What Are Industrial Filters?

In my experience, industrial filters are special devices that clean up industrial processes. They are designed to pull out things you don’t want, like solid bits, extra liquids, and gases. Their role is critical. They protect expensive machines, keep product quality the same, and help companies follow safety and environmental rules. When they capture these unwanted materials, filters help machines last longer. This also cuts down on expensive repairs and prevents work from stopping.

Major Sectors and Contaminant Targets

I consider industrial filters the quiet protectors of industry. I’ve seen them used in so many important jobs. They are essential for oil rigs and for protecting turbines in power plants. They keep our food safe, ensuring every snack is good to eat. Filters also clean our rivers, removing dangerous chemicals.

They are built to remove key contaminants, which include:

– Solid particles like dust, rust, and sludge

– Water and oil droplets

– Hazardous chemicals, toxic gases, and organic compounds

Leading Filter Types and Market Trends

Air and gas filtration systems are the biggest players in the industry. They hold up to 69.9% of the market based on 2025 data. I think this strong demand comes from tough rules about emissions and safety at work. You will find these systems most often in power plants, heavy industries, and petrochemical sites. They are used there to stop harmful emissions and particles from escaping.

Application Snapshots

From my experience, industrial filters are vital. In a drug manufacturing plant, HEPA filters work nonstop to remove tiny, harmful particles from the air. This process keeps the sterile rooms incredibly clean. They keep engine coolants clean and help make paint jobs perfect. After they upgraded their filtration system, they reduced faulty products by a third. These filters work everywhere, from hot metal foundries to plants that clean city water. In my opinion, they are the quiet protectors of quality and safety.

Industry Trends and Innovation

Smart Filters: More companies use filters with IoT and AI. This allows for real-time monitoring and can predict maintenance needs. The result is fewer breakdowns and better filtration.

Sustainable Choices: Industries are now using reusable filter designs and materials that are better for the planet. This helps them meet their sustainability and waste-reduction goals.

Expanding Markets: Fast industrial growth in developing economies is increasing the use of advanced filters. Based on my observations, this also pushes for constant upgrades in filter technology.

In my view, industrial filters are no longer optional. They are the backbone of modern industry. They support rule compliance, product quality, operational safety, and long-term environmental protection.

5 Common Types of Industrial Filters

Industrial filters have many special designs. Each one is made to handle different problems and uses. Based on my experience, I see five types used most often:

