FM-10 Ceramic Foam Filter for Copper Filtration

In the copper casting and processing industry, non-metallic inclusions and oxides in the metal can cause serious problems such as product defects, high breakage rates, and low production efficiency. As a leading global provider of metal filtration solutions, FoundryMax’s FM-10 copper filter is designed to address these challenges.

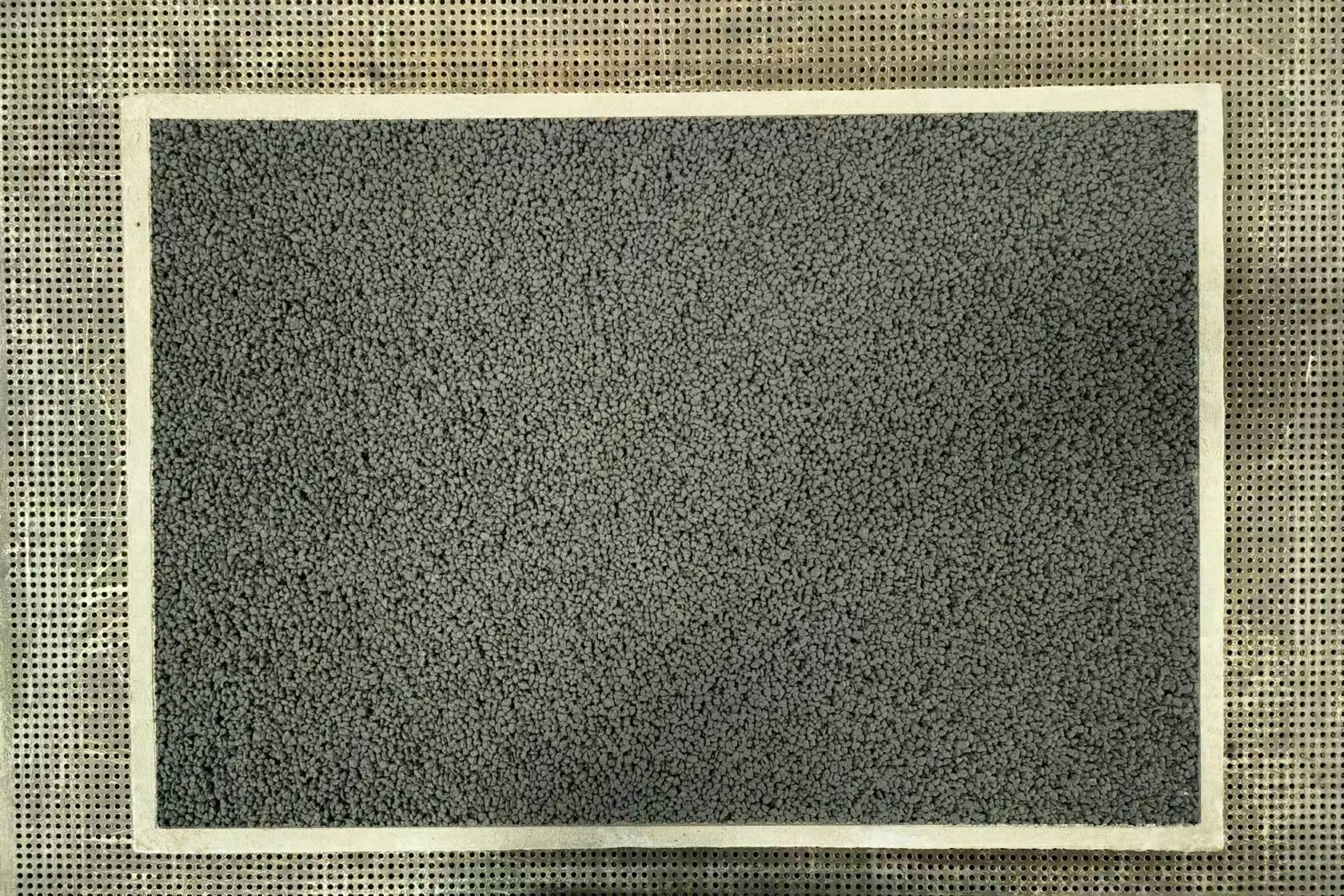

The FM-10 Ceramic Foam Filter for Copper Filtration utilizes advanced ceramic foam technology to create a three-dimensional network structure that effectively captures tiny particles and non-metallic inclusions in the copper solution. Its unique high-temperature stability and chemical inertness ensure efficient and reliable filtration under extreme conditions.

