Introduction to Industrial Ceramic Coating

Industrial ceramic coating applies advanced ceramic materials onto surfaces. These materials include chrome oxide, zirconium oxide, and alumina. You can apply them to metals, plastics, and glass. The coating creates a strong protective layer. This layer improves surface properties across many industries.

Key Properties and Benefits

Corrosion Resistance: Ceramic coatings form a barrier. This barrier protects against chemicals, salt environments, and abrasion. I’ve seen these coatings used in oil and gas, power generation, and chemical processing. They extend equipment lifespan by years.

Thermal Insulation: Ceramic coatings withstand temperatures above 1000°C. This makes them essential for engine parts. Industries like aerospace, metallurgy, and nuclear power rely on them to protect critical components.

Electrical Insulation: These coatings provide strong dielectric protection. They protect electronic devices, insulators, and critical electrical components.

Wear Resistance and Hardness Improvement: Coated surfaces gain much more hardness. Hardness rises from around 70 HV to as high as 1200 HV. This means wear lifespans increase up to five times longer. I recommend these coatings for steel production rolls.

Application Examples

I suggest ceramic coatings for their strong combination of heat resistance, surface hardness, and chemical inertness:

-

Aerospace: Manufacturers apply coatings to turbine blades and exhaust nozzles. This resists high temperatures and reduces heat transfer.

-

Oil & Gas: The coating protects pipes and valves from corrosion and pressure. This prevents maintenance outages.

-

Power Generation: Coatings shield turbines and reactor vessels. They protect from chemicals and extreme thermal cycles.

-

Food & Pharma: These coatings provide seal surfaces. They help reduce contamination and leaks during manufacturing.

-

Biomedical: Manufacturers use them in medical tubes, implants, and cochlear devices. They offer biocompatibility and inertness.

-

Military: The coating enhances shock resistance. It improves the durability of armor plating and bullet-proof jackets.

Industry Data and Impact

Increased Surface Hardness: Depending on the coating, hardness levels surge from 70 HV to 1200 HV or more.

Thermal Shock Protection: Ceramic multilayer systems work well in aerospace and missile components. A metallic base coat with a zirconium oxide top layer helps these components cope with sudden temperature changes.

Cost Savings: Based on my experience, ceramic coatings reduce equipment maintenance expenses by up to 40%. They extend usable life.

Lower Corrosion Rates: In chemical tank applications, these coatings cut the corrosion rate by a factor of 10. This compares to uncoated surfaces.

Major Industries Using Ceramic Coatings

- Aerospace

- Steel Production

- Power Generation: (Hydroelectric, coal, nuclear)

- Food & Pharmaceutical Manufacturing

- Oil and Gas: (Pipelines, valves)

- Military

- Biomedical

- Automotive: (Engine components, body panels)

I believe ceramic coatings are the preferred option. They offer a strong blend of thermal endurance, corrosion resistance, wear reduction, chemical inertness, and electrical insulation. These qualities meet the critical needs of today’s industrial world.

Purpose and Function of Industrial Ceramic Coating

I recommend industrial ceramic coatings for modern manufacturing. They do several important jobs. These include surface protection, heat control, electrical safety, and reducing friction.

Corrosion and Chemical Resistance

CermaKrome™ and ARC 855 offer strong protection against rust and chemicals. I suggest ARC 855 for old and new equipment that faces harsh chemicals and wear.

Here’s a clear example. We put an Al₂O₃ (alumina) ceramic layer on cast iron (EN-GJL-250). The corrosion rate dropped from 3.59 mm/year (no coating) to just 0.11 mm/year (double layer). With four layers, it went down to 0.09 mm/year. That’s a 30–40× boost in protection.

Corrosion current density also fell. It went from 138.3 µA/cm² (bare metal) to 30.01 µA/cm² (double layer) and 26.15 µA/cm² (four layers). This is a 4–5× drop.

CermaKrome™ resists salt spray for over 6,500 hours (ASTM B117). Based on my experience, this beats most single-layer coatings on the market.

Thermal Insulation and Heat Management

I like CermaKrome™, Ciloxide™, and CBX™ for extreme heat. They handle very high temperatures well.

