From my years of experience in materials engineering, I’ve come to see advanced industrial ceramics as the unsung heroes of modern technology. These aren’t your everyday pottery clays; they are engineered, high-performance materials designed to excel where metals and plastics fail. They offer an unparalleled combination of extreme hardness, exceptional thermal stability, superior wear and corrosion resistance, and excellent electrical insulation properties. The global advanced ceramics market is driven by demand from sectors like aerospace, electronics, medical technology, and energy, where reliability under duress is non-negotiable. Based on my professional assessment, the companies that lead this niche but critical industry are those that master the complex chemistry and precision manufacturing required to produce these remarkable materials consistently at scale.

Here is my breakdown of the top 10 largest and most influential advanced industrial ceramics companies shaping our technological landscape.

CoorsTek (USA): A Global Powerhouse in Engineered Ceramics

Headquartered in Golden, Colorado, CoorsTek stands, in my opinion, as the world’s largest privately held technical ceramics manufacturer. With a vast network of facilities across North America, Europe, and Asia-Pacific and over 5,000 employees, their scale is impressive. What truly sets them apart, from my perspective, is their immense material library—they have developed over 400 proprietary ceramic formulations.

Key Strengths and Applications:

-

Diverse Product Portfolio: I’ve specified CoorsTek components for applications ranging from silicon carbide seals in high-temperature pumps to zirconia-toughened alumina (ZTA) for extreme wear situations. Their expertise in carbon/silicon carbide composites is critical for industrial energy generation.

-

Specialized Solutions: They produce highly engineered products like ceramic armor, precision air-bearing guideways for semiconductor manufacturing, and biocompatible ceramics for medical implants. Their collaboration with NASA to develop ceramic membranes for the Mars 2020 mission, which produced oxygen from the Martian atmosphere, is a testament to their innovative capabilities.

-

Vertical Integration: I appreciate that CoorsTek controls the entire manufacturing process, from raw powder processing to final finishing. This vertical integration, supported by computer modeling and rapid prototyping, ensures exceptional quality control and accelerates innovation.

Why They’re a Leader: CoorsTek’s combination of massive scale, deep material science expertise, and a culture of solving the toughest technical challenges makes them a dominant force in the advanced ceramics industry.

Morgan Advanced Materials (UK): A Legacy of Engineering Excellence

With a history dating back to 1856, Morgan Advanced Materials brings over 160 years of materials expertise to the table. Based in Windsor, UK, and operating in 18 countries, this company has successfully evolved from a traditional crucible maker to a leader in advanced carbon and ceramic solutions.

Key Strengths and Applications:

Core Business Segments: Their operations are strategically divided into:

Thermal Products: Specializing in high-temperature insulation and fire protection systems.

Technical Ceramics: Producing advanced structural ceramics for semiconductor wafer handling, medical implants, and aerospace engine components.

Performance Carbon: Manufacturing essential carbon brushes, seals, and bearings for the electrical, transportation, and industrial sectors.

Market Reach: In my work, I’ve encountered Morgan’s components in diverse settings—from graphite crucibles in metallurgy to advanced ceramic insulation in jet engines. Their ability to serve such a wide range of industrial applications is a significant advantage.

Sustainability Focus: I note their strong commitment to ESG (Environmental, Social, and Governance) principles, including climate action and water stewardship, which is increasingly important in modern manufacturing.

Why They’re a Leader: Morgan’s long-standing reputation, global presence, and balanced focus on both ceramics and carbon-based materials secure their position as a top-tier supplier.

Kyocera Corporation (Japan): The Technology Giant

Founded in 1959 by the renowned Kazuo Inamori, Kyocera has grown from a fine ceramics specialist into a global diversified technology conglomerate. Their deep roots in materials science, however, remain the bedrock of their success.

Key Strengths and Applications:

Extensive Material Library: Kyocera has developed over 200 proprietary fine ceramic materials, including alumina, zirconia, silicon nitride, and silicon carbide. I’ve been particularly impressed by their leadership in producing large, high-quality single-crystal sapphire components.

Broad Industrial Footprint: Their advanced ceramic components are critical in more than ten major industries. They supply essential parts for semiconductor manufacturing equipment, cutting tools for industrial machinery, bioceramics for medical implants, and sensors for the automotive industry.

