Introduction to Ceramics

Ceramics fall into two main types: technical ceramics (advanced or engineering ceramics) and traditional ceramics. I recommend understanding their composition, properties, and uses to see how they differ.

Technical ceramics are made for high-performance tasks. Manufacturers produce them from refined materials like alumina (Al₂O₃), zirconia, silicon carbide, and boron nitride. Based on my experience, these ceramics stand out for high strength and hardness, strong wear, chemical, heat resistance, toughness and long service life.

Their design creates a uniform microstructure. This means no impurities or flaws. Engineers control their composition at the chemical level. I’ve seen technical ceramics used in many industries, such as aerospace, automotive, electronics, medical devices, foundry industry, industrial manufacturing, etc..

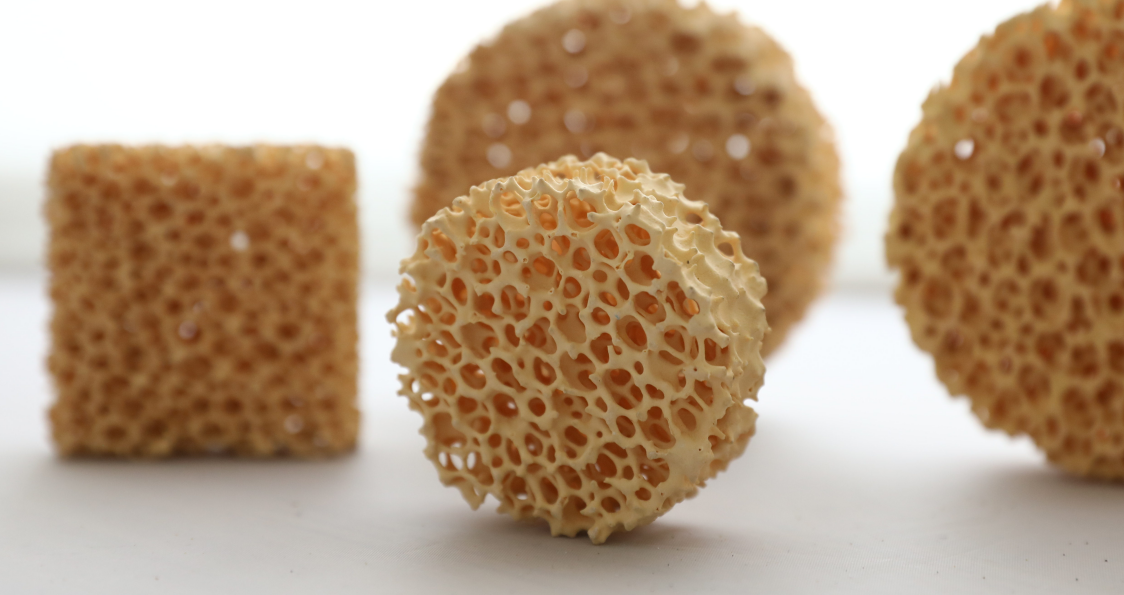

Take alumina as an example. Manufacturers use it to make cutting tools, ceramic foam filters, bearings, and pumps. Why? It combines strength, stiffness, and wear resistance.

Traditional ceramics come from natural materials like clay, feldspar, and quartz. Traditional ceramics have these features of moderate hardness, brittle texture, high-temperature tolerance, good insulation properties. You’ll find these ceramics in Building materials, Household items, Basic industrial uses. The production process includes:

- Raw material processing (crushing, screening, batching)

- Molding shaped by clay’s plasticity

- Drying to remove extra moisture

- High-temperature sintering to harden the product

Traditional ceramics show more defects or differences. Natural raw materials vary in quality. That’s just how they work.

Key Structural Differences

Composition and Uniformity: Technical ceramics have a controlled microstructure. This gives them specific properties. Traditional ceramics may have natural flaws because raw materials vary.

Post-Processing: Technical ceramics need extra machining or processing after sintering. This meets strict standards. Traditional ceramics don’t need these extra steps.

Thermal Conductivity: Some advanced ceramics (like MAX Phase ceramics) have thermal conductivity five times higher than traditional ceramics.

What Are Technical Ceramics?