CermaKrome™ works at temperatures up to 1,600°F (871°C). Ciloxide™ can handle even more—up to 2,000°F (1,093°C). This heat barrier keeps surfaces cool. It lowers burn risk and protects nearby parts.

I recommend CBX™ for engine parts. It stops heat transfer and makes components last longer.

Electrical Insulation and Conductivity

Most ceramic coatings block electricity. They insulate sensitive parts and keep them safe. This matters in systems where electrical isolation is key.

But here’s what I find interesting. CermaKrome™ and CBX™ keep surface conductivity. This helps with grounding or static control. Yet they still reduce electrical flow through the coating itself.

Friction Reduction and Wear Protection

Ceramic coatings have low friction. This cuts down wear on moving parts and improves performance.

I suggest Ciloxide™ for parts that move, flex, or touch repeatedly. It has great lubricating and release qualities. Think exhaust systems or brake surfaces.

Summary Table: Performance Data

| Sample | Corrosion Rate (mm/year) | Corrosion Current Density (µA/cm²) |

|---|---|---|

| Uncoated cast iron | 3.59 | 138.3 |

| 2 ceramic layers (30 µm) | 0.11 | 30.01 |

| 4 ceramic layers (60 µm) | 0.09 | 26.15 |

| CermaKrome™ salt spray resistance | >6,500 hours | – |

| Ciloxide™ substrate/environmental temp | Up to 2,000°F (1,093°C) | – |

| CermaKrome™ environmental temp | Up to 1,600°F (871°C) | – |

Application Examples by Function

Exhaust systems (automotive, industrial): I recommend CermaKrome™ and Ciloxide™. They protect against rust, resist heat, and reduce friction.

Engine components: Use CBX™. It cuts heat transfer and guards against heat and corrosion.

Industrial equipment: Try ARC 855 for chemical resistance and wear protection.

Brake components: Alumina plasma-sprayed coatings lower wear and stop corrosion on cast iron brakes.

Key Advantages Recap

- Blocks chemicals and rust. This extends part life by 30–40× for metals like cast iron.

- Handles temperatures up to 2,000°F (1,093°C). It gives strong heat protection.

- Insulates against electricity. Special coatings also allow controlled conductivity where you need it.

- Lowers friction. This means less wear and easier maintenance for moving parts.

- Works on metals, plastics, and composites. You can brush, roll, or spray it on.

Key Applications of Industrial Ceramic Coating

Industrial ceramic coatings play many critical roles across major sectors. I’ve seen how their unique properties make them essential for performance, protection, and meeting regulations.

Automotive Industry: Corrosion Protection & Advanced Finishes

- The automotive sector drives 32% of global ceramic coating demand.

- Key features: Scratch resistance, water repellency, UV protection.

- Used on both new vehicles and in aftermarket upgrades.

- In 2023, there were over 85 million motor vehicles produced around the world.

- Example: The Tesla Model S Plaid uses ceramic-coated brake rotors. These handle high temperatures and deliver top performance.

- Vehicle corrosion is a massive problem. It costs about USD 2.2 trillion each year* across the globe.

- I recommend ceramic coatings for electric vehicle batteries. They extend component life and boost performance.

Non-Stick Cookware: Healthier & More Durable Surfaces

Ceramic coatings have replaced Teflon in many leading cookware brands. I like them for heat stability, scratch resistance, and chemical safety. They eliminate concerns about harmful PFOA and PTFE compounds. Based on my experience, they provide smoother, tougher cooking surfaces. These maintain their performance over time.

Industrial Equipment & Pipe Protection

Ceramic coatings seal surfaces. They reduce leaks on heavy machinery and pipelines. I suggest them for equipment exposed to chemicals, wear, and high heat.

In North America, pipeline corrosion costs are about $9 billion each year. Most comes from carbon steel, which makes up about 85% of all steel produced. Ceramic coatings extend service life. They cut down ongoing maintenance costs for these assets.

