Why I Recommend Industrial Ceramic Materials for Everyday Use

Industrial ceramic materials are essential in our everyday lives. They resist high heat better than other materials. They are harder than most metals. They stay stable when exposed to chemicals. They also block electricity well. These qualities make them better than metals and polymers in many cases. Other materials fail where ceramics succeed.

How We Use Ceramics at Home and in Buildings

Ceramics surround us every day. Here are common examples I see:

-

Glass, bricks, cement, and tiles build our homes. They form the walls, floors, and surfaces we touch all the time.

-

Porcelain and pottery work as tools and decorations in our kitchens and living rooms.

-

Kitchenware like plates, mugs, and ovenware resist heat. They don’t react with food. This makes them safe and reliable for cooking and eating.

Economic and Technical Facts

The global advanced ceramics market passed $90 billion in 2023. This shows how important they are in engineering and consumer goods. Engineered ceramics handle temperatures over 1500°C. Most metals melt at much lower temperatures. For electrical insulation, alumina ceramics deliver high strength (over 10 kV/mm). Electronic devices need this property to work safely.

Why I Like These Material Benefits

Hardness: Silicon carbide and alumina ceramics are harder than most steel. They score above 9 on the Mohs hardness scale. I suggest using them where extreme durability matters.

Less maintenance: Based on my experience, ceramic parts last longer than metal or plastic. They resist wear and corrosion better. You replace them less often. This saves time and money.

Where Industries Use Ceramics

-

Aerospace: Ceramics protect engines and spacecraft from extreme heat and stress.

-

Electronics: They make substrates and semiconductors. They release heat and block electricity at the same time.

-

Healthcare: Doctors use them for sterile implants and medical tools. They work well inside the human body.

-

Automotive: They make car parts like bearings and spark plugs more efficient and reliable.

-

Industrial Processing: They line reactors and pipes. They resist strong chemicals that would damage other materials.

-

Food Industry: They keep processing equipment clean and safe.

I believe industrial ceramics work quietly behind everything we use. The tiles under your feet use ceramics. The microchips in your phone use them. The medical devices in hospitals depend on them. They provide strength, safety, and performance we count on every day.

Construction and Architecture: How Industrial Ceramics Build Our Modern World

I believe industrial ceramic materials are essential in construction and architecture. They offer strength, durability, and thermal insulation. These qualities make them a key part of modern buildings.

Major Uses of Ceramics in Buildings

Bricks and Roof Tiles

Most exterior bricks and roof tiles use ceramics. A standard ceramic brick or tile can last over 100 years. It provides fire resistance, soundproofing, and thermal insulation. These materials don’t emit VOCs. They don’t corrode either. So they help create energy-efficient, healthier buildings.

Facade and Wall Cladding

Ceramic tiles come in many types. Fiber-reinforced and thin-profile versions work well outside and inside buildings. These tiles give architects many colors, finishes, and textures. This supports creative and original building designs. Modern lightweight ceramic tiles reduce environmental impact. They also maintain durability.

Sanitary Fixtures

Toilets, sinks, and bathtubs use vitrified ceramics. This material resists moisture and stains. It also inhibits bacteria. Based on my experience, this ensures excellent hygiene for homes and public places.

Expanded Clay Aggregate

Expanded clay ceramics work as lightweight construction aggregates. They fit in walls, floors, and concrete mixes. They offer high strength and minimal weight. This improves building energy performance. It also boosts sustainability across the full lifecycle.

Structural Elements

Load-bearing ceramic bricks and blocks have high compressive strength. Builders use them in foundations. They also use them in the main structure of low- and mid-rise buildings. These often pair with steel and cement.

Partitions and Decorative Panels

I recommend ceramic materials for internal partitions, wall linings, and decorative architectural panels. Bricks, hollow blocks, and tiles are popular choices.

Household Appliances and Domestic Products: How Ceramics Power Our Everyday Comfort

Ceramic materials power a wide range of household appliances and domestic products. Why? They resist high temperatures well. They provide superior electrical insulation. They offer mechanical strength. They last a long time. I believe this unique mix of properties makes them perfect for home convenience and safety.

