From my experience, industrial ceramic products are made from inorganic, non-metallic materials. This composition allows them to perform very well in harsh settings. I think their most important features are hardness, heat resistance, and corrosion resistance. They are also great electrical insulators, making them essential in modern industry.

Alumina Ceramics (Aluminum Oxide, Al₂O₃)

From my experience, Alumina ceramics are one of the most important materials for industrial use. I suggest them often because they are very hard, handle heat well, and don’t react with chemicals.

Key Properties of Alumina Ceramics

- Hardness: It scores a 9 on the Mohs scale, right behind diamond. This makes it a great choice for jobs where there is a lot of wear.

- Thermal Stability: Its melting point is about 2,072°C. This means it works well in very hot places.

- Electrical Insulation: It has a high electrical resistivity of 10¹⁴ Ω·cm at 20°C. I find this makes it perfect for high-power electronics.

- Purity Ranges: You can get it in purity levels from 90% to 99.9%. I’ve found the higher purity versions are tougher and resist chemicals even better.

Major Industrial Uses

Abrasives and Grinding Tools: Alumina is the top material for sandpaper, grinding wheels, and lapping compounds. I recommend it for cut-off wheels and abrasive belts because it resists wear so well.

Refractories: It forms the foundation for kiln linings, furnace bricks, and incinerator interiors. These are used in steel, glass, and petrochemical plants. They can all take temperatures over 1,500°C.

Electrical Insulation: It’s used as a base layer in integrated circuits, LED packaging, and spark plugs. I believe this has changed how we design electronics for better performance and safety.

Medical Devices: This material is safe for the human body. So, it is a popular choice for prosthetics, hip bearings, dental implants, and bionic joints. In 2015, thousands of tons of medical alumina ceramics were used globally each year.

Armor and Ballistics: Strong and light alumina plates are now a standard for body armor. Law enforcement and security teams use them. You’ll also find them in vehicle plating and synthetic sapphire bulletproof windows.

Catalyst Support: Gamma alumina is a key support structure in industrial chemical processing. I find it is great for boosting chemical reactions.

Automotive Components: It works in spark plugs, engine seals, heat shields, and ceramic brake pads. It provides impressive resistance to both heat and friction.

Glass and Gemstone Production: People use it to make special glass stronger, like shatterproof and bulletproof types. Its crystal form, corundum, is used to create industrial sapphires and rubies.

High-Performance Composites: It is added to aerospace fibers like Nextel 610/720. Based on my experience, this improves the material’s strength and heat resistance.

In my opinion, alumina ceramics are crucial for things that need to be stable and work well in tough conditions. Its many uses and ongoing improvements mean we see it in more industries all the time.

Zirconia Ceramics (Zirconium Oxide Ceramics)

Zirconia ceramics, or zirconium oxide (ZrO₂), are known for being very strong and tough. They handle wear, chemicals, and heat well. This makes them a great choice for industries that work in harsh conditions. From my experience, what’s most impressive is how this material is both mechanically tough and useful in many areas. You can find it in electronics, medical devices, and everyday consumer goods.

Key Physical Properties and Performance

- Melting Point: ~2700°C, allowing effective use in extreme heat

- Compressive Strength: 2580 MPa – ideal for high-stress applications

- Vickers Hardness: 16.0 GPa in toughened grades

- Young’s Modulus: 337 GPa for structural rigidity

- Volume Resistivity: >10¹³ ohm·cm, making it a powerful electrical insulator

- Dielectric Constant: 11 at 1 MHz, supporting advanced electronics

- Thermal Shock Resistance: 450°C, withstanding rapid temperature changes

- Fracture Toughness: 4–5 MPa·m¹/², higher than most ceramics

Core Industrial and Consumer Applications

Wearables, Watches, Jewelry

Luxury Watches: Top brands like Apple, Chanel, and Radar choose zirconia ceramics. They use it for scratch resistance, comfort, and surfaces that don’t oxidize. In my opinion, customers value these features for everyday wear and active use.