Aerospace: Extreme Temperature Defense & Durability

Aerospace parts use ceramic coatings for heat barriers and anti-erosion protection. Applications include turbine blades, rocket exhaust cones, shuttle insulating tiles, and windshield panes. These coatings handle temperatures above 1,000°C. They improve durability and fuel efficiency at the same time.

Materials like oxide and carbide ceramics are standard choices. They improve performance and help meet regulations in rockets and jet engines.

Food, Pharmaceutical, and Medical Sectors: Cleanliness and Longevity

I believe coatings are critical for preventing contamination and sealing surfaces. They protect food processing and pharmaceutical equipment. Safe and inert ceramic types maintain hygiene standards. The industry requires these. Many companies use them in dental and orthopedic implants as well as medical devices.

Plasma-sprayed coatings offer wear resistance. They support long-term device stability.

Market Impact and Technology Trends

The global ceramic coating market reached USD 13.08 billion in 2025. It is projected to hit USD 27.98 billion by 2035 (CAGR: 7.9%). The thermal spray method represents about 50% of technology usage. People prize it for finish and chemical resistance.

Essential materials include: Alumina, silicon carbide, silicon nitride, titania, hafnia. Manufacturers choose them for superior heat and erosion resistance.

Benefits of Industrial Ceramic Coating

Ceramic coatings offer strong benefits across many industrial sectors. They help companies improve durability, reduce maintenance, and boost performance.

Enhanced Durability and Extended Lifespan

Industrial ceramic coatings protect key parts. These include engine parts, exhaust systems, brake components, valves, pumps, conveyor systems, chimneys, refractories, and bearings. Abrasion-resistant types lead in mining, construction, and manufacturing. They extend the life of high-wear items. Corrosion-resistant ceramic coatings create strong protection. They guard against harsh chemicals, moisture, and tough conditions. In the steel industry, ceramic-coated parts last twice as long or more compared to uncoated ones.

Lower Maintenance Requirements

Coated equipment sees up to 50% reduction in maintenance time. This happens because of hydrophobic and non-stick ceramic surfaces. These coatings repel water and contaminants. Cleaning is easier and less frequent. Liquids bead and roll off, carrying away dirt and reducing build-up. I recommend ceramic coatings for companies running heavy machinery. They report less downtime and fewer repairs. This results in greater productivity and lower maintenance costs.

Performance Optimization

Ceramic coatings have high hardness, shock resistance, and thermal insulation. These traits matter for aerospace, energy, marine, and electronics sectors. In automotive and transportation, ceramic coatings cut friction and boost heat dissipation. This leads to better fuel efficiency and reduced emissions. Surfaces treated with ceramics keep their attractive finish longer. They resist wear better, which enhances equipment performance.

Comprehensive Protective Qualities

Ceramic coatings provide increased chemical resistance. They protect against acid rain, tree sap, and other corrosive agents found in tough industrial and outdoor environments. Surfaces gain extra protection against minor scratches and abrasion. They offer a much stronger surface than conventional coatings. Total scratch-proofing is not guaranteed, though. UV protection and enhanced oxidation resistance keep coated parts intact and appealing in high-temperature and outdoor settings.

Industry and Market Impact

In 2023, the global industrial ceramic coating market reached USD 11.16 billion. Growth is projected to hit USD 19.20 billion by 2030. This reflects high demand in automotive, transportation, construction, mining, and steel production. Based on my experience, companies in developing markets are increasing adoption. They are drawn by proven cost savings and efficiency.

Key takeaway: Industrial ceramic coatings deliver real gains. They double part lifespans, cut maintenance in half, and drive efficiency in sectors that need superior durability and performance.

Types of Ceramic Coatings

Industrial ceramic coatings fall into several categories. Each type serves different environments, surfaces, and needs. The main types are high-temperature ceramic coatings, nano and hydrophobic coatings, silica and quartz coatings, and PTFE-based sprays.

High-Temperature Ceramic Coatings

I recommend high-temperature ceramic coatings for extreme heat and abrasion environments. Manufacturers build them from dense inorganic compounds. Think silicon carbide and silicon dioxide. Both materials offer durability and protection.

