Ever wonder what turns simple mud or stone into a shiny white sink or a glossy, heat-proof plate? Clay, feldspar, and silica are the key players here. These raw materials make ceramics work. Each one has its own strengths and jobs. I’ve noticed people talk about recipes and kilns a lot.

Clay: Properties, Uses & Main Sources

In my experience, clay is the foundation of the ceramics world. People value it because it’s plastic, malleable, and turns glass-like (vitrifies) when fired at high temperatures.

Key Properties of Clay in Ceramics

- Plasticity: When you add water, clay gets soft and workable. This makes it easy to shape into detailed forms.

- Vitrification: After firing it between 900–1100 °C, I find the clay gets hard, dense, and strong. It also won’t absorb water.

- Particle Size: Kaolin particles are usually 2–20 μm. Ball clay particles are smaller, often under 1 μm. From what I’ve seen, this smaller size gives you better workability and a smoother finish.

- Chemical Composition: Industrial clays usually have 46–55% SiO₂ and 19–21% Al₂O₃. You will also find 6.7–10.8% Fe₂O₃ and 8–10% alkali/alkaline earth elements. This mix affects the clay’s color, firing temperature, and final strength.

- Color After Firing: Clays with a lot of iron fire to a reddish or brown color. Low-iron clays, like kaolin, give you a bright white finish. This is why I suggest kaolin for making porcelain and sanitaryware.

- Shrinkage and Density: When you fire clay, it shrinks by about 0.5–7%. Its density increases from 1.74 to 2.21 g/cm³. I have also observed a weight loss of 4–9% during firing.

- Water Absorption: As you increase the firing temperature, the clay absorbs less water. For example, it can drop from 17% to 14%. This shows the clay is becoming more glass-like.

Major Types of Industrial Clay

Kaolin (China Clay): This type is very pure with little iron, and it fires to a bright white. I recommend it for porcelain, tiles, whiteware, and sanitaryware. You can find it in the USA, UK, Brazil, and China.

Ball Clay: This clay is very plastic and has fine particles smaller than 1 μm. I often see it blended with other clays to improve workability and strength. Top producers include the UK, USA, and Thailand.

Fire Clay: Fire clay can handle high heat. This makes it perfect for kiln bricks and other heat-resistant items. Major sources are the USA, Germany, and China.

Common Ceramic & Industrial Uses

- Pottery and Sculptural Work: Mugs, plates, vases, and decorative ceramics.

- Porcelain & Whiteware: Sinks, toilets, and fine china all use blends with a high amount of kaolin.

- Tiles and Bricks: You can make both glazed and unglazed products. The clay blend determines the color and strength. For instance, some clays in Cameroon with an 18–38% clay fraction make strong, colored tiles and bricks.

- Refractory Ceramics: This includes firebricks, parts for kilns, and plates that resist high temperatures.

- Advanced Ceramics: Clay is also used in modern applications like electrical insulators, medical implants, and catalytic devices.

- Composites: It is a key ingredient in cements, concrete, paints, and coatings.

Feldspar: Properties, Uses & Main Sources

Key Properties of Feldspar in Ceramics

Its chemical makeup consists of alkali aluminosilicates. These include albite (sodium), orthoclase (potassium), and anorthite (calcium). It has a hardness of 6 on the Mohs scale. This gives ceramic products good resistance to wear.

It has high thermal resistance. This feature helps ceramics and glass handle high firing temperatures without warping.

As a fluxing agent, it lowers the melting point of other materials, like quartz. In my experience, it also promotes vitrification. This forms a glassy phase that binds ceramic particles together.

It resists chemical weathering. This resistance improves the durability of the final product. Its crystal structure provides strength. It also helps control how the material melts during firing.

Major Uses in the Ceramic Industry

Flux in Clay Bodies: I recommend using feldspar as a flux in clay bodies. It lowers firing temperatures, which makes the ceramics stronger and denser.

