Introduction to Increasing Porosity in Ceramics

I recommend increasing porosity in ceramics for filtration, catalysis, insulation, and lightweight structures. High and controlled porosity requires the right additives, processing methods, and forming techniques. These adjust pore size, shape, and interconnection.

Common Methods and Additives for Porosity Control

Pore-forming agents: I suggest mixing additives like starch, polymers (polyethylene glycol, polystyrene spheres, PMMA microspheres), and cellulose derivatives (methylcellulose, carboxymethylcellulose) into the ceramic. These agents burn out at 200°C–500°C. They create pore sizes from a few micrometers (synthetic polymers) up to 50 μm (large starch granules).

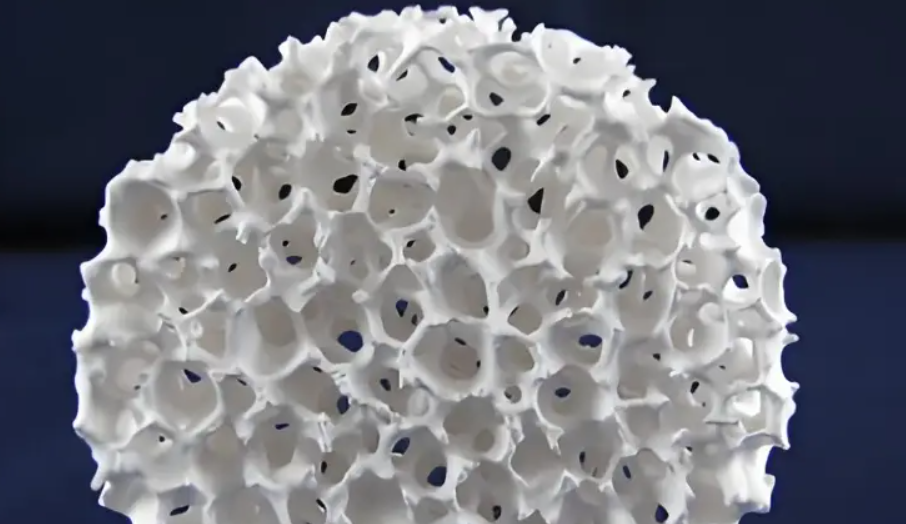

Foam impregnation: Ceramic slurries are soaked in organic foams, then sintered. This can yield very high porosity. One study achieved 93% porosity in alumina by firing at 1200°C for 2 hours. This produced interconnected, three-dimensional pore networks.

Inorganic pore-formers: Materials like calcium carbonate (decomposition at around 900°C), metal carbides, and salt compounds (e.g., ammonium chloride decomposing at 350°C) release gases or sublime. They leave spherical or fine uniform pores without residues.

Key Processing Techniques

Direct mixing and burnout: The additive is blended with ceramic powder. It burns out in an oxidizing atmosphere. This ensures even pore formation.

In-situ reaction during sintering: Additives like carbonates decompose during heat treatment. They produce pores from released gases.

Compaction and extrusion: Workers compact or extrude powders mixed with additives. After burnout and sintering, pore orientation and distribution reflect the forming technique. Extrusion often produces cylindrical, oriented pores.

Foam-gelcasting: Adding foaming agents to gel-forming polymers helps tailor porosity gradients in ceramics. This happens after gelation and burnout.

Freeze-drying: Freeze a ceramic-water slurry. Then sublime the ice crystals. This forms directional pores with specific orientation. Freezing parameters control pore size, orientation, and connectivity.

Notable Examples and Data

Porous alumina with 93% porosity: Czelusniak and Amorim reported this. They achieved it through organic foam sintering at 1200°C.

Optimized pore structures for catalysts: Zhou et al. used MgO and CeO₂ with ZrO₂. This enhanced sintering. It created stable, efficient pore networks.

Starch and polymer-based approaches: Starch creates large and uniform macropores. Polymer microspheres are chosen for finer, well-controlled pores. Based on my experience, the choice depends on your target pore size.

The additives you choose determine the final ceramic’s microstructure and properties. The processing route matters too. So do the specific firing conditions you select during manufacturing. I believe careful selection of these factors is critical for success.

Common Additives for Porosity Control in Ceramics

Choosing the right additives helps you control ceramic porosity. This matters for filtration, insulation, and lightweight structures. I recommend these additives because they affect pore size, distribution, water absorption, and strength.

Organic Pore-Formers

Polymer-Based Additives

Common options include polyethylene glycol (PEG), polymethyl methacrylate (PMMA), and polystyrene spheres. They burn out at 200°C–500°C. This creates uniform pores. I suggest PMMA microspheres for precise, controlled structures. They work well in aerospace and bioengineering. Stable pore design matters in these fields.