Heat Resistance: These coatings endure temperatures from 1100°F to 1400°F (593°C to 760°C).

Abrasion & Erosion Protection: Fused powders create dense, hard films. These films resist wear, particle impact, fretting, and cavitation. They also stand up to harsh chemical attack.

Typical Applications: Missile steering vanes, Aerospace engine parts, Industrial exhaust systems, Process rolls and armature shafts (using high-purity, low-porosity powder options)

Example product:

– Saint-Gobain #290: This product is known for its abrasive wear resistance. It works well in engine and industrial equipment.

Nano, Hydrophobic, Silica, Glass, and Quartz Coatings

This group sees common use in the automotive sector. It also protects industrial equipment that needs strong surface protection without adding bulk.

- Nano-scale Film: Ultra-thin yet tough. It stays invisible on painted or clear surfaces.

- Hydrophobicity: It repels water, oils, and grime. Cleaning becomes easy.

- Silica (SiO₂) and Quartz Content: This delivers strong hardness—up to 9H pencil hardness. It offers better scratch resistance than regular paints.

- Longevity: Premium nano or quartz ceramic coatings protect for 2–5 years in harsh outdoor conditions. Marine and transport sectors see the same benefits.

- Substrate Compatibility: These coatings work on metals (steel, aluminum, zinc, magnesium), glass, and ceramics.

Performance Example:

– Automotive nano coatings keep gloss and water repellency for years. They beat short-lived wax or PTFE-based sprays.

PTFE-Based Ceramic Sprays

Companies market these as “ceramic” for consumers or budget users.

- Technology: These use fluoropolymers (PTFE).

- Protection: They create temporary non-stick and heat-resistant surfaces. They handle –200°C to 260°C.

- Lifespan: They last for a few months. I suggest these for quick, low-cost upgrades. But they fall short in durability and chemical strength compared to professional ceramic products.

Performance Comparison Table

| Coating Type | Typical Use Cases | Temperature Resistance | Hardness | Chemistry | Properties | Lifespan |

|---|---|---|---|---|---|---|

| High-Temp Ceramic | Aerospace, industrial, turbines | 1100–1400°F (593–760°C) | Very High | Silicon carbide/silica | Resists abrasion, erosion, corrosion | Multiple years |

| Silica/Nano/Quartz | Auto, glass, marine, tools | Up to ~500°C | High | SiO₂/quartz/silica | 9H hardness, hydrophobic | 2–5 years |

| PTFE-Based Sprays | Quick consumer uses | -200°C to 260°C | Medium | Fluoropolymer resin | Non-stick, heat resistant | Few months |

Specialty and Military-Grade Ceramic Coatings

- CHEMEON TCP-HF: This is a trivalent chromate ceramic. Military and EU standards approve it for corrosion resistance.

- ZIRCARMold Mix 6: This coating works for glass molding with high precision. It shows the flexibility of ceramic coating technologies for detailed industrial processes.

- Self-healing zinc-rich formulas: These protect steel structures. They provide cathodic protection. Large-scale infrastructure needs this.

Shared Features and Advantages

- Thermal insulation saves energy

- Chemical inertness resists acids, alkalis, and solvents

- High dielectric strength provides electrical insulation

- Low porosity blocks moisture and aggressive agents

Based on my experience, ceramic coatings offer advanced surface protection. They work on metals, plastics, glass, and composites. I like how they ensure equipment and critical parts perform well even under tough conditions.

Industrial Processes and Materials

I’ve seen how industrial ceramic coatings use advanced application techniques and different engineered ceramic materials. They create long-lasting, high-performance surfaces for tough work environments.

