Industrial water filters are special systems built to clean industrial water. I see them as essential for removing things like solids, germs, dissolved materials, organic matter, and chemicals. Based on my experience, their main jobs are to improve water quality and protect your expensive equipment. They also help you meet environmental rules and keep your operations running efficiently.

Key Types of Industrial Water Filters

In my experience, industrial water filters have a few main types. Each type handles different pollutants and work needs. I find that picking the right filter is key. It affects water quality, how long your system lasts, and your plant’s efficiency.

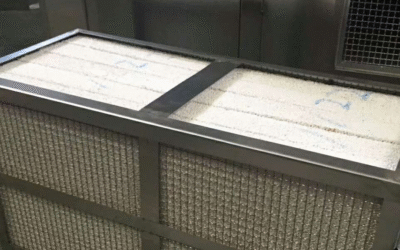

Strainers and Basket Filters

I find these to be straightforward mechanical filters. They have baskets with holes or mesh inside. They are very effective for catching larger particles, down to about 75 microns. Their main purpose is to protect your pumps and other equipment from damage caused by debris.

Automatic Self-cleaning Strainers

I am a big fan of these systems. They cleverly use the system’s own pressure to flush out built-up debris. You don’t have to stop the water flow. This means less maintenance for your team, and your plant can operate continuously.

Cartridge and Bag Filters

If you need to filter out very fine particles, I recommend looking at cartridge or bag filters. Cartridges can filter down to 1-5 microns, while bags handle particles down to about 50 microns. You should know they have a limited capacity for dirt, so you will need to replace them regularly.

Depth (Deep Bed) Filters

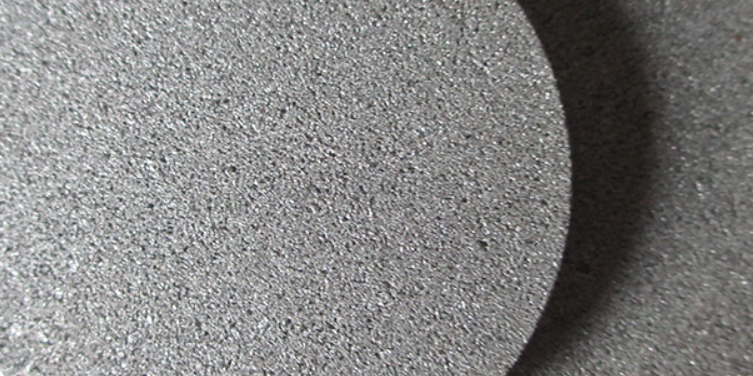

These filters use layers of materials like sand, anthracite, or zeolite. They capture particles throughout the entire filter bed. In my opinion, their biggest strength is holding a lot more dirt. They do an excellent job removing solids suspended in the water.

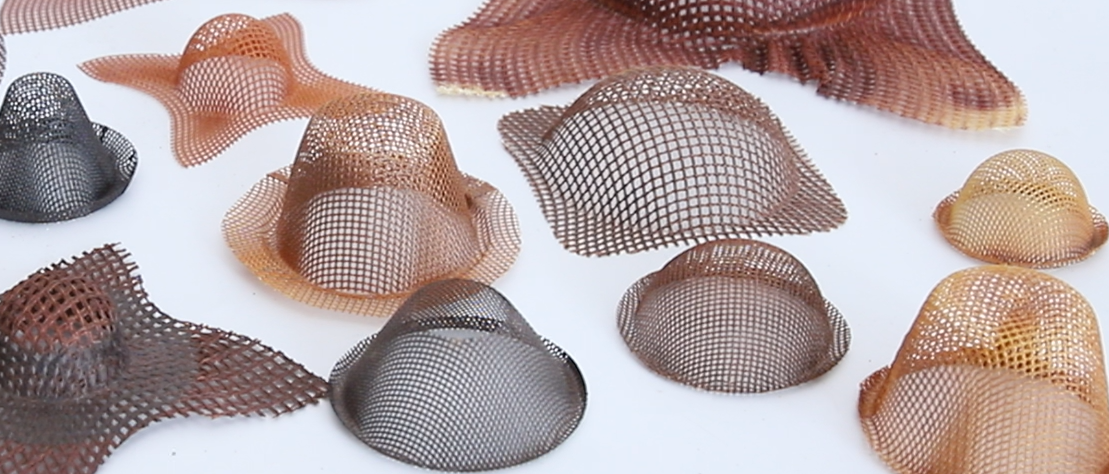

Disc Filters

These are made of stacked plastic discs that trap particles between 50 and 130 microns. I personally like their compact and modular design. They use less water during cleaning and often last longer than deep-bed or cartridge filters. The cleaning cycle, called backwashing, is often automated.

