Selecting the right industrial filter size is one of the most critical decisions I make in process design and filtration system design. It’s a delicate balance—remove too little, and you risk contaminating your system or product; remove too much, and you face frequent clogging, pressure drops, and unnecessary operational costs. Over the years, I’ve learned that successful filter selection isn’t just about picking a number—it’s about understanding your process, your fluid, and your operational goals. Whether you’re filtering water, chemicals, oils, or process fluids, getting the size right is crucial for industrial filtration optimization and will save you time, money, and headaches down the line.

Key Factors in Industrial Filter Sizing

Before diving into calculations or product catalogs, I always start with these foundational questions. They help frame the problem and point toward the right type and size of filter, ensuring proper micron rating selection and flow rate calculation.

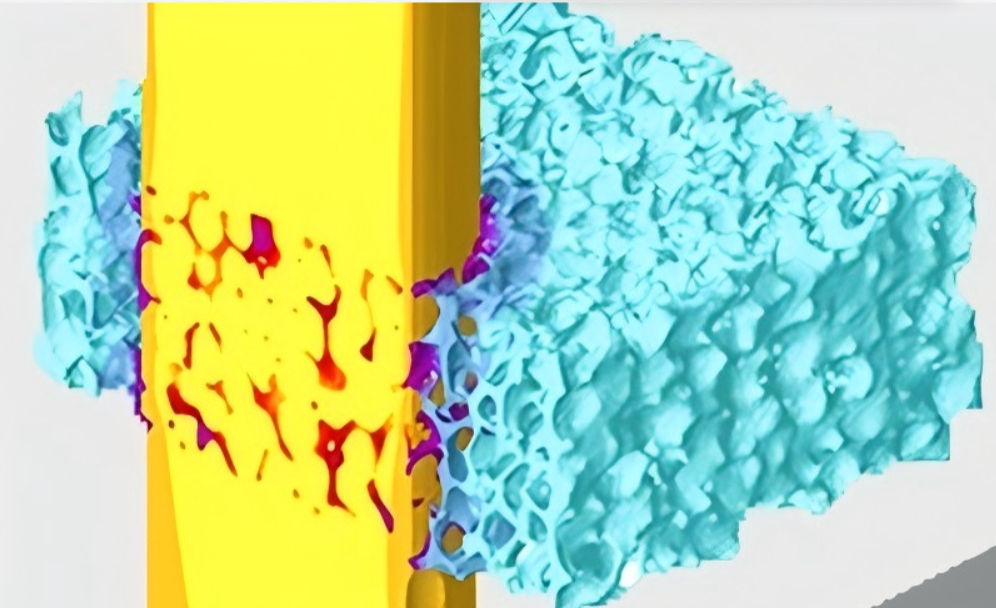

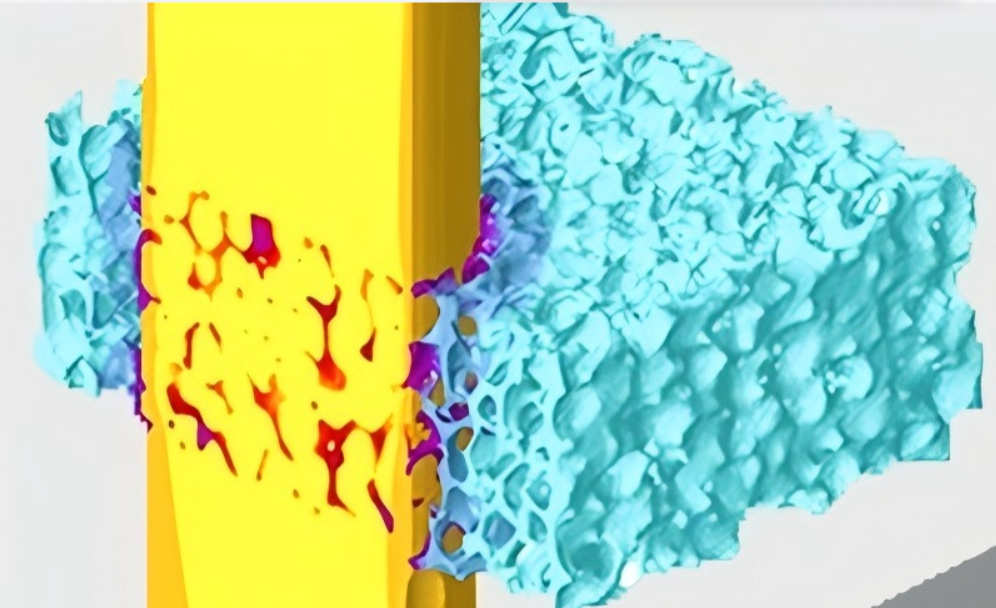

Particle Size and Micron Rating

The first thing I look at is what I’m trying to remove. Understanding micron ratings in filtration is fundamental. Industrial liquid filters are rated in microns (µm), typically ranging from 0.2 to 1000 microns. It helps to visualize these sizes. A human hair is about 70-100 microns thick. Fine beach sand can be as small as 0.3-60 microns, while a dust mite is around 100-300 microns. If I’m targeting visible sediment, I might be looking at 50+ microns. If I’m protecting a sensitive membrane or ensuring product sterility, I might need to go down to 1 micron or even sub-micron levels.

Nominal vs. Absolute Rating: This is a crucial distinction in filter efficiency standards that I always clarify with suppliers.

-

Nominal Rating: This means the filter will remove a certain percentage (often 75-80%) of particles of a given size. I use these for pre-filtration or in less critical applications where some particle pass-through is acceptable.

-

Absolute Rating: This means the filter will retain nearly all (typically 99.9% or more) particles at or above the rated micron size. I specify absolute-rated filters for any critical control point, final product polishing, or when protecting high-value equipment like reverse osmosis membranes or instrument bearings. This is key for absolute vs nominal filtration decisions.

