When it comes to maintaining air quality in industrial environments, I’ve learned that choosing the right filtration system isn’t just a technical decision—it’s a crucial investment in safety, efficiency, and compliance. Over the years, I’ve seen how poor air quality can impact everything from equipment longevity to employee health. That’s why understanding the different types of industrial air filtration systems is so important. Whether you’re dealing with fine particulate matter, hazardous fumes, or microbial contaminants, there’s a solution designed to meet those specific challenges.

Cartridge Filters: High-Efficiency Industrial Dust & Fume Removal

From my experience, cartridge filters are a key part of industrial air filtration. I find they work very well for capturing dry dust and fumes. These particles come from processes using fine materials like metals, composites, or chemical powders. The filters have a pleated material inside a hard cylinder. This design gives a larger surface area to catch more contaminants as air flows through.

Core Features and Advantages

- Low Pressure Drop: Designers make these cartridges to allow airflow that saves energy.

- Longevity: I’ve found that their strong build and large pleated surface help them last longer.

- Flexible Installation: They come in round, oval, and flat-cone shapes. Their modular design fits different dust collectors, whether top- or bottom-loading.

- Easy Maintenance: I really like how easy they are to maintain. You can replace most cartridges without any tools. This means quick swaps and less downtime for your equipment.

- Adaptability: These filters can handle scrapes and some moisture. I recommend using an optional pre-filter to make the main filter last even longer.

- Cost-Efficiency: They are cost-effective because of their small size. They also have low setup and running costs. You have a choice between disposable and replaceable cartridges.

Industry-Specific Applications

For metal fabrication, I’ve seen people install several units at welding stations. This helps control dangerous dust like hexavalent chromium. In pharma and food processing, high-MERV or HEPA cartridge systems are used. They help maintain cleanroom-level air quality. I find them very effective in auto and aerospace shops. They collect dust from sanding, grinding, and painting, and stand up to abrasive materials.

Maintenance and Optimization

In my experience, you must check your filters regularly. Plan for scheduled replacements, especially in dusty areas. This keeps the system working well and protects your workers.

You can add optional after-filters. I suggest HEPA or Activated Carbon filters if you need extra help with contaminants or odors.

I believe cartridge filters are a top choice for industrial air quality. They are reliable, efficient, and flexible, fitting well with the tough demands of today’s manufacturing plants.

Bag or Pocket Filters: A Practical Guide for Industrial & Commercial Air Quality

From my experience, bag or pocket filters are essential for industrial and commercial HVAC systems. They do a great job of filtering out particles like dust, fibers, and debris. I like their multi-pocket, V-shaped design because it adds more surface area. This means they can hold more dust and last longer before needing a change.

Key Specifications & Performance Metrics

Filter Media & Frame Materials: You have options for the filter material, including polypropylene, Polyester, fiberglass, or other synthetics. I find that the frames, which are usually metal or plastic, provide good durability and stability for tough conditions.

If you need to protect a sensitive area like a hospital or food plant, I suggest using high-grade filters. Models rated ePM1 or MERV13-14 can trap tiny particles, even as small as 1 micron.

A great feature is the large filter surface. This gives you good dust retention with a low initial pressure drop. I’ve found many models are designed for low-resistance airflow. This helps lower your energy bills and makes the filters last longer.

Operational Environment & Application Flexibility

I’ve seen these bag filters work well even in tough spots. They can handle 100% humidity and temperatures up to 80°C.

I use them as prefilters in multi-stage filtration to protect HEPA/ULPA layers. They also work as final filters in areas with moderate air quality needs. I see them used all the time in manufacturing plants, paint booths, food processing, healthcare, and commercial buildings.

Examples of Bag and Pocket Filters in Action

- Hot-melt Pocket Filters: With ratings of MERV5-14, I find these popular in both industrial and healthcare settings to manage different dust levels.

- Paint Pocket Filters: These have MERV5-8 ratings. They are a good choice for manufacturing and automotive paint lines because they capture paint particles well.

- Medium Efficiency Pocket Filters (G4-F9): These filters use electrostatic charging. This improves their capture ability and moisture resistance. I think they are a solid choice for many industrial jobs.

Main Features & Customization

- Multi-pocket Design: I like the multi-pocket design because it improves filter performance and extends its life.

- Customizable Options: You can customize these filters. I recommend tailoring the length, pocket count, and media to fit your specific air handling units.

- Certified Quality: Based on my experience, it’s best to choose filters that meet global standards like Eurovent and ISO 16890.

- Cost & Maintenance: These filters save money over time. They last long, hold a lot of dust, and have a strong build. Replacement is fast and doesn’t require tools.

