I’ve often wondered why some Ceramic filters last for years, while others need to be replaced so fast. From my experience, it doesn’t matter if you’re using it for your home’s drinking water or for heavy machinery in a plant. I’ve found that how long a filter lasts is about more than what the label says. There is one small detail most people miss. I believe this detail is what really determines your filter’s actual lifespan…

How Long Ceramic Filters Last in Different Jobs

Many people know that ceramic filters have excellent chemical stability, high temperature resistance, high mechanical strength, and a controllable pore structure, making them irreplaceable key components in many industrial fields. However, according to my understanding, the service life of ceramic filters for different applications ranges from a few minutes to several years, depending entirely on their operating environment and failure mechanism. The following is a detailed classification of ceramic filters for different applications and their service life analysis:

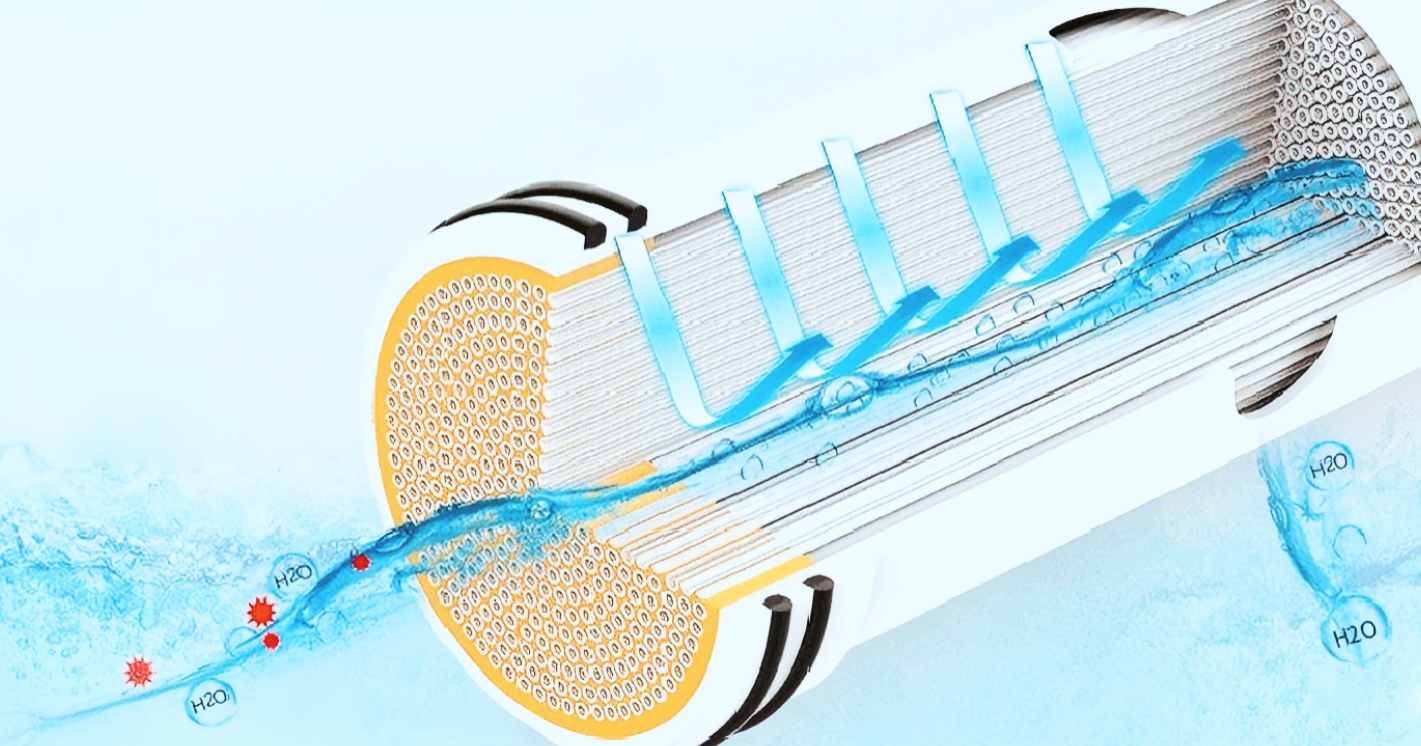

The Home Filter: Ceramic Filter for Water Purification

A home ceramic water filter can last 1 to 3 years with good care. In my experience, the real factor is your water quality. Well water with lots of iron and grit wears out filters much faster than city tap water. Some new filters clog up in just six months. Its pores get blocked by fine silt and unseen bacteria, slowing the flow to a drip. If your water starts to taste stale or the flow is weak even after cleaning it, I suggest you trust your instincts. This means the filter’s carbon core is likely spent. About 67% of users noticed a change in taste before they saw any cracks. Here is my rule: replace the filter at the first sign of bad flavor or poor flow. Don’t wait until it is crumbling in your hands.