Centrifugal Water Separators

These devices use a spinning vortex motion to separate heavy particles like sand and silt. I have seen them used in well water treatment and industrial water recycling systems. A series I often recommend is the Lakos ILB, ILS, and IHB.

Reverse Osmosis (RO) Systems

RO units are incredibly effective. They use special membranes that can remove up to 99% of dissolved salts, heavy metals, bacteria, and organic matter. You can expect a removal rate of 95–99%. I believe RO is essential if your work requires high-purity water.

Activated Carbon Filtration

Activated carbon acts like a sponge. It absorbs chlorine, organic chemicals, and things that cause bad tastes and odors. I suggest using it as a pre-filter or as a final “polishing” step. Just be aware, it is not effective for removing salts or minerals.

Ultraviolet (UV) Purification

UV systems use light to disinfect water. The light damages the DNA of microorganisms, which stops bacteria and viruses. I often suggest this as a final sterilization step because it adds no chemicals to the water.

Media Filters

You can think of these as multi-layer filters. They contain sand, gravel, and anthracite. I find them ideal for removing cloudiness (turbidity), iron, and large suspended particles. The flow rate will depend on the materials used and the depth of the filter bed.

Separators and Inline Sand Filters

These are great maintenance-free devices that remove heavier solids and sand. They play a key role in protecting sensitive equipment like RO membranes and pumps. From my experience, the Lakos SandMaster is a popular inline choice.

Here are some common examples I’ve seen:

- Automotive plants: I’ve worked with auto plants that use multi-stage filtration. This helps them manage debris, solids, and oils to get the high-purity rinse water they need.

- Beverage factories: These factories must ensure their products are safe. They often use UV purification after other filtering steps to guarantee microbial safety.

- Mining industry: This industry recycles a lot of water. It uses centrifugal separators and sand filters to clean process water and reduce its environmental impact.

When it’s time to choose a filter, I suggest you consider several things. Think about your contaminant type, flow rate, and target water quality. You also need to consider your maintenance capacity, available space, and budget.

Well-known brands and models I’ve seen in the field include Lakos centrifugal separators and SandMaster inline sand filters. Modular deep bed and disc filters are also popular choices across many industries.

Membrane Filtration: MF, UF, NF, RO

- Microfiltration (MF) Membranes: Made of Polypropylene (PP), glass fiber, or PES. Remove suspended solids, bacteria, and some viruses. I’ve seen these used in food and beverage making and for treating wastewater.

-

Ultrafiltration (UF) Membranes: It takes out proteins, viruses, large molecules, and germs. You’ll find these in pharma, dairy, and biotech plants.

-

Nanofiltration (NF) Membranes: Remove divalent ions (Ca²⁺, Mg²⁺), organics, and small molecules. I recommend them for softening water, some salt removal, and making beverages.

-

Reverse Osmosis (RO) Membranes: They are used for removing salts, heavy metals, dissolved ions, and small organics from water, in electronics, and for making ultra-pure water for medicine. From what I’ve seen, chip makers need RO systems to get the extremely pure water they require.

Media, Cartridge, and Specialized Filters

- Depth (Deep Bed) Filters: These are common in oil and gas, mining, paper mills, and city water plants. Based on my experience, city water plants use depth filters to clean cloudy water.

-

Cartridge and Bag Filters: You’ll need to change these often. They are great for catching very small particles.

-

Disc Filters: Stacked plastic discs for sediment capture. They work well for big jobs like farm irrigation and save a lot of water when cleaning.

Adsorption, Disinfection, and Ion Exchange

Activated Carbon Block Filters

I find these filters are very effective at removing chlorine, VOCs, and pesticides. They change water with a bad chemical taste into something fresh and clean.

UV Filters

Based on my experience with pharmaceutical plants, their water must meet very high purity standards. I find that UV filters are the final, critical step to guarantee this. These systems use powerful ultraviolet light to destroy the genetic material of bacteria and viruses. This method sterilizes the water, and I strongly recommend it because it leaves no chemical traces.