Notable Benefits for Industrial Use

They are an affordable choice for dusty workplaces. They trap contaminants, which helps reduce maintenance on your other equipment. They improve indoor air quality and help you meet air cleanliness standards.

I believe bag or pocket filters are necessary for keeping work environments clean, healthy, and running smoothly. In my opinion, their high capacity, flexibility, and reliability make them a smart pick for any tough filtration job.

HEPA (High-Efficiency Particulate Air) Filters: A Guide for Cleanrooms, Hospitals, & Industry

From my experience, HEPA filters excel at capturing tiny particles. They remove at least 99.97% of particles that are 0.3 microns in size, which is the hardest size to catch. You can find HEPA and ULPA filters in different performance classes:

- H13: ≥99.95% efficiency (EN1822 standard). I find this class is perfect for cleanrooms in the pharmaceutical and food industries.

- H14: ≥99.995%. Based on my work, this is what you’ll want for surgical theaters and BSL-3 laboratories.

- U15–U17: Up to ≥99.999995% efficiency. These offer incredible performance for critical areas like semiconductor or nano-lithography cleanrooms.

- U.S. DOE requirement: ≥99.97% at 0.3 microns.

Filter Structure & How HEPA Filters Work

Inside a HEPA filter, you’ll find pleated glass or Synthetic fibers. These fibers create a thick mat designed to trap particles in three ways: interception, impaction, and diffusion. The design of these pleats is important because it controls the airflow resistance. This results in a pressure drop of around 300 pascals (0.044 psi) during normal operation.

Particle Types & Real-World Efficiency

What can a HEPA filter remove? I’ve seen them catch everything from dust and pollen to bacteria, mold, and even some viruses. Yes, even particles smaller than 0.3 microns can be trapped due to the physics of how filtration works. The 0.3-micron efficiency rating is just a baseline test. In real-world use, their performance is often better for both smaller and larger particles.

HEPA Classes & Typical Uses

| Class | Particle Removal (0.3μm) | Example Application |

|---|---|---|

| H13 | ≥99.95% | Cleanrooms, pharmaceuticals |

| H14 | ≥99.995% | Surgery, advanced labs |

| U15 | ≥99.9995% | Semiconductor fabs |

| U16 | ≥99.99995% | Aerospace, ultra-clean sites |

| U17 | ≥99.999995% | ISO 1 cleanrooms |

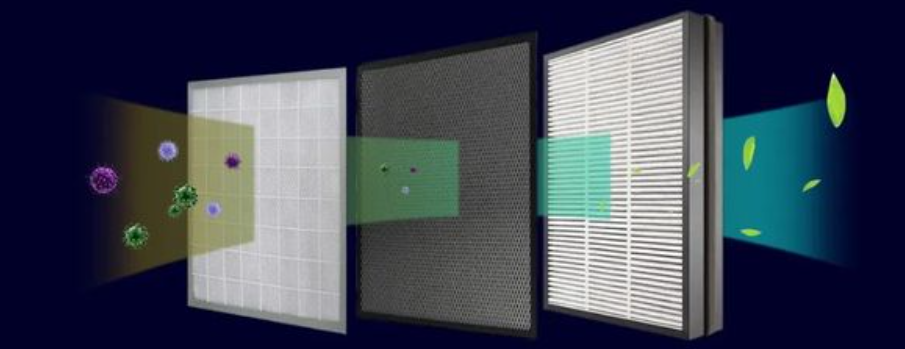

Essential Features & Custom Options

Based on my experience, many industrial HEPA systems have three stages: a pre-filter, a carbon filter, and then the HEPA filter. This setup improves efficiency and extends the filter’s life. For any critical job where air quality impacts safety or product quality, I recommend using certified, true HEPA filters.

In my opinion, HEPA filters are the top choice for controlling airborne contaminants. They offer tested and proven removal efficiency. Their effectiveness is seen across many industries, from healthcare to aerospace, and they meet strict regulatory standards.

Activated Carbon Filters: Removing Industrial Odors & Gases

From my experience, activated carbon filters are a must-have. They catch pollutants that other filters miss. This includes gases, volatile organic compounds (VOCs), chemical vapors, and bad smells. The process is called adsorption. Pollutants stick to the carbon’s huge internal surface. One gram of this carbon can have 1,000 to 2,000 m² of surface area.

How I See Activated Carbon Filters Working

A normal fiber filter traps dust. I see Activated carbon as something different. It uses its porous surface to grab onto VOCs, fumes, and chemical vapors.

I’ve seen these filters get rid of many tough problems. They remove organic smells, smoke, and dangerous gases that other filters just can’t handle.