Glaze Manufacturing: It is used to make glazes. It lowers the glaze’s melting temperature and helps create a smooth, glossy finish.

Glassmaking: This use accounts for about 66% of US feldspar consumption.

You can find it used as a filler or extender in paints, plastics, and rubber. It also serves as a mild abrasive in household cleaners and personal care items.

Feldspar Types Used in Ceramics

- Potassium Feldspar (K-spar): This type improves translucency and strength. I suggest it for high-quality porcelain.

- Sodium Feldspar (Albite): This is useful for lowering the melting temperature. I use it for glazes and whiteware.

- Calcium Feldspar (Anorthite): This type is used in very specific ceramic formulas.

Kaolin (China Clay): Properties, Uses & Main Sources

From my experience, kaolin’s primary component is the mineral kaolinite (Al₂Si₂O₅(OH)₄). It forms when feldspar-rich granites weather over time. I value kaolin for its bright white color. This whiteness comes from its low iron and alkali content. For making pure white ceramics, this quality is essential. I’ve seen some deposits with a light tint, but suppliers refine them for top-quality products.

You can find industrial kaolin in grades from 0.5 to 100 µm. I find that for the best ceramics, like bone china, you need ultra-fine grades of 1–5 µm. These small particles give you a smooth finish and a strong final product. Using larger particles weakens the item, so I always suggest precise grading.

Kaolin itself has medium plasticity. I recommend blending it with ball clay. This mixture improves shaping, molding, and strength before firing. I find this combination is perfect for creating complex shapes and large tiles without any cracks.

Kaolin shows low shrink-swell behavior. This means the ceramic body stays stable. It will not warp during the drying and firing stages. This stability gives you precise sizing, which is vital for sanitaryware and technical porcelain.

Kaolin has a high fusion point, up to 1,800°C. This lets you create ceramics that keep their strength and color at very high firing temperatures. I believe this makes it a core material for porcelain, refractory items, and high-end technical ceramics.

In my work, I see how kaolin improves green (unfired) strength. It also adds a great deal to the final flexural and compressive strength of a piece after firing. Kaolin is stable and almost inert, with a neutral pH around 4.5. This property prevents unwanted reactions during both firing and use. I trust it to create safe surfaces for food, medical, or cosmetic ceramics.

Ceramic Applications:

- Porcelain & Bone China: I use high-kaolin blends to achieve translucency, color, and a silky texture. A good example recipe is 50% kaolin, 25% feldspar, 25% bone ash.

- Sanitaryware & Whiteware: A high kaolin content gives pieces whiteness, dimensional stability, and strength.

- Tiles (Wall & Floor): Kaolin adds thermal shock resistance and durability.

- General Pottery: I use it for fine, decorative, and functional ceramics.

Silica (Quartz/Silica Sand): Its Structure, Purity, and Use in Ceramics

In my experience, silica sand is the foundation of making ceramics. It’s a high-purity material for tough jobs. Good ceramic-grade silica sand contains ≥98.5% SiO₂. Some top grades even reach 99.997% SiO₂. I believe this high purity is necessary to make perfect ceramic surfaces and bodies.

Chemical Makeup and Purity Rules

- Purity Levels: I suggest using ceramic-grade silica with ≤0.3% impurities like iron or alumina. This stops the final piece from changing color when fired.

- Moisture Level: You should keep moisture at ≤1%. This helps prevent cracks during the drying stage.

- Particle Size: I recommend a controlled size from 50-400 mesh. For glazes, use 200-400 mesh grades to get a smooth, ideal surface finish.

Important Thermal and Physical Qualities

High Melting Point: It can handle kiln heat up to 1,600°C without warping. I’ve found this is vital for making strong ceramics.

It doesn’t react with glazes or colors. This means you get true, consistent color in your finished ceramic piece. It cuts down on warping and cracking when you heat and cool it fast. This creates dense, even surfaces. It also helps the material act predictably during shaping and firing.