Fashion Jewelry: Labels such as Bvlgari, Chanel, and Cartier make zirconia jewelry. I think these pieces are popular because they are light, non-allergenic, very durable, and look elegant.

Optical, Automotive, and Aerospace Parts

Optical Fiber Connectors: This is a popular option for high-precision ferrules and sleeves. It helps reduce signal loss. It also keeps data transmission stable over the long run.

Turbine Blades and Heat Shields: From my experience, aerospace companies count on zirconia. Its ability to handle sudden temperature changes is perfect for important engine and turbine parts.

Biomedical and Healthcare Devices

Dental Crowns and Bridges: Because it is so tough and resists cracking, it’s a top choice for dentists.

Hip Replacements and Surgical Scalpels: Surgeons use zirconia because it is safe for the body, durable, and easy to sterilize. Hip prostheses made from it last longer. They also resist wear better than older materials.

Industrial, Chemical, and Refractory Applications

Cutting Blades, Pump Valves, Bearings: Zirconia’s hardness and wear resistance mean a longer tool life. This leads to less maintenance in high-load and corrosive settings.

Crucibles and Kiln Linings: It can handle up to 2700°C and resists chemical attacks. This makes it impossible to replace for melting certain metals and for harsh chemical jobs.

Refractory Fibers: In furnaces and kilns, it holds its structure and insulates above 1600°C. It performs better than alumina and mullite fibers.

Everyday Products

Ceramic Knives, Kitchenware, and Antibacterial Tableware: I like that the material’s hardness keeps knives sharp. Its clean surface also adds style and hygiene to kitchen items for everyday use.

Why Zirconia Ceramics Stand Out

- High wear and scratch resistance: It lasts longer than many other advanced ceramics and metals.

- Works well in extreme temperatures and corrosive settings.

- Very safe and compatible for medical use.

- Has a natural antibacterial quality for kitchen and consumer goods.

- Offers an elegant, glossy look for luxury products.

Zirconia ceramics are a key material in industries where performance, reliability, and appearance are all important. Based on my experience, its properties make it vital for the next generation of electronics, medical devices, and high-value consumer products.

Silicon Carbide Ceramics (SiC): Superior Hardness and High-Temperature Applications

Silicon carbide ceramics, which I’ll call SiC, are famous for a few key things. They offer high strength, hardness close to a diamond, and excellent resistance to wear and corrosion. They also handle heat very well. Based on my experience, SiC is essential wherever you need extreme durability and stability.

Key Physical and Functional Properties

- Hardness: Almost diamond level, at 9–9.5 on the Mohs scale.

- Flexural Strength: Often between 350–400 MPa. Top grades can go above 600 MPa.

- Elastic Modulus: Shows powerful rigidity at 410 GPa.

- Density: Around 3.2 g/cm³. This gives SiC a good strength-to-weight ratio.

- Thermal Conductivity: Very efficient at ~120–270 W/m·K, though it depends on the grade.

- Maximum Use Temperature: Up to 1600°C in air. I find this ideal for high-heat jobs.

- Electrical Properties: Its volume resistivity stays stable between 1000–1500°C. This makes it perfect for resistance heating elements and semiconductors.

Industrial and High-Tech Application Examples

Extreme Environment Structural Uses

Heat Exchangers and Kiln Furniture: I’ve seen it used for support beams and tubes in various kilns. It provides a longer life and better reliability, especially with constant high-temperature use.

Mechanical Seals and Bearings: It’s a key material for pumps, valves, and chemical pipelines. SiC extends the life of equipment when dealing with corrosive and abrasive materials.

Mining and Energy: Using SiC linings for ore crushers increases the time between maintenance checks. I also find it impressive that SiC gear parts in wind and hydro turbines can last 2–3 times longer than steel ones.

Transportation, Electronics, and Defense

Automotive and Aerospace: Companies put it into parts like the AGT100 GM gas turbine. You can find it in combustion chamber rings, rotors, and guide vanes. I’m also seeing SiC disc brakes and clutches appear in high-performance cars.

Bulletproof Armor: It combines hardness with low density. This makes SiC armor strong yet lightweight, which is ideal for protecting people and vehicles.