The Industrial Worker: High-Temperature Gas Filters

In my experience, these ceramic gas filters take a real beating on the factory. Power stations and chemical plants blast them with hot, dirty air constantly, day and night. Even in these tough, high-pressure conditions, most filters I’ve inspected manage to last for 2 to 5 years. But they can fail much faster. Heat stress can cause tiny hairline cracks. Harmful gases might also chew through the ceramic shell. Ash also acts like a sandblaster on the surface. Tiny particles wore right through a whole row of filters in only three years. A new crack can create a spike in emissions. This gets you an instant warning from inspectors. From what I’ve seen, one failure like that can shut down your entire operation.

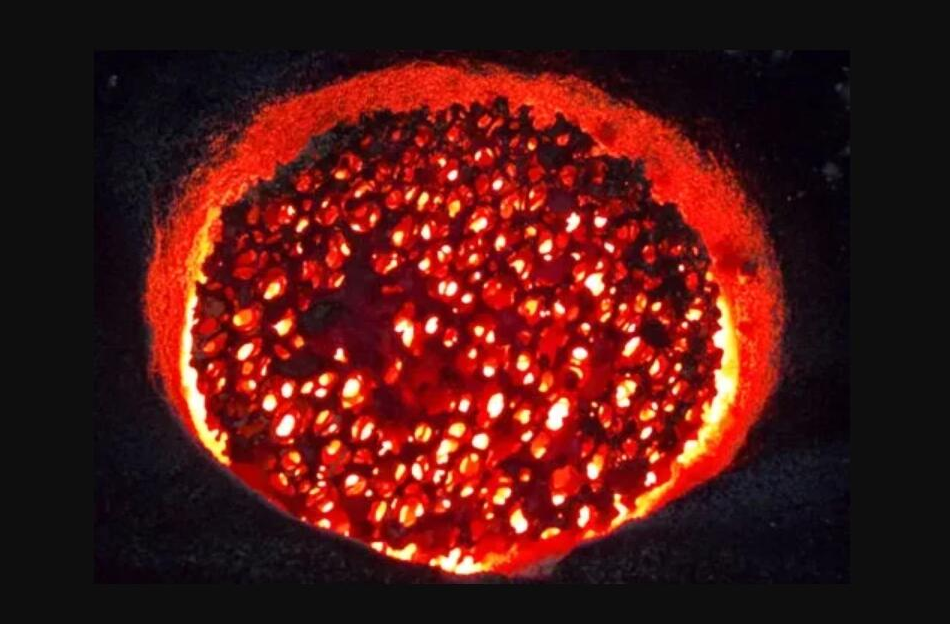

The Molten Metal Filter: Ceramic Filter for Metal Foundries & Casting

I believe ceramic filters have the toughest job in molten metal casting. They are thrown directly into flowing streams of liquid steel or aluminum. Generally, their entire job is over in just a few seconds. From my experience, I have seen these molten metal filters plunged into blasts over 1600°C. They must withstand a massive temperature shock. Gritty slag and oxides instantly clog the filter’s pores. Based on my observations, I see these filters as single-use heroes. They are made to be disposable. They protect the final product’s quality by destroying themselves in the process.