I recommend pleated Panel Filters for tight spaces. They give great adsorption with low pressure. They also work well in tough spots, handling up to 80°C and 100% humidity. Pocket/bag filters are another option. They use special carbon fibers for quick adsorption. You can get them with tough galvanized or stainless steel frames for a long life. I suggest V-Bank and sponge filters you need the most adsorption power or have high air flow.

For compressed air, I like cartridge filters. They are made to clean oil vapor from the air, getting it down to <0.003 mg/m³. I believe this is key for critical air systems.

I often pair carbon filters with HEPA or prefilters. This provides a complete air cleaning solution for businesses.

Media Types & My Suggestions

- Granulated Activated Carbon (GAC): This is the most popular type. I find it works best in deep beds or cartridges for heavy pollutant loads.

- Pelletized Carbon: This type has a low pressure drop and is strong. I recommend it for big industrial air systems.

- Activated Carbon Cloths/Fibers: These are great for small, flexible uses. You’ll find them in protective gear and medical items.

- Impregnated Carbon: We can treat the carbon with chemicals like potassium permanganate or silver. This helps it remove specific things like hydrogen sulfide, ammonia, or mercury.

Real-World Benefits I’ve Observed

A good setup can cut down on acetone, MEK, and other solvent vapors. This helps you meet exposure limits and control workplace odors. In industrial settings, you can often achieve up to 95% reduction in stubborn chemical vapors.

My clients use these to meet legal requirements. They also make the workday better by removing harmful gases and bad fumes.

The installation is flexible. I’ve set them up as standalone units, as HVAC add-ons, or with other high-efficiency filters.

A wide variety of setups and media types means we can find a precise solution for your specific needs.

Electrostatic Precipitators: High-Efficiency Removal of Fine Dust, Smoke & Mist

Electrostatic precipitators (ESPs) are powerful filters that clean factory air by removing fine dust, smoke, and mist. I think their working method is quite smart. They use electricity to give particles an electric charge. These charged particles then stick to collection plates that have an opposite charge. Based on my experience, this technology has an impressive collection efficiency. It captures even tiny particles as small as 0.1 microns.

Performance and Efficiency I Recommend

- High Efficiency: In my experience, ESPs usually offer more than 99% collection efficiency. This applies to particles down to 0.1 micron.

- Wide Capacity Range: You can find systems for air volumes between 1,000 m³/h and 1,000,000 m³/h. I feel this makes them suitable for small workshops and large industrial plants.

- Smart Energy Use: They have a low pressure drop. I like this because it means they use less energy than baghouses or cyclone separators.

- Better Airflow: You will probably see up to an 80% cut in the make-up air needed for ventilation. This reduces your operating costs a great deal.

My Final Thoughts

In my opinion, electrostatic precipitators are an efficient, low-maintenance choice for large-scale industrial air filtering. I believe they work best in places with fine, sticky, or greasy particles. They run with consistency and are cost-effective, where other filter types might fail. This makes them my top recommendation for industrial air quality control and meeting regulations.

Centrifugal (Cyclone) Filters: High-Capacity Dust Separation & Pre-Filtration

From my perspective, Cyclone filters are a go-to solution for handling lots of coarse dust in tough industrial settings. They work by using centrifugal force. Dirty air spins at high speed inside a chamber. This motion pushes heavier dust to the outer wall. From there, the dust drops down for collection, and cleaner air flows out from the top or middle.

Key Specifications & Performance Metrics

- Airflow Range: I’ve seen these filters work in all kinds of places, from small workshops to big manufacturing plants. You can get them in many capacities, from 119 m³/h to 15,000 m³/h (about 70 to 9,000 scfm at 7 bar/100 psig).

- Model Examples:

- 1650 m³/h unit: Holds 12.5 L, weighs 24 kg

- 5000 m³/h model: Volume 52 L, weight 70 kg

- 15,000 m³/h version: Volume 438 L, weight 255 kg

- Operating Pressure: Smaller models handle up to 16 bar. Larger, high-capacity versions can take up to 10 bar. I find it reassuring that the systems are tested up to 24 bar for safety.

- Temperature Tolerance: These filters operate well between +1°C and +65°C. This temperature range fits most factory climates I’ve worked in.

Performance & Efficiency Considerations

I find these filters are most effective on particles larger than 10–20 microns. They typically remove 80% to 99% of dust above 20 microns. For very fine particles under 10 microns, their performance is not as strong.

If your operation is extremely dusty, I suggest installing cyclones in a series. You could also pair one with a secondary bag filter to improve efficiency.

To pick the right cyclone, I recommend you base your choice on your system’s real airflow (in m³/h or cfm). You also need to know your target pressure drop and the kind of dust in your airstream.

