Services

At FOUNDRY MAX, we go beyond providing quality industrial filters to providing a comprehensive range of filter services to solve your most challenging foundry problems.

Consulting Filter Services

We will provide you with a no-obligation consulting industrial filter service that includes an initial analysis of your current foundry process and identification of potential improvement opportunities. Our team of metallurgical and filtration experts are ready to discuss your specific foundry challenges and quality goals. Whether you are struggling to solve inclusion-related defects, seeking to optimize metal flow, or looking to improve overall casting consistency, we have the expertise and solutions to help you achieve breakthrough results.

Technical Services

FOUNDRY MAX Technical Services perfectly combines professional metallurgical expertise with practical experience in implementing filtration technologies to improve casting quality and production efficiency. Our dedicated foundry experts have filtration solutions developed and proven in thousands of filter applications around the world, ensuring rapid implementation, casting quality improvement and measurable return on investment.

Our technical services cover all aspects of foundry filtration technology and are tailored to your specific operation:

Casting Defect Analysis and Diagnosis

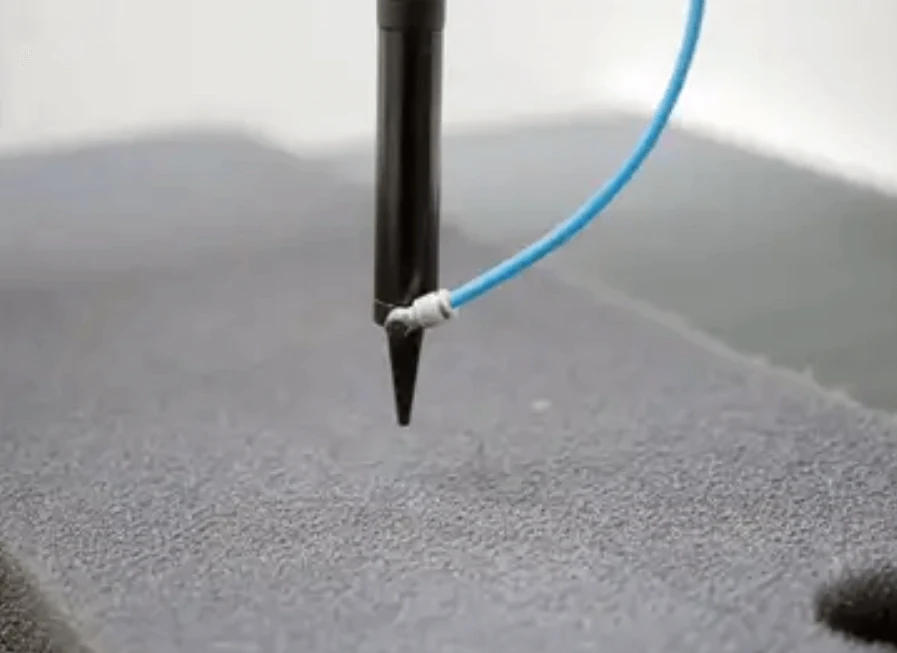

Our metallurgical experts will use advanced filter technology to accurately identify the type of inclusions, their source and their impact on the quality of the final casting product. We trace the root cause of inclusions, whether they originate from the raw materials, melting process or treatment procedures.

Filtration System Design and Engineering

We design optimized complete metal filtration solutions based on your specific metal composition and casting parameters. Our designs strike a balance between optimal impurity removal and suitable flow characteristics to maximize both quality and production efficiency.

Casting System Optimization

In addition to the filter product itself, we also delve into the casting system. Whether you need a comprehensive filtration system redesign or targeted optimization of an existing process, our technical services can significantly improve your profitability.

Custom Filter Services

Our custom development filter services have helped many high-end foundry companies solve technical challenges that standard materials cannot cope with, supporting them to produce higher quality and higher value-added casting products.

Foundry Max’s custom development filter services are designed for metal foundries that have special process requirements that cannot be met by standard materials. Our custom service features include:

Exclusive Formulation Design

Develop optimized filter material formulations based on the customer’s specific alloy system, casting temperature, and process requirements. This personalized formulation can provide the best chemical stability and thermal matching, avoid defects caused by material incompatibility, and help customers achieve zero-defect casting goals.

Precisely Controlled Microstructure

Through advanced filter manufacturing processes, the pore size distribution and through-porosity of the material are precisely controlled (adjustable from 10-60 PPI). This microscopic control ensures that the material has the best filtration efficiency and fluid mechanics, reduces the design pressure of the pouring system, and improves the fluidity and filling capacity of the molten metal.

Custom Filter Shape and Size

Meet the special size and shape requirements of non-standard casting systems and provide perfectly matched filter material solutions. This precise matching reduces the workload of installation and adjustment, improves work efficiency, and ensures the stability of the ceramic filter during use.

Performance parameter optimization

Balance the performance parameters such as material strength, filtration efficiency, and service life according to actual metal filtration application requirements. This optimized design ensures that the material performs at its best in specific application scenarios, extends the service life, and reduces the material cost per unit casting.

FoundryMax combines precise scientific measurement, in-depth technical analysis and professional custom development to help you solve the problems encountered by filter sheets in casting. With 20 years of professional accumulation and cutting-edge technology research and development, we not only provide products, but also provide practical insights and solutions to help you significantly improve casting quality, optimize production efficiency, reduce operating costs, and enhance market competitiveness. When you work with Foundry Max, you choose a professional technical partner who truly understands your casting process needs.