Semiconductor Fabrication: I believe SiC is vital for making semiconductors and solar panels. Key components include cutting wires (3–12 inch), wafer supports, and substrates for high-power circuits.

Other Advanced Uses

Cutting Tools: In my observations, coating inserts with SiC can make them last 3–5 times longer than tungsten carbide steel tools. This is especially true in abrasive settings.

Catalyst Carriers and Ceramic Membranes: SiC provides stable and durable structures. I suggest using it for chemical reactors and advanced filtration systems.

Petrochemical Containers and Pipelines: SiC equipment stays reliable in high-pressure, corrosive environments. From what I know, it performs better than nearly any metal in these conditions.

To sum it up, I find that silicon carbide ceramics give you an amazing mix of features. You get extreme hardness, resistance to chemicals, and the ability to withstand high heat. This is why they are central to advanced manufacturing and modern tech.

Silicon Nitride Ceramics: A Tough Material for Tough Jobs

From my experience, Silicon Nitride ceramics (Si₃N₄) are some of the most dependable advanced materials you can find. I have seen them succeed in tough jobs that involve heat, force, and chemicals. These ceramics work great in situations where most other materials would simply fail.

Key Properties and Advantages

Handles Extreme Heat: It stays strong in air up to 1500°C. I believe this makes it perfect for parts that get very hot or switch between hot and cold temperatures.

Incredibly Strong:

- Compressive strength: 689–2760 MPa

- High fracture toughness (Kic): 5.0–8.0 MPa·m¹ᐟ²

Very Hard and Resists Wear:

- Mohs hardness: 9 (It’s almost as hard as silicon carbide)

- Knoop hardness: 2200 kg/mm²

- In my view, it beats most metals and other ceramics in high-friction or abrasive environments.

Lightweight and Waterproof:

- Density: 3.31 g/cm³

- Water absorption: 0% at room temperature.

Resists Thermal Shock and Chemicals: It performs excellently, handling temperature swings up to 750°C without cracking. It does not react with or get damaged by most chemicals and melted metals.

Core Industrial and High-Tech Applications

Aerospace & Aviation

Gas Turbine Blades and Guide Vanes: I suggest using Si₃N₄ to replace heavy nickel alloys. It improves turbine efficiency and saves weight. It operates well above 1000°C, which is exactly what you need for jet engines.

Missile Tail Nozzles & Nuclear Reactor Spacers: It provides stability. It also stays intact even with high heat and radiation.

Automotive and Transportation

Turbocharger Rotors, Rocker Arm Pads, Glow Plugs, Exhaust Valves: It handles quick temperature changes and high mechanical stress. I’ve found this improves a vehicle’s performance and lifespan.

Rolling Bearings: In my experience, bearings made from silicon nitride are a game-changer. They last up to 10 times longer than steel ones. They can also run three times faster in hot, corrosive, or heavy-load situations.

Mechanical Manufacturing

High-Speed Cutting Tools: Its hardness and toughness are great for cutting metals. This makes tools last longer and cut more precisely.

Mechanical Seals and Pump Components: It protects against wear and chemicals in industrial pumps. This helps factories run longer without interruptions.

Electronics and Semiconductors

Thin Films for Semiconductor Devices: I recommend silicon nitride layers for these devices. They serve as reliable barriers and insulators in circuits, displays, and chips. They protect sensitive parts from moisture and chemicals, making the electronics last longer.

Medical/Biomedical Solutions

Orthopedic and Dental Implants, Spinal Fusion Spacers: From what I’ve seen, it’s biocompatible and stable for the long term. It also resists bacteria, which could mean fewer follow-up surgeries for patients.

Dental Drill Micro-Bearings: These small, hard bearings make medical tools more wear-resistant and faster.

A key biological benefit: Its surface shows antimicrobial effects. It actively defends against viruses like SARS-CoV-2 and drug-resistant bacteria.

Molten Metal, Welding & Furnace Tech

Thermocouple Sheaths and Arc Welding Nozzle Tips: Its resistance to thermal shock and chemicals allows for accurate readings. It also makes foundries and welding systems safer to operate.