Starch-Based Pore Formers

Starches like potato, corn, or wheat break down between 250°C and 400°C. Pore size depends on starch grain size. You can achieve porosity above 60% with proper formulation. Water absorption rates reach close to 40%. I recommend starch for industrial ceramics that need thermal insulation.

Cellulose Derivatives

Methylcellulose and carboxymethylcellulose break down at 300°C–450°C. They create elongated, connected pores. These work well for thermal shock resistance. They also help control permeability.

Inorganic Pore-Formers

Carbonate Compounds

Calcium carbonate (CaCO₃) breaks down near 900°C. It releases CO₂ and forms round pores. Magnesium and sodium carbonates offer different firing profiles. I like these for specialized ceramics where gas release timing matters.

Metal Carbides

Silicon carbide (SiC) and titanium carbide create porosity through oxidation at high heat. SiC burns out at around 1200°C. This method works for refractory ceramics. These ceramics need stability at high temperatures.

Salt Compounds

Ammonium chloride sublimes and breaks down at 350°C. It creates uniform, fine porosity without residues. Sodium chloride is another option for fine-porous ceramics.

Additional Fugitive Agents

Carbon Black

This boosts both permeability and thermal insulation. Higher loading increases porosity. It also reduces density and raises water absorption.

Paraffin Wax and Expandable Polystyrene Beads

These melt or break down. They produce large, connected pores. The result is lightweight ceramics with superior insulation. I’ve seen these used in architectural and industrial applications.

MASHS Materials

More MASHS content means thinner ceramic plates. You get smaller particle junctions (sintering necks) and better pore connectivity. Porosity can reach 63%. Water absorption can be close to 40%. This exceeds standard ceramic tile properties by far.

Polyurethane Foams and Dolomite

These work in processes that need controllable pore size and alignment. They benefit from both thermal and mechanical ceramic properties.

Thickening and Suspension Control Additives

Binders and Modifiers

Specialized binders help with additive dispersion. Rheology modifiers (like acrylic acid polymers, cellulose, and gums) and antifoam agents adjust drying rates. This fine-tunes pore distribution.

Key Examples

Methylcellulose, guar gum, xanthan gum, sodium carbonate, sodium silicate, alginates, and surfactants (TENSIOJET L, TENSIOL K10) keep the slurry uniform. They maintain consistent pore structure.

Performance Data and Industry Usage

-

Typical apparent porosity: 40–65%.

-

Water absorption: up to 40%.

-

Sintering neck size: Gets smaller with more additives. This improves connectivity and permeability.

-

Additive burnout temperatures:

-

Starch: 250–400°C

-

PMMA/polymers: 200–500°C

-

Ammonium chloride: 350°C

-

CaCO₃: 900°C

-

Silicon carbide: ~1200°C

-

Industrial and Application Examples

-

Aerospace: I recommend PMMA or starch for controlled insulation layers.

-

Industrial ceramics: Carbonates and fugitive agents balance insulation and strength. You’ll find these in heat exchangers and furnace linings.

-

Bioengineering: PLA, PMMA, and starch-based additives support open, permeable structures. These work well for scaffolds.

Based on my experience, careful selection and combination of these additives enable you to create custom ceramic porosity. Match them with your processing requirements. This meets diverse technical needs.

How to Process Porosity Additives in Ceramic Manufacturing

Controlling ceramic porosity is about choosing the right additives. You also need to match them with the right processing methods. Here are the key processing techniques I recommend. I’ll share industry examples and results that help you optimize porosity in ceramics.

Organic Foam Impregnation Method

The organic foam impregnation method is one of the most common industrial techniques. Zhang et al. introduced it in 1963. Based on my experience, this technique works well. Here’s how it works:

-

Immerse an organic foam with a 3D network structure in ceramic slurry.

-

Remove excess slurry from the foam surface.

-

Dry and sinter the soaked foam.

This method creates interconnected porous ceramic. It produces uniform pore networks. I suggest this for advanced filtration and insulation applications.

Hydrothermal Powder Treatment

Pre-treating ceramic powders by hydrothermal treatment can change both reactivity and final porosity. Here’s what happens:

-

Treat α-Al₂O₃ powder in phosphoric acid. This produces surface phosphate phases (Al(PO₃)₃, AlPO₄).

-

Phosphate condensation happens faster at lower temperatures. Treated powder needs 150°C. Untreated powder needs 165°C.

