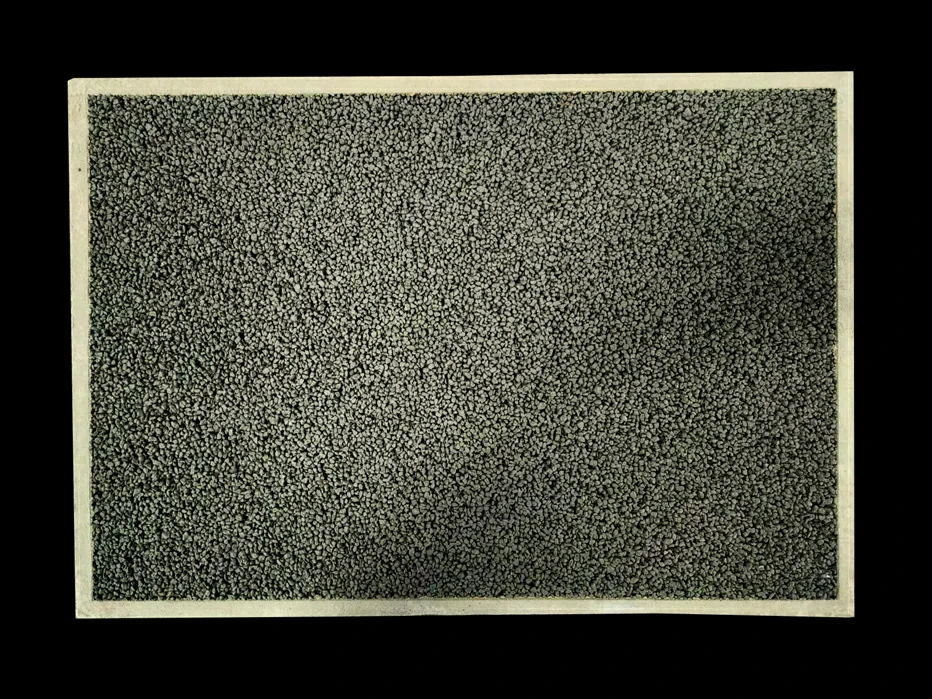

FM-09 Silicon Carbide Bonded Particle Filter

The aluminum casting industry has long faced quality issues caused by oxides and inclusions in the molten metal. These defects severely impact the mechanical properties, airtightness, and surface quality of castings, increasing scrap rates and reducing production costs.

The FM-09 silicon carbide bonded particle filter, with its unique porous structure, effectively captures and removes impurities from aluminum molten metal, providing aluminum foundries with a one-stop solution for melt purification. Made from high-purity silicon carbide raw material, this filter offers excellent thermal stability, chemical inertness, and mechanical strength, maintaining stable performance even in the harsh, high-temperature molten metal environment.

Aluminum alloy melts filtered by the FM-09 exhibit improved fluidity and reduced porosity. Significantly improve the mechanical properties and surface quality of castings, and reduce scrap rates by over 30%, delivering significant economic benefits and competitive advantages to foundries.

Made from high-purity silicon carbide particles, offering excellent high-temperature performance.

Excellent chemical stability, non-reactive with molten aluminum.

High mechanical strength, excellent thermal shock resistance, and long service life.

Suitable for various casting processes, flexible to meet diverse production needs.

Easy installation, requiring no changes to existing casting system design.

Cost-effective, improving casting quality while reducing overall production costs.

Custom Size: Fully customizable sizes and shapes based on customer-specific gating system requirements.

Porosity Range: Available in 6, 8, 10, and 12 pore sizes, balancing filtration efficiency and flow requirements.

High-Efficiency Melt Filtration for Aluminum Alloy Casting Quality

FM-09 Silicon Carbide Bonded Particle Filter is a high-performance melt filtration solution designed specifically for aluminum and aluminum alloy casting processes. Made from high-purity silicon carbide particles, it offers excellent strength, chemical stability, and a long service life. It effectively removes oxides and inclusions from molten metal, significantly improving casting quality and production efficiency.

Filter Performance Comparison

| Item | Silicon Carbide Particle Filter | Alumina Ceramic Foam Filter |

| Main Component | SiC | Al2O3 |

| Average Porosity (%) | 45 | 70-90 |

| Porosity Diameter (um) | 200-800 | 250-3000 |

| Maximum Working Temperature (℃) | 1250 | 1200 |

| Density (g/cm³) | 1.8-1.9 | 0.45-0.65 |

| Strength (kg/cm²) | 30 | 1.2 |

|

Thermal Expansion Coefficient (*10-7mm/℃) |

35 | 80 |

| Thermal Conductivity (W/(m*K)) | 240 | 30 |

| Heating Time at 800℃ (min) | 10 | 20-30 |

Custom Solutions for Cleaner Aluminum Castings

The FM-09 silicon carbide bonded particle filter series offers a variety of sizes and shapes to meet the specific needs of various casting processes. Each filter is made from the same high-quality silicon carbide raw material and optimized for the application and filtration requirements.