Technical ceramics are inorganic, non-metallic materials. Engineers design them for tough industrial and tech jobs. Traditional ceramics use natural raw materials. Technical ceramics are different. They use advanced oxides, carbides, nitrides, and similar compounds. Here are the main types:

- Alumina (Al₂O₃)

- Zirconia (ZrO₂)

- Silicon carbide (SiC)

- Silicon nitride (Si₃N₄)

- Boron nitride (BN)

- Sapphire (single-crystal Al₂O₃)

- Aluminum nitride (AlN)

Manufacturers make these technical ceramic materials from high-purity powders. They shape them at room temperature. Then they fire them at high temperatures. This process is called sintering. It creates a dense, uniform structure. The properties are controlled with great accuracy. I recommend these ceramics for extreme conditions. They perform far better than traditional ceramics or metals in harsh environments.

Key Performance Properties

-

Extreme hardness: Technical ceramics can be over four times harder than stainless steel. This makes them perfect for wear-resistant tools and machine parts.

-

High compressive strength: These ceramics handle pressures from 1,000 MPa up to more than 4,000 MPa. They outperform metals like titanium.

-

Low density: Most range between 2 and 6 g/cm³. They offer weight advantages compared to metals. For example, stainless steel weighs about 8 g/cm³.

-

Great thermal stability: They stay stable at temperatures above 1,750°C (3,182°F). Based on my experience, this is critical for high-heat applications.

-

Low thermal expansion: They expand very little under heat. This prevents cracking or warping. I suggest these ceramics for aerospace, optics, and electronics because of this property.

-

Chemical and corrosion resistance: Ionic and covalent bonds protect them. They resist acids, alkalis, and oxidation.

-

Electrical insulation or conduction: The material type determines this. Some serve as high-performance insulators, like alumina. Others conduct electricity, like SiC.

-

Customizable properties: You can customize them for specific needs. For instance, biocompatibility for medical implants. Or optical clarity for lenses.

Industrial Uses and Data

I’ve seen technical ceramics used across many industries:

- Aerospace: Heat shields, turbine blades, and advanced sensors.

- Automotive: Engine components, braking systems, sensors.

- Electronics: Substrates, insulating parts, capacitors.

- Medical devices: Implants, surgical tools, dental crowns.

- Industrial manufacturing: Cutting tools, wear plates, furnace components for high temperatures.

Material Comparison Table

| Material | Chemical Formula | Notable Properties | Typical Applications |

|---|---|---|---|

| Alumina | Al₂O₃ | High hardness, excellent insulation | Insulators, medical, wear parts, foundry industry |

| Zirconia | ZrO₂ | High toughness, biocompatibility | Bearings, medical implants, ceramic filters |

| Silicon Carbide | SiC | Extreme hardness, high thermal conductivity | Heating elements, cutting tools, filter media |

| Silicon Nitride | Si₃N₄ | Strength, thermal shock resistance | Bearings, engine components |

| Boron Nitride | BN | Lubricity, thermal conductivity | Insulators, aerospace |

| Sapphire | Al₂O₃ (crystal) | Optical clarity, extreme hardness | Lenses, windows, sensors |

| Aluminum Nitride | AlN | Great thermal conductivity | Heat sinks, substrates |

In short, technical ceramics deliver maximum performance, reliability, and durability. They meet the demanding needs of modern industry and technology. Engineers control their composition, purity, and processing with high accuracy. I like these materials because they solve problems that metals and traditional ceramics cannot handle.

What Traditional Ceramics Are

Traditional ceramics come from natural minerals. Clay, quartz, and feldspar are the main ones. We don’t heavily purify or modify them.

I find it amazing that these ceramics are among humanity’s oldest inventions. Clay vessels from over 10,000 years ago prove this. People made them in the Neolithic period.

What Goes Into Traditional Ceramics

- Clay: This is the core ingredient. It gives ceramics their shape and plasticity.

- Silica (Quartz): It boosts strength and makes ceramics last longer.

- Feldspar: This acts as a flux. It lowers the melting point and binds particles together.

- Quartz sand: We use it as-is. It adds hardness and structure.

How Traditional Ceramics Evolved

Traditional ceramics have a rich history. They started as basic tools. Now we use them in many ways.

People once used abrasive stones and ceramics to sharpen tools. Firing clay was a big step forward. It made objects tougher and water-resistant.

Some of the first composite materials were sun-dried clay bricks. People added straw fibers to make them stronger.

I see traditional ceramics everywhere today:

– Household products: Mugs, cups, vases, bowls, and tableware from fired clay or porcelain.

– Construction materials: Bricks, roofing tiles, and other clay-based building parts.