Furnace Fixtures: These structural parts keep their shape over long periods of use, even with repeated heating cycles.

Typical Product Examples

- Turbocharger rotors

- Si₃N₄ ball/roller bearings

- Orthopedic knee/hip inserts

- Thermocouple protective tubes

- Arc welding nozzle tips

- Integrated circuit chemical barrier films

- High-speed cutting tools and pump seal rings

In my opinion, silicon nitride ceramics are changing the game. They are perfect for future applications that need to be tough, stable, and heat-resistant. I see their impact everywhere, from advanced jet engines and medical implants to cutting-edge semiconductors.

Steatite Ceramics (Magnesium Silicate): Properties, Grades, and Industrial Applications

From my experience, Steatite ceramics, also called magnesium silicate ceramics, are a valuable material for industrial work. They provide reliable electrical insulation and can perform well in high heat, up to 1,200°C (2,200°F). I find they are a popular choice for low-cost electrical insulation. These ceramics offer a good combination of safety, durability, and flexibility for many electrical and mechanical jobs.

Common Industrial Applications

Electrical Insulation: I use it for high-frequency insulation, resistor and fuse cores, lighting system insulators, and insulating washers and beads.

Electrical and Electronic Components: You will find it in halogen lamp sockets, NH fuses, stand-off insulators, and casings for resistors and thermostat switches.

Mechanical Supports: It works well for heating element supports, base plates, control housings, spacers, and supports inside appliances.

Aerospace and Automotive: In these industries, I see it used for appliance insulators. It’s also for components needing moderate strength and electrical resistance in tough conditions.

Versatile Shaping: You can form it into complex shapes before the final firing. This makes it ideal for custom industrial parts.

Industrial Example List

- Electrical socket blocks

- Fuse bodies

- Heating element supports

- Insulating washers and bushings

- Lighting system components

- Thermostat switch circuits

- Automotive resistor casings

- Aerospace appliance insulators

Based on my experience, steatite ceramics offer a dependable, cost-effective choice. They provide good mechanical strength and excellent electrical insulation. That is why I see them in high demand in the electrical, automotive, and aerospace sectors. Their ability to be formed into custom shapes before firing makes them a very flexible solution for modern industry.