Where Ceramics Make a Difference in Household Appliances

Cooktops, Ovens, and Microwaves:

Glass-ceramic surfaces (like SCHOTT CERAN®) dominate modern kitchen cooktops. These materials resist thermal shock. They are easy to clean. Over 200 million households worldwide use them. Oven doors and microwave plates also use glass ceramics. They endure heat well and resist impact.

Electrical Components:

Manufacturers rely on steatite ceramics for insulators in thermostats, switches, and electrical connectors. Steatite has high dielectric strength and low dissipation. More than 60% of household appliance insulators use steatite. It offers reliability at a good price.

Electronics Inside Devices:

Alumina ceramics provide excellent electrical and thermal insulation. They form substrates and insulators in smartphones, laptops, LED bulbs, and TVs. Over $4.5 trillion worth of global electronic products depend on ceramics. They enable miniaturization and reliability.

Heating Elements and Thermal Parts:

Makers shape silicon carbide and cordierite ceramics into heating elements for ovens, toasters, and electric kettles. They conduct heat well. They endure repeated rapid heating. They resist corrosion.

Smartphone and Tablet Screens:

Leading brands have adopted ultra-tough glass-ceramic materials (such as ZERODUR®) in phone and tablet screens. These materials offer outstanding impact and thermal stability.

Kitchenware and Decorative Items:

Porcelain, stoneware, and earthenware ceramics provide plates, mugs, cookware, and decorative vases. These materials are non-porous. They are very durable. They look appealing. Plus, they don’t react with food or drink. I recommend bakeware and rustic kitchenware made from high-temperature ceramics. They can handle direct flame or oven temperatures over 500°C without cracking.

Strength and Lifespan: Why I Prefer Ceramics

Advanced ceramic elements in appliances can last up to 20 years. This happens even with constant heating and cooling cycles.

Ceramic cookware (porcelain and alumina) can withstand oven and flame heat exceeding 500°C. Based on my experience, they beat metals or plastics for durability and safety.

Common Domestic Products Using Ceramics

-

Electric kettle heating elements (alumina, silicon carbide)

-

Inductive cooktop surfaces (glass-ceramic)

-

Microwave oven turntables (glass-ceramic)

-

Toaster thermal plates (cordierite)

-

Thermostat, switch, and plug insulators (steatite)

-

Smartphone/tablet screens (ultra-tough glass-ceramic)

-

LED bulb casings/heat sinks (alumina, zirconia)

-

Cookware, mugs, plates, and bakeware (porcelain, stoneware)

-

Decorative vases and planters (earthenware, stoneware)

Ceramics enable the performance, safety, cleanliness, and beauty of reliable household appliances. They do this behind the scenes. From the kitchen counter to living room gadgets, ceramics form the backbone of modern home comfort. I suggest you look around your home. You’ll find ceramics everywhere, making life easier and safer.

Electronics and Technology: How Industrial Ceramics Power Modern Devices

Industrial ceramics now form the backbone of modern electronics and technology. They offer unique properties. High thermal conductivity. Outstanding electrical insulation. Chemical stability. Strong mechanical strength. These qualities make them essential.

Essential Roles of Ceramics in Electronics

Ceramic substrates have replaced metals in tablets, smartphones, high-performance computers, and communication devices. They are lightweight and thin. This makes electronics portable and efficient.

Low-temperature and high-temperature co-fired ceramics (LTCC & HTCC) produce precise, compact, and affordable parts in electronic circuits. I’ve seen these used in countless applications.

Core Types of Ceramic Materials and Their Electronics Applications

-

Alumina (Al₂O₃): Used for electronic substrates and packages. Engineers choose it for its high dielectric strength. It offers excellent thermal conductivity. It resists corrosion and chemicals.

-

Aluminum Nitride (AlN): This material is essential for components that need rapid heat transfer. Think high-power computer chips and LED modules.

-

Barium Titanate (BaTiO₃) and Lead Zirconate Titanate (PZT): These ceramics turn mechanical stress into an electrical signal. They power piezoelectric sensors, actuators, and sonar systems.

-

Ferrites: These store magnetic data. Memory devices need them.

Where You Find Ceramics in Everyday Technology

Ceramic PCBs (Printed Circuit Boards):

-

Materials: Alumina, aluminum nitride, beryllium oxide

-

Used in: RF electronics, microwave circuits, radar, LED lighting, power modules

-

Benefits: Better heat management and longer device life. LED modules with ceramic bases have over 30% longer lifespan than those with conventional materials.