-

3D-printed parts show decreased overall porosity. But they show improved microstructure uniformity compared to non-treated alumina.

Freeze Casting Techniques

Freeze casting creates directional pores. It uses different freezing vehicles:

-

Common vehicles include water, camphene (terpenes), and tertiary butyl alcohol (TBA).

-

The liquid solidifies. Ceramic particles are pushed aside. This forms aligned porous pathways.

-

You can adjust the vehicle type and freezing parameters. This shapes the final pore structure (size, shape, and connectivity).

Template-Based and Additive Methods

I like using template-based methods. They give you good control:

-

Add polymeric spheres and beads (like PMMA or polystyrene) to the slurry. They act as pore generators.

-

These create pores with tight size distribution and specific geometry. The organic spheres burn away during sintering through pyrolysis.

-

Sublimable terpenes in custom slurries develop small dendritic pores. They vaporize during heating.

Foaming-Injection Molding with Reaction Sintering

This combined approach gives impressive results:

-

Mix 6 wt% AlF₃·3H₂O mullite with 6 wt% ZrO₂ . The ceramic reaches 68.6% porosity. It has flexural strength of 11.3 MPa. It has compressive strength of 29.4 MPa.

-

Add 8 wt% Y₂O₃ to adjust properties further. This yields porosity of 66.4% and an average pore diameter of 168 μm. Flexural strength increases by 20.5%. Compressive strength increases by 19%.

These results prove you can control pore structure, size, and mechanical properties. You just need to match additives with the right processing techniques. This improves performance in filtration ceramics, catalyst supports, and lightweight insulation materials. I recommend testing these methods based on your specific application needs.

Structural Templating Methods for Porous Ceramics

I’ve found that structural templating techniques in ceramic manufacturing give you precise control over pore shape and alignment. This optimizes materials for filtration, catalysis, and lightweight uses. These methods copy the structure of a sacrificial or self-assembled template. The result? Ceramics with unique, layered pore structures.

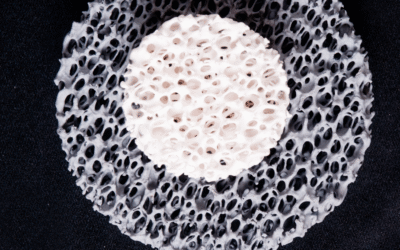

Wood Templating for Layered Porous Ceramics

Natural wood acts as a scaffold. First, the wood soaks in ceramic precursors at 20–80°C. Then it undergoes pyrolysis and high-temperature oxidation. The final ceramics (like Al₂O₃, Fe₂O₃, TiO₂, ZrO₂ ) copy the wood’s layered, one-direction pore structure.

You get ceramics with two or more pore sizes. Larger pores come from wood vessels. Smaller pores form from oxide clusters. Aligned pores create mechanical anisotropy and outstanding capillarity. Water can rise over 1 meter. They also boost permeability.

Example: I recommend wood-derived alumina for specialty filters and catalyst supports. Its open, aligned pore network makes it ideal.

Freeze Casting (Ice Templating) for Aligned Porosity

-

Freeze casting uses directional freezing of a ceramic slurry. Ice crystals form and grow. They push ceramic particles aside and create aligned channels.

-

The frozen liquid evaporates. This leaves a porous structure. High-temperature sintering finishes the process.

-

You can reach porosity up to 67% (like in yttria-stabilized zirconia, YSZ). You get straight, aligned micron-scale channels.

-

Adjust the freezing rate, thermal gradients, and slurry thickness to control pore size and direction.

You can add function to pore surfaces. For instance, apply a 100 nm conformal Al₂O₃ coating through atomic layer deposition. This reduces the entrance diameter but keeps the open network intact. Mercury intrusion and SEM confirm this.

Based on my experience, these ceramics keep excellent mechanical strength even after sintering above 1,150°C.

Colloidal and Self-Assembled Templating

I use assemblies of block copolymers, surfactants, or colloidal rods as structure-directing agents. They form nanoscale templates. After condensation and removal of the organic template, you get a well-ordered, periodic porous structure. Pore diameters range from tens to hundreds of angstroms. You achieve uniform, cellular solid shapes at the nanoscale. You can create both horizontal and vertically aligned 3D templates. This offers directional, interconnected pore networks.

Example: I suggest these templated ceramics for microreactors and bone scaffolds. Their tuned nanoscale porosity and connectivity make them perfect.

