Ceramic Foam Filter CFF Series SiC/Alumina/Zirconia/Magnesia

Industrial Ceramic Foam Filter – Precision Molten Metal Filtration for Superior Casting Quality

Custom sizes

Any dimension from 40mm to 500mm; thickness 11-50mm

Special shapes

Round, oval, hexagonal, or irregular shapes for unique filter box designs

Filter Pore Sizes

10PPI, 15PPI, 20PPI, 25PPI, 30PPI, 40PPI, 50PPI, 60PPI Foam Filters

Contact our technical team today for a free application analysis and customized filter recommendation for your specific casting process. We’ll help you select the optimal foam filter specification, provide competitive factory-direct pricing, and outline expected quality improvements and ROI.

Industrial Ceramic Foam Filter Molten Metal Filtration

Modern metal casting operations face critical quality challenges from oxide films, slag particles, and non-metallic inclusions that compromise mechanical properties and surface finish. Traditional filtration methods often fail under extreme temperatures or provide inconsistent performance across production runs.

Our Ceramic Foam Filter technology delivers a breakthrough solution through precisely engineered three-dimensional porous ceramic structures.

Manufactured using advanced ceramic processing and controlled sintering, each filter features interconnected open cells that create tortuous flow paths, mechanically trapping impurities while maintaining optimal metal flow rates. The ceramic matrix—available in silicon carbide (SiC), alumina (Al₂O₃), zirconia (ZrO₂), or magnesia (MgO)—withstands extreme foundry temperatures while maintaining structural integrity throughout the casting process.

Foundries using our ceramic foam filtration systems experience significant results: lower scrap costs, enhanced product consistency, and improved competitiveness in demanding applications from automotive components to aerospace castings.

Different Types of Ceramic Foam Filters

Advanced porous ceramic filtration technology designed for foundries and casthouses worldwide. Our ceramic foam filters effectively remove metal oxides, non-metallic inclusions, and impurities from molten aluminum, copper, iron, and steel. Engineered with controlled pore structures (10-60PPI) and exceptional thermal stability up to 1700°C, delivering consistent filtration performance that reduces scrap rates and enhances mechanical properties of final castings.

FM-01 Silicon Carbide (SiC) Ceramic Foam Filter

Feature: High-temperature SiC ceramic matrix with superior thermal shock resistance

Pore sizes: 10PPI, 15PPI, 20PPI, 25PPI, 30PPI

Advantage: Withstands rapid temperature fluctuations and maintains structural stability at 1500°C

Applications: Ductile iron, gray iron, copper alloy

Benefit: Ideal for iron casting operations where extreme temperatures and thermal cycling are common; reduces filter breakage and ensures consistent filtration

FM-03 Zirconia (ZrO₂) Ceramic Foam Filter

Feature: Ultra-high temperature zirconia ceramic with enhanced mechanical strength

Temperature range: Up to 1700°C, Highest temperature capability

Applications: Superalloys, specialty steels, precision investment casting

Advantage: Operates reliably at temperatures up to 1700°C with minimal thermal expansion

Benefit: Specialized solution for high-temperature steel casting and precision applications requiring maximum thermal performance and dimensional stability

FM-04 Alumina (Al₂O₃) Ceramic Foam Filter

Feature: High-purity alumina composition with excellent chemical inertness

Temperature range: Up to 1200°C

Advantage: Does not react with molten aluminum

Applications: Aluminum alloys, aluminum casthouse operations

Benefit: Industry-standard choice for aluminum casthouses and foundries; prevents contamination and delivers superior surface finish on aluminum castings

FM-08 Magnesia (MgO) Ceramic Foam Filter

Feature: Magnesia-based for magnesium alloy casting

Temperature range: Up to 1200°C

Pore sizes: 10PPI, 20PPI, 30PPI

Benefit: Prevents metal contamination in magnesium alloy foundry operations; improves casting quality for magnesium alloy casting applications

What Molten Metal is Filtered?

Through continuous innovation in material technology, our filtration solutions have expanded from the foundry industry to the environmental protection field, and are committed to providing more efficient and sustainable product support for industrial manufacturing and green life.

Iron Filtration

Gray iron, ductile iron, malleable iron, and other cast iron; optimal with SiC filters

Steel Casting

Carbon steel, alloy steel, stainless grades; optimal with SiC or zirconia filters

