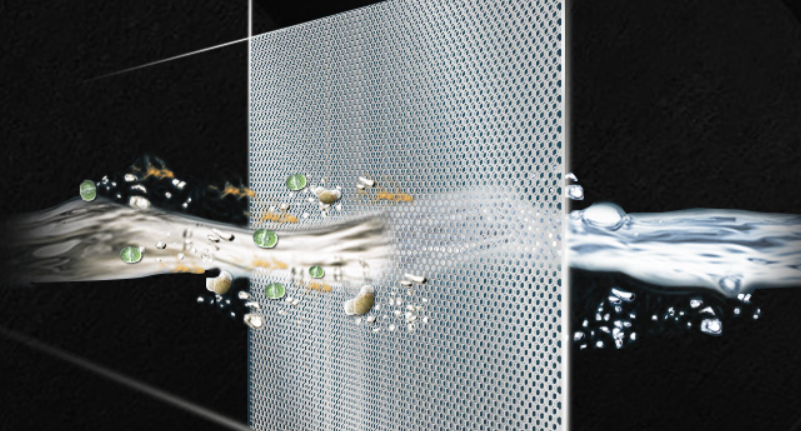

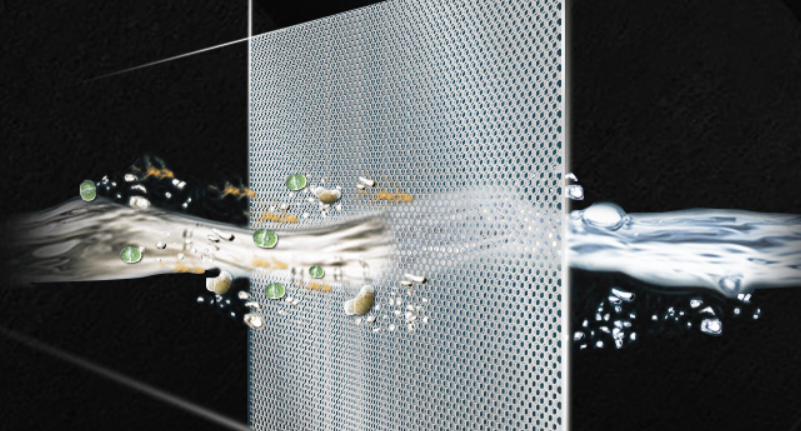

Industrial gas filtration is a critical process for removing harmful particles and toxic gases from industrial air streams. It ensures environmental compliance, protects worker safety, and extends equipment lifespan. Key technologies include durable sintered metal filters for high-temperature particle removal, versatile Activated carbon filters for adsorbing gases like SO₂ and VOCs, corrosion-resistant Ceramic filters for hot flue gases, and precision membrane filters. These systems can achieve over 99% removal of hazardous PM and gases, making them essential for hot processes, data centers, and various industrial sectors.

Selecting the right filtration depends on contaminant type, operating conditions like temperature and pressure, and regulatory requirements. I believe choosing the proper technology is vital for optimal performance and compliance.

Key Filter Material Types for Toxic Industrial Gas Filtration

Your filter material choice affects three things: removal efficiency, how long it lasts, and your total system cost. Here’s what I recommend for toxic industrial gas filtration based on my experience.

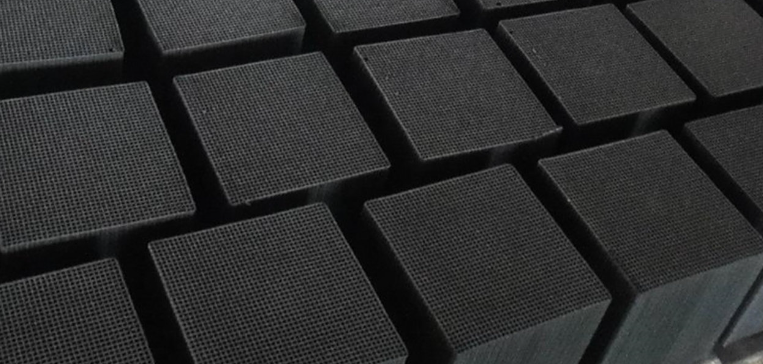

Activated Carbon: Broad-Spectrum Gas Removal

Primary use: Adsorption of VOCs, sulfur compounds, organic gases, and odors

I suggest activated carbon filter cartridges when you need to remove trace hydrocarbons and volatile organics from gas streams. They work well for this task.