Its Role in the Ceramic Body

- Main Ingredient: Mix it with clay and feldspar. This creates a strong, lasting body for things like tiles, tableware, and sanitaryware.

- Green Strength: Its grainy makeup helps pieces hold their shape while being formed and dried.

- Durability: The final product is stronger and resists thermal shock. This is very useful for items like functional pottery that see quick temperature changes.

- A Word of Caution: Quartz expands a lot with heat. If you don’t balance it correctly in the mix, it can cause cracking.

Uses in Specialty and Technical Ceramics

Porcelain & Bone China: It provides a delicate, partly see-through look and a pure white color. These are important qualities for fine ceramics.

Technical Ceramics: I choose high-purity grades for kiln furniture, furnace linings, and other advanced parts where heat shock resistance is key.

Art & Architectural Pottery: Coarse silica sand can create interesting textures you can feel on the surface.

Electronics & Aerospace: Very pure silica is used for making silicon carbide. This is for things like semiconductor parts and heat shields.

So, my recommendation is to pay close attention to purity, particle size, and the correct grade of silica sand. If you do, you can make ceramics that are strong, tough, and beautiful. This works for everything from home tiles to high-tech parts.

Alumina: Properties, Uses & Main Sources

Alumina, or aluminum oxide (Al₂O₃), is what I consider a core material in the ceramic industry. I like it because it’s durable, stable at high temperatures, and has many technical uses in today’s industries.

Key Properties of Alumina in Ceramics

Alumina can handle very high temperatures up to 1650°C (2900°F). Sometimes, it can take even more. This makes it my top choice for high-temperature jobs. It holds up well against acids and alkalis. I often see it used in places with harsh chemicals.

Alumina is a very hard material. Based on my experience, this hardness helps parts endure. They last longer in systems that experience a lot of wear. I find it to be a great insulator. It works even at high temperatures that cause other materials to fail, which is essential for electronic parts.

Major Uses of Alumina in the Ceramic Industry

- Electronics: I recommend it for semiconductors and high-voltage insulation. Alumina is perfect for substrates and circuit boards because it does not conduct electricity and handles heat and pressure well.

- Aerospace: For aerospace, I suggest it for heat shields and key structural parts. If a component needs strength and must resist sudden temperature changes, alumina is my preferred choice.

- Automotive Components: You will find alumina in car engine parts and emission control devices. For these components, resistance to both heat and wear is a must.

- Industrial Machinery: I see it used for durable seals, liners, and bearings. Its hardness makes these parts work for a long time, even in rough industrial settings.

- Medical Field: In medicine, you can find alumina in joint replacements and prostheses. It is safe for the body and resists wear, making it an excellent choice for precise medical ceramics.

Sourcing and Refinement

Alumina mainly comes from a raw material called bauxite. The most common way to get it is the Bayer process. This method dissolves bauxite in caustic soda to separate the aluminum oxide.

Some advanced ceramics need very pure alumina, known as HPA. This can be 99.999% pure (5N). From my experience, using HPA gives the best results for high-performance electronics and LEDs.

Alumina ceramic parts can be made into very precise shapes. We use methods like isostatic pressing and injection molding to meet these tight standards.

Zirconium Silicate (Zircon): Properties, Uses & Main Sources

Zirconium silicate (ZrSiO₄), which most people call zircon, is a key ingredient in ceramics. I believe its special physical and chemical properties make it so important for the industry.

Principal Uses in Ceramic Industry

Opacifier for Glazes & Enamels:

It’s necessary for a white, non-see-through look. It also makes glazes glossier and smoother. You’ll see it used in tiles, tableware, and sanitaryware. In my opinion, it improves both how they look and perform.

Advanced & Related Applications

- It is used in refractory linings for kilns and industrial furnaces.

- It is the base material for making zirconium metal, used in special high-tech products.

- It is a key part of glass enamels and high-quality glass products.

- It is also used in electronics for packaging materials and in biomedical devices like artificial bones and teeth.