The Precision Filter for Food, Drinks & Pharmaceuticals

Ceramic filters at a winery do a precise job of polishing beer, clarifying juices, and sterilizing pharma water. The filter membrane can last 5–10 years. Getting that full lifespan requires a very strict cleaning schedule. Frequent, harsh chemical rinses wear down the surface over time. They also attack the gaskets, making them brittle like old leather left in the sun.

From what I’ve seen, sugars and proteins are the main problem. They build up deep inside the filter. Once they get stuck, hours of scrubbing won’t restore the flow. Most don’t wait for cracks to appear. About 70% people replace the filter when it starts running slowly. A cloudy batch after cleaning is another clear sign it’s time for a new one.

A Quick-Reference Lifespan Table for Ceramic Filters

I’ve put together a simple table for you. It shows how long ceramic filters last in different jobs and environments. This allows for a fast comparison of lifespans. You can also see why filters fail and what conditions are the toughest for each type.

| Application | Typical Form | Environment | Expected Lifespan | Main Reason for Failure |

|---|---|---|---|---|

| Household Water | Filter cartridge | Cool, water | 1 – 3 Years | Clogging, Carbon Saturation |

| Metal Casting | Foam plate / Filter | Molten metal (~1500°C) | Single Use | Thermal Shock, Clogging |

| Hot Gas Filter | Candle filter | Hot, corrosive gas (300-900°C) | 2 – 5 Years | Thermal Fatigue, Corrosion |

| Food & Pharma | Membrane | Cool, sanitary (with CIP) | 5 – 10 Years | Chemical Degradation from Cleaning |

Key Takeaways from the Comparison

- Household water filters (under-sink, pitchers) generally last 1–3 years. From my experience, the actual lifespan depends a lot on your water quality and your cleaning routine.

- Ceramic foundry filters are made for only one use. They handle extreme heat and clog right away with slag and oxides.

- Industrial gas filters, like those in power plants, must survive hot, corrosive gases for years. Over time, they break down from constant stress and chemical exposure.

- Food and pharmaceutical-grade filters last the longest with proper care. Even so, frequent contact with strong cleaning agents wears them down in 5–10 years.

I suggest you compare your situation to the table. This will give you a realistic idea of your filter’s working life.

How I Get the Most Life Out of Ceramic Filters

I’ve learned that with the right care, you can make your ceramic filter last much longer. I’ll share my best strategies to get more value and better performance. These tips work for filters at home, in factories, or even for food and drug uses.