Capacitors and Non-Volatile Memory: High-dielectric ceramic components create ultra-small, efficient capacitors. You find them in phones, computers, and cars.

Electronic Insulators:

-

Found in spark plugs, packaging for microchips, tube holders, and arc tubes.

-

Features: Ceramics handle voltages up to hundreds of kV. This is vital for safety and reliability.

Sensors and Actuators: Technical ceramics drive precision sensors, motors, and micro-actuators. I’ve seen them in medical equipment, automotive control, and smart devices.

Ceramics enable modern electronics to be faster, more reliable, and more compact. I recommend industrial ceramics for anyone developing or choosing tech products. Based on my experience, they offer a rare mix of safety, performance, and longevity. Metals or polymers can’t match this. Your phone uses them. Your car uses them. Your wireless network uses them. Ceramics deliver the power, speed, and durability you depend on every day.

Medical Applications: How Industrial Ceramics Transform Modern Healthcare

Industrial ceramic materials have reshaped healthcare. They offer chemical stability, strength, and biocompatibility. I find these properties essential for medical implants, tools, and advanced therapies.

Key Uses of Ceramics in Medical Devices and Surgery

Medical Implants:

-

Zirconia and alumina ceramics form the core of hip and knee replacements. They also work well in dental implants and facial bone repairs.

-

Zirconia has a compressive strength of 150–200 MPa. This makes it very resistant to fracture.

-

Alumina hip prostheses have ultra-low wear rates. This extends how long the implant lasts.

-

Over 1.5 million joint replacements worldwide use ceramic parts each year.

Dental Applications and Orthodontics:

-

More than 50% of modern dental crowns are now ceramic. This improves both looks and biocompatibility.

-

I recommend materials like silica, leucite, lithium disilicate, alumina, and zirconia. These are tough. They mimic natural tooth color well.

-

All-ceramic root implants and orthodontic devices reduce metal allergy risks.

Less Invasive Surgery:

-

Thin ceramic tubes (down to 0.165 mm thickness) create precise tools. Doctors use these for endoscopy and laparoscopy.

-

Ceramics offer chemical stability and electrical insulation. This makes devices safer.

-

Piezoelectric ceramics power ultrasonic medical sensors and therapy devices.

Medical Tools and Equipment:

-

Ceramic surgical scalpels and scissors stay sharper longer. This improves surgical outcomes.

-

Ceramic blood valves and pumps in infusion equipment stay sterile. They resist chemical wear.

Advanced Medical Treatments Enabled by Ceramics

Drug Delivery and Radiotherapy:

-

Ceramic microspheres and nanoparticles target drug delivery. They work well in cancer radiotherapy.

-

Hydroxyapatite nanocomposites release therapeutic agents over time. They also support tissue regeneration.

Tissue Engineering and Bone Grafting:

-

Bioceramic scaffolds use tricalcium phosphate and hydroxyapatite for bone repair. They promote natural tissue integration.

-

Bioactive glasses help in spinal surgery and gum therapy. They speed healing.

Medical Imaging and Electronic Devices:

-

Ceramic insulators and supports are critical for MRI, CT, and PET imaging machines.

-

Small implantable devices treat sleep apnea or depression. These neurostimulators use ceramic-to-metal assemblies. This ensures long-term reliability inside the body.

I think advanced medicine will depend more on industrial ceramic materials. Their durability is unmatched. They work well with body tissue. They resist chemicals and wear. In my view, ceramics drive new medical breakthroughs. These benefit millions every year.

Automotive and Transportation: How Industrial Ceramics Drive Modern Vehicles

Industrial ceramics are changing the car and transport industries. They bring strength, heat resistance, and light weight together. I see ceramics as the foundation for safer, cleaner, and more efficient vehicles. Cars use them in engines and electric systems. This makes them vital for both regular cars and future transport options.

Key Applications of Industrial Ceramics in Automobiles

Engine and Powertrain Components

Ceramic spark plug and glow plug insulators use alumina or silicon nitride. They work well in extreme engine heat—over 1000°C. They also maintain high voltage strength. This gives reliable ignition, even in tough conditions.

Thermal barrier ceramic coatings go on cylinder heads and pistons. They cut heat loss by 10–15%. This improves fuel efficiency. It also allows higher operating temperatures.