By selecting the appropriate FM-09 ceramic filter for their specific process, aluminum foundries can significantly reduce inclusion-related defects.

Multiple filter types available – Choose from vertical gate, box, or tubular designs

Easy integration – Works smoothly with different casting systems to provide comprehensive melt purification solutions

Better metal flow – Improves filling and reduces porosity

Higher-quality surfaces – Smoother finish on cast parts

Lowers costs – Less scrap, easier machining, more profit

Boosts competitiveness – Better products at lower production costs

FM-09 Silicon Carbide Bonded Particle Filter for Aluminum Casting Melt Filtration

FM-09 silicon carbide bonded particle filter is the most reliable melt purification solution for the aluminum alloy casting industry. With superior filtration efficiency, excellent thermal stability, and extended service life, it helps foundries significantly improve product quality, reduce scrap rates, and save production costs. We provide not only filtration products but also comprehensive melt quality management expertise to help customers achieve superior casting processes and gain a competitive advantage in the market.

Filter Application

Applicable to all aluminum and aluminum alloy casting systems

Compatible with gravity casting (permanent mold) systems

Applicable to high-pressure die casting equipment

Compatible with low-pressure casting systems

Applicable to squeeze casting processes

Compatible with high-performance sand casting systems

Can be integrated with various gating systems and metal handling equipment

Applicable to various aluminum alloy grades

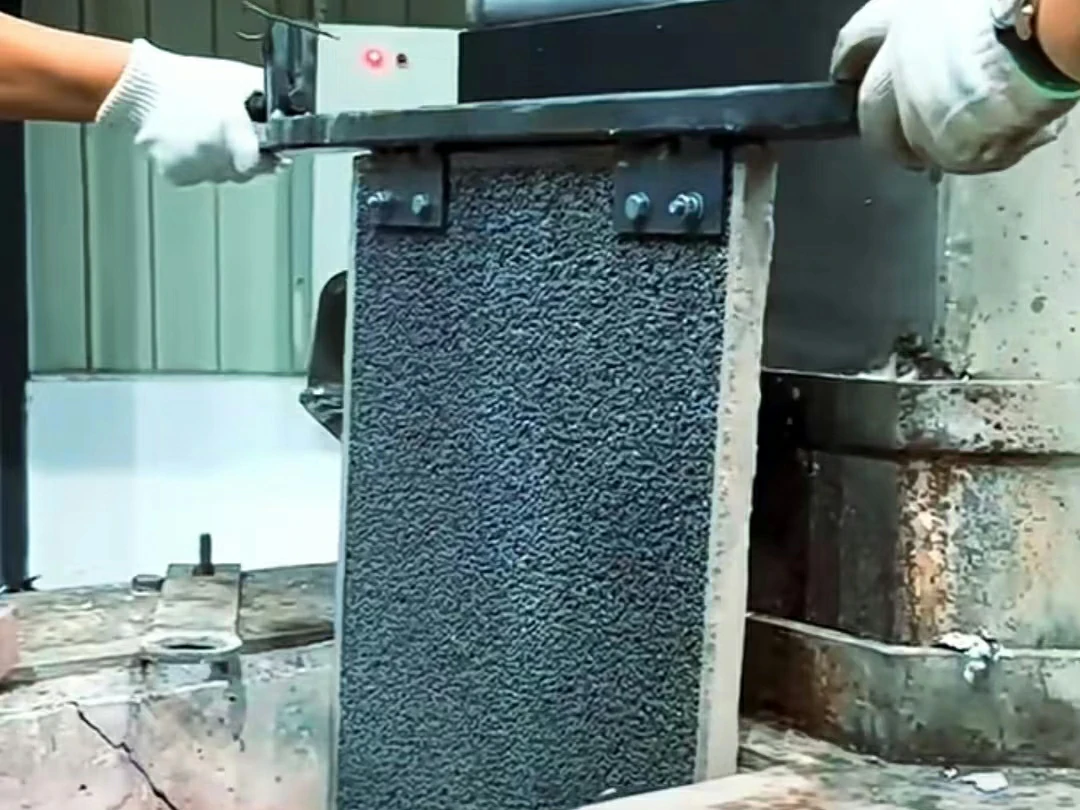

Vertical Gate Filter Applications

The FM-09 vertical gate filter is installed in the gating system of the mold, which is the most common application. Molten aluminum alloy enters the mold cavity through the filter, effectively intercepting inclusions. This configuration is particularly suitable for the production of automotive parts such as cylinder heads, cylinder blocks, and wheels.

Aluminum Casting Quality Improvement

Reduced Scrap Rate

Improved Internal Casting Quality

Enhanced Mechanical Properties

Reduced Labor Costs

FM-09 Silicon Carbide Bonded Particle Filter is the best choice for resolving inclusion issues in aluminum castings. Our dedicated team will provide you with customized aluminum melt filtration solutions to significantly reduce scrap, improve product performance, and save production costs. Contact us for product samples and technical support to take your casting process to the next level!

Related Casting Filter Products

As an experienced filter manufacturer, we craft durable and efficient molten metal filters tailored for foundry needs

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China