Many industries use them for ultra-pure gas needs. I’ve seen them in chemical processing, food and beverage, and ultra-clean manufacturing.

Performance highlight: Activated carbon achieves gas purity levels for sensitive applications. It’s cost-efficient because you can reuse it until saturation.

Stainless Steel (316L): High-Temperature & Corrosive Gas Filtration

Primary use: Filtering gases under high temperature and pressure in corrosive environments

I recommend stainless steel cartridges, 316L grade, for excellent durability. They’re reusable and cleanable. They work well in harsh industrial settings like semiconductor fabs and natural gas plants.

Specifications & data:

- Internal surface finishes: 5-25 µin (0.13–0.63 µm Ra). This ensures minimal particle entrapment.

- Helium leak tested down to 10⁻⁷ atm·cm³/s.

- Flow rates available up to 1,500 slpm for large system requirements.

Ceramic Media: Extreme Heat & Acid Gas Applications

Primary use: Filtering acid gases, particulates, and some heavy metals at high temperatures

Ceramic Filter Media come housed in stainless steel. This provides strong filtration in processes like hazardous waste incineration and metallurgy.

Performance data: Ceramic media assemblies handle flows up to 1,000 slpm.

Polypropylene & Polyester: Chemical Resistance and Durability

Polypropylene: I like this for resistance to acids, bases, and aggressive chemicals. You’ll find it in liquid and gas filtration where harsh chemicals are present.

Polyester: High strength, abrasion resistance, and moisture tolerance.

- Washable and reusable in humid conditions or with abrasive particle content.

- Temperature operating range: -40°C to 120°C.

Cellulose and Paper: Cost-Effective Particulate Removal

Primary use: Low-cost removal of solid particles

You’ll find these in pharmaceutical, cosmetic, and food & beverage processes. They capture particles with filtration down to 1–10 microns.

Nickel and PTFE Membranes: Specialized & High-Purity Filtration

Nickel: I recommend this for high-temperature and corrosive gases in chemical and semiconductor industries.

PTFE (Membrane Filters): These remove submicron particles. They’re critical in semiconductor and pharmaceutical gas purification.

Example Filter Elements and Applications

Pleated filters: Enlarged surface area for higher efficiency. Many operations use them in gas and liquid filtration.

Cartridge filters: You can configure these with materials like activated carbon or polypropylene. I’ve seen them across chemical plants, data centers, and industrial settings for VOC, sulfur, and odor removal.

Bag and screen filters: These work for dust, bulk solids, or coarse contaminants in power and cement industries.

Membrane filters: Control filtration pore size for ultra-fine toxic particle control.

Summary Table: Material Selection by Application

| Material | Best For | Max Flow Rate |

|---|---|---|

| Activated Carbon | VOCs, Organics, Odors | — |

| Stainless Steel | Harsh/corrosive, high-temp gases | 1,500 slpm |

| Ceramic | High-temp, acid gases, particulates | 1,000 slpm |

| Polypropylene | Aggressive chemicals in gases/liquids | — |

| Polyester | Humid, abrasive, moisture-rich environments | — |

| Cellulose/Paper | Cost-driven, general particulate applications | — |

| Nickel | Corrosive high-temp gas streams | — |

| PTFE Membrane | Submicron, high-purity gas requirements | — |

I suggest you consider two things: your contaminant profile and your desired removal efficiency. Match your application to the right filter material. This ensures regulatory compliance, equipment protection, and cost-effective operation.

