What Are Ceramics and Refractories?

Ceramics are hard, brittle materials. They come from inorganic, nonmetallic minerals. We make them by firing at high temperatures. These materials have high compressive strength. They conduct little electricity or heat. They resist chemicals well. They also have high melting points.

Refractories are a special type of ceramics. We design them for extreme environments. They can handle temperatures above 1500°C (2732°F). They don’t melt, deform, or corrode at these levels. The ASTM C71 standard says refractories are non-metallic materials. They work in environments exceeding 538°C (1000°F).

Key Features and Requirements of Refractories

- They resist breakdown and chemical reactions at very high temperatures.

- They keep their strength and shape during heating and cooling cycles. They also hold up under heavy loads.

- They resist abrasion, corrosion, and wear from solids, molten metals, liquids, and gases.

- They trap and hold heat inside industrial equipment like furnaces and kilns.

- They have low thermal expansion. This keeps their size stable during temperature changes.

Classification and Applications of Refractory Products

Refractory products come in two forms:

- Shaped refractories: These include bricks and pre-cast shapes. We optimize them for structural uses with precise density and porosity.

- Unshaped (monolithic) refractories: These are rammable, castable, or sprayable. They suit complex shapes and quick repairs.

Usage Highlights:

– 70% of refractories serve the basic metals industry. They line blast furnaces, kilns, incinerators, reactors, and crucibles.

– Iron and steel production needs them. They handle heat, slag, molten metal, and abrasion.

– Special ceramic types power the electronics industry. They appear in semiconductors and superconductors.

Refractory Ceramics and Their Thermal Conductivity

- Conducting refractories: Silicon carbide (SiC), zirconium carbide (ZrC)

- Nonconducting refractories: Silica, alumina

- Insulating refractories: Calcium silicate, kaolin, zirconia

Essential Differences

Ceramics: We know them for hardness, brittleness, chemical stability, and high melting points.

Refractories: These are engineered ceramics. They perform well at extreme temperatures. They resist chemicals and last long. I suggest them for heavy industry and metallurgy.

Key Properties of Refractories

I recommend understanding these key properties before selecting Refractory materials. Modern refractories are built to handle extreme heat in industrial settings. Here’s what you need to know:

High Melting Point: Most refractories resist temperatures above 1580°C. advanced grades work continuously up to 1800°C or higher. This makes them reliable in furnaces, kilns, and reactors.

Bulk Density: Values range from 1.8 to 3.0 g/cm³. Higher density means better heat retention. It also improves resistance to abrasion. Less slag or molten material penetrates the surface. I suggest using high-density bricks in areas with severe mechanical stress.

Cold Crushing Strength (CCS): CCS shows the maximum load a refractory brick can handle at room temperature. Most industrial refractories range between 1500–5000 kg/cm² (150–500 MPa). High CCS means longer life. It also means better load tolerance in tough environments.

- Formula:

[\text{CCS} = \frac{P}{A}]

where P is the failure load and A is the cross-sectional area.

Flexural Strength / Modulus of Rupture (MOR): This property shows how well a material resists bending. Castable refractories show 3–20 MPa. This supports stability in furnace linings and critical areas.

Apparent Porosity: Lower open pore volume (below 15–20%) boosts thermal insulation. It also improves chemical resistance. Higher porosity allows more penetration. This makes the material weaker against slag and chemical attack.

Thermal Conductivity: Dense refractory bricks conduct heat at 1–2 W/m·K. Insulating bricks offer much lower values (0.2–0.5 W/m·K). I like using materials with lower thermal conductivity to cut heat loss in energy-heavy processes.

Thermal Shock Resistance: Good refractories handle fast temperature changes without cracking. You can achieve this by mixing raw materials carefully. Adding zirconia helps. Using alumina-silicate bonds also works.

Creep Resistance: Stability under high heat and load matters. Refractories with high creep resistance perform well in steel production. They also work in continuous process furnaces.