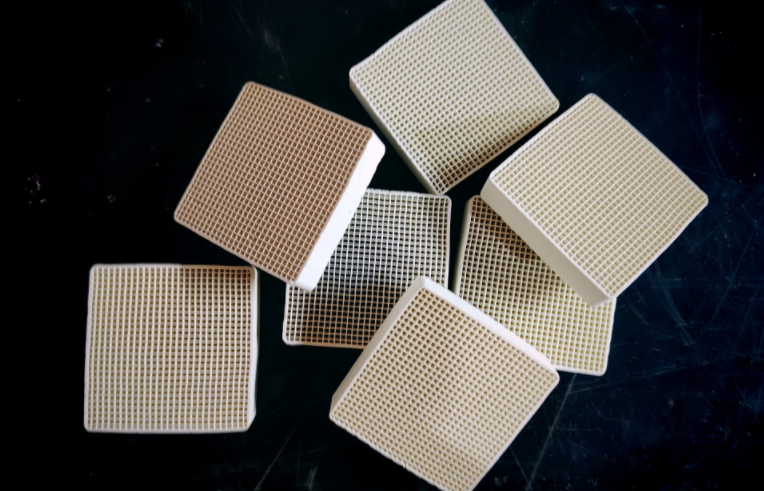

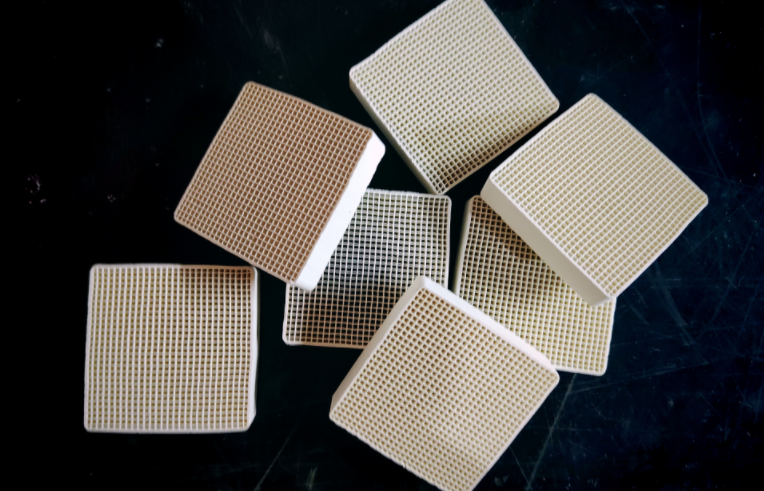

Cordierite Ceramics: Thermal Shock Resistance and Industrial Applications

From my experience, Cordierite ceramics are a top choice for high-temperature jobs. They are a type of magnesium aluminum silicate (2MgO·2Al₂O₃·5SiO₂). Industries love them because they have excellent thermal shock resistance. They also have a low thermal expansion coefficient and good chemical stability. This makes cordierite a preferred material for any setting with fast heating and cooling.

Key Properties and Technical Data

- Continuous Use Temperature: 1000–1200°C

- Sintering Range: 1350–1460°C

- Thermal Expansion Coefficient: 1.4–2.6 × 10⁻⁶/K (which is very low)

- Thermal Conductivity: 120–245 W/mK

- Mohs Hardness: ~7, similar to quartz

- Elastic Modulus: 139–150 GPa

- Porosity: Can be quite high. This is particularly true for foam or honeycomb shapes, allowing for better insulation and filtration.

- Electrical Conductivity: It has very low electrical conductivity. I consider it an excellent electrical insulator.

Typical Material Composition

| Component | Content (%) | Main Benefit |

|---|---|---|

| SiO₂ | 50–55 | Thermal/chemical resistance |

| Al₂O₃ | 30–35 | Hardness/mechanical stability |

| MgO | 10–15 | Thermal shock resistance |

| Fe₂O₃ | <0.5 | Minor impurity (color) |

| CaO | <0.1 | Phase stability |

Core Industrial Applications

Kiln Furniture: I like that cordierite shelves, plates, and columns are 60–70% lighter than other materials. This makes them easier to handle and lowers energy costs during firing.

Automotive Catalytic Converter Substrates: In cars, you’ll find cordierite honeycomb ceramics inside catalytic converters. They support the catalyst, filter exhaust gases well, and handle constant temperature changes.

Industrial Ovens and Furnaces: I recommend them for insulation in industrial ovens and furnaces. They work well in places that need frequent and rapid temperature shifts.

Molten Metal Filtration: For filtering molten metal, cordierite in honeycomb or foam form is great. It purifies metals during casting by catching impurities. I find this improves the final product and cuts filtration costs.

Electronic Components: I see it chosen for electronic parts like fuse bodies and thermostats. Its stable insulation is a key reason for its use in modern lighting.

Cookware and Kitchen Use: In the kitchen, cordierite is popular for pizza and baking stones. It’s also in BBQ parts and casserole dishes. People value its ability to hold heat and resist direct flame.

Aerospace and Specialty Insulation: In aerospace, engineers use it for special lightweight insulation. It’s perfect where temperature changes and weight are major factors.

Industry Value and My Perspective

I believe cordierite ceramics are vital in automotive, metallurgy, electronics, and cookware. You need them anywhere reliable thermal stability and insulation are required. In my view, seeing it used in catalytic converters and quality cookware shows its great balance of performance and cost. When I talk to manufacturers and engineers about thermal or filtration problems, cordierite is my first suggestion. I recommend it because of its great mix of low thermal expansion, chemical resistance, and lightweight design.

Mullite Ceramics: High-Temperature Strength, Thermal Shock Resistance, and Key Industrial Applications

From my experience, Mullite ceramics are advanced materials that I often recommend. They offer a special mix of high strength, resistance to thermal shock, and toughness against chemicals. These features make them effective in tough industrial settings. I find they work well in places with high heat and quick temperature shifts.