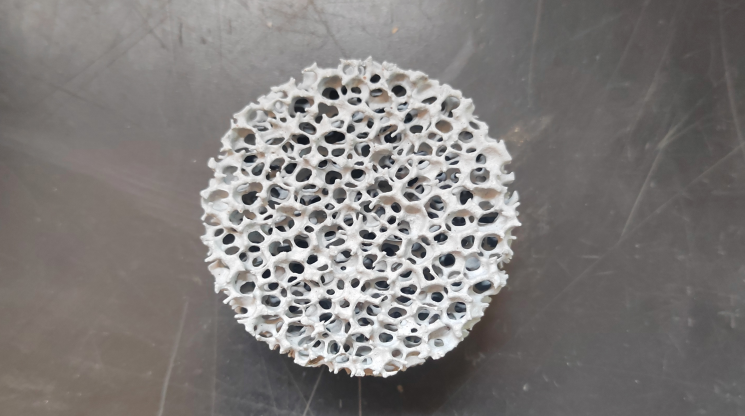

Replica Templating with Sacrificial Scaffolds

This method uses open-cell polymer foams, textile meshes, or biological frameworks. You soak them with ceramic slurry. After soaking, burn out or dissolve the scaffold. A negative ceramic replica remains. This process creates ceramics with large, open, and well-connected porosity. They follow the shape of the sacrificial template.

Example: I like porous alumina made this way. It shows custom porosity and strong interconnectivity. Both ceramic filters and catalyst carriers benefit.

Summary of Achievable Pore Characteristics

-

Wood templating: Millimeter to micrometer pores, one-direction alignment, multiple pore sizes.

-

Ice templating: Micrometer-scale straight, aligned pores. The freezing front sets the direction.

-

Colloidal templating: Nanoscale, well-ordered pores with controlled diameter and network orientation.

-

Replica methods: Open foam-like, interconnected pores. Scaffold geometry determines porosity.

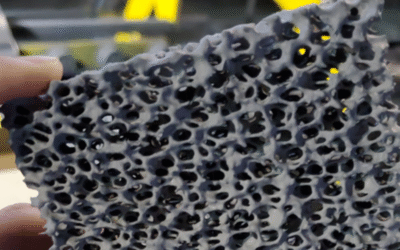

Direct Foaming and Gas-Incorporation Methods for Ceramic Porosity

I recommend direct foaming and gas-incorporation methods for making ceramics more porous. These approaches introduce gas bubbles into the ceramic slurry. You can precisely tune pore size, porosity percentage, and connectivity.

Core Methods and Mechanisms

Gas Introduction Techniques: Mechanical agitation (whipping or stirring) injects air into the mixture. In situ chemical reactions create gases like CO₂ during processing. Emulsion foaming forms liquid emulsions (such as water-in-oil). When you remove or evaporate the dispersed droplets, pores remain.

Foaming and Stabilization: Surfactants (proteins, synthetic surfactants—anionic, cationic, or nonionic) keep bubbles stable in the slurry. They resist collapse. Gelling agents or rapid polymerization (such as sodium alginate or specific organic monomers) harden the structure around the gas bubbles.

Technical Highlights and Quantitative Results

Porosity: You can achieve up to 97.5% after sintering .

Pore Size: Control ranges from 0.5 mm to 3 mm . This depends on foaming conditions and stabilization additives.

Microstructure: The structure is interconnected, open-celled, and uniform. It offers excellent reproducibility.

Process Flexibility: You can tune final properties through the type and concentration of foaming agents. Also adjust agitation speed, gas formation rate, gelation and drying kinetics, and sintering schedule.

Examples and Industrial Applications

Based on my experience, here are key applications:

-

Metallurgical Filters: Foamed ceramics with high open-cell porosity work best for removing impurities from molten metals.

-

Thermal Insulation: I suggest lightweight ceramic foams for efficient insulation in construction.

-

Biomedical Scaffolds: Interconnected macropores support tissue engineering and implant needs.

-

Chemical Processing: Macroporous ceramics work as catalyst carriers and membrane supports. They benefit from precise pore network control.

Key Advantages

I like these methods for several reasons:

-

Simple and scalable for industrial-scale production.

-

Accurate pore control for both micro- and macro-porosity.

-

Lightweight and custom-built ceramics ideal for filtration, insulation, and specialty engineering uses.

Process Considerations and Challenges

Foam stability is critical. It depends on choosing the right surfactant or additive. Advanced stabilization (e.g., gel-casting or rapid polymerization) may increase complexity and cost. This is true for tight pore size distributions or hybrid structures.

You need careful adjustment of process parameters (e.g., drying, sintering temperature). This maintains open, interconnected pores with mechanical strength.