– Industrial uses: Abrasive wheels, furnace linings, and portland cement.

– Everyday items: Jugs, pots, planters, and kitchenware.

What Makes Traditional Ceramics Unique

The properties of traditional ceramics depend on where their raw clay comes from. This creates several key traits:

- Complex chemical structures come from mixed or local minerals.

- Higher impurity content affects how they look and how strong they are.

- Irregular and porous microstructure makes uniform quality hard to reach.

- Texture and final quality change based on local resources.

- Imperfections are common. I think they add character to traditional ceramics.

How We Make Traditional Ceramics

We produce traditional ceramics using natural minerals and wet forming methods. Here are the common steps:

- Shape the clay by hand, pressing, or grouting.

- Refine or purify the materials very little.

- Heat the object at high temperature to harden it. This is called sintering.

How Traditional Ceramics Differ from Advanced Ceramics

I recommend traditional ceramics for everyday use. They focus on practical, general-purpose tasks. They aren’t built for specialized industrial functions. They don’t have the advanced mechanical or physical qualities that technical ceramics do.

Their structure and performance come from their raw materials’ natural properties. High-precision processing doesn’t shape them. Strict compositional control doesn’t define them either.

Key Differences Between Technical and Traditional Ceramics

I’ve worked with both technical and advanced ceramics, and I can tell you the differences are significant. Let me break down what sets them apart.

Materials and Composition

Traditional ceramics use natural minerals. Think clay, feldspar, quartz, and sand. These raw materials often have impurities. Quality varies depending on where you source them.

Advanced Technical ceramics are different. They start with high-purity compounds. I’m talking about alumina (Al₂O₃), silicon carbide (SiC), and zirconia (ZrO₂). Many of these are synthetic or purified. This approach gives you consistent quality. Properties stay precise batch after batch.

Microstructure and Manufacturing

Traditional ceramics have uneven, porous structures. Local mineral variations create imperfections. This lowers reliability.

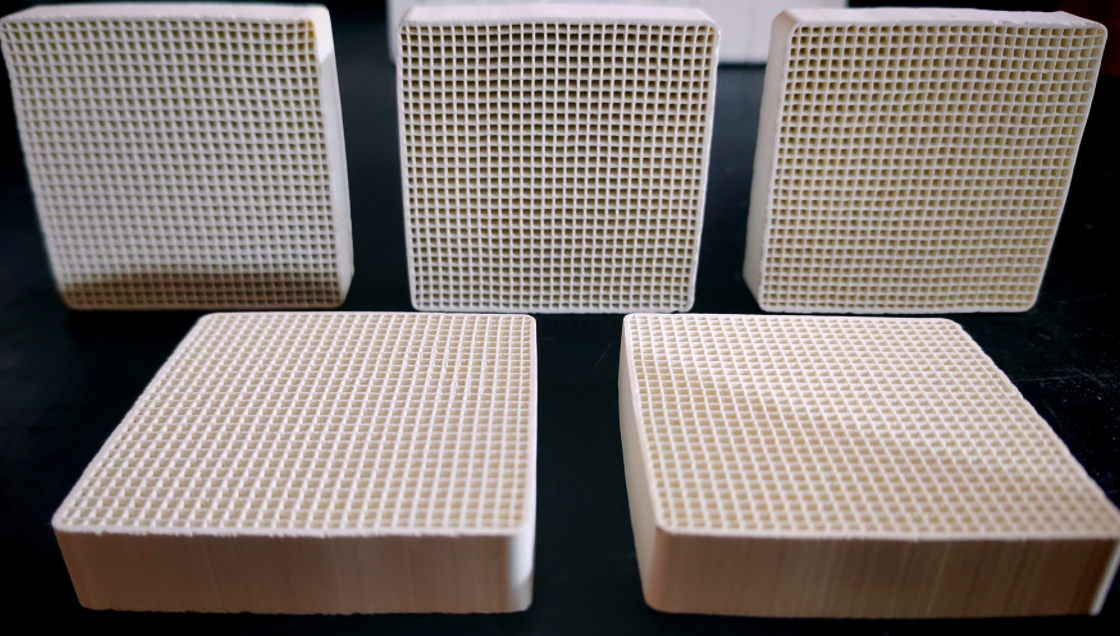

Technical ceramics use controlled, engineered structures. I recommend looking at their manufacturing process. It includes precision shaping and high-temperature sintering. Advanced post-processing like machining and grinding follows. The result? Less porosity. Fewer impurities. Better performance you can count on.