Chemical Composition: You choose between silica, alumina, magnesia, zirconia, or carbon-based materials based on your chemical environment. This protects against corrosion and erosion from gases, slags, or molten metals.

Pyrometric Cone Equivalent (PCE): PCE measures the softening temperature. This is critical for picking refractories for high-intensity applications.

Classification of Refractories

We classify refractories based on six key criteria: chemical makeup, chemical behavior, physical form, how we make them, heat properties, and where we use them. I recommend understanding these categories. They help you pick the right materials for high-heat industrial work.

Classification by Chemical Composition

Refractories fall into three main groups:

Acid Refractories: These resist acidic slags and harsh environments. But alkalis damage them. Common types are silica bricks (SiO₂ content >93%), semi-silica bricks, fireclay bricks, and alumino-silicate refractories. Fireclay bricks make up about 75% of all refractory production by volume. The iron, steel, glass, and cement industries use them the most. A typical fireclay brick has up to 78% SiO₂ and up to 44% Al₂O₃. Fusion points often go beyond 1,615°C.

Basic Refractories: These stay stable in alkaline settings and against basic slags. Acids attack them though. Main examples include magnesite bricks (MgO >85%), dolomite bricks (CaO and MgO blend), magnesia-chrome bricks, and magnesia-carbon bricks. Magnesia bricks melt above 2,800°C. I’ve seen them used as vital linings in steelmaking.

Neutral Refractories: These stay stable in both acidic and basic conditions. Your options include chromite bricks, high-alumina bricks (Al₂O₃ >45%), and high-purity carbon or graphite refractories. Graphite bricks melt above 3,650°C. Based on my experience, they work best where slag chemistry changes often.

Classification by Physical Form

Shaped Refractories: We make these into solid pieces with standard or custom sizes. People call them refractory bricks. Special shapes fit unique furnace sections.

Unshaped (Monolithic) Refractories: We deliver these as powders, granules, or mixtures. You install them on-site. These include castables, ramming masses, plastics, and gunning mixes. I suggest monolithics for jointless linings and quick repairs.

Classification by Compactness

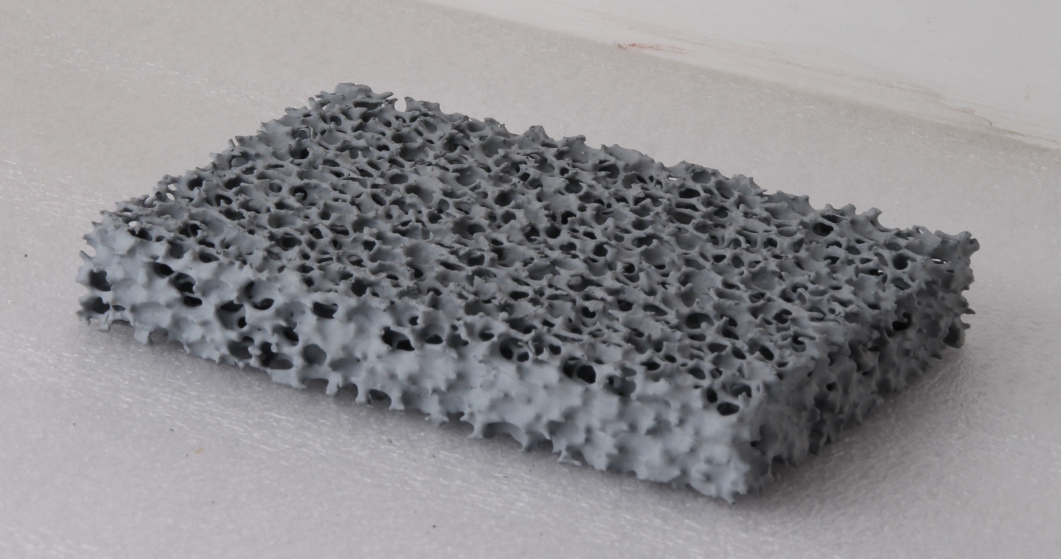

Dense Refractories: These have less than 45% true porosity. They resist high-heat slags, gases, and mechanical loads directly. Common bulk density sits above 1.9 g/cm³.