Hybrid and Combination Techniques

I suggest mixing mechanical foaming with chemical gas evolution . This expands tunability further. For example, using decomposing agents that release gas during gelation can boost porosity. It also helps tailor pore architecture to your needs.

In my opinion, direct foaming and gas-incorporation create new possibilities for ultra-porous, strong ceramics. You get customizable structures and high-performance properties. These methods offer flexibility and precision that traditional approaches lack.

Factors Affecting Porosity in Ceramics

I believe understanding what influences ceramic porosity is key for designing materials with specific performance features. Here are the core aspects that impact porosity and how they relate to making ceramics more porous:

Key Factors Influencing Ceramic Porosity

Starting Material Particle Size: Finer particles increase the overall surface area. Smaller particle sizes can trap more air during shaping and sintering. This leads to higher porosity. But this may also decrease heat flow. Why? Enhanced phonon scattering occurs. This can be good for insulation uses.

Sintering Process Parameters: Lower sintering temperatures limit how dense the ceramic becomes. Shorter firing times do the same. This results in more pores. You get greater overall porosity. On the flip side, longer high-temperature sintering closes up the pores. Grain coalescence happens. Porosity drops and mechanical strength rises. I suggest fine-tuning sintering schedules. This allows you to hit the porosity target for your needs.

Additives and Impurities: You can add pore-forming agents. Examples include starch, polymers, or cellulose derivatives. These increase porosity on purpose. Some impurities may disrupt particle packing even if unintended. They can cause local gas evolution. This also leads to more pores. Additives increase porosity. But they can also create a more insulating ceramic. They may lower its overall strength.

Grain Size and Microstructure: Larger grains reduce the total number of grain boundaries in a ceramic. This results in fewer sites for porosity. You get lower pore content. Smaller grains that are well-controlled create more sites for pore growth. This provides a more connected pore network.

Environmental Factors During Formation: Air pressure during forming and sintering impacts pore development. Lower pressures (vacuum) can increase porosity. Humidity also plays a role. It affects how ceramic slurries set and dry. This changes the size and shape of the pores.

Notable Examples and Technical Data

-

Porous Alumina: I often see this used for filtration. It achieves controlled porosity. This gives you targeted capture efficiency.

-

Porous Silicon Carbide (SiC): This is ideal for high-temperature filtering uses. It works well for advanced ceramic functions. It maintains pore structure under extreme heat.

Methods to Optimize and Increase Porosity

Use of Pore-Forming Agents: Add materials like starch, PMMA, or cellulose derivatives. These will decompose and burn out. They leave behind a custom porous structure.

Controlled Sintering Conditions: Set lower sintering temperatures. Shorten dwell times. This ensures the pores remain open and connected.

Variation in Particle Size: Mix ceramics with a blend of large and small particles. This creates micro-gaps. You get higher porosity.

These factors work together. Particle size, additives, sintering, grain structure, and environmental controls shape the pore volume. They affect size distribution and the mechanical-thermal profile of ceramic materials. Based on my experience, I recommend adjusting each variable with care. This gives you full control over ceramic porosity. You can suit a broad range of technical uses.

Typical Numeric Data & Key Results

Porosity and pore size are basic metrics for ceramic uses like filters and insulators. Here are key data points on how to increase ceramic porosity. I recommend these methods based on common industry practices:

Porosity Ranges in Functional Ceramics

-

Filter Ceramics: Open porosity is 30%–50% for filtration. This ensures good fluid flow while trapping dirt.

-

Refractory Ceramics: Porosity is controlled within 10%–20% for best thermal insulation in high-heat areas.

-

General Ceramics: Porosity levels range from a few percent to over 30%. It depends on what you need.

Pore Size Distribution

Effective Methods for Increasing Porosity

Pore-Forming Additives: Add starch or organic powders to the ceramic mix. They burn out during firing. This creates well-spread pores.

Controlled Sintering: Lower sintering temperatures or reduce time. This keeps pore structures intact and boosts final porosity.

Phase Segregation in Composites: Creates porosity when phases separate or have different sintering densities.

Application Examples and Results

Ceramic Filters: Wastewater treatment ceramics, Porosity of 30%–50%. This supports strong filtration and effectively traps particles.

Thermal Refractories: Insulation ceramics, 10%–20% porosity. This gives thermal efficiency and long life.

Summary

Through my years working with ceramic materials, I’ve learned that mastering porosity control isn’t just about following recipes—it’s about understanding how each variable connects. Every project teaches me something new about balancing strength, function, and cost. I encourage you to experiment thoughtfully with these methods, measure carefully, and trust the data. Your perfect porous ceramic is waiting to be discovered through patient optimization and creative problem-solving.