How to Choose Filter Materials for Toxic Industrial Gas

I recommend you consider several key factors when choosing filter materials for toxic gas filtration. Here are the main points and examples I suggest:

Chemical Compatibility

Why this matters: Your filter media must resist damage from toxic gases and other contaminants.

My top picks:

I recommend Polypropylene and PTFE for strong acids, bases, and harsh solvents. Use 316L stainless steel for corrosive, reactive, or specialty gas streams.

Temperature Resistance

Why this matters: Your filters must handle process temperatures. Some exceed 200°C.

Best materials I suggest:

Stainless steel and ceramic elements last longer at extreme heat. Polymer-based filters like polyester and polypropylene work well for moderate temperatures. They break down above their heat limits.

How Well It Filters and Particle Size

Why this matters: You need to remove hazardous particles or aerosols. This drives your material choice.

Top performers: PTFE membranes, activated carbon, sintered metal capture submicron particles and trap VOCs well.

Strength and Durability

Why this matters: High pressures, particle wear, and pulsing flows need strong filters.

Material examples I recommend: Metal mesh, woven steel, sintered metal, reinforced polymers handle tough mechanical demands. They also enable longer service periods.

Meeting Regulations

Why this matters: You must comply with industrial gas filtration codes. This is non-negotiable.

Certifications to look for: I suggest filters certified to API, ISO, NACE, and ATEX for hazardous or explosive environments.

Maintenance and Safety Needs

Why this matters: Safe, easy maintenance protects your operators and uptime.

My advice:

- Pick materials that are easy to clean or replace.

- Choose fire-resistant media and compatible gasket/seal options. I recommend Viton, PTFE, or BUNA to prevent leaks or emissions.

Installation Limits

Why this matters: Space, weight, and retrofit needs affect your filter form and media.

What I suggest:

- Use lighter or compact filters like pleated cartridges if space is tight.

- Large bag filters may work well for high-dust, bulk flow situations.

Performance Data and Real Examples

- Polypropylene cloth: Resists acids and solvents in chemical manufacturing and ceramics. It is conductive and wear-resistant.

- Polyester media: Handles up to 150°C. It is cost-effective for food/pharma/metals, very durable, and easy to clean.

- Activated carbon: Has a high surface area (~1000 m²/g). It is ideal for gas-phase VOC and sulfur removal.

- 316L stainless steel: Polished finish (0.13–0.63 µm Ra). Common in semiconductors and hazardous gas applications. Helium leak-tested to 10⁻⁷ atm·cm³/s.

- Sintered metal cartridges: Can be used above 300°C and 100 bar. You can clean and reuse them in harsh gas processes.

- PTFE pleated cartridges: Capture particles below 0.1 µm with >99.999% efficiency. They are essential for ultra-clean semiconductor and high-purity gas systems.

Quick Guide: Common Filter Materials and Uses

- Polypropylene: Acid/alkaline fumes and atmospheres

- Polyester: High temp, organic solvents

- Nylon: Oils, fuels, mild acids/bases

- Activated carbon: VOCs, odors, sulfurous gases

- 316L stainless steel: Corrosive, high-temp, high-pressure gas streams

- Ceramic: Very hot, harsh gases

- Cellulose: Low-toxicity particles, economic large-volume dust collection

I recommend you match filter materials to the chemical and heat demands, removal needs, and compliance standards of your application. This approach ensures safe, effective, and long-lasting toxic gas filtration solutions.

Best Materials for Toxic Gas Filtration

Choosing the right filtration material can make a huge difference in removal efficiency, safety, and operational costs. I’ve seen this impact firsthand in toxic industrial gas streams. Let me share some top materials and their specific advantages in modern industrial gas filtration.

Activated Carbon & Impregnated Carbon Variants

Activated carbon filters work great for broad-spectrum control. I recommend advanced types like ASZM-TEDA and metal salt impregnated carbon. They handle toxic gases, organic compounds, VOCs, and strong odors.