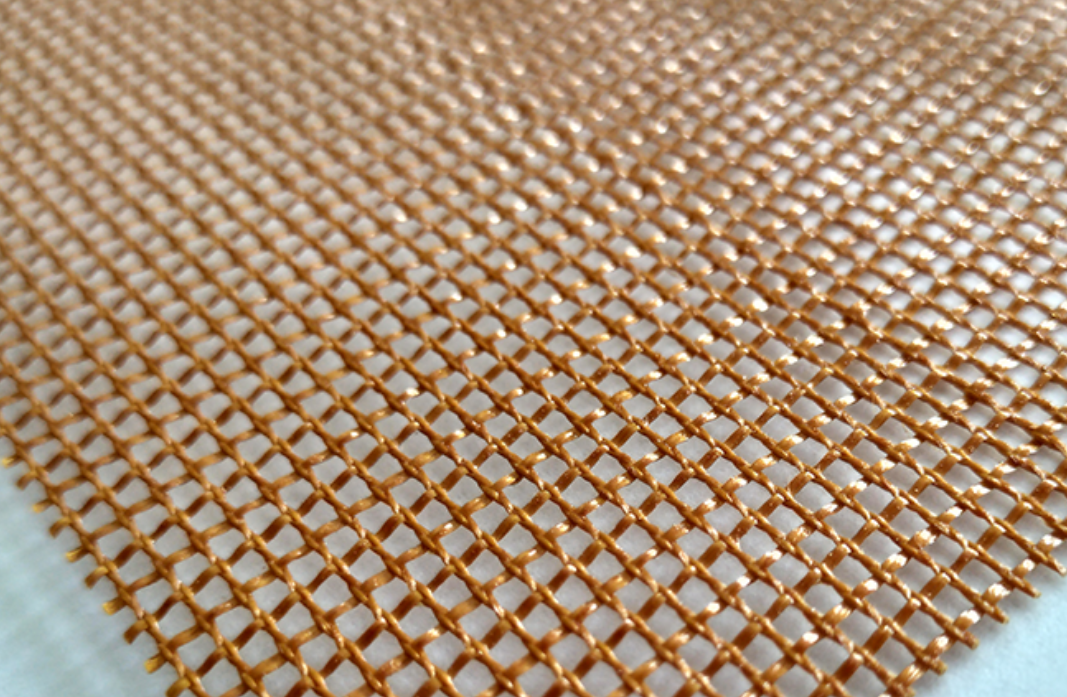

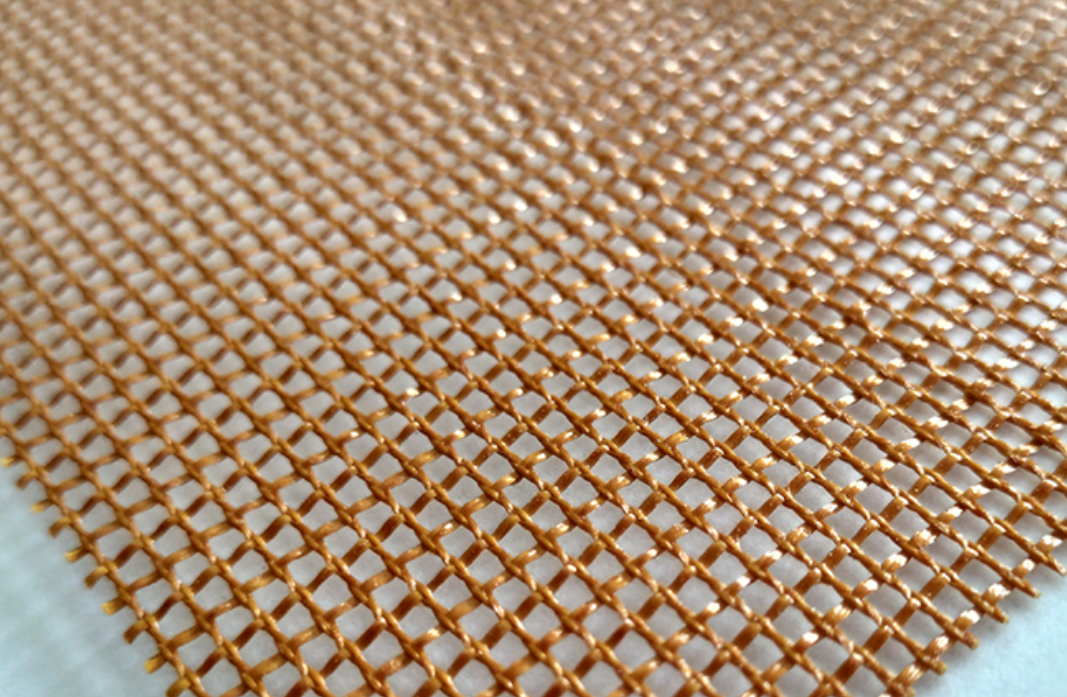

Mechanical Filters

I see mechanical filters as frontline shields. They use mesh screens and pleated cartridges to guard against things like sawdust and mineral dust in your factory air.

From my experience, if your job needs tighter control, I recommend pleated filters. These are made from felt layers that can trap debris as fine as 1 micron. This process makes products like paint and juice look crystal clear.

If you’re trying to capture fine powder or fumes, I’d suggest a MERV 14–16 filter. About 67% of plant managers I’ve spoken with say it’s their go-to choice for keeping the production line spotless.

Absorption Filters

These filters use materials that soak things up, mainly activated carbon. It captures organic pollutants and unwanted chemicals by making them stick to its surface.

I find the activated carbon filter essential for chemical processing, pharma, and food making. They are also vital for air cleaning where you need to control gassy pollutants and smells.

Activated carbon is excellent at targeting volatile organic compounds (VOCs), bad smells, and harmful gases.

Example: Think of cleaning VOCs from a factory’s exhaust. Or, you can use them for odor control in a food plant.

Membrane Filters

These use very specific membranes with tiny pores. The pores block particles based on their size. The filtration can be as fine as 0.01 micron or even down to 0.001 micron.

In my opinion, these are critical for jobs that require extreme purity. This includes water for pharma, biotech processes, and advanced water treatment that must remove germs or viruses.

Example: A common use is removing bacteria and viruses. This helps meet the strict water standards in the pharmaceutical industry.