Based on my experience, I believe cyclone filters are an excellent investment. This is true for any facility that deals with heavy, visible dust. They extend the life of your system, cut maintenance costs, and act as a reliable first defense in a multi-stage air filtration setup.

Oil Mist Filters/Coalescing Filters: Better Air Filtration for Oil Mist, Aerosols & Smoke

Oil Mist Filters, also known as Coalescing Filters, are systems made to catch fine oil mist, aerosols, and smoke. This is the kind of stuff you see during machine work and other industrial jobs. Based on my experience, these filters are essential. They protect your workers’ health and keep your equipment dependable. I also find they are great for helping facilities recycle expensive fluids.

Key Design Features & Technology

- Multi-Stage Filtration: These filters use a mix of methods, including centrifugal separation and coalescing fiber layers. Some also have a final HEPA stage. A spinning drum or special pads merge small droplets into larger ones. These then drain away to be collected or recycled.

- Filter Media & Construction: Most filter elements use glassfibre cartridges or self-draining cassettes with up to 225 ft² of filter area per unit. I’ve seen that their construction is strong, which means they last a long time and are easy to clean or replace.

- Oil Collection & Recycling: I believe the savings here are significant. With systems like the A•Mist 40TF, you can recover up to 3.1 barrels of oil per inlet each year. This is a big cost-saver if your plant runs 24/7.

- Modularity & Scalability: Centralized, modular systems help lower costs. I like them because you have fewer service points, which saves time on installation and maintenance. You can connect these units to ductwork for multiple machines or mount them directly.

Example Industrial Applications

- CNC machining centers

- Grinding, spark erosion (EDM) & metal cutting systems

- Automated lathes using neat oils or mist cooling

- Food processing plants needing oil vapor control

Real-World Benefits

These filters remove harmful aerosols and mist, which helps you comply with health and safety standards. Cleaner air protects your staff. It also helps your equipment last longer. Oil and coolant recovery, easy filter maintenance, and modular installation all help reduce your long-term costs.

From what I’ve seen, modern oil mist filters offer many benefits. I’m talking about high-efficiency filtration, low maintenance, and getting to reuse your fluids. In my opinion, they are a must-have for any industrial shop where oil mist or smoke could impact air quality or how well your operations run.

Extra Air Filtration Methods

To get the best industrial air quality, I find that extra air filtration is very important. These filters solve specific problems. They can handle germs, lots of large particles, and offer a cheap first layer of filtering. In my experience, they are key to building custom air filter plans for factories, hospitals, and commercial spaces.

UV Light Filters (UV-C Air Filtration)

How They Work: UV light filters, and I would highlight UV-C systems, use ultraviolet light. This light neutralizes bacteria, viruses, and mold as they pass through HVAC ducts.

You’ll often find these in hospitals, labs, and cleanrooms. I suggest placing UV-C lamps near cooling coils and drain pans. This stops the slimy buildup and germ growth that can hurt air quality and waste energy. Studies show a good UV-C setup can kill up to 99.9% of microbes on surfaces. I see this as a strong defense against airborne germs, which is vital in sensitive places.

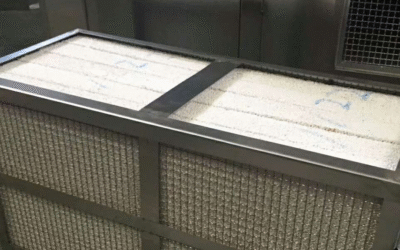

Panel and Pre-Filters

I view panel filters as the first line of defense. They catch large dust, lint, and fibers. This protects the more expensive filters, like HEPA or carbon, making them last longer and saving you money.

These filters are usually a flat or folded material, like fiberglass or synthetic. This material sits inside a metal or cardboard frame. MERV 1–4 (10–50% effective for particles >10 microns). They are a budget-friendly way to handle large outdoor dust and debris. In dusty places, I recommend changing them every one to three months. This keeps air flowing well and saves energy.

Pleated Filters

Pleated filters use materials folded into V-shapes to create more surface area. Based on my experience, this improves filtering and holds more dust without blocking airflow. I see them used a lot in offices, schools, and on production floors. These places need decent air quality, but don’t always need a full HEPA filter.

Fiberglass Filters

Fiberglass filters are a basic, low-cost option. I recommend them for capturing large dust and lint particles. You’ll see them mainly in homes or light industrial systems where filtration needs are low.

For tough environments with different types of dirt, I suggest more advanced setups. You could pair an aluminum mesh or foam pre-filter with a pleated or HEPA unit. From my viewpoint, choosing the right extra filter comes down to airflow, the particles you need to catch, and your budget.

By smartly using these extra filter types, I believe industrial sites can improve their main air filtration systems. They will work better, last longer, and be more affordable. This creates cleaner and safer air for everyone.