Filter Materials for Copper Alloy Castings

Copper alloy casting is a molding process that uses copper as a base and adds elements such as zinc, tin, and nickel to create alloy materials with specific properties. Its most notable feature is the ability to achieve diverse material properties, ranging from high conductivity to high strength, through compositional adjustments. It is widely used in electronics, shipbuilding, and construction.

This versatile nature of copper alloy casting has made it a shining example in specialized fields such as precision instrumentation and artistic castings. Modern copper alloy casting, through the introduction of advanced processes such as vacuum melting and electromagnetic stirring, has further improved the material’s density and performance stability, expanding its application in emerging fields such as 5G heat sinks and new energy vehicle motors.

Copper Alloy Casting Filter Function

During the copper alloy casting process, the molten metal easily produces impurities such as oxides and slag. These impurities directly affect the conductivity, corrosion resistance, and mechanical strength of the casting. Ceramic foam filters and glass fiber filters serve as key purification methods, effectively removing tiny inclusions from molten copper through physical interception and adsorption.

The ceramic foam filter, with its three-dimensional mesh structure, is particularly suitable for capturing micron-sized impurities, while the glass fiber filter effectively removes larger oxide and slag particles. Their combined use not only significantly improves the purity of the molten copper but also enhances metal fluidity, resulting in denser and more uniform casting microstructures.

This filtration technology is particularly effective in the production of high-quality copper castings, such as high-conductivity copper alloys and wear-resistant bronzes, effectively reducing porosity and inclusion defects, ensuring excellent electrical conductivity and mechanical properties while lowering subsequent processing costs and providing a reliable guarantee for the quality of complex, precision copper castings.

Impurity Removal and Purification: Efficiently removes impurities such as oxides and slag, enhancing the purity of the molten copper.

Performance Improvement: Ensures key performance indicators such as conductivity, corrosion resistance, and mechanical strength.

Process Optimization: Stabilizes metal fluidity and reduces porosity and shrinkage defects.

Filter Applications in Copper Alloy Casting

High-performance filtration systems precisely intercept oxides and slag from the melt, significantly improving the conductivity and mechanical strength of castings. Our copper alloy-specific foam ceramic filters and glass fiber filters, with their excellent resistance to copper molten corrosion and gradient filtration properties, are widely used in the production of a variety of critical copper castings, providing customers with comprehensive filtration solutions for materials ranging from high-conductivity materials to wear-resistant alloys.