Ceramic valves, bearings, and turbocharger parts weigh less than metal. They resist wear. They survive high mechanical stress. They help engines last longer and waste less energy.

Exhaust and Emissions Control

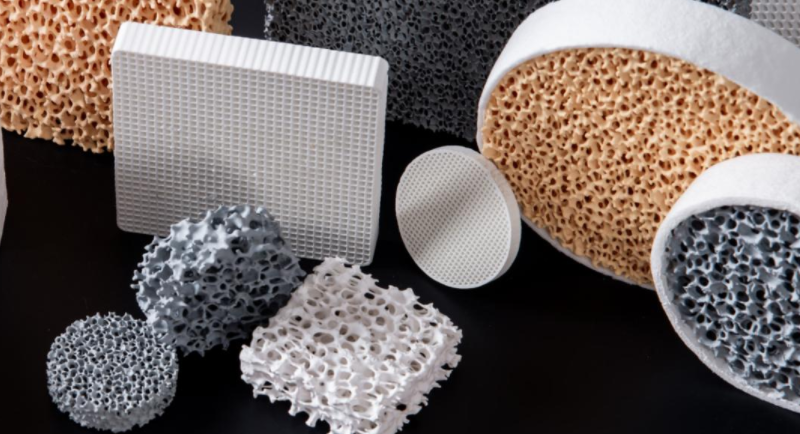

Ceramic substrates in catalytic converters include cordierite, alumina, or titania. Almost every modern vehicle has them. Their honeycomb structure converts harmful gases into less toxic emissions.

Zirconia and spinel ceramic oxygen sensors track lambda, NOx, and particulate matter. They provide the precision needed for strict emissions control.

Diesel particulate filters (DPFs) use porous ceramics. They capture soot. They keep air cleaner.

Brake Systems

Ceramic brake discs use silicon carbide composite. They cut disc weight by up to 60% compared to cast iron. They handle temperatures above 1000°C. They last 2–5 times longer. I recommend them for high-performance and electric vehicles. Better heat management in ceramic brakes means less brake fade. It also means better overall safety.

Thermal and Electrical Management

Ceramic heat shields and exhaust parts protect vehicle systems. They manage temperatures over 1000°C. In electric and hybrid vehicles, ceramics insulate power electronics, batteries, and fuel cells. They prevent overheating. They support high-voltage operations. They lower the risk of thermal runaway.

Sensors and Electronic Systems

Over 90% of new vehicles have ceramic-based sensors. These sensors monitor oxygen, temperature, pressure, and fluid levels. They are essential for precise engine management. They also support safety features. PTC ceramic elements heat electric car cabins fast. They improve comfort with less power use.

Leading Ceramic Materials

-

Alumina (Al₂O₃): Great electrical insulator. Works well at high temperatures.

-

Zirconia (ZrO₂): Very tough. Ideal for sensors and actuators.

-

Silicon nitride (Si₃N₄) & Silicon carbide (SiC): Handle extreme mechanical and heat demands. They reduce weight. They extend part life.

-

Cordierite: Low thermal expansion. Critical for exhaust and emissions systems.

My view: Industrial ceramics drive major advances in vehicle efficiency, durability, and emission reduction. As the market shifts to electric power and stricter rules, ceramics will play a bigger role. They will make our cars safer, greener, and more reliable.

Aerospace and Defense: The Role of Industrial Ceramic Materials

I believe industrial ceramics are essential in aerospace and defense. They offer lightweight strength, extreme hardness, and resistance to high heat and harsh chemicals. Metals and polymers simply can’t match these benefits.

Key Applications of Ceramics in Aerospace and Defense

Ballistic Armor and Personal Protection

Silicon carbide (SiC), boron carbide (B₄C), and alumina (Al₂O₃) are used in armor plates. You’ll find them in helicopters, tanks, and personal body armor.

Ceramic armor cuts weight by up to 40% compared to traditional steel. This makes vehicles lighter and helps personnel move more easily.

Boron carbide ceramics (2.5 g/cm³) meet strict protection levels like STANAG 4569 Level IV and MIL-STD-662F V50. They absorb and spread out the energy of incoming bullets.