Real-world application results show that customers using the FM-10 filter report improved production continuity, significantly improved final product quality, reduced scrap rates, and a 15-20% reduction in overall production costs.

Adaptable to various copper alloy casting processes and casting equipment, perfectly compatible with existing copper casting production lines and gating systems

Capable of capturing minute impurities and oxides, improving product surface quality by over 40%

Provides a cost-effective basic filtration solution to maximize filtration effectiveness and return on investment

Customized filtration solutions based on the customer’s specific copper metal production process parameters

FM-10 Advanced Ceramic Foam Filter for Copper Metal Filtration

The FM-10 high temperature filter utilizes advanced ceramic foam technology to effectively remove non-metallic inclusions and oxides from copper metal solutions, reducing breakage, significantly improving production continuity and finished product quality. It is an ideal choice for copper casting production.

Size Custom

Customize to the customer’s launder or tundish dimensions

Pore Size

Choose the pore size based on specific impurity type and size

Shape Custom

Square, round, oval, and special shapes

What Can We Offer?

The FM-10 copper molten metal ceramic filtration system utilizes advanced porous ceramic material technology and manufacturing processes to create a filter media with superior performance.

Our core technology lies in our specialized ceramic slurry formulation and precisely controlled molding process, which creates a three-dimensional, interconnected network structure with an optimal pore size distribution and porosity. This structure optimizes the filter’s impurity capture capacity, effectively capturing tiny impurities while ensuring smooth copper flow, extending effective filtration time, and minimizing pressure loss.

Applicable to all major copper alloys, including pure copper, brass, bronze, and more

Compatible with major copper casting equipment and filtration systems

Can be installed in the tundish, launder, or mold inlet

Compatible with major casting processes, including continuous and semi-continuous casting

Suitable for the production of various copper products, including copper wire, copper sheet, copper tube, copper rod, and more

Professional Copper Casting Filtration

The FM-10 copper molten metal filtration system utilizes unique ceramic foam technology and customized solutions to provide copper processing companies with industry-leading filtration results, significantly improving product quality and reducing production costs. We provide not only filter products but also comprehensive technical support, from process evaluation to implementation follow-up, to help customers maximize their return on investment

- Improved surface quality of copper castings

- Extended production uptime

- Reduced overall production costs

Filter Application

The FM-10 copper molten metal filtration system is designed to integrate seamlessly with various copper casting processes and foundry equipment. Whether it’s a continuous casting line, semi-continuous casting line, or gravity casting system, the FM-10 ceramic filter can be easily adapted.

Specific Industry Applications:

Automotive: Improving the mechanical properties and service life of copper alloy parts

Electrical and Electronics: Ensuring high-purity copper materials for precision electronic components

Offshore: Improving the performance and reliability of corrosion-resistant copper alloys

Heat Exchange: Enhancing the thermal conductivity of copper tubes and heat exchanger components

Precision Machinery: Ensure high precision and surface quality of copper parts

Frequently Asked Questions

How does the FM-10 ceramic filter improve the quality of copper alloy castings?

The FM-10 ceramic foam filter effectively captures non-metallic inclusions and oxides in the copper molten metal through its three-dimensional ceramic mesh structure, reducing the amount of these impurities that enter the final product. This significantly reduces defects in the product, improves mechanical properties, conductivity, and surface quality, and ensures more consistent and reliable quality in copper alloy castings.

What is the service life of the copper filter?

The FM-10 filter is designed for single-furnace operation and can provide continuous filtration for 8-12 hours under standard operating conditions. The actual service life depends on the copper molten metal temperature, impurity content, and flow rate. Some customers have been able to extend the service life with low impurity levels, but we recommend regular replacement according to technical specifications to ensure optimal filtration performance.

What are the advantages of the FM-10 foam filter over other filtration methods?

Compared to fiber glass filtration, the FM-10 foam filter offers higher filtration efficiency, better high-temperature stability, more uniform filtration, and lower pressure loss. Its unique three-dimensional mesh structure not only captures large impurities but also effectively removes tiny oxides and gas inclusions, providing a comprehensive filtration solution.

More Foundry Filters

We supply various molten metal filter materials, backed by years of expertise in supporting foundry operations globally

The FM-10 copper metal filtration system will significantly improve your product quality, increase production uptime, and reduce maintenance costs. Our dedicated team provides comprehensive support from evaluation to implementation, helping you achieve a rapid return on investment. Contact us to embark on a new era of high-quality copper processing!

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China