Insulating Refractories: These have true porosity greater than 45%. Densities range from 0.4–1.2 g/cm³. We use them as backup layers for heat insulation. They don’t face extreme conditions directly.

Other Major Types and Data Points

-

High Alumina refractories: With 45–99% Al₂O₃, we use these in cement kilns, blast furnaces, and incinerators.

-

Silica Bricks: These are key materials in coke ovens and glass furnaces. Melting point sits above 1,700°C.

-

Magnesia-Carbon Bricks: Steel ladles favor these for great thermal shock and slag resistance. MgO content runs above 97%.

-

Chromite Refractories: Based on FeCr₂O₄, these deliver corrosion resistance in non-ferrous metal and steel refining. Chromite melts at around 2,180°C.

-

Chamotte (Calcined Fireclay): This contains 60–70% SiO₂ and 25–35% Al₂O₃. Heat resistance reaches near 1,659°C. We use it in fireclay bricks and backup linings.

In summary: We classify refractories by their chemical makeup (acidic, basic, neutral), shape (shaped vs. unshaped), and density (dense or insulating). Industry needs also play a role. Each type gives you clear benefits for performance, resistance, and efficiency in tough industrial settings.

Raw Materials Used in Refractories

I’ve worked with refractory materials for years. I can tell you that these raw materials form the backbone of industrial ceramics and refractory products. Their chemical makeup, purity, melting point, and thermal stability decide how they perform under extreme heat.

Key Types of Refractory Raw Materials

Alumina-Containing Minerals (Al₂O₃)

Bauxite: This is the main source for High-alumina Refractories. It typically contains 85–90% Al₂O₃. We calcine bauxite to improve phase stability. This also raises its refractoriness. I recommend it for fused alumina and as aggregate in high-performance bricks. Premium bauxite has density above 3.35 g/cm³. It should have minimal iron or titania impurities. Major suppliers are China, India, and Brazil.

Fireclay: We use this for alumino-silicate refractories. It’s rich in kaolinite. Refractoriness is above 1580°C. Hard fireclays work best for bricks because of their high purity and low plasticity. Soft types suit many different uses.

Silica-Based Minerals (SiO₂)

- Chamotte (Calcined Fireclay): This contains 60–70% SiO₂ and 25–35% Al₂O₃. Refractoriness is around 1659°C. Bulk density reaches up to 2.2 g/cm³. Chamotte is the core material for fireclay bricks, insulation layers, and coke oven linings. Top producers include China, Germany, USA, and Brazil.

- Silica Sand/Quartz: I suggest this for silica bricks and acid refractories. It has high thermal stability.

Magnesia-Based Minerals (MgO)

- Magnesite: This is a key component for basic refractories and magnesia-chromite bricks. It resists basic slags well at high temperatures.

- Dolomite: We use this for cost-effective basic bricks. It provides strong stability against lime and iron oxide slags.

Chromite (FeCr₂O₄): We use this in chrome-magnesia and chromite refractories. Melting point is near 2180°C. Density ranges from 2.5–3.0 g/cm³. Sourced from South Africa, Kazakhstan, and Turkey. I like chromite because it resists slag corrosion in metal and ferro-alloy furnaces.

Carbon and Graphite: We apply these in high-temperature, reducing conditions. They work in special combinations for added resistance or conductivity.

Zirconia (ZrO₂): We reserve this for super-high refractories needing resistance beyond 2000°C. It’s used in glass melting and metal processing.

Raw Material Quality & Selection Criteria

- High chemical purity matters. Impurity levels affect resistance and life.

- Melting point: For ordinary service (1580–1770°C), advanced (1770–2000°C), and super-duty refractories (>2000°C).

- Grain size distribution and bulk density control mechanical strength. They also control heat transfer.

- Sourcing region: Consistent quality in processing and supply matters.