Innovation in Manufacturing: Kyocera is at the forefront of adopting ceramic 3D printing and other advanced manufacturing techniques, allowing for rapid prototyping and the production of complex geometries that are impossible with traditional methods.

Why They’re a Leader: Kyocera’s massive R&D investments, unparalleled diversity of applications, and integration of ceramics into high-growth sectors like electronics and healthcare make them an undeniable leader.

CeramTec GmbH (Germany): The Precision Specialist

Based in Plochingen, Germany, CeramTec is a pure-play advanced ceramics company with a remarkable reputation for precision and quality. With 18 production sites worldwide and a revenue of €746 million (2024), they are a European powerhouse with a global reach.

Key Strengths and Applications:

-

Product Breadth: CeramTec boasts a portfolio of over 10,000 products made from more than 100 different ceramic materials. They excel at producing both standard components and highly customized solutions.

-

Medical Technology Leadership: In my view, CeramTec is a world leader in bioceramics. Their ceramic hip and knee joints, dental implants, and surgical tools are renowned for their longevity and reliability, setting the standard in the medical ceramics market.

-

Engineering Focus: Their components for the automotive and eMobility sectors (sensors, seals), industrial machinery (valves, wear parts), and electronics are engineered to the highest tolerances. Their century-long history has honed a culture of precision engineering.

Why They’re a Leader: CeramTec’s unwavering focus on technical ceramics, deep expertise in medically certified production, and commitment to precision manufacturing make them a trusted partner for the most demanding applications.

3M (USA): The Diversified Innovator

While 3M is known for its consumer products, its division focused on advanced industrial ceramics is a major force. Leveraging its vast R&D capabilities, 3M develops high-performance ceramic materials that solve complex problems across multiple industries.

Key Strengths and Applications:

High-Performance Materials: 3M’s product lines include:

Silicon Nitride Ceramics: Known for high strength, fracture toughness, and light weight, used in bearings and valve components.

Boron Carbide: One of the hardest known materials, used for abrasives and armor.

Nextel™ Ceramic Fibers: Excellent heat and flame resistance for aerospace and industrial composites.

Cross-Industry Application: I’ve seen 3M’s ceramics used in everything from thrust bearings in oil and gas drilling to electrical insulators in electronics and lightweight armor for defense. Their ability to adapt ceramic technology to diverse needs is a key strength.

Global Supply Chain: 3M’s extensive global network ensures reliable supply and technical support for large-scale industrial customers.

Why They’re a Leader: 3M leverages its culture of innovation and massive scale to bring advanced ceramic solutions to a broader industrial base, often creating new markets in the process.

Saint-Gobain Ceramic Materials (France): The Sustainable Solutions Provider

As part of the colossal Saint-Gobain Group, Saint-Gobain Ceramic Materials benefits from immense resources and a long-term view. They are a leader in developing ceramic materials that address global challenges in energy and sustainability.

Key Strengths and Applications:

World-Class R&D: Their research center, Saint-Gobain Research Provence, is a hub of innovation, equipped with advanced facilities like furnaces exceeding 2,000°C. They focus heavily on materials for energy efficiency and green technology.

Focus on Future Markets: Their product development is strategically aligned with megatrends. They are a key supplier of materials for lithium-ion batteries, solar energy systems, and lightweight solutions for transportation.

-

Strategic Partnerships: I am impressed by their active participation in EU Horizon projects and their joint laboratory with CNRS, France’s national scientific research center, which keeps them at the cutting edge of materials science.

Why They’re a Leader: Saint-Gobain combines deep ceramic expertise with a strong commitment to sustainability, positioning them as a crucial partner for industries transitioning to cleaner technologies.

Murata Manufacturing (Japan): The Electronics Ceramics Champion

Murata is a dominant global leader in electronic ceramics, particularly multilayer ceramic capacitors (MLCCs). Their components are the fundamental building blocks of modern electronics.

Key Strengths and Applications:

-

Unmatched Scale: Murata has produced over 9 trillion MLCCs—a staggering number that highlights their manufacturing prowess. A single smartphone can contain up to 800 of their tiny, reliable capacitors.