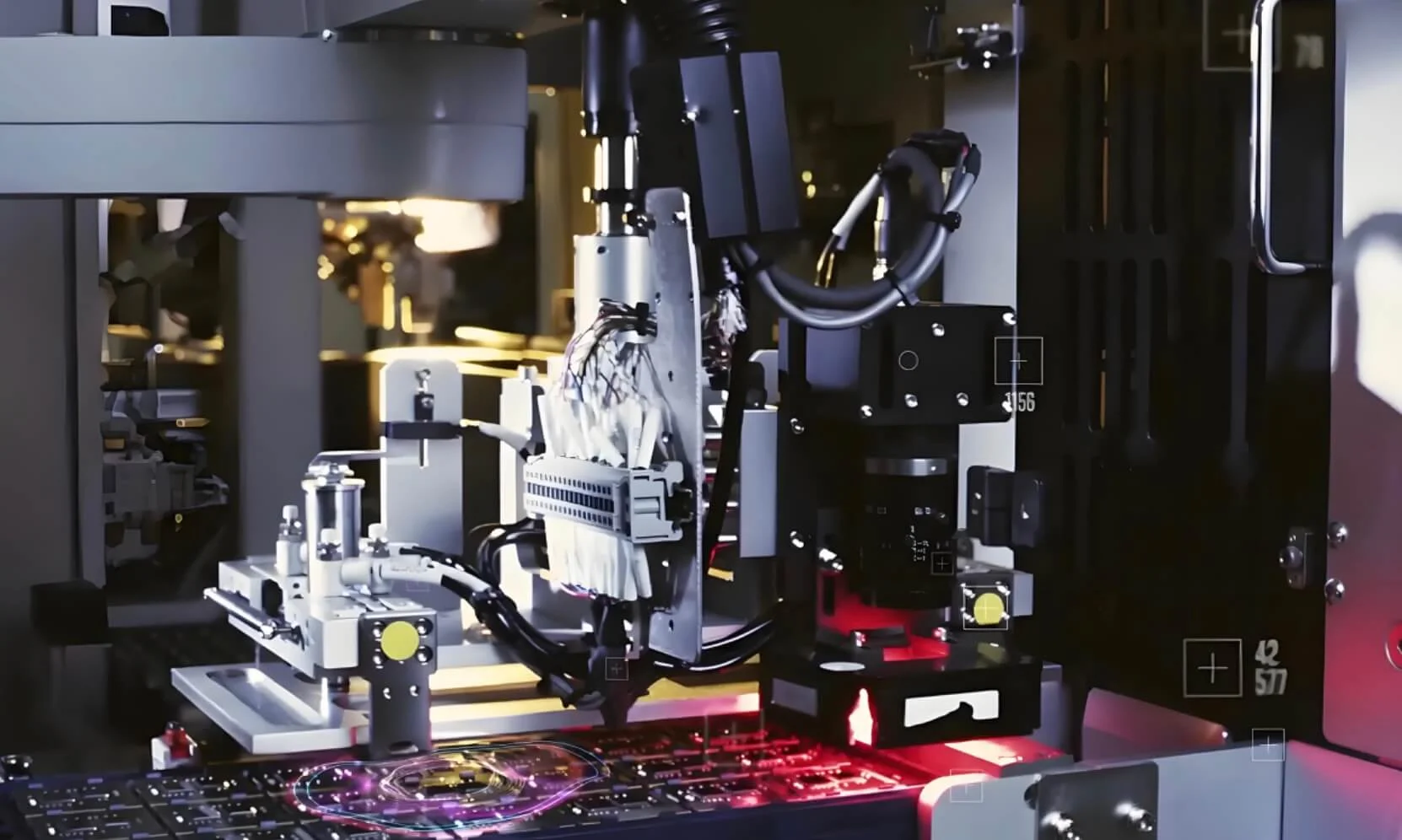

Electronics and Electrical Industry

Applied in the production of high-conductivity components, including circuit board connectors, conductive bars, and heat sinks. By removing trace oxides from the copper melt, these filters ensure more stable conductivity and significantly reduce signal transmission loss, meeting the stringent material purity requirements of modern high-frequency circuits. Through precision filtration technology, excellent electrical and thermal conductivity and stable signal transmission are ensured.

Marine and Offshore Engineering

These filtration technologies are used to manufacture critical components resistant to seawater corrosion. The shipbuilding industry relies on copper alloy castings to produce critical seawater-resistant components, such as propellers, seawater pump bodies, and valves. Optimized filtration processes can significantly improve the corrosion resistance and service life of castings in salt spray environments.