Sourcing and Cost Considerations

Major Producers:

- Bauxite: China, India, Brazil

- Chamotte: China, Germany, USA, India, Brazil

- Chromite: South Africa, Kazakhstan, Turkey

Functional Roles

- Main raw materials: These determine body stability and heat resistance.

- Binders/Auxiliaries: These add plasticity, strength, or workability. Examples include clays, cements, and resins.

- Additives: These boost mechanical, chemical, or thermal properties.

Based on my experience, selecting the right raw materials is crucial. You need refractory products that can handle target temperatures, loads, and corrosive conditions in heavy industries.

Applications of Refractories

High-temperature industries need refractories. These materials resist heat, corrosion, and chemical damage. I recommend understanding their uses across different sectors. Each sector needs specific materials for best results.

Major Industrial Applications

Iron and Steel Industry:

Over 70% of global refractories go into steelmaking. This is a huge market. Companies line blast furnaces, oxygen converters, electric arc furnaces, ladles, and tundishes with these materials. Popular products include magnesia-carbon bricks, doloma, and graphite-based refractories. I suggest these materials because they resist thermal shock. They also handle harsh basic slags well.

Non-Ferrous Metals:

Refractories help smelt and refine aluminum, copper, nickel, and platinum. Magnesia-chrome bricks and spinel refractories work great here. Based on my experience, these materials last long. They resist slag damage in copper and nickel smelters.

Cement and Lime Industry:

Rotary kiln linings use doloma (CaO-MgO) bricks and high-alumina bricks. These bricks last longer. They resist basic atmospheres. Good refractory linings make kilns more fuel-efficient. They also help control emissions. I recommend investing in quality linings for better performance.

Glass Manufacturing:

Regenerator chambers, melting tanks, and feeder channels need special linings. Manufacturers use silica bricks and clay bricks. These bricks resist corrosion from molten glass. They handle constant heating and cooling cycles. I prefer these materials for glass plants.

Power Generation:

Boilers, incinerators, and gasifiers need protection. Magnesia, silica, and alumina-based bricks do this job. They protect against acid attack. They handle extreme temperatures. I suggest using these for power plants.

Petrochemical, Chemical, and Waste Incineration:

Monolithic refractories are popular here. These include castables, plastics, and gunning mixes. They line reactors, gasifiers, and hazardous waste incinerators. Phenolic resin-bonded products offer strong chemical stability. They allow fast repairs in harsh conditions. I like these for emergency maintenance.

Ceramics Industry and Kiln Furniture:

Mullite-based, alumina, and fireclay refractories form kiln furniture. This includes shelves, saggars, and supports. They stay stable at high temperatures. They insulate well. I recommend these for ceramic kilns.

Aerospace and Defense:

These industries use refractories as thermal barriers and heat shields. You find them in engines, turbines, and spacecraft. Special refractory ceramics and composite materials work best. They have low heat transfer. They stay strong at extreme temperatures. I suggest these for critical aerospace applications.

Typical Refractory Products and Application Areas

-

Clay bricks: These work for glass kiln linings, blast furnace linings, and hot-blast stoves. They are versatile and affordable.

-

Magnesium bricks: Use these in electric furnaces, iron foundries, lime kilns, and power plant desulfurization systems. They handle basic environments well.

-

Corundum bricks (≥90% Al₂O₃): These go into critical blast furnace areas. They work for refining outside the furnace. They fit slide gate mechanisms. I recommend corundum for demanding steel applications.

-

Chamotte/fireclay: These contain 60–70% SiO₂ and 25–35% Al₂O₃. Steel foundries use them. They line coke oven walls and fireplaces. They serve as insulation layers. Based on my experience, they offer good value.

-

Chromite-based refractories: Spinel and magnesia-chrome bricks are standard for non-ferrous metal vessels. They resist slag and heat very well.

-

Graphite: Graphite melts near 3,650°C. This makes it ideal for electrodes, magnesia-carbon bricks, crucibles, slide gates, and tap hole mixes. I like graphite for its extreme temperature resistance.