A common mistake I see is using a finer filter than necessary. If a 25-micron filter does the job, using a 5-micron filter will lead to much faster clogging, higher pressure drop, and increased replacement costs. I always choose the coarsest filter that still meets the process requirement, a core principle of industrial filter sizing.

Flow Rate and Fluid Viscosity

The filter must be able to handle the volume of fluid passing through your system without creating a bottleneck. Accurate flow rate calculation is essential.

I always size the filter for the system’s maximum operating flow rate. For example, if my pump can move 150 Gallons per Minute (GPM), I need a filter housing and element rated for at least 150 GPM. It’s often wise to add a 10-25% safety factor to account for surges or future capacity increases. This is a fundamental aspect of filter housing selection and calculating filter pressure drop.

The thickness of your fluid significantly impacts flow. Water (low viscosity) flows easily through a fine filter, while a heavy oil or syrup (high viscosity) will require a much larger filter surface area to achieve the same flow rate at a reasonable pressure. I always check the fluid’s viscosity at the operating temperature and consult the manufacturer’s flow rate charts, which are often based on water. They provide viscosity correction factors that are essential for accurate sizing in industrial fluid filtration.

Operating Pressure and Pressure Drop

Filters create resistance, which results in a pressure drop (ΔP) across the element. Managing this is critical for industrial filtration optimization.

The filter housing must be rated to withstand the maximum operating pressure of your system, including any pressure spikes. Standard housings might be rated for 150 psi, while high-pressure systems may require units rated for thousands of psi, a key point in filter housing selection.

A new, clean filter has an initial pressure drop. As it collects contaminants, the ΔP increases. I advise my clients to monitor this closely. A common rule of thumb is to plan for a filter change or cleaning when the ΔP reaches 15-30 PSID. Allowing the ΔP to get too high can collapse the filter element, force open the bypass valve (sending dirty fluid downstream), or strain the pump. A larger filter surface area generally results in a lower initial and final pressure drop, extending service life. Understanding calculating filter pressure drop is vital for system health.