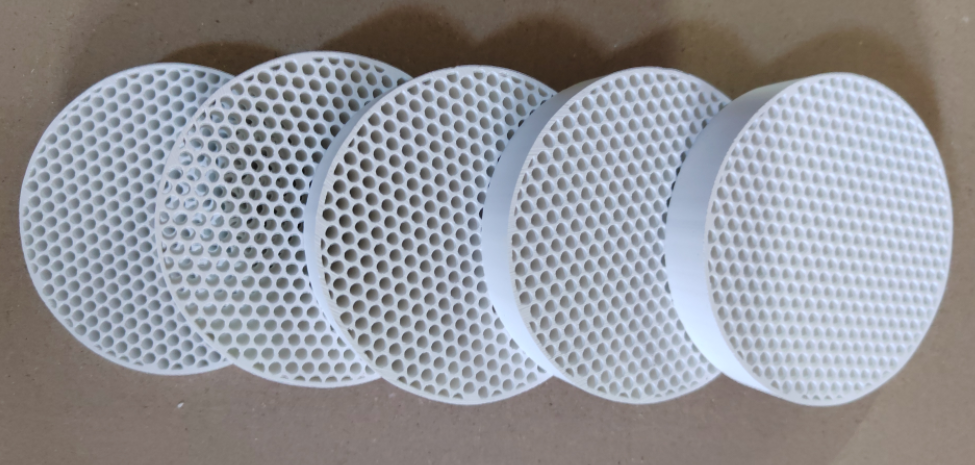

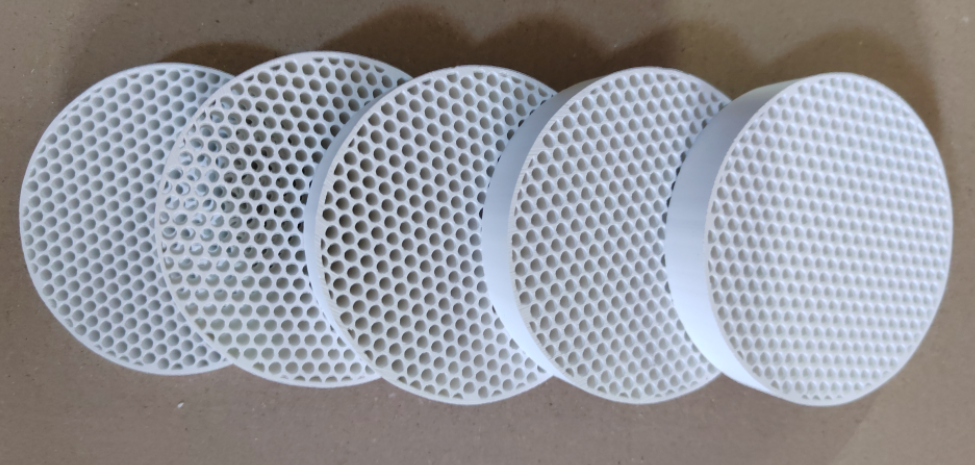

Based on my experience, the porous ceramic walls of these filters have a fine weave. They act as a strong barrier against bacteria and small specks of grit.

Ion Exchange Filters

They remove calcium and magnesium ions from the water and replace them with sodium. I think it is like a bouncer at a club, keeping the bad elements out. This process turns hard water full of minerals into a soft, scale-free flow. Based on my experience, this helps protect boilers from harmful buildup. That buildup can cut the life of the equipment by almost half.

My Guide to Industrial Water Filters

Here’s a summary I put together on key industrial water filters. I’ll explain how they work, what they remove, and where I recommend using them. You’ll also find some key performance numbers. This information covers the main technologies companies use to purify water, treat process water, and meet environmental rules.