Physical and Mechanical Properties

Traditional ceramics:

– Tensile strength: around 10–20 MPa (building brick is a good example)

– Moderate strength and toughness

– Water absorption varies (earthenware absorbs more, porcelain less)

– Temperature resistance up to 1,300°C

Technical ceramics:

– Alumina: compressive strength >300 MPa, hardness ~15 GPa, excellent electrical insulation (>10¹⁴ Ω·cm)

– Silicon carbide: thermal conductivity ~120 W/m·K, hardness 25–28 GPa

– Zirconia: fracture toughness up to 10 MPa·m½—far higher than most traditional options

– Many handle temperatures >1,600°C

– Outstanding wear resistance

– Excellent chemical resistance

Uses and Applications

Traditional ceramics show up in everyday items. You’ll find them in tableware, tiles, bricks, sanitary ware, and construction materials. Household goods use them too.

Technical ceramics serve demanding industries. Based on my experience, they’re critical for:

– Aerospace (turbine parts, heat exchangers)

– Electronics (substrates, capacitors, insulators)

– Medical field (implants, dental crowns)

– Automotive (bearings, sensors, spark plugs)

Industry Adoption

More than 70% of electronic components depend on technical ceramics. They provide reliable insulation and heat management. They perform well in extreme environments.

I’ve seen technical ceramics dominate sectors that need durability. High-precision parts use them. Chemically-resistant components need them. Think aerospace, medical devices, and automotive engineering.

Summary Table

| Aspect | Traditional Ceramics | Technical Ceramics |

|---|---|---|

| Raw Material | Natural (clay, quartz, etc.) | Synthetic/purified (alumina, SiC) |

| Structure | Imperfect, variable | Uniform, engineered |

| Manufacturing | Simple, less precise | Complex, high precision |

| Key Properties | Lower strength, more brittle | Superior strength and resistance |

| Main Uses | Everyday goods, buildings | Industry, medical, electronics |

In short:

Technical ceramics use engineered composition. They deliver extreme performance. Precise manufacturing makes them ideal for specialized applications.

Traditional ceramics use natural materials and simple methods. They focus on everyday functions and construction needs.

Applications of Technical Ceramics

I’ve worked with technical ceramics for years, and I can tell you they are essential in industries that need high performance, durability, and reliability. These materials have unique properties. They resist high temperatures. They are extremely hard. They provide electrical insulation. They resist chemical damage. Based on my experience, these qualities make them vital in advanced engineering and modern technology.

Key Application Areas for Technical Ceramics

Industrial Machinery: Bearings, seals, valves, and pump linings depend on ceramics. I recommend using alumina, zirconia, and silicon carbide. They withstand harsh wear and chemical attack. These parts work well in aggressive chemical environments. They reduce maintenance costs. They cut downtime.

Electronics and Electrical Engineering: Ceramic substrates, insulators, and heat sinks use alumina and steatite. They are critical in semiconductor manufacturing, circuit boards, capacitors, and high-frequency devices. I like that their electrical insulation and heat dissipation are excellent. They allow for smaller designs. They boost reliability in smartphones, computers, automotive electronics, and power modules.

Aerospace and Defense: Engine turbine blades, heat shields, and nose cones use ceramic matrix composites (CMCs) and oxide ceramics. They handle extreme temperatures and mechanical stress. Ceramic insulation was used in spacecraft like the Hayabusa asteroid probe. Ceramic terminal blocks are in the Large Hadron Collider at CERN. I find these applications impressive.

Automotive Sector: Zirconia oxygen sensors, ceramic spark plugs, and ceramic brake discs improve fuel efficiency, emissions control, and safety. These components withstand high temperatures and friction. Ceramic brakes reduce wear rates by up to 50% compared to metal. I suggest considering them for performance vehicles.

Medical Technology: Zirconia and alumina ceramics are used in hip and knee implants, dental crowns, prosthetics, and surgical tools. They are biocompatible, hard, and resist corrosion. This results in longer-lasting, safer solutions for patients. I recommend these materials for medical applications.

Energy and Environmental Engineering: Ceramics are key in fuel cells, solar panels, high-voltage insulators, and fusion reactor insulators (e.g., ITER’s million-volt ceramic rings). They are also used in advanced battery technologies. Ceramic membranes and filters purify water, separate gases, and filter industrial processes. They achieve ultra-precise separation at nanometer scales. They offer chemical durability and long service life. I believe these are the future of clean energy.