Key Application Methods for Industrial Ceramic Coating

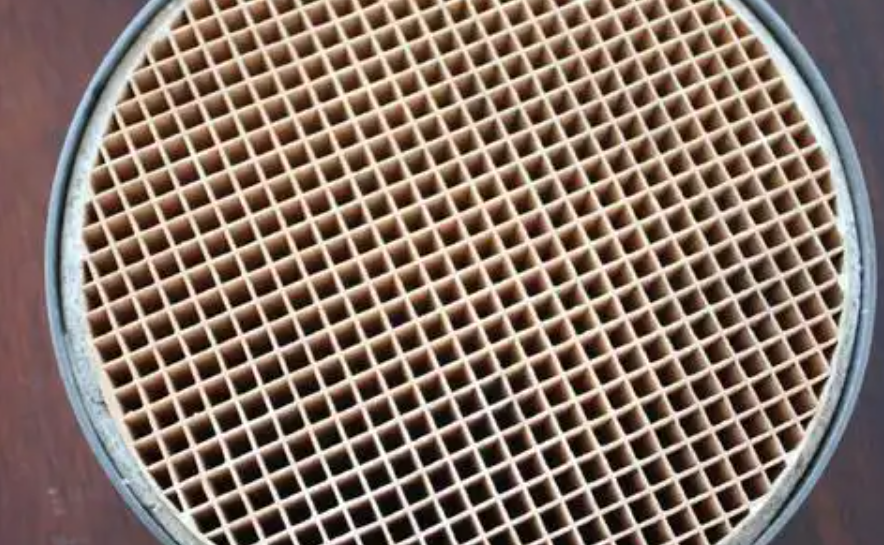

Thermal Spraying and Plasma Spraying: Many aerospace, steel, and power generation companies use these methods. Powders like zirconium oxide, alumina, and titanium dioxide get heated until soft. Then they shoot onto prepared surfaces at high speed. Coatings go from 5 to 500 microns thick. They give strong wear and heat protection for parts like turbine blades and steel rolls.

Physical Vapor Deposition (PVD): This works well for thin, exact coatings. You need it when tight tolerances and wear resistance matter. Electronics and precision engineering shops use it often.

Chemical Vapor Deposition (CVD): This delivers even, controlled ceramic layers on complex shapes. Many companies use it for uniform surface protection. Semiconductor industries depend on it.

Dipping and Sol-Gel: You apply this to components that need full and even coverage. I recommend this method for parts with odd or detailed shapes.

Advanced Methods: Techniques like micro-oxidation, packed diffusion, ionic beam, and laser-assisted treatments handle specialty surfaces. Military-grade applications need these.

Spray gun technology helps you achieve uniform coatings on complex parts like boom arms and turbine vanes. It works even with large or awkward shapes. After you apply the coating, infrared light curing is common. It improves adhesion. It boosts dimensional accuracy. It ensures an even surface finish.

Essential Ceramic Materials

- Zirconium Oxide (ZrO₂): This gives high-temperature resistance and top electrical insulation.

- Titanium Dioxide (TiO₂): This has chemical stability and wear resistance. You’ll find it in places with harsh chemicals.

- Alumina (Al₂O₃): This offers hardness and excellent abrasion resistance. It’s standard for industrial rolls and component protection.

- Silicon Dioxide (SiO₂): This creates a water-repelling, chemical-resistant barrier. Auto body panels and marine uses favor it.

Most industrial applications use ceramics in powdered forms for thermal spraying. They also use liquid-based resins with ceramic particles for surfaces that need flexibility or thin films.

Industry Application Examples

- Aerospace: Plasma-sprayed zirconia on turbine blades for extreme heat resistance.

- Steel Industry: Alumina coatings cut wear and shield production equipment from corrosion.

- Hydroelectric Power: Protective ceramic layers make turbines last longer. They reduce erosion.

- Automotive: Silicon dioxide coatings protect vehicle exteriors from chemicals and abrasion.

Process Parameters and Best Practices

- Thickness range: 5–500 microns (µm), matched to exposure level and mechanical demand.

- Ambient application temperature: Best at 25°C (±5°C) for top adhesion and uniformity.

- Curing time: Goes from minutes (spray-on) to several hours (thermal spray). This depends on material and thickness.

- Failure rates: Field data shows over 65% of coating failures happen because of poor surface prep or technique. This proves expert application and carefully controlled conditions are valuable.

Preparation steps matter—cleanliness, pressure, and temperature control are key. I’ve found that well-applied ceramic coatings last for years, even in harsh industrial settings. They maximize your return on investment. They cut unplanned maintenance.