Summary: Why I Recommend Zirconium Silicate for Ceramics

Based on my experience, zirconium silicate is essential for modern ceramics. It provides opacity, durability, strength, and chemical stability. It also offers excellent heat resistance. You can see its benefits in many quality ceramic products, from dinnerware and toilets to architectural tiles and advanced industrial parts.

Talc: Properties, Uses & Main Sources in Ceramic Industry

Based on my experience, talc is a vital raw material for the ceramic industry. I value it for its special properties and the many ways it can be used.

Key Properties of Talc for Ceramics

- Chemical Makeup: Talc’s formula is Mg₃Si₄O₁₀(OH)₂. What I find impressive is how soft it is (Mohs hardness 1). It is also very white (94–98%) and has almost no iron.

- Physical Form: It has a plate-like structure. This makes talc easy to work with and improves the flexibility of ceramic clays.

- Heat Resistance: Talc handles high heat quite well. It helps make ceramics less likely to crack from rapid heating or cooling.

- Water-Repellent: Talc naturally pushes water away. This means finished ceramics absorb less water and are less prone to leaks.

- Chemically Stable: It offers strong resistance to acid. This protects ceramic items from breaking down if they contact chemicals.

- Particle Size: You can get it in custom grinds, from 325–2000 mesh. I suggest you select a size that fits your specific ceramic project.

Main Ceramic Applications

- Sanitaryware: I’ve seen it used in toilets, sinks, and bathtubs. It gives them a high-gloss white finish, better water resistance, and protection from acids.

- Wall & Floor Tiles: It helps make tiles stronger, gives them a smoother surface, and improves how they handle temperature changes.

- Tableware & Artware: Using talc can increase the gloss and surface quality of dishes. It also helps prevent crazing, which are tiny cracks in the glaze.

- Industrial Ceramics: It is a core material for steatite ceramics and cordierite bodies. It improves their resistance to heat and cracks.

- Glazes: Talc works as a flux, which lowers the melting point of a glaze. This process can help you create smoother, glossier, or textured surfaces.

Magnesia (Magnesium Oxide): Properties, Key Uses & Sources in Ceramics

Essential Properties of Magnesia for Ceramics

Magnesia melts at a very high temperature of 2800°C. I find this makes it stable during high-temperature processes. From my experience, it resists oxidation and corrosion from molten metals. This makes it essential for harsh ceramic firing conditions.

I think magnesia is unique. It transfers heat well but also works as an electrical insulator. This is a valuable combination for many advanced ceramic products.

Main Uses of Magnesia in Ceramic Industry

I often see magnesia used for parts that get very hot, like crucibles, thermocouple tubes, and heating element insulators. It holds up to repeated heating and cooling, which helps kiln parts and furnaces last longer.

It can produce special matte finishes on glazes, which are popular in both decorative and functional ceramics. Because of its electro-optical properties, I’ve seen magnesia used to create strong protective films for items like plasma display screens.

How Magnesia is Sourced: Raw Materials and Production

The main natural materials are calcined magnesite (MgCO₃), dolomite, and talc. These are processed at high temperatures. I believe this process produces a high-purity magnesium oxide that is good for ceramics.

Magnesia is also produced on a large scale from seawater and magnesium-rich brine. In my opinion, these sources provide a steady amount for the industry and help keep costs competitive.

Advanced Ceramic Applications & Innovations

- Composite Ceramics: I recommend mixing magnesia with other oxides like yttria (Y₂O₃) to create custom ceramic composites. This improves the material’s strength, toughness, and resistance to thermal shock for modern ceramic parts.