Missile, Aircraft, and Hypersonic Components

Missile guidance radomes use silicon nitride or BN–SiO₂ composites. These materials need to be transparent to electromagnetic waves. They can exceed 90% transmission at Ka-band frequencies. This ensures accurate targeting above Mach 5 speeds. Nose cones made from ZrB₂–SiC composites survive temperatures over 1650°C during hypersonic flight. Rocket nozzles with C/C–SiC composites handle over 2200°C.

I recommend these ceramics because they help engineers design safer, faster craft for space and military missions.

Thermal Protection and Jet Engine Parts

Ceramic matrix composites (CMCs) like 8YSZ go into turbine blades and vanes. They handle continuous temperatures up to 1600°C. They also decrease turbine heat by 100–300°C. This improves efficiency and extends component life. Ceramics are key in aircraft exhaust, combustion liners, and acoustic panels. Their heat stability also protects thermocouples and high-resistance sensor parts.

Advanced Functional Applications and Materials

Structural, Electronic, and Optical Ceramics

Satellite bearings made from silicon nitride work in a vacuum. Their friction coefficients go as low as 0.01. This increases reliability and extends the life of critical aerospace parts.

Ceramics are central to radar-absorbing materials (RAM) for stealth technology. They greatly reduce an aircraft’s radar signature.

Space optics use lightweight Zerodur and quartz windows. Ceramic windshield coatings protect against scratches and quick temperature changes.

Precision Manufacturing and Casting

Aluminosilicate ceramic cores create intricate shapes for investment casting turbine blades and vanes. They form cooling channels that are crucial for modern jet performance.

Nuclear and Space Defense:

-

SiC/SiC ceramic composites serve as fuel cladding. They prevent leaks under extreme conditions in nuclear propulsion.

-

MgAl₂O₄ spinel ceramics offer high infrared transparency. This is vital for advanced missile domes and transparent armor.

My Personal View:

Based on my experience, I find industrial ceramic materials essential for modern aerospace and defense. They make aircraft lighter and body armor tougher. They power reliable sensors and stealth technology. Ceramics redefine what’s possible. They deliver the safety, strength, and cutting-edge performance that today’s advanced systems demand.

Lifestyle and Consumer Products

Ceramic materials shape our lives. Often, we don’t even notice them. They last long. They resist heat. They stay stable with chemicals. These traits make ceramics vital in many consumer products. Technology needs them. So do fashion, personal health, and home items. Ceramics offer performance and safety that few materials can match.

Ceramics in Electronics and Appliances We Use Every Day

Consumer Electronics:

Most smartphones, tablets, and laptops have ceramics inside. Alumina (Al₂O₃) and aluminum nitride (AlN) serve as insulators. They also package circuits. Touchscreen displays depend on glass ceramics. This protects them from scratches and keeps them clear. Ceramic arc tubes make energy-efficient lighting work.

Home Appliances:

Coffee makers, ovens, and hairdryers all use ceramic parts. These include heating elements, seals, and bearings. Alumina and silicon nitride keep them working well. High heat doesn’t break them. Frequent use doesn’t wear them out.

Smart Wearables:

Fitness trackers and smartwatches have ceramic backplates and sensor housings. These resist sweat and heat. They protect delicate electronics. Piezoelectric ceramics like PZT create haptic feedback. This makes devices feel responsive. I find this improves the user experience.

Ceramics in Tableware, Kitchens, and Bathrooms

Tableware and Cookware: Plates, mugs, and bowls are everywhere. Over 100 billion pieces are made every year. Today’s porcelain and silicate ceramics resist chips better. They shine brighter too. High-end kitchenware uses advanced ceramics. I recommend them for durability and food safety.

Sanitary Ware: Toilets, sinks, and fixtures are almost always ceramic. Manufacturers produce over 500 million ceramic sanitary fixtures each year. These products clean easily. They never absorb stains or odors.

Ceramics for Health, Fashion, and Vision

Medical and Dental Applications: Alumina and zirconia ceramics form the core of dental crowns, implants, and hip replacements. Doctors place over 10 million ceramic medical implants each year. People choose them for their safety. They also resist wear for a long time.

Fashion Accessories: Luxury watches feature zirconia ceramic cases. Textiles use ceramic beads and fasteners. These combine hardness with striking looks. The ceramic jewelry and watch market is worth more than $3 billion a year. Based on my experience, this shows strong demand.

