From my experience, industrial air filtration systems are vital. They capture harmful airborne particles like dust, fumes, and vapors common in factories. I’ve worked with industries like fertilizer, petrochemical, and cement production. For them, I recommend effective air filtration to protect product quality, ensure worker safety, and meet legal standards.

I can tell you that removing airborne particles with these filtration systems offers many great advantages:

– Protects your machines: It lowers equipment rust, clogs, and overheating. This means I’ve seen companies spend less on maintenance and find their equipment lasts longer.

– Makes the workplace safer: It reduces how many hazardous particles workers are exposed to. This helps lower the risk of breathing problems.

– Helps you follow legal rules: It assists industries in meeting standards for emissions and VOCs in markets like the European Union, North America, and Asia.

My opinion is clear: these days, I believe industrial air filtration systems are fundamental for any factory. As technology advances and new rules appear, I expect their use and impact in modern industry to grow even more.

Industrial Air Filtration Systems Change Worker Health and Safety

I believe installing an industrial air filtration system greatly improves worker health and safety. Studies show that better indoor air quality (IAQ) can slash employee sick days by up to 35% (World Green Building Council). From my experience, poor IAQ can also drop output in factories and offices by 3–9%.

The Impact of Airborne Contaminants on Employees

PM2.5 Exposure: I find that indoors, PM2.5 particle levels are often up to five times higher than outdoors. Long-term exposure increases the risk of lung and heart diseases, based on data from the California Air Resources Board.

Volatile Organic Compounds (VOCs): VOC levels are 2–5 times higher indoors. I’ve seen that workers exposed to these compounds often suffer from headaches, breathing problems, and other long-term health issues.

Microbiological Hazards and Viruses: I recommend air filtration in industries like food and beverage. It stops germs and VOCs from spreading. In hospitals, using HEPA filters right where viruses are released can lead to almost zero skin contamination from airborne germs.

Advanced Air Filtration Technologies

Modern systems use UV waves and ionization. This tech neutralizes viruses before they can infect your staff. I feel this is vital in high-risk fields like healthcare, manufacturing, and food processing. Clean, safe air is a must-have in these places.

Tangible Outcomes at a Glance

- Up to 35% fewer sick days and less time off.

- Lower rates of breathing and heart-related sickness.

- Almost total removal of virus exposure in clinic-like settings.

- Up to a 70% drop in harmful indoor particle levels.

- Meeting strict industry health and safety rules.

- A clear drop in Sick Building Syndrome symptoms for a large number of building occupants.

Based on my experience, investing in air filtration pays off. You’ll see real gains in worker health, safety, and efficiency. It helps build a safer and more productive workplace.

Industrial Air Filtration Systems for Better Equipment Performance and Longer Life

I recommend industrial air filtration systems to make your equipment run better and last longer. This is important for any commercial or manufacturing setting.

How I’ve Seen Air Filtration Protect Equipment

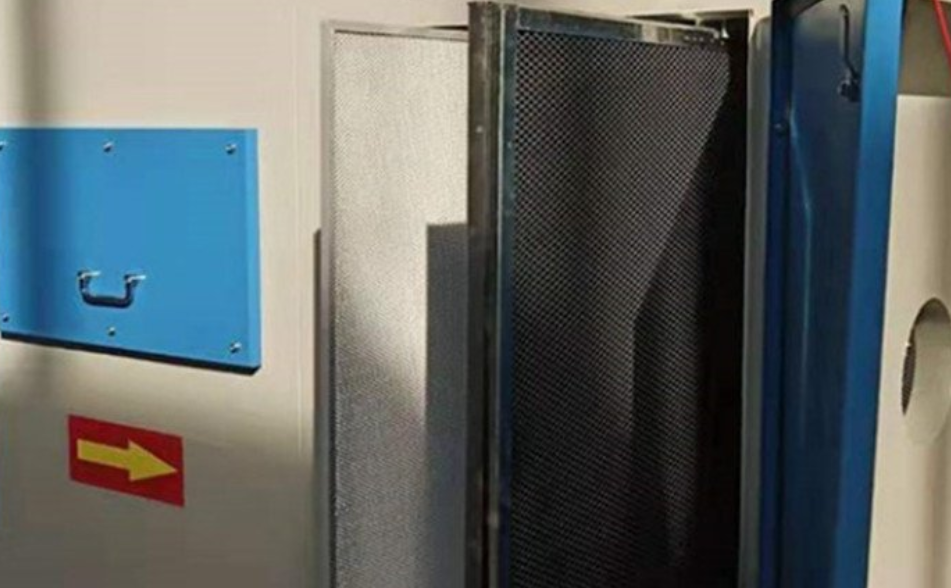

Stops Buildup of Dust and Oil: These systems capture dust, oil mist, and chemical vapors. This prevents gunk from collecting on machine surfaces. As a result, you see less corrosion, fewer clogs, and no overheating. These are the main reasons equipment fails early.