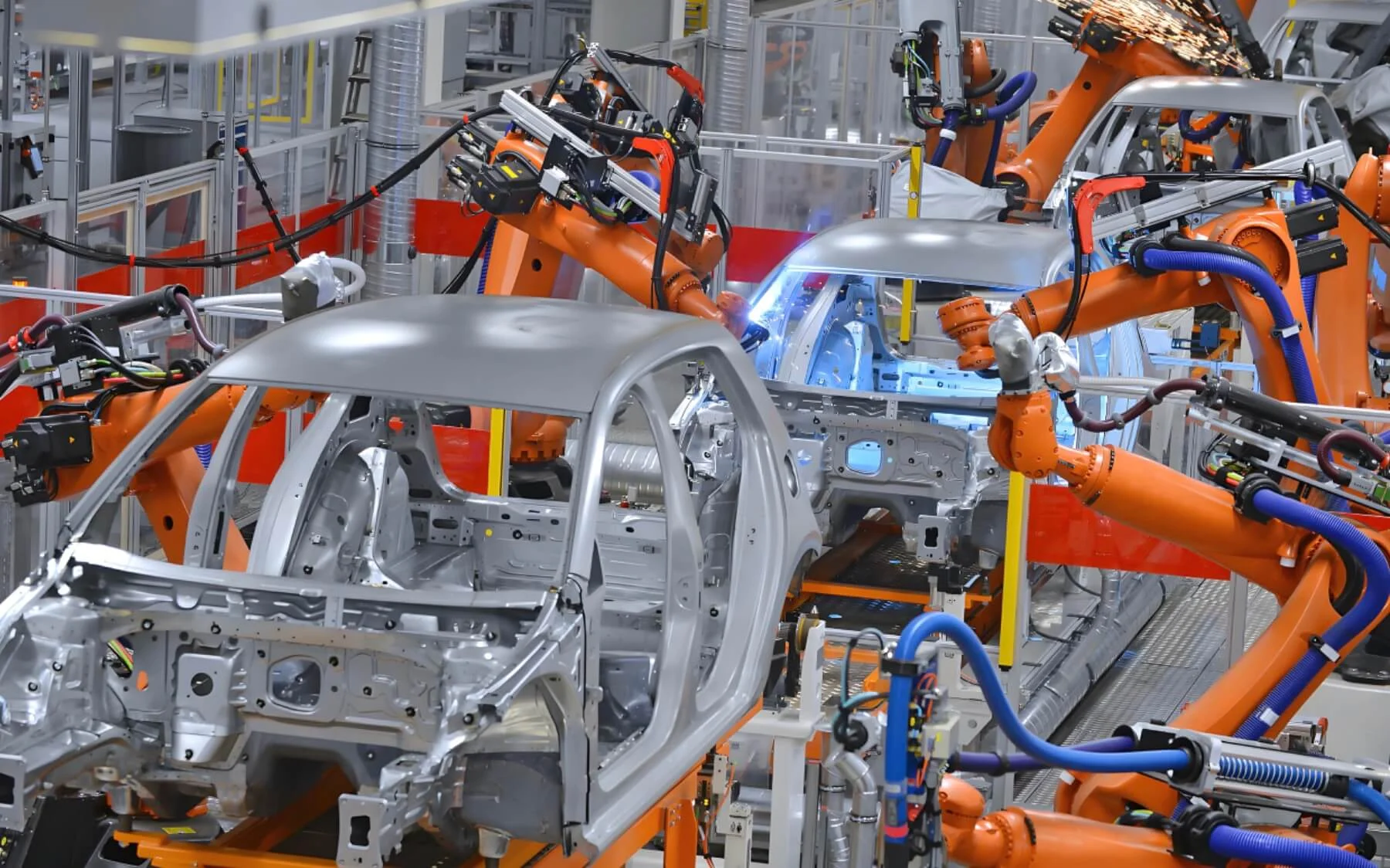

Automotive Industry

In the automotive industry, particularly in the new energy vehicle sector, these filters play an irreplaceable role in the manufacture of high-voltage charging interfaces. By optimizing the purity of copper-chromium-zirconium alloy, the charging interface maintains a contact resistance of less than 5mΩ after 1,000 plug-in/plug-out cycles, while also increasing production efficiency by 25%. This high-purity filtration system ensures component wear resistance and fatigue strength under complex operating conditions.

Machinery Manufacturing

In heavy machinery manufacturing, filtration technology addresses the reliability challenges of copper alloy bearings. The machinery manufacturing industry uses copper alloy casting to produce high-pressure hydraulic components, injection molding screws, and mining machinery bushings. Gradient filtration technology effectively improves the material’s self-lubricating and anti-seizure properties.

Architecture and Art

Filtration technology modernizes traditional crafts. In the architectural art field, copper alloy casting is used to create sculptures, decorative architectural components, and replicas of historical artifacts. Professional filtration solutions ensure that the surface quality and weather resistance of the castings meet state-of-the-art standards.

Specific Filter Application Cases in the Copper Alloy Casting Process

FM-07 Glass Fiber Filters Application in Production of 5G Base Station Heat Sinks

A Chinese communications equipment supplier was experiencing a long-term yield rate of around 75% due to oxide inclusions when die-casting high-conductivity copper alloy heat sinks. By adopting the FM-07 glass fiber filter combined with a two-stage filtration system, the product’s conductivity improved by 15% and heat dissipation efficiency by 20%.

The production line’s scrap rate dropped from 25% to below 5% within six months, saving over 800,000 RMB in material costs annually. The improved heat sinks demonstrated more stable temperature control performance in actual 5G base station operations, helping the client secure bulk orders from multiple overseas operators.

Contact us today for a no-obligation consultation that help you solve your copper alloy casting problems and learn how our filters can help you improve the quality and output of copper alloy casting and save production costs for your plant!