-

Proprietary Material Science: They have deep expertise in formulating barium titanate-based ceramics, allowing them to push the performance boundaries of miniaturization, capacitance, and stability.

-

High-Reliability Markets: Murata’s components are certified for critical applications in aerospace (e.g., JAXA satellites), medical devices (e.g., pacemakers), and automotive electronics, where failure is not an option. Their recent partnership with QuantumScape on solid-state battery technology underscores their forward-looking strategy.

Why They’re a Leader: In the world of electronic ceramics, Murata is virtually synonymous with quality, innovation, and scale. Their products are essential to the continued miniaturization and advancement of electronics.

Corning Incorporated (USA): The Specialist in Glass Ceramics

Corning is a world-renowned innovator in materials science, and their work in specialty glasses and glass-ceramics places them firmly in the advanced ceramics market. They have a unique ability to develop entirely new material categories.

Key Strengths and Applications:

Flagship Products:

-

MACOR®: A machinable glass-ceramic that is a favorite among engineers (myself included) for prototyping and producing complex, high-precision parts for aerospace and electronics.

-

Corning® Gorilla® Glass: While often viewed as a glass, its composition and manufacturing place it in the glass-ceramic family. Its incredible damage resistance has defined the smartphone industry.

Advanced Substrates: Their ribbon ceramics—ultra-thin, flexible ceramic sheets—are critical substrates for microelectronics, LEDs, and emerging solid-state batteries, enabling continuous roll-to-roll manufacturing.

Why They’re a Leader: Corning doesn’t just make components; they create enabling materials that allow other industries to innovate. Their focus on high-value, proprietary products gives them a unique and powerful market position.

Nippon Carbon Co., Ltd. (Japan): The Carbon and Composites Expert

Nippon Carbon, with a history stretching back to 1915, has deep expertise in both carbon products and advanced ceramic fibers. They are a key player in the supply chain for several high-tech industries.

Key Strengths and Applications:

Nicalon™ SiC Fibers: This is their crown jewel. These continuous silicon carbide fibers are the reinforcement material in ceramic matrix composites (CMCs), which are revolutionizing jet engine and aerospace design by allowing for lighter, more heat-resistant components.

Graphite and Anode Materials: They are a major supplier of high-purity graphite for semiconductors and anode materials for lithium-ion batteries, tying them directly to the electronics and electric vehicle revolutions.

Why They’re a Leader: Nippon Carbon’s specialization in critical, high-performance materials like SiC fibers and high-purity graphite makes them an indispensable, albeit sometimes less visible, leader in the advanced materials space.