Lowers Mechanical Wear: Your equipment will run cleaner and have fewer surprise breakdowns. From what I’ve seen, this leads to much less wear and tear over time.

Reduces Repair and Maintenance Costs: With protected machinery, you’ll have lower repair costs and need fewer new parts. I’ve noticed this firsthand in industries with expensive precision equipment. Their sensitive parts really need clean air to work well.

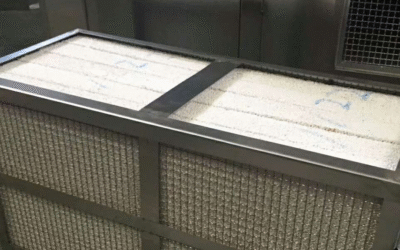

Improves How a Machine Runs: Clean machines use less power and don’t stop for maintenance as often. This means fewer repairs. Advanced HEPA filters can take out up to 99.97% of tiny airborne particles (0.3–1.0 microns). I believe this is a game-changer for precision tools and electronics.

Real-World Results and Market Impact

Less Downtime Saves Money: Facilities that use quality filtration systems, like those from Camfil, report better outcomes. Their filters last longer, and production stops less for maintenance. They also don’t need as much backup cooling.

Energy Savings: Good filtration lowers the resistance in filters, an effect called pressure drop. This helps air flow better through HVAC and cooling systems. I’ve found this is a great way to cut electricity use and keep operating costs down.

Long-Term Savings and Better Performance

You might worry about the cost of a good filtration system and new filters. But, in my experience, the savings make it worthwhile. You save money from fewer equipment failures, a longer machine life, and better performance.

Industrial Air Filtration Systems for Protecting Product Quality

From my experience, industrial air filters are vital for protecting products. This is true in industries like food, pharma, biotech, and beverage making.