-

Pressed refractories: Nozzles and cover plates in steel ladles use these products. They control flow precisely. I suggest these for accurate pouring operations.

Product Forms and Specialized Functions

-

Bricks (fired shapes): These line areas that need mechanical strength and wear resistance. Think furnaces, kilns, and reactors. They provide structural support.

-

Monolithic/unshaped refractories: These work for repairs. They line irregular shapes. They allow rapid installation. Forms include gunning, ramming, castables, and spray coatings. I prefer these for quick fixes and custom shapes.

-

Fibrous and insulating boards: These often serve as backup insulation in kilns and reactors. They cut energy loss. I recommend adding these to improve efficiency.

refractory materials are vital for high-temperature equipment. They handle aggressive physical and chemical conditions. Your choice matters—bricks, monolithics, or insulation. This choice affects safety, efficiency, and equipment lifespan. I suggest careful selection based on your specific needs. Match the material to your operating conditions for best results.

Differences Between Ceramics and Refractories

Ceramics and refractories are both inorganic, non-metallic materials. They both go through high-temperature processing. But their functions differ a lot. Their performance characteristics also differ.

You need to understand these differences. This helps you select the right materials for tough industrial jobs or technical uses.

Functional and Application Differences

Ceramics: You can use them for many things. Floor tiles, sanitaryware, electrical insulators, metal filtration, and advanced technical parts. Their applications can be structural or decorative. They also work in technical fields like electronics or engineering.

Refractories: These are a special type of ceramic. They are built for high-temperature environments. You’ll find them as linings in industrial furnaces, kilns, reactors, and crucibles. Industries like metallurgy, glass, and cement rely on them.

Temperature Resistance and Thermal Properties

Ceramics: Heat tolerance changes a lot depending on the type. technical ceramics can work up to 1300–1700°C. But most common ceramics can’t handle long exposure to extreme heat.

Refractories: These are built for service temperatures above 1500°C. The best types, like corundum, exceed 1900°C. They resist melting and deformation. They also handle thermal damage in harsh industrial settings.

Technical and Economic Comparison Table

| Property | Corundum | Alumina | Cordierite | Mullite | R-SiC (Refractory SiC) |

|---|---|---|---|---|---|

| Mohs Hardness | 9 | 8.5–9 | 6–7 | 6–7 | 9 |

| Max Service Temp (°C) | 1900 | 1700 | 1300 | 1600 | 1650 |

| Thermal Expansion | Medium | Medium | Very Low | Medium | Low |

| Thermal Shock Resistance | Moderate | Good | Excellent | Excellent | Excellent |

| Mechanical Strength | High | High | Low | Moderate | High |

| Thermal Conductivity (W/m·K @ 1000°C) | – | 5–6 | – | – | 40–50 |

Summary of Key Differences

Refractories have exceptional resistance to melting and deformation at extreme temperatures. This makes them necessary in heavy industry. Ceramics is a broader category. Refractories are the subcategory made for the toughest thermal and mechanical demands.

Based on my experience, use ceramics for general technical and everyday purposes. But choose refractories for jobs that need consistent strength, chemical durability, and high thermal resistance.

Typical Refractory Types and Applications

Calcined Bauxite & Brown-Fused Alumina: These high alumina refractories contain 87–88% alumina. Bulk density is 3.25–3.35 gm/cc. They provide strong structure. I recommend them for heavy-duty jobs.

Silica and Alumina-Based Bricks: These are common for furnace lining. Many industries use them for construction.

Magnesia-Based Bricks: Steel and ferrous metallurgy industries prefer these. They have very high melting points.

Summary

I’ve worked with these refractory ceramic materials for years. Here’s what I learned: picking the right refractory goes beyond just meeting specs. You need to understand your operating conditions. You also need to think about your long-term goals.

Are you lining a blast furnace? Or building a kiln? I suggest you spend time on material selection. It matters more than you think.

Make the right choice today. You’ll get safer operations. You’ll cut maintenance costs. And you’ll see better performance down the road.