Krosaki Harima Corporation (Japan): The Refractories Leader

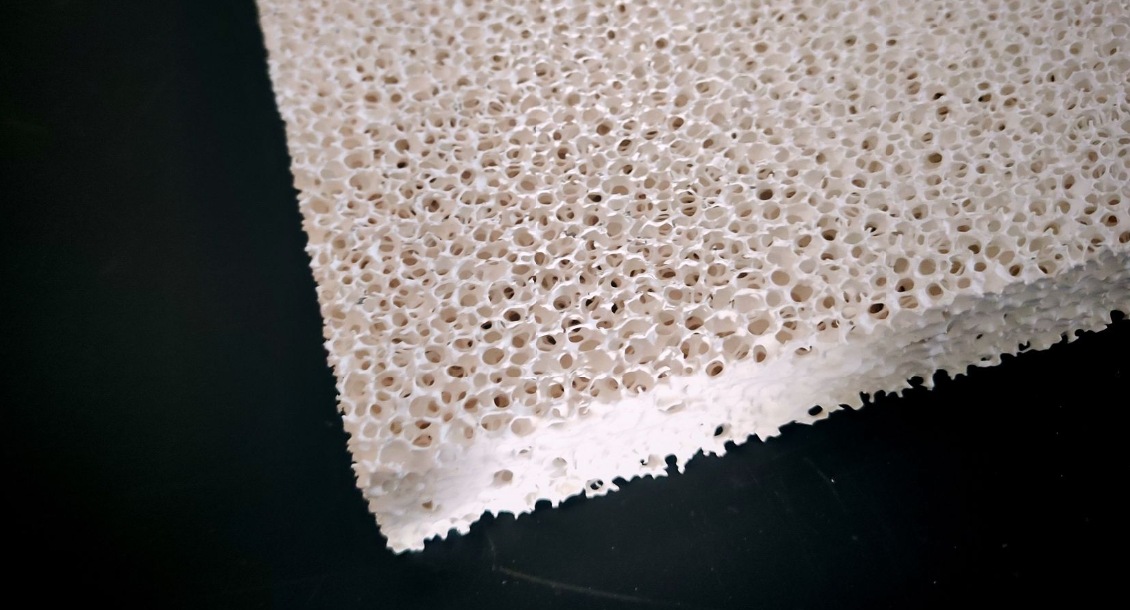

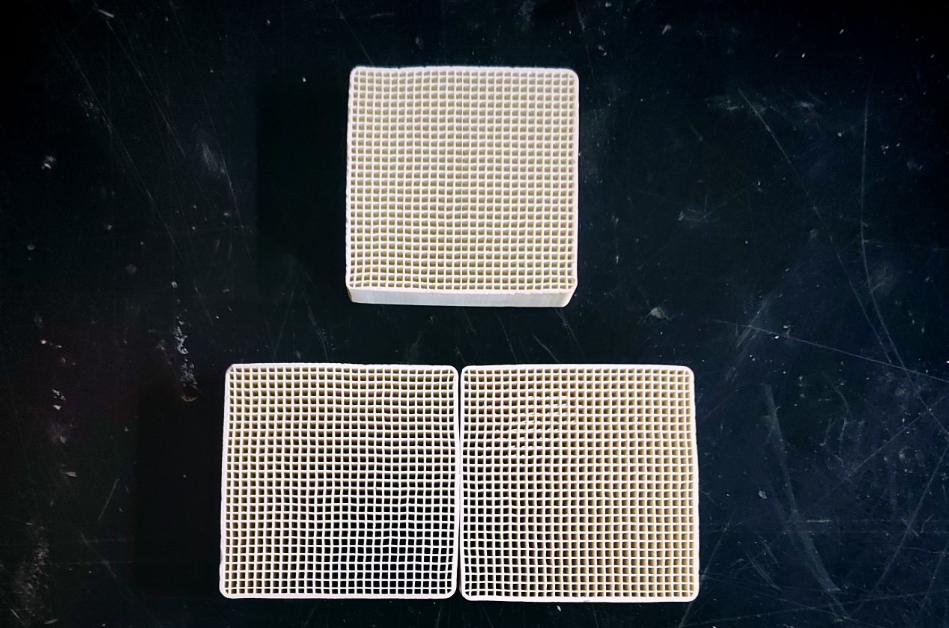

While many companies on this list focus on components, Krosaki Harima is a dominant force in industrial refractory ceramics—the heat-resistant materials that line high-temperature industrial furnaces.

Key Strengths and Applications:

Foundation of Heavy Industry: Their refractory products are essential for steelmaking (blast furnaces, electric arc furnaces), glass production, and non-ferrous metal processing. The efficiency and longevity of these industries depend heavily on Krosaki’s materials.

Advanced Functional Ceramics: They also produce specialized products like near-zero expansion ceramics (NEXCERA™) for precision equipment and advanced kiln furniture for the electronics industry.

Why They’re a Leader: You cannot run a modern steel plant without advanced refractories. Krosaki Harima’s leadership in this fundamental sector solidifies their importance in the global industrial landscape.

Conclusion

From my perspective, the top advanced ceramics companies each excel through a blend of scale, deep specialization, and relentless innovation. The global advanced ceramics market is not a monolith; it’s a collection of niches where material properties must be perfectly tailored to application demands. Whether it’s CoorsTek’s unparalleled breadth, CeramTec’s medical precision, Murata’s electronic dominance, or Krosaki’s foundational refractories, each of these leaders plays a vital role in enabling the technologies that define our modern world. As industries push the boundaries of temperature, pressure, and miniaturization, the strategic importance of these advanced industrial ceramics manufacturers will only continue to grow.