Process Conditions and Fluid Compatibility

The filter has to survive in its environment. I never skip a thorough compatibility check, which is a cornerstone of filter selection.

The Filter Media selection and housing material must be resistant to the fluid being filtered. I consult chemical compatibility charts for materials like polypropylene, stainless steel (304 or 316), nylon, PTFE, and EPDM seals. An incompatible material can swell, degrade, or leach chemicals into your process stream.

Both the filter media and the housing seals have temperature limits. A polypropylene housing might be limited to 180°F (82°C), while a stainless steel housing with high-temperature seals can handle 400°F (200°C) or more. Operating outside these limits can lead to catastrophic failure.

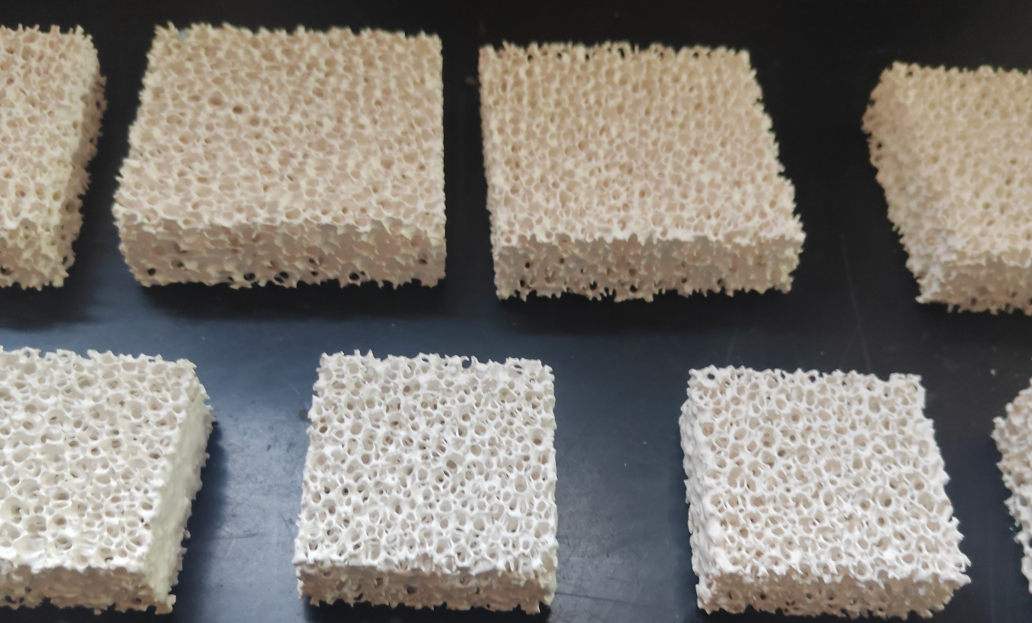

Is the fluid laden with abrasive particles, sticky sludge, or gelatinous organic matter? Abrasive particles can wear out certain media, while gelatinous materials may require depth filters instead of surface filters. Understanding the nature of the “dirt” is key to selecting the right media and is part of industrial filtration best practices.

A Step-by-Step Process for Sizing Industrial Filters

Here is the practical, step-by-step methodology I use on project after project. It helps me move from system specs to a specific filter recommendation, following a clear filter sizing process.

Step 1: Gather System Specifications

I start by collecting all the basic data about the system the filter will be installed in.

-

Pipe Size: The filter’s inlet and outlet connections must match the pipe size. A 4-inch pipeline needs a filter with 4-inch NPT or flanged connections. Mismatched sizes require expensive adapters and can create flow turbulence.

-

Pipe Configuration: I look at the physical layout. Is the pipe run horizontal or vertical? Is space limited, requiring a right-angle filter housing? This determines the housing style I can use and impacts filter housing selection.

Step 2: Determine the Flow Rate

This is perhaps the most critical number for flow rate calculation. I determine the system’s minimum, normal, and maximum flow rates, always in consistent units (GPM or LPM).