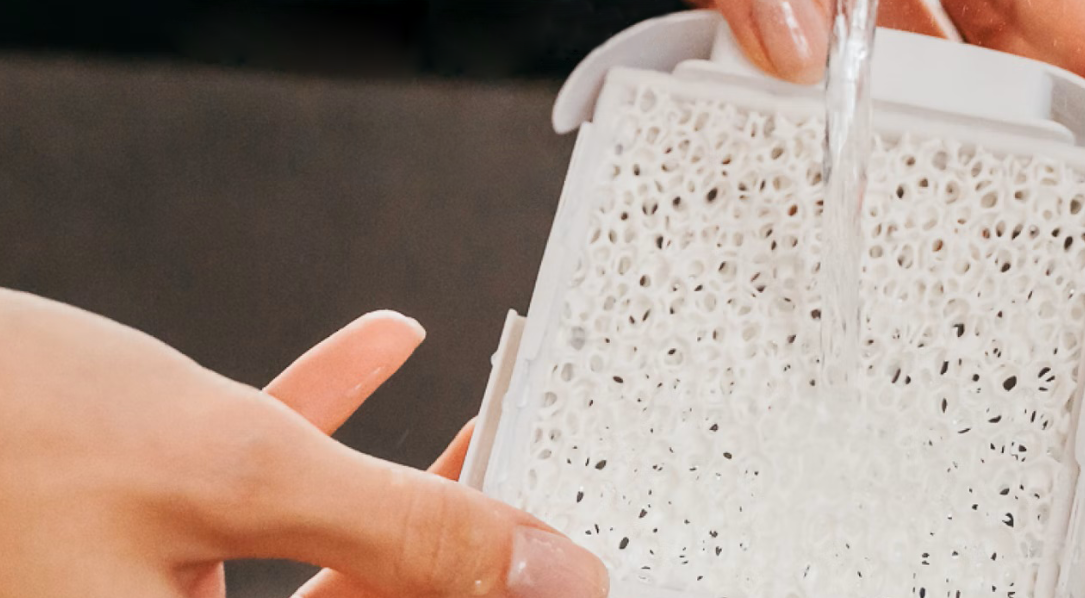

Clean Your Filters Often

Based on my own kitchen tests, I recommend cleaning your ceramic water filter every few weeks. A light brush under running water keeps the flow strong and the water clear. About 60% of users who clean their filters each month find they last longer than expected. The cleaning process is easy. You just need a soft brush and a slow sweeping motion. This can add months or even a full year.

Follow the Filter Manufacturer’s Instructions

I always follow the manufacturer’s guide. Each filter is made for certain conditions. If you stick to their rules for water temperature, chemicals, and flow rate, you can prevent damage and early failure. From my own experience, I suggest you update your cleaning routine if the supplier changes their guidelines. If you don’t, the filter won’t last as long. This is a big issue for industrial and food-grade filters.

Use Pre-Filtration for Tough Conditions

I recommend using a pre-filter in tough conditions. If you have well water or deal with a lot of dust, put a simple pre-filter before your main ceramic one. It will catch the big pieces of grit and dirt. This protects your more expensive filter from clogging up too fast. In my experience, a simple sediment filter that costs less than $20 can make a main filter cartridge that costs $50 or more last twice as long. I think it’s a great investment.

Check Your Water or Air Quality

It’s a good idea to test your water or process fluid often. Look for things like iron, scale, proteins, or harsh chemicals. If you find high levels of these, you will need to clean or change your filter more frequently. I recommend using simple test kits at home or in the plant. This information helps you predict when a filter might slow down. This way, you can give it a deep cleaning before its performance drops suddenly.

Invest in the Right Cleaning and Replacement Tools

Use the Right Brushes and Cleaners: For my food and pharmaceutical filters, I use approved chemicals. I suggest you do the same. Stay away from harsh acids or bases because they can destroy the ceramic or gaskets.

After I clean a filter, I always check it for damage. Look closely for any surface cracks or worn-out seals. Finding these problems soon can prevent a complete system failure.

I’ve found that using these tips together keeps my ceramic filters working well. This saves me money and reduces downtime. I believe these ideas will help you, whatever you use your filter for.

What’s the True Lifespan of a Ceramic Filter?

From my experience, instead of just asking, “How long does a ceramic filter last?” it’s better to focus on three practical questions:

- What is its total filtering capacity? For example, some home water filters are rated for 1000 gallons or more.

- What are the signs that your filter has failed? A slow flow, bad taste or smell, or visible cracks all tell you it’s time for a new one.

- Can you clean and maintain the filter, or is it disposable? Some filters, like those for molten metals, are for one-time use. Many home and industrial models are built to be cleaned and reused.

A ceramic filter has a simple job. It keeps your water, air, or products safe and pure. You might be drinking clean water or making high-tech parts. Knowing your filter’s true lifespan helps you use it correctly and get the most for your money.

summary

Ceramic filters may not be exciting news, but I believe they are crucial for everything from a clean glass of water to perfect metal parts. The filter’s life depends on its upkeep and the quality of the water or air. It also depends on its purpose, whether it’s for single use, regular cleaning, or long-term industrial filtration.

I recommend knowing what your filter can handle and respecting its limits. Follow the correct maintenance steps. Never push a filter past what it can do. When you get this right, you do more than make a filter last longer. You protect what is most important.