Industrial Applications and Real-World Examples

Furnace and Kiln Furniture: I recommend mullite for kiln parts in industries like ceramics, glass, and cement. It works well for slabs, rollers, and sight tubes because it lasts long and needs little maintenance.

Thermocouple Protection Tubes: These tubes can handle constant use at 1500–1600°C in different atmospheres. I find they are more durable and chemically stable than alumina or silicon nitride tubes.

Refractories and Linings: I consider them essential for linings in glass and cement kilns. They are also used in high-temperature chemical reactors for their long-term resistance to corrosion and thermal shock.

Aerospace and Advanced Engineering: The aerospace industry uses mullite. You’ll find it in electronic substrates, turbine engine parts, radomes, and IR windows because of its strong mechanical and thermal properties.

Mullite Fibers and Whiskers:

I suggest using the fibers for high-temperature insulation and kiln seals. They are also great for electrical insulation and diesel emission filters because they insulate so well at high temperatures.

These short fibers reinforce other ceramics and metals. This greatly improves how composite materials perform in extreme conditions.

Steel Industry: In the steel industry, tools that need to be abrasive and wear-resistant work better with mullite due to its hardness and stability.

Quick Reference: Key Data Table

| Property/Feature | Value/Example |

|---|---|

| Chemical Formula | Al₆Si₂O₁₃ |

| Density | ~2.3 g/cc |

| Flexural Strength | ~115 MPa (20°C) |

| Safe Temp. | 1500–1600°C |

| Water Absorption | 0.00% (impervious) |

| COTE | (5.1 \times 10^{-6}) (20–1000°C) |

| Wear Resistance | High |

| Major Applications | Kiln rollers, thermocouple tubes, emission filters, fibers, reactor linings, composite reinforcement |

| Special Forms | Fibers, whiskers, coatings, composites |

To sum up, I believe mullite ceramics provide a great mix of properties. They are lightweight but strong, with low thermal expansion. They also resist oxidation, corrosion, and wear very well. For key structural, refractory, and filtration jobs where you need both thermal and chemical stability, I recommend mullite. It offers top-tier value and performance.

Magnesium Aluminum Silicate Ceramics: Machinable Glass Ceramics for Precision Industrial Applications

In my experience, Magnesium Aluminum Silicate ceramics are special because they are easy to machine, handle heat well, and are great electrical insulators. I often call them machinable glass-ceramics. Their structure contains tiny, plate-like crystals inside a glass-like material. We create this useful structure through a controlled crystallization process.

Common Forms and Manufacturing Flexibility

You can get these ceramics in many shapes, such as solid discs, rods, hollow cylinders, lugs, insulators, and rings. I find this versatility is why they are a popular choice for custom electrical insulators, prototype parts, and precision mechanical components in special industrial equipment.

Industrial and High-Tech Applications

- Ultra-High Vacuum Technology: I see them used in vacuum chambers, feedthroughs, and support structures. These are common in semiconductor, scientific, and aerospace facilities.

- High-Voltage Insulators: Their ability to resist electricity and be easily shaped makes them ideal for custom, precision insulation. I recommend them for energy technology.

- High-Temperature Components: They serve as reliable parts for furnace hardware and support structures.

- Prototyping and Small-Batch Fabrication: I find that engineers favor these ceramics for small production runs or when quick adaptations are needed. This allows for rapid development without spending money on expensive dies or molds.

Real-World Value and Industry Perspective

From my own experience, these ceramics always perform well where you need precision, chemical durability, and stable performance in extreme environments. When I am prototyping high-voltage insulators or making specialty machine parts for an ultra-high vacuum, this material is a top choice. It provides an unmatched blend of easy machining, consistent electrical properties, and an adaptable form. To me, it is a go-to solution in advanced manufacturing, electronics, and laboratory technology.

Boron Nitride Ceramics: Uses in Lubrication, Electronics, and High-Performance Fields

From my experience, Boron Nitride ceramics are top-tier industrial materials. I value them for their heat resistance, great insulation, and self-lubricating ability. They can work in temperatures up to 2000 °C in an inert gas and have a strong dielectric strength of 10–15 kV/mm. This makes boron nitride a key material for tough, high-tech jobs.