If a cooling water loop operates at a normal flow of 200 GPM but can surge to 250 GPM, I must size the filter for 250 GPM. Undersizing will cause problems during those surge periods. I always confirm a filter’s flow rating with the manufacturer, as it can vary based on the specific element inside.

Step 3: Confirm Pressure and Temperature Requirements

I cross-reference the system’s conditions with the filter’s ratings.

-

Pressure Rating: The filter housing’s pressure rating must exceed the system’s maximum pressure. For a 100 psi system, I’d select a housing rated for at least 125-150 psi.

-

Temperature Rating: I ensure the filter media and seals are compatible with the fluid’s operating temperature. I always consider the worst-case scenario, not just the average.

Step 4: Define Filtration Goals (Contaminant Removal)

Now I link back to the “why” of the filter, which centers on micron rating selection.

-

Target Particle Size: Based on my process needs, I define the required micron rating. Is 10 microns sufficient to protect my equipment, or do I need 1 micron for product purity?

-

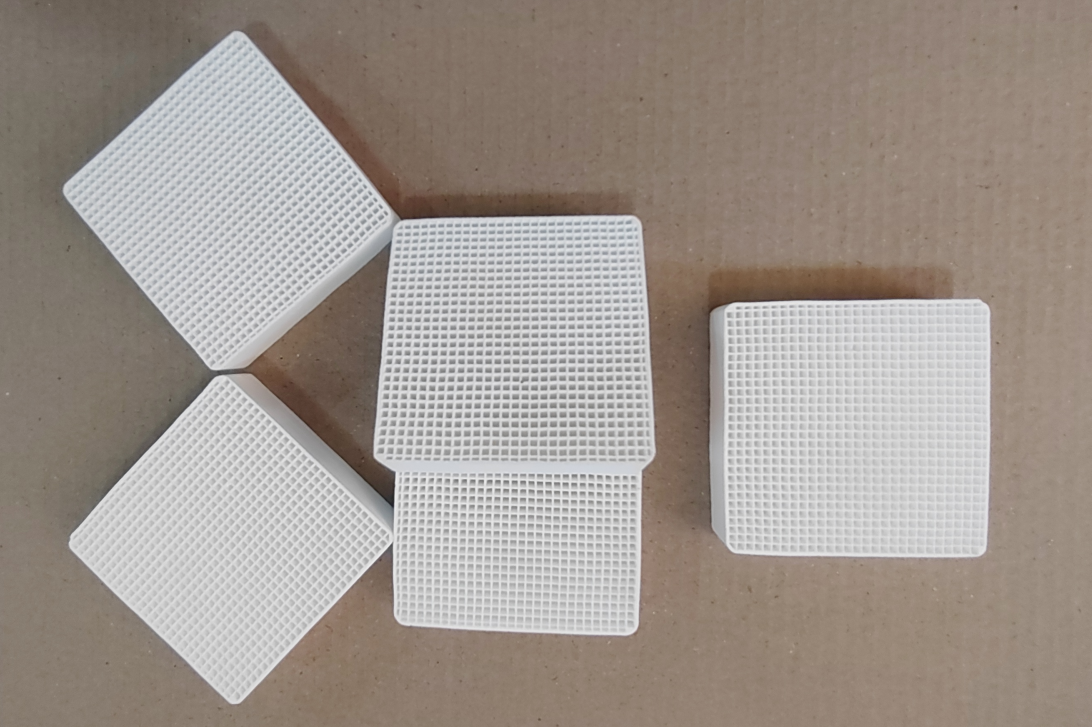

Efficiency Level: I decide between a nominal or absolute rating based on the criticality of the application, following filter efficiency standards. For a robust system, I often recommend a multi-stage approach: a coarse nominal filter (e.g., 50 micron) upstream to remove the bulk of the contamination, followed by a fine absolute filter (e.g., 10 micron) downstream for final protection.

Step 5: Calculate Required Surface Area

A filter’s dirt-holding capacity and service life are directly related to its surface area.