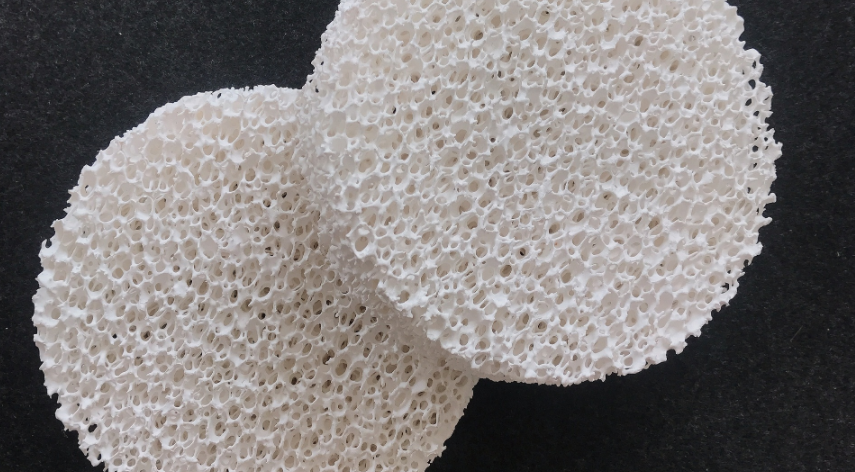

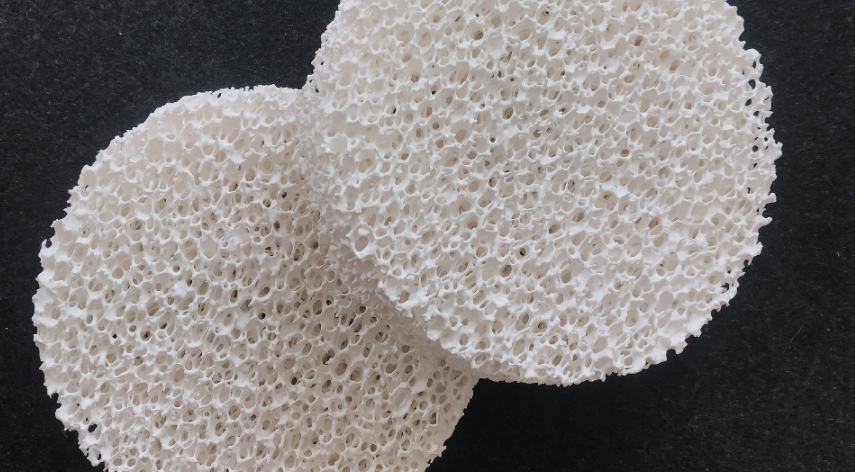

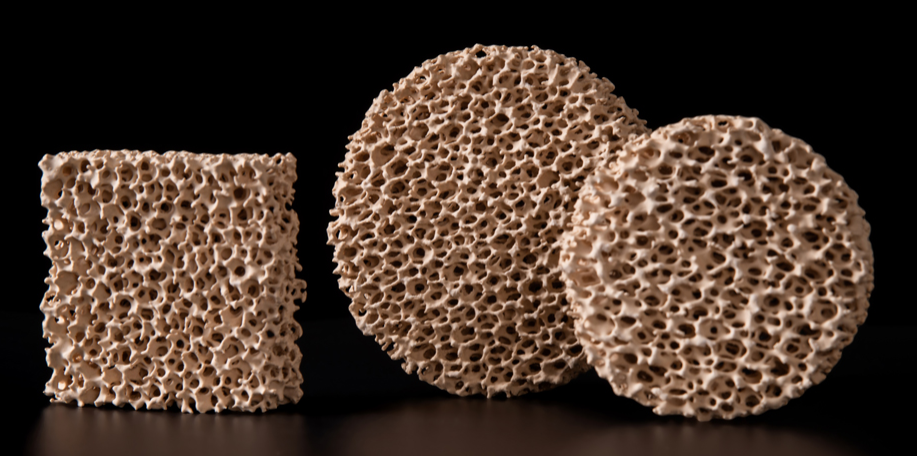

- Foam Ceramic Filters: I’ve found that magnesia-based filters are a standard for molten metal filtration. They improve the metal’s purity and reduce casting defects. This offers vital protection for high-value metal parts.

