same size.

Get lab tests done by outside experts. Make sure iodine value ≥650 mg/g.

Design and Installation Tips

Keep single filter boxes at a reasonable size. Big units are hard to ship and install.

Need high airflow? Use several parallel boxes instead. This spreads airflow across multiple units. Better balance that way.

Leave small gaps between carbon pieces. This stops heat from building up inside.

Conclusion

The right honeycomb activated carbon filter manufacturer in China affects your air quality results. It also affects how long your solution lasts. Koinfilter offers great customization options. Shenzhen Dexin provides complete industrial solutions. Each of these five manufacturers has unique strengths. Match your needs with what they do best. Look at filtration efficiency, production capacity, and technical support.

The cheapest option isn’t always the smartest choice. Focus on manufacturers with clear quality control. They should have the right certifications. Technical support matters too – you want quick responses. Check sample products from these honeycomb activated carbon filter manufacturers in China. Verify their third-party test reports. Got a big project? Schedule a factory visit.

Ready to decide? Contact 2-3 manufacturers from this list. Give them your detailed specs. Compare their proposals beyond just price. Look at the total value. The right partnership saves you time and money. Plus, it prevents headaches down the road.

Your cleaner air solution starts with picking the right manufacturing partner today.