| Type of Filter | What It Removes | How It Works / Key Features | My Recommended Applications | Typical Performance | Examples |

|---|---|---|---|---|---|

| Mechanical (Sediment) Filter | Particles, sand, silt, rust, scale | It is a physical barrier. It uses a cartridge, mesh, or deep bed of materials like sand and anthracite. | Pre-treatment for industrial or city water, mining, hotels | 1–5 microns (cartridge), 15–25 microns (deep bed) | Cartridge, bag, disc filters |

| Activated Carbon Filter | Chlorine, organics, odors, pesticides, VOCs | It uses porous carbon with a high surface area. This surface adsorbs unwanted materials. | Drinking or process water, food plants, final polishing stage | Flow rates up to 170 m³/h, high FRC removal | INDION Activated Carbon Filters |

| Reverse Osmosis (RO) | Dissolved salts, heavy metals, bacteria, viruses | This system uses a special membrane under high pressure to purify water. | Industrial purification, desalination, rinsing | Up to 99% contaminant removal, 95–99% salt removal | Industrial RO units, modular RO systems |

| Ultrafiltration (UF) | Bacteria, viruses, suspended solids | It uses a fine membrane to filter. I like that it saves energy and keeps good minerals in the water. | Wastewater treatment, pre-filter for RO systems | Keeps minerals while removing germs | UF polymer membranes |

| Ion Exchange Filter | Hardness ions (Ca²⁺, Mg²⁺), some heavy metals | Special resins inside the filter swap “hard” ions (calcium/magnesium) for “soft” ions (sodium). | Boiler feedwater, water softening, power stations | It reduces scale buildup. This extends the life of boilers and pipes. | Water softeners, industrial demineralizers |

| UV Filtration | Microorganisms (bacteria, viruses, protozoa) | It uses UV light to damage the DNA of germs. I recommend it because it adds no chemicals to the water. | Pharma, hospitals, final sterilization for beverages | Chemical-free, high kill rates for germs | UV sterilization chambers |

| Gravity-Based Filter | Sediment, chlorine, some microorganisms | These are portable units with layered cartridges. Gravity pushes the water through the filter. | Emergency situations, rural areas | They are affordable and do not need power. | Portable gravity purification units |

| Automatic Self-Cleaning Filter | Particulates, organic matter | These have built-in screens. They clean themselves with a vacuum or scraper, so the system keeps running. | Industrial, municipal, irrigation | It allows for continuous operation. You can customize the screen/brush. | Forsta, Filtaworx, Fil-trek models |

| Depth Filters (Deep Bed) | Sediment, larger organics | They use multiple layers of media like sand or zeolite. They hold a lot of dirt and have a modular design. | Petrochemical, mining, city water, agriculture | They keep pressure drops low and have a long filter life. | Deep bed, multigrade, modular sand filters |

| Disc Filter | Particulates, sediment | I find these systems use stacked plastic discs. They feature an automated backwash to clean themselves. | Industrial processes, farm irrigation | They have a longer life and use less water for cleaning. | Automatic disc filter units |

| KDF Filter Cartridge | Chlorine, heavy metals (lead, mercury, chromium), H₂S | It uses a process with copper-zinc granules. This process stops germs from growing. | Pre-treatment for RO systems, metal removal | Removes multiple metals, chlorine, and bacteria | KDF filter cartridges |

| Media Filter (Sand/Anthracite) | Suspended solids, turbidity | This filter uses grainy media. You can often backwash it. From my experience, it handles large water flows very well. | City water filtration, industrial final treatment | It has a modular option for continuous or batch flow. | INDION Continuous Sand Filters |

| Ceramic Filter | Bacteria, protozoa, and fine sediment | A porous ceramic material removes germs and fine particles. I like that you can wash and reuse them. | Drinking water, high sediment loads | Removes suspended germs and dirt | Ceramic cartridge/filter units |

| Bag Filter/Cartridge Filter | Fine sediment, particles | These use disposable bags or cartridges. They work well for low-to-moderate flows but need regular changes. | Bulk pre-filtration in factories | Can filter down to 1 micron | Multi-cartridge/bag filter housings |

| Separator (Hydrocyclone/Oil-Water) | Oil, hydrocarbons, coarse suspended solids | It separates materials using gravity or centrifugal force. No filter media is needed. I suggest these for high-flow jobs and low maintenance. | Oil/water separation, mining, protecting RO systems/pumps | Removes bulk materials in large flows | Oil-water separators, hydrocyclones (Lakos SandMaster) |

summary

Based on my experience in industrial water treatment, I want to share something important. Choosing the right industrial filter does more than just clean your water. It also protects your equipment and the environment.

I believe the key is to first understand your specific water issues. Then you can combine the right technologies to address them. This is true for any business, small or large. The right filtration system will save you money. It will make your equipment last longer. It also helps you follow all the rules.

My advice is to take the time to look at your water quality. I also recommend you talk with experts. You should invest in a system that can grow along with your business.