ASZM-TEDA carbon is the U.S. military-approved filter for comprehensive CBRN (Chemical, Biological, Radiological, Nuclear) protection. It adsorbs a huge range of toxic industrial chemicals. Its breakthrough resistance is high.

I suggest these carbons for both industrial safety systems and military-grade respiratory protection. They deliver breakthrough times far beyond standard carbon. U.S. Army tests have verified this performance.

Sintered Metal Filters (Stainless Steel)

Sintered stainless steel filters stand out for processing hot gases and corrosive chemical vapors. They last long and resist temperature well. They operate reliably above 400°C. This makes them ideal for power plants, flue gas cleaning, catalyst recovery, and natural gas purification. These filters remove particulates down to the submicron level. They are cost-effective too. You can regenerate them fully by cleaning or backwash. This reduces replacement frequency.

Synthetic Polymer Fiber Filters

Polypropylene and polyester fiber filters are my go-to solution for general toxic gas filtration. Their chemical resistance covers acids, bases, and hydrocarbons. This ensures safe use in chemical processing and low- to moderate-toxicity emission streams. These materials come as dense fiber pads or panels. They offer efficient particle removal. They provide a cost-effective solution for everyday industrial needs.

High-Surface Area Adsorbents: Silica Gel & Activated Alumina

Filters based on silica gel and activated alumina (aluminum oxide) feature huge surface areas. Silica gel has 750–800 m²/g. This gives them top performance for moisture removal and polar compound adsorption in compressed air and gas drying. Silica gel can be regenerated (even by microwave) for long service life. It works well with other filtration media.

Zeolite Molecular Sieve Gas Filters

Molecular sieves (zeolites) are engineered for tight, selective adsorption. I recommend them for natural gas, petrochemicals, and any stream where water, CO₂, and polar impurity levels must be controlled with precision. Zeolites can dry natural gas to less than 1 ppm water content.

Specialized Chemical and Advanced Adsorbents

Potassium permanganate filters excel at oxidizing and removing sulfur compounds (hydrogen sulfide, H₂S). They achieve >99% removal rates in wastewater treatment and odor control. These results are proven.

Metal–organic framework (MOF) filters are at the frontier of custom gas capture. These innovative materials offer tunable adsorption characteristics. They can target very specific toxic gases. Advanced trials show >90% efficiency in CO₂ and select VOC capture.

Typical Applications and Performance Data

- Activated carbon filters (ASZM-TEDA): I’ve seen these used in critical safety and military environments. They achieve superior breakthrough times for the full spectrum of toxic gases.

- Sintered stainless steel: Reliable in harsh flue and process gas scenarios. They withstand >400°C and high pressures without degradation.

- Polypropylene/polyester: Everyday chemical sites benefit from their resistance and low cost. Best for non-extreme environments.

- Silica gel: Ensures gas line dryness and prevents corrosion. Surface area: 750–800 m²/g.

- Zeolite: Ensures strict gas purity for demanding petrochemical and energy sectors.

- Potassium permanganate: Industry standard in H₂S abatement for municipal wastewater.

- MOFs: Advanced research supports >90% toxic gas capture efficiency in specialty industrial settings.

Material Selection Summary

Based on my experience, common filter material choices in industrial gas filtration include:

– Activated carbon (including impregnated/ASZM-TEDA types)

– Sintered stainless steel

– Polypropylene and polyester

– Silica gel and activated alumina

– Zeolite/molecular sieves

– Potassium permanganate

– Metal-organic frameworks (MOFs)

Each material offers distinct advantages. These include chemical compatibility, filtration efficiency, and suitability for critical environments. I believe material selection is vital. It ensures regulatory compliance, equipment protection, and worker safety in toxic gas scenarios. Choose wisely based on your specific needs.

Case Examples & Applications: Real-World Success in Toxic Industrial Gas Filtration

Chemical & Power Plants: Maximizing Uptime and Asset Protection

Cydsa (Mexico) Chemical Plant: This facility faced engine failures from corrosive gases. They installed FG PuraGrid activated carbon filters. The result? Uptime jumped from under 90% to 92-94%. The filters removed over 90% of airborne contaminants. They also used FG Drop Safe® moisture barrier prefilters. These handled gas-phase and particulate threats together. The plant added a Corrosion Monitoring Unit (CMU) for equipment monitoring. This created a complete, long-term filtration solution. I recommend this approach for similar chemical plants.