Heating, Furnaces, and Domestic Appliances: Industrial furnaces, laboratory crucibles, hair dryer elements, and stovetop components use ceramics. They operate above 1,200°C. They resist thermal shock. They provide strong electrical insulation. I like using them in high-heat applications.

Applications of Traditional Ceramics

Traditional ceramics stay important across many industries. They combine old methods with new ideas. I see their uses as varied and growing to meet global needs.

Pottery, Tableware, and Kitchenware

Traditional ceramics lead the pottery and tableware market. This market is valued at $12.3 billion in 2025. It will reach $18.9 billion by 2035 with a CAGR of 4.4%. Popular items include porcelain dishes, clay mugs, and decorative plates.

I recommend watching consumer interest in handcrafted and artisan styles. This drives the projected North American ceramics market size of $40 billion by 2026. Online shopping has opened access to more ceramics. This boosts demand for unique and locally inspired kitchenware.

Building Materials: Bricks, Tiles, and Sanitary Ware

Traditional ceramics make up 68.8% of the global ceramics market (2024). Bricks, tiles, and sanitary ware dominate this share. These materials are vital in home and business construction. The Asia-Pacific region leads due to fast city growth and high building investment.

Tiles and sanitary ceramics are prized for durability, hygiene, and heat resistance. They represent 56.0% of revenue in 2024 in these areas. New construction and renovation in North America and Europe keep demand steady.

Decorative Artware and Luxury Ceramics

The artware and decorative ceramics segment includes sculptures, fountains, and luxury home items. It held a 6.4% market share in 2022. This segment will grow at 4.1% each year.

High-end ceramics appear in luxury buildings and custom interior projects. I like examples such as custom-made porcelain sets, detailed sculptures, and large decorative fountains. These are often ordered for high-profile buildings and homes.

Industrial Applications: Refractory Linings and Abrasives

Traditional ceramics serve strong industrial needs. They work well in refractory linings for kilns and furnaces and abrasive products for manufacturing. They can handle high heat and wear. This supports key manufacturing and metal processes. Traditional ceramics stay strong in this area thanks to reliable performance and low cost.

Market Trends and Technological Advances

The global traditional ceramics market value varies. Estimates range from $77.17 billion (2025) to $154.46 billion (2025). Forecasts go up to $256.43 billion by 2035 with CAGRs from 2.7% to 5.2%.

Growth comes from city expansion in Asia-Pacific. Steady replacement and renovation markets in developed regions also help. New technology includes digital manufacturing, 3D printing, and advanced kiln controls. These raise product quality, design options, and customization.

Based on my experience, additive manufacturing is a fast-growing segment. It expands from $137 million in 2022 to a projected $1.7 billion in 2032 at a growth rate of 30.4%.

Sustainability and eco-friendly production now get more focus. Manufacturers invest in greener raw materials and efficient firing methods. Major players like LIXIL Group, Kohler, and TOTO push innovation through R&D and new product launches.

Employment and Economic Contribution

I expect the traditional ceramics sector to see 6% employment growth from 2020 to 2030. This reflects steady demand for skilled artisans, technical operators, and digital manufacturing specialists.

Summary of Key Applications and Data:

– Pottery/Tableware: $12.3B (2025); projected $18.9B (2035); 4.4% CAGR

– Tiles, Bricks, Sanitary Ware: 68.8% of global ceramics market (2024); 56.0% of segment revenue

– Artware/Decor: 6.4% market share; 4.1% annual growth

– Industrial/Refractory Use: Kiln linings, abrasives, furnace bricks

– Additive Manufacturing: $137M (2022) to $1.7B (2032); 30.4% CAGR

– Employment: 6% projected growth (2020–2030)

– Global Market: $77.17B–$154.46B (2025 estimates); up to $256.43B by 2035

Traditional ceramics bring key value across consumer, construction, art, and industrial sectors. They meet practical, money, and beauty needs around the world.

Summary

I’ve worked in the ceramics industry for years. Here’s what I’ve learned: both technical and traditional ceramics have value you can’t replace.

Technical ceramics push limits in extreme environments. Traditional ceramics bring beauty and function to our lives every day.

I recommend understanding their differences. This helps you pick the right material for your needs. You’ll get the most from these amazing materials in today’s world.