The General Rule: More surface area = longer life and lower pressure drop. Pleated filter cartridges have a high surface area-to-size ratio, which is why they are so common. If I double the surface area, I can typically double the time between filter changes for the same contaminant load. This is a key part of industrial filter sizing.

Using Beta Ratios: For precision applications, I use the Beta ratio (βx=c) from multi-pass tests. A β10=1000 means the filter is 99.9% efficient at removing particles 10 microns and larger. This provides a much more accurate measure of performance than a simple micron rating and is a core industrial filtration best practice.

Step 6: Plan for Maintenance and Uptime

How will the filter be serviced? Downtime is expensive. Planning this is part of industrial filtration optimization.

Continuous Processes: For systems that run 24/7, I almost always recommend a duplex (twin) filter system. This allows me to isolate one chamber for maintenance while the other continues to filter, with zero process interruption.

High Contaminant Loads: For fluids with very high solids content, self-cleaning filters (e.g., backwashing or scraper types) are often the most economical choice, despite a higher upfront cost, because they eliminate frequent cartridge replacements.

Batch Processes: For batch operations, a single housing is often sufficient, as maintenance can be scheduled between batches.

Step 7: Select Materials and Verify Compliance

The final step is specifying the details, crucial for filter media selection and filter housing selection.

-

Material Selection: I match the housing (e.g., carbon steel, 316SS, plastic) and media material to the fluid’s corrosiveness and temperature.

-

Regulatory Compliance: I check if the application requires certifications like ASME, CE, PED, FDA, or USP. This is common in food, pharmaceutical, and potable water applications.

Practical Example: Sizing a Coolant Filtration System

Let’s walk through a real-world example I’ve encountered, applying this filter sizing guide. A machining center uses a water-soluble coolant at 70°F. The system flow rate is 100 GPM, with an operating pressure of 60 psi. The goal is to remove fine metal swarf and grit to extend coolant life and protect machine tools. The particles are primarily in the 5-25 micron range.

My Sizing Approach:

Micron Rating ( micron rating selection ): I need to capture particles down to 5 microns. To ensure good service life, I’ll use a two-stage system. I’ll select a 50-micron nominal-rated bag filter as a pre-filter to catch the larger swarf, followed by a 10-micron absolute-rated pleated cartridge filter for fine polishing.

Flow Rate ( flow rate calculation ): The filter system must handle 100 GPM. I’ll select a duplex housing rated for 100 GPM per chamber. This allows me to switch to the clean side when the ΔP on the dirty side gets too high.

Pressure & Temperature: The system pressure is 60 psi, so a standard 150 psi rated housing is more than adequate. The temperature is mild, so standard nitrile seals and polypropylene media are compatible.

Materials ( filter media selection ): Coolant can be mildly corrosive and may contain tramp oils. I’ll specify a 304 stainless steel housing and hydrophobic media in the final filter to help reject oil.

Maintenance ( industrial filtration optimization ): The duplex design allows for online maintenance. I’ll also install a pressure gauge across the filter to visually indicate when it’s time to switch chambers or replace the bag.

This setup provides excellent protection, maximizes filter life, and ensures uninterrupted operation.

Conclusion

Choosing the right industrial filter size is a systems-thinking exercise. It requires a clear understanding of the interaction between the fluid, the contaminant, the filter, and the operational goals. By following this structured filter sizing guide and industrial filtration guide—starting with the key factors like micron rating selection and flow rate calculation, moving through the filter sizing process, and being mindful of common pitfalls—you can confidently select a filter that will provide reliable, cost-effective performance for years to come. This approach is the foundation of effective industrial filtration optimization. Remember, the goal is not just to filter, but to do so efficiently, minimizing both operational cost and environmental impact. When in doubt, don’t hesitate to leverage the expertise of filter manufacturers; their application engineers are a valuable resource I use regularly to double-check my assumptions and explore new technologies, ensuring I follow the best industrial filtration best practices.