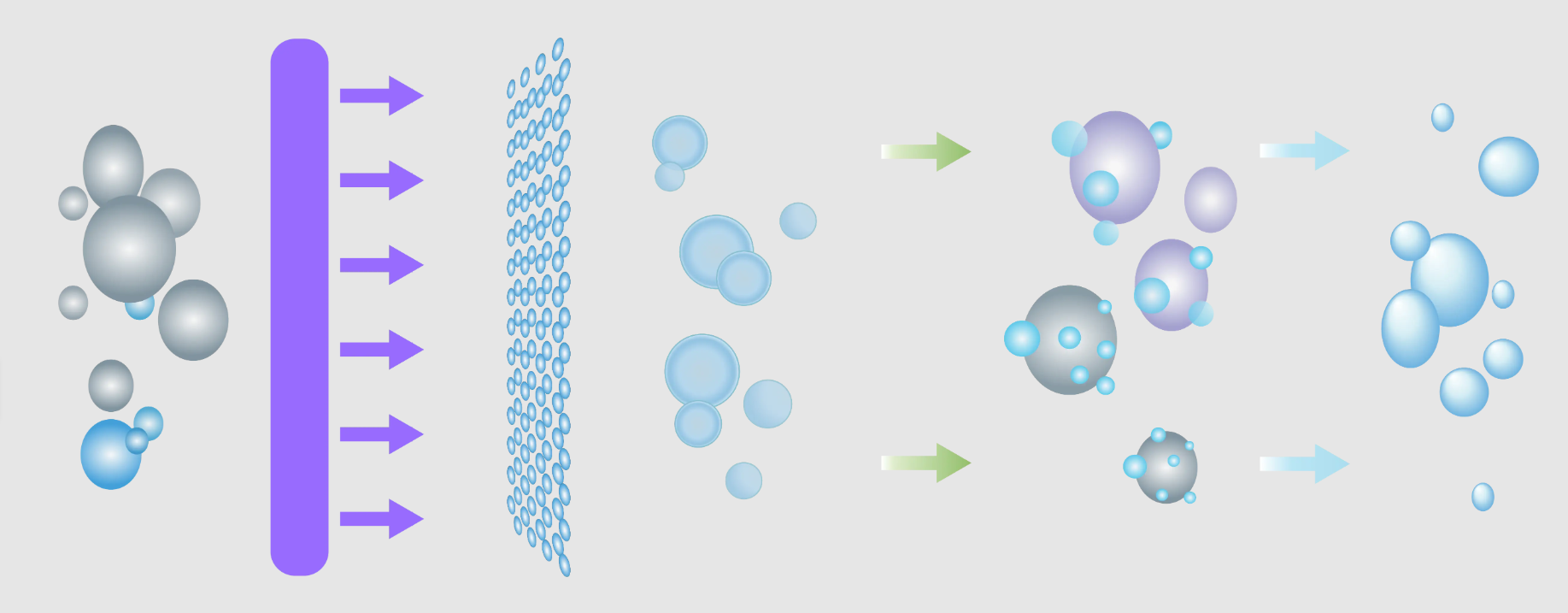

Coalescing Filters

I recommend these when you need to remove liquid. They are designed to collect tiny liquid droplets, like oil or water. They merge them into larger drops, which makes them easier to separate from air or gas.

They are common in compressed air systems and the oil & gas industry. I also see them in food processing where clean, dry air is a must.

Advanced units can remove droplets as small as 0.01 micron.

Example: A great example is removing oil mist from compressed air lines. This protects machinery and keeps processes running smoothly.

Gravity/Pressure Filters

These use gravity or outside pressure to push fluids through a filter material, like a sand bed. This method works well to separate solids from liquids in large volumes.

From what I’ve seen, they are perfect for city water treatment, handling mining slurry, and other high-volume liquid jobs.

Example: City water plants use sand filtration. Mines use them to remove heavy solids from slurry.

Industrial Filter Selection Key Facts

I always say to check the Micron rating. A smaller number, like 1 micron, means finer filtration. You must match the filter type to what your process needs.

Here is what I typically see in different industries:

- Food & beverage: They often use FDA-compliant pleated filters. This ensures the products are clear and safe.

- Chemical processing: I suggest a mix of absorption and membrane filters. This combination removes toxic chemicals and organic materials.