Clear Ceramics and Optics: High-end sunglasses use sapphire (Al₂O₃ single crystal). So do smartphone camera lenses and optical devices. Sapphire resists scratches better than most materials. It also stays clear.

My Take: Why Ceramics Matter in Consumer Products

I see ceramics as the gold standard for reliability and beauty in consumer products. They make my favorite mug last longer. They give luxury watch faces their shine. They keep appliances safe. This hidden support from ceramics keeps homes cleaner. It makes gadgets work longer. Products look great year after year. I believe their flexibility and performance make them a smart pick. They work for everyday living. They also fit the latest high-tech trends. I suggest paying attention to ceramics when choosing products. They make a real difference.

Summary Table: 7 Common Uses of Industrial Ceramics

I’ve put together this overview of industrial ceramic materials. It shows how they support our lives and modern technology:

|

Ceramic Material |

Key Properties |

Representative Uses and Industrial Examples |

Relevant Data/Figures |

|---|---|---|---|

|

Alumina (Al₂O₃) |

Extreme hardness, thermal/electrical insulation, resists corrosion |

Bearings (wear-resistant), cutting tools, electrical insulators, biomedical implants, electronics substrates |

Vickers hardness: 13.0–20.0 GPa; Melting point: ~2050°C; Most-used by tonnage |

|

Boron Nitride (BN) |

Thermal stability/conductivity, slippery, electrical insulation |

High-temp insulators, mold release agents, thermal management in electronics, aerospace parts |

Thermal conductivity (hexagonal BN): up to 200 W/m·K; Crucibles and aerospace substrates |

|

Silicon Carbide (SiC) |

Very hard, thermal stability, resists chemicals |

Abrasives, semiconductors, kiln/heating elements, automotive brakes |

Mohs hardness: ~9.2–9.5; Use temp >1600°C; Found in bulletproof vests and car brakes |

|

Silicon Nitride (Si₃N₄) |

Resists thermal shock, high strength and toughness |

Engine/turbine parts, food processing bearings, tools, medical implants |

Flexural strength: 700–1000 MPa; Service life in engines +20%; Shock resistance >350°C |

|

Zirconia (ZrO₂) |

Fracture toughness, high thermal expansion, safe for body use |

Dental/orthopedic implants, fuel cells, thermal barrier coatings |

Fracture toughness: 7–10 MPa·m0.5; >70% dental crowns worldwide; Melting point: ~2715°C |

|

Glass Ceramics |

Thermal stability, impact resistance, electrical insulation |

Cooktop panels, cookware, smartphone screens, aerospace, optical devices |

>90% in induction cooktops; Strength 300–500 MPa; Near-zero CTE |

|

Mullite |

High thermal shock resistance, stable at high temps |

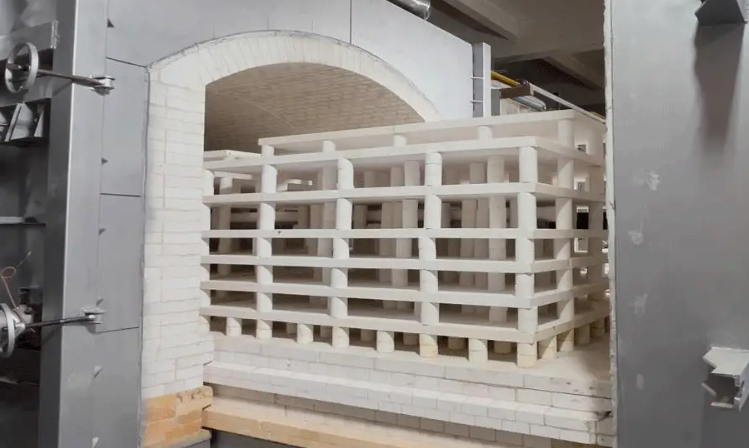

Kiln linings, glass furnace bricks, petrochemical, precision casting |

Operates up to 1700°C; Extensive use in heat treatment & glass industries |

I believe industrial ceramic materials are the backbone of modern technology and lifestyle products. They combine strength, heat resistance, electrical insulation, and long-lasting durability. This makes them essential for consumer electronics, medical devices, cookware, cars, and factory equipment. Based on my experience, no other materials can replace them in these critical applications.