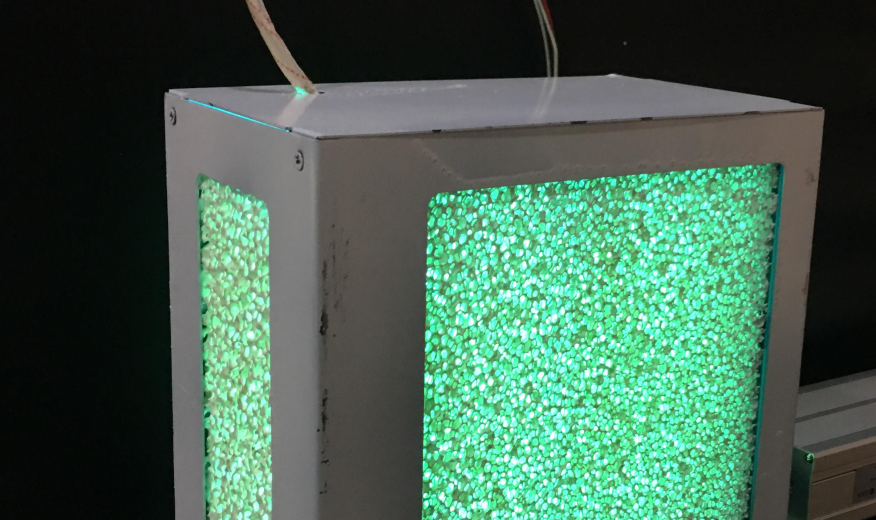

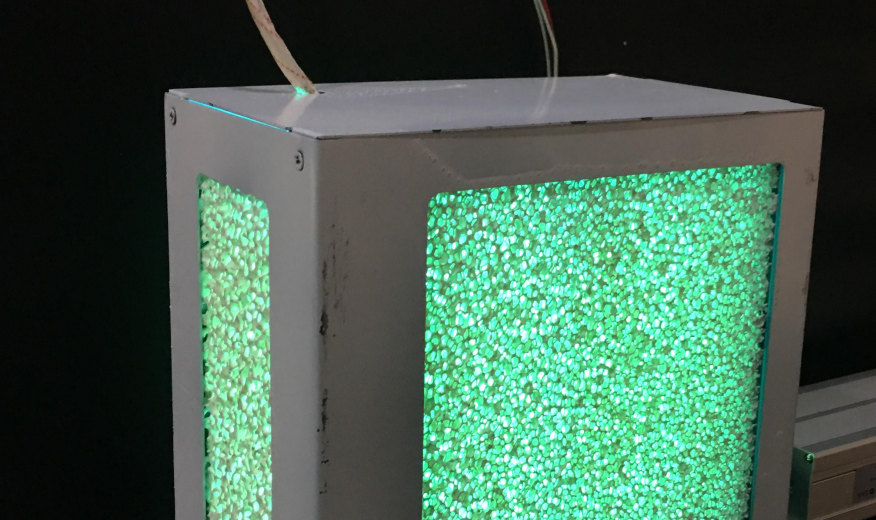

How Air Filtration Stops Contamination

- In my view, pharmaceutical cleanrooms need top-tier solutions. HEPA filters like Pharmaseal® and Pharmaslim® stop airborne microbes. This protects sensitive items, leads to fewer rejects, and reduces cross-contamination.

- I recommend special attention for beverage plants. Their air conveyor fans can blow dust and oil into empty bottles. Good filtration prevents this from happening and keeps the filling process safe.

- Air filtration systems get rid of metal dust, oil mist, germs, VOCs, and fine smoke. These things harm finished goods. They can also clog machines and cause safety or compliance problems.

Based on my experience, your product’s integrity depends on a solid, well-kept air filtration system. This is how you make sure every item meets high standards for safety, quality, and compliance.

Following the Rules: How to Meet Industrial Air Quality Standards

From my experience, industrial air filters are essential for following air quality rules. They help your facility meet tough standards set by groups like the EPA, OSHA, CCOHS, and similar organizations worldwide.

Key Rules and Industry Standards

- OSHA Regulations: Businesses must watch their indoor air quality. You need to limit worker exposure to dust, chemicals (VOCs), and other harmful emissions. I’ve seen serious violations lead to fines up to $13,653 per incident. Repeat offenders face even bigger penalties.

- EPA Clean Air Act: This act requires limits on different pollutants you can release. You must have an air management plan and submit your air quality data on a regular basis.

- ISO 16890 & ASHRAE 52.2: These are global standards for filter performance. I recommend you follow them. They are vital if your company does business internationally or exports products.

- Industrial Emissions Directive (EU): The EU sets legal emission limits. This pushes industries to use better filters. I suggest looking into HEPA filters, which capture 99.97% of particles ≥0.3 microns. You might also consider activated carbon and electrostatic precipitators.

My Recommended System Features for Compliance

HEPA Filters: They capture at least 99.97% of particles as small as 0.3 microns.

Routine Performance Testing: Your systems need performance checks every 6 months. I also suggest certification reviews every 4-6 weeks to stay compliant.

Mandatory Air Quality Monitoring: I believe you must equip your facilities with real-time monitoring and reporting systems.

Detailed Documentation: You must record all maintenance and system performance. Keep these records ready for official audits and third-party checks.

Examples from Different Industries

Healthcare: I’ve noticed they enforce the use of medical-grade filters. These must have a bacterial filtration rate above 95%.

Chemical & Pharmaceutical Plants: Here, I suggest multi-stage filtration (MERV 13+ and Activated Carbon). It handles dangerous aerosols and toxins, which is very important after the pandemic.

Metalworking & Food Processing: I recommend using baghouse filters and specific VOC removal systems. This helps you meet your industry’s emission standards.

Benefits of Adoption and Certification

Many companies switched to high-efficiency filters (like HEPA and MERV 13+) after the COVID-19 pandemic. I find this move makes it easier to follow regulations and improves employee safety.

Getting a new system certified usually takes about 3 months. This process includes independent lab testing, energy efficiency checks, and reviewing maintenance documents.

Why Following the Rules Matters

I believe investing in a compliant industrial air filtration system is a smart move. It helps you:

– Satisfy current and future legal rules for your industry

– Lower your legal, financial, and business interruption risks

– Build trust with the public and protect your company’s name

– Make sure you can keep operating and exporting your products

In summary, the advantages of using these systems to follow regulations are obvious. Their measurable performance, strict documentation, and continual upgrades ensure you meet today’s and tomorrow’s standards from global and national regulators.

Industrial Air Filtration System Saves Energy and Cuts Your Operating Costs

Based on my experience, putting in an industrial air filtration system is a direct way to boost energy efficiency and lower your operational costs. I want to show you how these systems create real savings and provide value for years.

Better Airflow Means Lower Energy Bills

Easier Airflow: Good filters keep your ducts and vents clean. This means your HVAC system doesn’t have to work as hard to move air. MANN+HUMMEL reports that Air Filters can make up 16% of a commercial building’s power bill. I always recommend choosing energy-efficient filters. Some types use three times more energy than others but provide the same air quality.