- Manufacturing: Here, I recommend mechanical cartridge filters with MERV 10–16 ratings. They help control dust, recycle water, and protect equipment.

| Filter Type | Mechanism | Particle Size Range | Example Applications | Key Example |

|---|---|---|---|---|

| Mechanical | Physical barrier | 1–200 micron | Water, metal finishing, coatings | Removing sawdust |

| Absorption | Binds chemicals to surface | <1 micron (gases, VOCs) | Chemical, air cleaning, pharma | Capturing VOCs with carbon |

| Membrane | Porous media blocks by size | 0.001–0.1 micron | Pharma, biotech, pure water | Removing germs/viruses |

| Coalescing | Merges liquid droplets | ~0.01 micron | Oil/gas, compressed air | Removing oil mist |

| Gravity/Pressure | Pushed by gravity/pressure | Variable | Water treatment, mining, big jobs | Filtering water with sand |

Key Uses for Industrial Filters

From my experience, industrial filters are essential in many fields. They clean air and liquids. They remove unwanted materials. They also help companies follow strict environmental and safety rules. They are a core part of manufacturing, energy, pharma, food and beverage, and automotive work worldwide.

Core Industry Applications

Manufacturing & Process Industries

Filters trap dust, oil, and small particles from the air. Based on my observations, this makes the air cleaner, helps machines last longer, and meets clean air rules.

Chemical & Petrochemical Plants

Filtering liquids and gases keeps processes stable and stops equipment from getting clogged. I recommend them because these filters help chemical reactions run smoothly and cut down on repair time.

Automotive Industry

In the automotive industry, the use of high-performance ceramic filters in the production of auto parts can effectively remove impurities from molten metal, helping to produce high-quality automotive castings and improve vehicle performance.

Pharmaceutical Production

For pharmaceuticals, special filters like HEPA create clean, sterile areas. They trap tiny particles and germs. This step is crucial for making safe products and getting them approved.

Food and Beverage Processing

In my opinion, filters are key in food and beverage. They make liquids like beer and juice clear. They get rid of bad smells and make sure water is safe. This is how companies meet tough food safety and hygiene rules.

Power Generation

Filters for dust and particles shield turbines and boilers from damaging debris. I believe reliable filtration in power plants is what allows them to run safely without stopping.

Application Trends & Regional Insights

Air filtration is in high demand because of safety and air quality needs. I see this growth centered in North America and the Asia Pacific region.

Liquid filtration is vital for treating water, running chemical plants, and cleaning industrial waste.

I’ve noticed a clear shift to filters and materials that are better for the environment. This helps reduce our overall impact.

Examples of Industrial Filter Integration

I suggest using HEPA filters in factories. They stop fine dust from escaping, which helps meet air quality laws.

Water treatment plants often use several filter stages. I’ve seen them use activated carbon, filter paper, and fiberglass to pull out different pollutants. This makes water safe to reuse or release.

Food factories use certain filters to keep products tasting great and lasting longer on the shelf. This practice aligns with hygiene regulations.

Emerging Trends in Filtration

I’m excited about smart, IoT-connected filter systems. They let you monitor them from anywhere and predict when they need maintenance. This improves reliability and cuts operating costs.

We are also seeing new filter materials, like modern fibers and special coatings. They last longer and work better. I believe this opens up new uses for filtration in more industries.

In my view, industrial filters are fundamental. They ensure operations are safe, products are pure, and equipment is protected. They also help meet regulations. These needs continue to grow as global standards become stricter.

My Take: Key Facts About Industrial Filters

Real-World Applications

- Baghouse filters: These control particle emissions in power plants.

- Activated carbon & sand filters: They are used to clean water and industrial wastewater.

- HEPA filters: I recommend these to ensure products are pure in the drug and food industries.

- Scrubbers with mesh pads: These clean flue gases inside chemical refineries.

- Smart/IoT sensors: I think these are a game-changer. They track filters in real-time. This allows for early maintenance warnings. It boosts uptime in food, beverage, and pharma.

Industry Impact & Market Innovations

These filters help companies follow the rules. They also keep product quality high in regulated fields. In my experience, filters make equipment last longer. They also cut down on downtime. Automated and easy-to-maintain designs are a big advantage. Filters are vital for clean production. This is important for industries needing very high purity, like life sciences, food, and beverage.

To sum up: My view is that the industrial filter market is set for solid growth. Better filter technology is a major growth factor. Tighter environmental rules and the need for clean processes are also key drivers across the globe.

Factors for Selecting an Industrial Filter

From my experience, picking the right industrial filter is key. It helps your operations run smoothly, keeps quality high, and ensures you follow the rules.