Boron in Ceramics: Boron Nitride, Borosilicate Glass & Advanced Borates

From my experience, boron compounds are vital in the ceramic industry. They change the properties of materials, which lets us create high-performance products.

The Role of Boron Oxide (B₂O₃) and Refined Borates

I find that Boron oxide (B₂O₃) is one of the best ceramic fluxes available. It lowers melting points quite a bit, making ceramic processing more energy-efficient. It acts as both a network former and network modifier in glass. This helps replace some silica and lowers viscosity. As a result, the melt flows better and supports quicker firing.

I suggest using products like Neobor® and Dehybor®. They are free from water and give you clear advantages in processing. They help stabilize formulas, make batches more consistent, and lower furnace emissions compared to unrefined borates. Because they have more boric oxide, you can use lower firing temperatures. You won’t lose any glaze quality. This gives you smoother, glossier surfaces that look perfectly uniform.

Based on my experience, using raw, unrefined borates can cause problems. You might see pinholing, crazing, and color that isn’t consistent. There’s also a risk of toxic heavy metal contamination and other visible flaws.

Hexagonal Boron Nitride (h-BN): The “White Graphite”

Boron Nitride Properties:

- Density: 1.6 g/cm³.

- Working Temperatures: 900–2100°C.

- Thermal Conductivity: 45 W/m·K.

- Electrical Resistivity: >10¹⁴ Ω·cm.

- Three-point Bending Strength: 18 MPa.

- Compressive Strength: 45 MPa.

- Thermal Expansion: 1.5 × 10⁻⁶/K (20–1000°C).

I recommend h-BN for its great thermal stability. It does not react with most harsh chemicals and is an excellent electrical insulator. Its self-lubricating, low-friction surface is perfect for applications that need to resist heat and wear.

This material is inert, making it a good choice for medical uses. I think it’s well-suited for medical devices, dental implants, prosthetics, bone grafts, and delivering drugs.

Main Applications:

- Insulators in high-temperature furnaces and gaskets for melting glass

- Substrates for semiconductors and electrical insulators for vacuum systems

- Crucibles for growing crystals and parts for horizontal casting machines

- Components for ion implantation and high-voltage electrical feedthroughs

- Seals for automotive oxygen sensors when you mix it with boron oxide binders

- Charge barrier coatings for laser printer drums

As you can see, boron compounds are key for making advanced ceramics. We use refined borates for glazes, high-performance h-BN, or super-hard B₄C. They all help produce ceramics with better thermal, mechanical, and chemical properties. In my opinion, using these compounds leads to more reliable processes and superior products. It also provides a way into valuable sectors from electronics and healthcare to materials engineering.

Limestone/Calcite (Calcium Carbonate): A Look at Properties, Uses & Sourcing for Ceramics

In my work, I see limestone and calcite as key raw materials for ceramics. They are both natural forms of calcium carbonate. I find them valuable as a filler and as a CaO source for glazes and the main ceramic body.

My View on Key Properties in Ceramics

I use calcium carbonate to get a clean, bright finish. It makes tiles, sanitaryware, and dinnerware look great. It stays stable at high firing temperatures. This helps products keep their shape and strength as they bake. Adding it helps me control shrinkage. I can maintain the exact dimensions I need for my ceramic pieces.

From my experience, fine-grained calcite gives you the best brightness. Coarser grains can make colors look dull and you might even see the grains on the finished surface. Adding more calcium carbonate often reduces a product’s flexural strength. I’ve found that using about 5% is a good way to balance the mechanical properties. It helps form anorthite and increases the glassy part of the ceramic. This changes the final durability and structure. I’ve noticed fine particles increase how much water a piece absorbs. Coarser grains tend to lower water absorption.

Major Uses I See in the Ceramic Industry

It’s a great filler material to lower costs and adjust density. I see this used a lot in tile and sanitaryware production.

I find it essential for making stoneware and porcelain glazes. It helps me control how the glaze melts and how glossy the surface becomes.