650 MW Power Station (USA): This plant used industrial baghouse systems to filter flue gases from coal combustion. The system removed hazardous particulates. It also met regulatory standards.

GPSC Thailand: The facility upgraded gas turbines with TurboPulse T12 cartridge filters. Annual savings hit $520,000. They saved 166,000 MMBtu in fuel. CO₂ emissions dropped by 8,800 tons per year. Compressor reliability tripled. Based on my experience, these numbers speak for themselves.

Oil & Gas: Extended Filter Life and Reduced Risks

Refinery Hydrocracker Unit: The refinery switched to FTC Invicta filtration. Filter changeouts dropped from every two weeks to much longer periods. This cut operational risk. It also lowered maintenance costs.

Permian Basin Gas Processors: These sites upgraded to FTC Invicta® elements. Filter runtime extended by up to five weeks. Replacement costs went down. Process stability improved. I suggest this upgrade for any gas processing facility.

Metal & Steel Industries: Boosting Filter Longevity and Output

Mexican Steel Producer: The plant used advanced blower filtration. Final filter life increased 16 times. Pre-filter life went up four times. The plant achieved 100% uptime.

Process Gas Reduction Iron Plant: The facility studied its contaminants in detail. Then they rebuilt their filter setup. This cut emergency shutdowns. It also reduced off-spec products from gas purity problems.

Data Centers, Healthcare, and Food Processing: Clean Air & Reliability

Data Center Applications: I like how Camfil’s Hi-Flo XLT bag filters and 30/30 panels created major energy savings. Advanced air-phase filtration boosted system integrity and uptime.

CCC Pesquería (Mexico): TurboPulse T10 filter upgrades added 20,000 MWh per year in output. That’s more than $600,000 in profits. Compressor outages decreased. The carbon footprint shrank too.

Hospitals and Schools: Camfil’s HEPA H14 filters captured biological and toxic particles. This protected sensitive indoor spaces.

Zeppelin Reimelt GmbH (Food Industry): Automated filter systems cleaned air in high-volume food processing. Airborne contamination dropped. Downtime decreased.

Industry-Wide Benefits: Performance Data and Key Takeaways

- 90%+ contaminant removal (acid/corrosive gas) using activated carbon grids (FG PuraGrid)

- Up to 16x filter life extension (steel plant, blower upgrades)

- 5x longer interval between filter changes (FTC Invicta tech)

- $600,000+ annual energy profit, 8,800 tons CO₂ cut per year (TurboPulse)

- Advanced monitoring (CMU) provides real-time threat assessment. It preserves assets.

Top Materials & Technologies in Action

- Activated carbon grids: For acidic and corrosive gas scrubbing

- Moisture barrier prefilters: Defense against mixed contaminants

- High-efficiency pleated bag/cartridge filters: For fine industrial particles and VOCs

- HEPA H14: Top-level protection against biological and toxic particles

- Real-time monitoring systems: For proactive maintenance and risk reduction

Typical Domains of Application

- Chemical/power plants (gas turbines, coal boilers)

- Refineries/oil & gas

- Steel and metal industries

- Food manufacturing

- Data centers and electronics hubs

- Healthcare and educational environments

- Community and industrial air quality control

Summary: Choosing the Best Filter Materials for Toxic Industrial Gas Filtration

I’ve worked on many industrial filtration projects. I’ve learned one key truth: the right filter material does more than meet standards. It protects lives and saves you money.

You might deal with corrosive fumes. You might handle tiny particles. Either way, I recommend investing in quality filtration. It pays back fast. You get safer operations. Your equipment lasts longer. You save real money.

Choose the right filters. Monitor your system often. It will protect you for years.