Key Grades and Forms of Boron Nitride Ceramics

High-Purity Boron Nitride (BN) Ceramics: This grade has a BN content of 99.5% or more. It’s made by hot pressing, which I find gives the best insulation and purity. You see it a lot in semiconductors, vacuum systems, and aerospace parts. These applications need materials that can handle intense heat and chemicals.

Pyrolytic Boron Nitride (PBN): PBN reaches 99.99% purity or higher using a method called chemical vapor deposition (CVD). This ceramic is very clean and dense. I recommend it for high-vacuum wafer processing, growing crystals for optoelectronics, and specific thin-film tools.

Composite BN Ceramics: This is a BN material mixed with Al2O3, AlN, SiC, ZrO2, or glass. The blend gives it better resistance to wear, chemicals, and sudden temperature changes. I have seen these used in tough metallurgy, energy, and defense applications.

Notable Product and Market Examples

You will find it used in markets like semiconductors, metallurgy, aerospace, and electronics. It is also common in energy tech and scientific research. PBN crucibles are the standard choice for growing high-precision semiconductor crystals. BN-coated metal molds can last up to 10 times longer in plastic or metal forming. Self-lubricating BN plates reduce how often you need to do maintenance on vacuum pumps and bearings. High-purity BN boards help maintain a vacuum and ensure high-voltage systems are reliable in semiconductor and research gear.

Refractories: High-Temperature Industrial Ceramics for Heat Protection

From my experience, refractories are essential industrial ceramic products. I see them used in extremely hot environments, often above 1,600°C. They act as the protective linings for furnaces, kilns, and reactors. I’ve worked with them in sectors like metallurgy, glass, cement, aerospace, and automotive. Their main job is to provide heat insulation. They also protect equipment from rust, chemical damage, and general wear and tear.

Types and Materials of Refractories

I find it helpful to group refractories by their chemical makeup and behavior.

Basic Refractories:

These are made from magnesite (≥85% MgO), dolomite (CaMg(CO₃)₂), and magnesia-chrome mixes (MgO + Cr₂O₃). I recommend these for steelmaking. They resist basic waste materials and handle heavy physical stress. For example, I’ve seen dense magnesite bricks used to line blast furnaces. They hold up well against lime-rich slags.

Neutral Refractories:

These contain alumina (≥50% Al₂O₃), chromia (Cr₂O₃), and graphite (carbon). They are stable in both acidic and basic conditions. I think they are a great choice for low-oxygen areas, like certain furnace sections.

Acid Refractories:

These products have a high amount of silica. I suggest using them for settings with high corrosion and acid. As a case in point, silica bricks line glass tanks to protect them from acidic slag.

Special Refractories:

This category includes zircon (ZrSiO₄), zirconia-mullite blends, and man-made refractory fibers like blankets and papers. I like that adding zirconia makes these bricks tougher and resistant to sudden temperature changes. This makes them perfect for specific, high-stress jobs.

Structure and Performance

Dense vs. Insulating:

I think of dense refractories as the choice for maximum strength and a long life. They are ideal for blast furnaces and cement kilns. Insulating refractories, on the other hand, are designed to keep heat in. They help cut energy loss and make operations more efficient.

Alumina Content:

I find that low-alumina (<48%) refractories offer more flexibility. I’ve seen them used when working with metals other than iron. For greater strength, I recommend high-alumina (>48%) types. They are popular for linings in the steel and cement industries.

Summary

Looking back at my journey with these ten industrial ceramics, I’m amazed by how far we’ve come. From my experience, each material is the result of years of smart ideas and hard work. I think about the super-tough alumina in our smartphones and the heat-resistant zirconia in jet engines. These ceramics are essential in shaping our modern world. I believe that as technology moves forward, these materials will become even more vital. To me, they aren’t just products. They are the building blocks for tomorrow’s big steps in space exploration, medicine, and sustainable energy.