It helps prevent too much shrinkage and warping. This means I get more good, accurately sized products from each batch.

Being able to control the grain size allows me to fine-tune the final product’s physical look and properties.

Common Applications

- Ceramic Tiles: I use it to get extra whiteness, control shrinkage, and save on costs.

- Sanitaryware/Dinnerware: It gives these items better opacity and a great-looking surface finish.

- Glaze Recipes: It’s a dependable CaO source. This gives me consistent melting and good surface quality every time.

Summary Table: Top 10 Materials—Properties & Major Uses

Here is my quick guide to the most essential ceramic raw materials. I cover their main features and what they are used for in the industry. For each one, I included technical details and market data. My goal is to give ceramic makers a helpful reference.

| Material | Key Properties | Major Uses | Data, Sourcing & Value |

|---|---|---|---|

| Clay (incl. Kaolin) | Plastic and simple to shape; variable particle size; fires to a hard, dense body | Main body for tiles, pottery, porcelain, bricks, whiteware, sanitaryware | 46–55% SiO₂, 19–21% Al₂O₃; China, USA, UK, Brazil; $0.2–$1/lb depending on grade |

| Ball Clay | Very fine particles; great plasticity; strong binding power | Blended to improve workability, shape complexity, and strength; common in whiteware, sanitaryware | <1 μm particle size; UK, USA, Thailand |

| Fire Clay | Resists heat; high in alumina | Kiln bricks, firebricks, refractories, high-temperature insulators | Higher Al₂O₃; USA, Germany, China |

| Feldspar (Soda/Potash) | Melts at low temperatures (flux); creates a glassy finish; adds strength | Flux for clay bodies, porcelain, tiles, glass, sanitaryware, glazes, tableware, dental ceramics | 10–35% of body; Turkey, India, China, Thailand; 23m t/yr production; $0.10–$0.20/lb |

| Quartz/Silica | Adds strength; resists thermal shock; has high purity; controls shrinkage | Tiles, glazes, porcelain, tableware, sanitaryware, kiln furniture | 98.5–99.997% purity; USA, Brazil, India; 32m t/yr used in ceramics/glass |

| Talc | Very soft (Mohs 1); plate-like structure; resists thermal shock and acid | Tiles, sanitaryware, artware, steatite ceramics, glazes, industrial ceramics for heat resistance and smoothness | 94–98% whiteness; China, India, USA, Europe; 325–2000 mesh; 17% of global talc for ceramics |

| Alumina (Al₂O₃) | Very hard; resists wear and corrosion; good electrical insulator | Technical ceramics, electronic substrates, chemical-resistant tiles, medical devices, abrasives, kiln furniture | From bauxite; Germany, China, Australia; HPA $3–$8/lb; up to 99.999% pure for technical use |

| Zirconium Silicate (Zircon) | High melt point (2550°C); adds hardness, gloss, and opacity; chemically stable | Opacifier for glazes, tiles, tableware, sanitaryware, heat-resistant ceramics, industrial parts | 1.2m t/yr; Australia, S. Africa, China; 5–10% in glazes |

| Magnesia (MgO) | Excellent heat stability; great insulator; high melt point (2800°C) | Refractory ceramics, crucibles, kiln linings, glazes, insulation, metal filtration filters | Sourced from magnesite, dolomite, brine; China, Austria, Russia |

| Boron Compounds | A powerful flux that forms glass; lowers melting points; adds durability | Borosilicate glass, fluxes in glazes, technical ceramics (BN, B₄C); improves durability, controls melt behavior | Turkey, USA, S. America; Borax $1.80/lb, boric acid $2.92/lb |

| Calcium Compounds (Calcite, Whiting) | Used as a filler; controls shrinkage; improves whiteness and opacity | Filler for tiles, whiteware, glazes, bone china, sanitaryware, stoneware, glass manufacturing | Limestone, calcite; $0.74/lb; found worldwide; optimal dose ~5% for balance of strength and properties |