Aluminum Filtration

Aluminum & Aluminum Alloys: All grades; optimal with alumina or SiC filters

Copper Filtration

Pure copper, brass, bronze; optimal with zirconia or silicon carbide filters

What Casting Process Can be Used

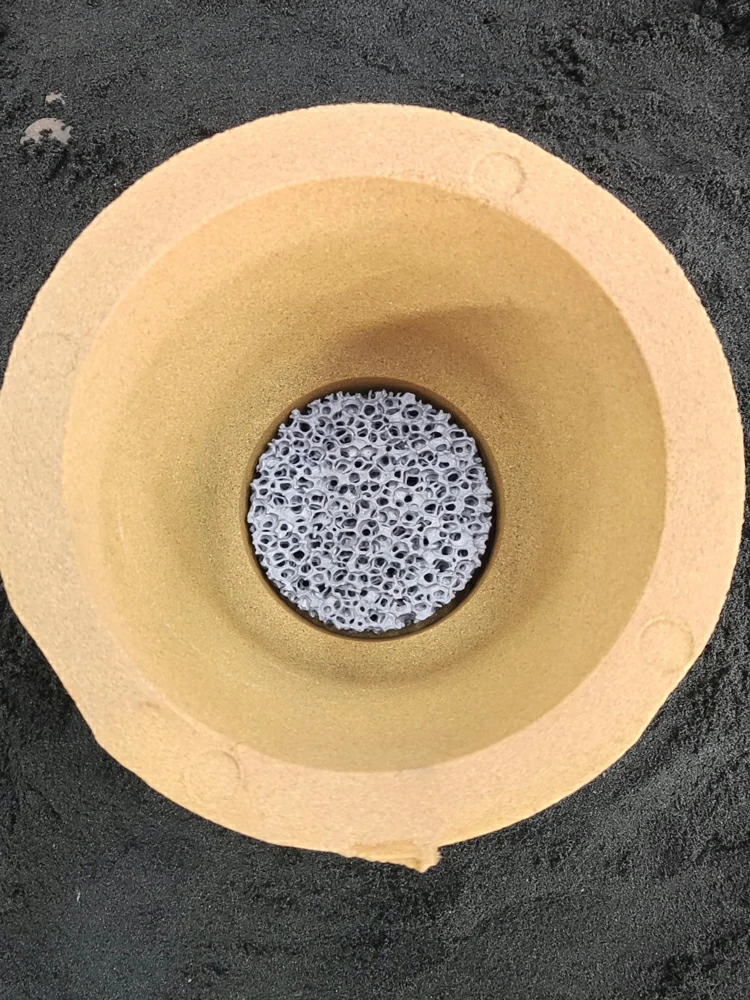

Sand Casting: Filters positioned in pouring basin, runner system, or in-gate depending on mold complexity and metal flow pattern. Typical placement: immediately before mold cavity entry to capture final impurities

Permanent Mold Casting: Filter integration into pouring basin or sprue; reusable filter boxes recommended for high-volume production

Investment Casting: Filters incorporated into ceramic shell pouring cup or integrated into gating system; ultra-high purity materials required for aerospace applications

Why Choose FoundryMax Ceramic Foam Filters

As a direct manufacturer with ISO 9001 certification and 20+ years of ceramic engineering expertise, we deliver premium ceramic foam filters that combine superior filtration efficiency, exceptional thermal performance (up to 1700°C), and cost-effective factory pricing. Our comprehensive material portfolio (SiC, alumina, zirconia, magnesia), precision pore engineering (10-60PPI), and full OEM/ODM customization capabilities enable foundries and casthouses worldwide to achieve 35-60% scrap reduction, enhanced mechanical properties, and improved competitive positioning—backed by expert technical support and rapid delivery.

Three-Dimensional Interconnected Pore Architecture

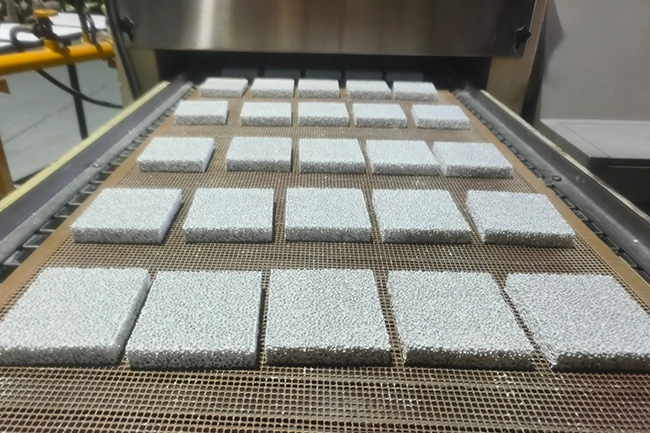

Our ceramic foam filters are manufactured using a proprietary polymer foam replication process combined with advanced ceramic processing technology, creating a unique three-dimensional interconnected pore structure that sets our product apart from conventional filtration media.

Foam Filter Manufacturing Process Innovation

The production begins with precision-engineered polyurethane foam templates with controlled cell size and porosity. These templates are impregnated with specially formulated ceramic slurries containing high-purity silicon carbide, alumina, zirconia, or magnesia powders, along with carefully selected binders and rheology modifiers. Through controlled dipping and squeezing cycles, we achieve uniform ceramic coating on all foam struts while maintaining open cell structure.

Porous Ceramic Structural Advantages

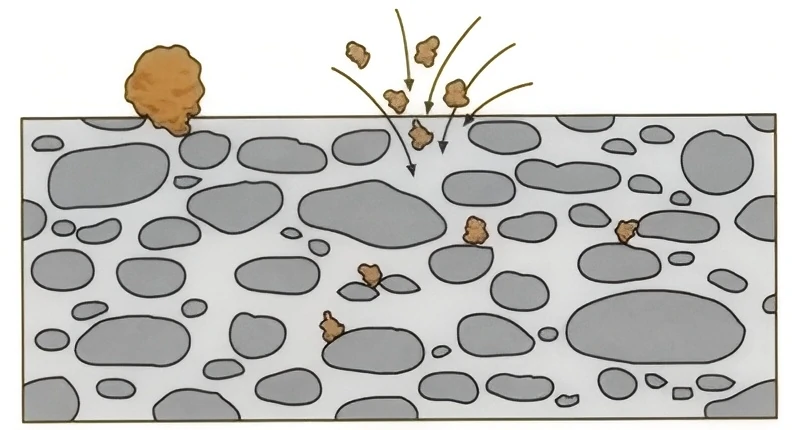

The resulting structure features 80-90% open porosity with interconnected cells ranging from 10PPI (2.5mm cells) to 60PPI (0.4mm cells). Unlike traditional ceramic filters with straight-through pores, our three-dimensional tortuous pathway forces molten metal to navigate through multiple direction changes. This creates:

- Mechanical Entrapment: Larger particles (>100μm) are physically blocked at pore entrances

- Cake Filtration: Medium particles (30-100μm) accumulate on filter surfaces, creating a secondary filtration layer

- Depth Filtration: Small particles (10-30μm) are captured within the filter matrix through adhesion and interception

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China