Recirculate More Clean Air: Modern filters allow you to recirculate more of your indoor air. This reduces the need to heat or cool large amounts of fresh air from outside. I’ve seen many facilities cut their total energy costs by up to 20% just by upgrading their filters and improving their ventilation plan.

Advanced Filters: High Efficiency, Low Power Use

High-performance filters are made to have a low pressure drop. This lets your fans run more easily. Studies show that reducing the filter pressure drop by just 1 Pascal can save about 11 kWh per year. That’s around €2–3 in annual savings for every single unit. Many modern MERV 13 filters have a lower pressure drop than older, less efficient MERV 8 filters. You get cleaner air for less energy.

It’s a common myth that high-efficiency filters (up to MERV 13) will increase your HVAC energy bills. They do not cost more to run than dirty or less efficient filters. I’ve found that well-made filters keep a steady energy draw throughout their service life. This helps you avoid unexpected spikes in your operating costs.

Reduce Maintenance and Equipment Wear

Clean air leaves less dirt on your equipment, fans, and heat exchangers. This leads to fewer breakdowns, less cleaning, and more time between replacing parts. With less dust buildup, you have a lower chance of fan or heat exchanger failure. This adds up to big savings on maintenance.

Real-World Results and Industry Awards

By using smart filtration and managing their air well, some manufacturers have cut their compressed air energy use by up to 60% in certain areas. Programs such as the Camfil ECI (Energy Cost Index) give awards to facilities that achieve the greatest energy savings with advanced filtration. They show clear proof of lower operating and material costs.

A Quick Look: How Industrial Air Filtration Saves Money

- Saves a lot of energy, particularly with fan and compressor use.

- Helps keep operational costs down all year.

- Reduces time spent on maintenance and money spent on replacement parts.

- Helps you meet your goals for sustainability and energy efficiency.

From what I’ve seen, picking the right industrial air filtration system is a direct investment in lower operating bills and a healthier facility over the long run. When you use smarter filters and perform regular system upgrades, you will see real, lasting improvements in your energy spending and maintenance budget.

Improve Your Team’s Productivity and Spirit

From my experience, installing an industrial air filtration system gives a big boost to your team’s output and happiness. Clean air affects how well your people work. It also shapes how they feel about their job and whether they stick around.

How Clean Air Lifts Productivity

Research shows that even a small increase in air pollution hurts productivity. A 10 μg/m³ rise in PM2.5 particles over 25 days causes a 1% drop in output. For farm workers, that same pollution spike led to a 6% productivity loss. I’ve found that cleaner air simply means more work gets done with fewer errors.

A Harvard University study found something amazing. Better air quality can improve an employee’s decision-making skills by up to 61%. I see this in practice. When staff work in clean air with low PM2.5 levels, they are more alert and focused.

Cut Down on Absences and Health Problems

The World Health Organization finds that bad air is a major reason for sick leave. A good air filtration system reduces things that irritate the lungs. This results in fewer headaches, eye issues, and other sicknesses. I recommend it because fewer sick days mean lower hidden labor costs.

I’ve seen that when a company invests in clean air, more employees stay. People who are unhappy with the air quality often look for another job. This creates extra costs for hiring and training new staff.

Boost Comfort and Happiness at Work

Your team will feel more energized and less tired in a clean-air space. For example, keeping PM2.5 levels below 6.5 μg/m³ makes a huge difference, especially when it’s 67 μg/m³ outside. A good filter system also keeps CO2 below 750 ppm. This stops people from feeling sleepy and helps them maintain consistent output.

I find that people are happier and more loyal when their workspace is clean and healthy. This simple fact leads to lower turnover and creates stronger, more stable teams.

Better Equipment and Other Gains

Clean air reduces dust on computers and hydraulic machines. This prevents unexpected equipment breakdowns. As a result, you avoid work stoppages that lose money and reduce the chance of accidents. My recommendation is to invest in good air filtration. It makes important factory equipment last longer. This ensures your productivity remains high for years to come.

The Main Benefits

- Fewer employee sick days and absences

- Higher work output and fewer errors in production

- More reliable equipment, which prevents accidents and expensive downtime

- Better team morale, job satisfaction, and people staying longer

- Lower hiring and training costs because fewer staff leave

Based on my experience, I suggest you view a quality air filtration system as more than just a rule to follow. I see it as a smart investment in a more energetic and productive workplace. These systems create real value over time. They do this by protecting your two most important assets: your people and your equipment.

My Recommendation:

I believe installing an industrial air filtration system is a smart choice for any modern facility. You get direct benefits like safer workers, smooth operations, and high-quality products. You will save money on energy and maintenance, stay compliant with laws, and have a healthier, happier team.