Industrial ceramic filters are now essential in many Australian industries. I’ve seen their strong stability, fine filtration ability, and wide use across sectors like water treatment, metal casting, mining, and food processing.

Manufacturers choose ceramic filters made from alumina, zirconia, and silicon carbide. These materials resist high temperatures, harsh chemicals, and tough mechanical conditions better than traditional polymer filters. Based on my experience, this makes them a superior choice.

Industrial Ceramic Filter Technology in Australia

Ceramic filters in the Australian market are built for precision. They cover a broad industrial filtration range:

– Microfiltration: stops particles between 0.1–1.4 microns (μm)

– Ultrafiltration: targets 15–300 kilodaltons (kDa)

– Nanofiltration: removes contaminants sized 1–10 kDa

Filteroo® Joey 12L Gravity Ceramic Water Filter

Key Features & Specifications

Total Capacity: 12.4 litres (3.4L top tank, 9L bottom tank)

Dimensions: 540mm height, 236mm diameter at base; fits well on kitchen counters or office tables

Materials: Handcrafted, glazed stoneware clay—lead and cadmium-free, non-toxic

Included Filtration:

- Filteroo® 5.5″ slow flow carbon block gravity cartridge

- This cartridge removes chlorine, chloramine, lead, bacteria, and cysts

- You can add the Ultraceram gravity candle to filter fluoride

- Labs tested and certified each cartridge for safe contaminant reduction

Filtration Performance

The filter removes many common contaminants, better contaminant removal means better water hydration, you can get safe, clean drinking water, this supports your gut health. I like that it keeps essential minerals for better health and taste.

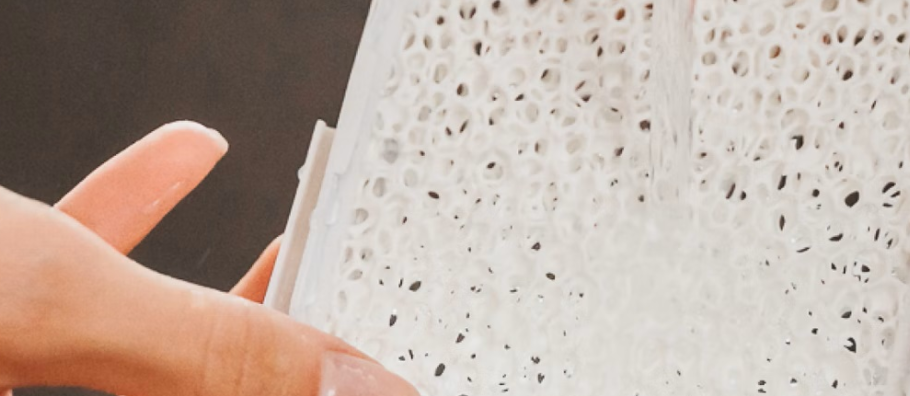

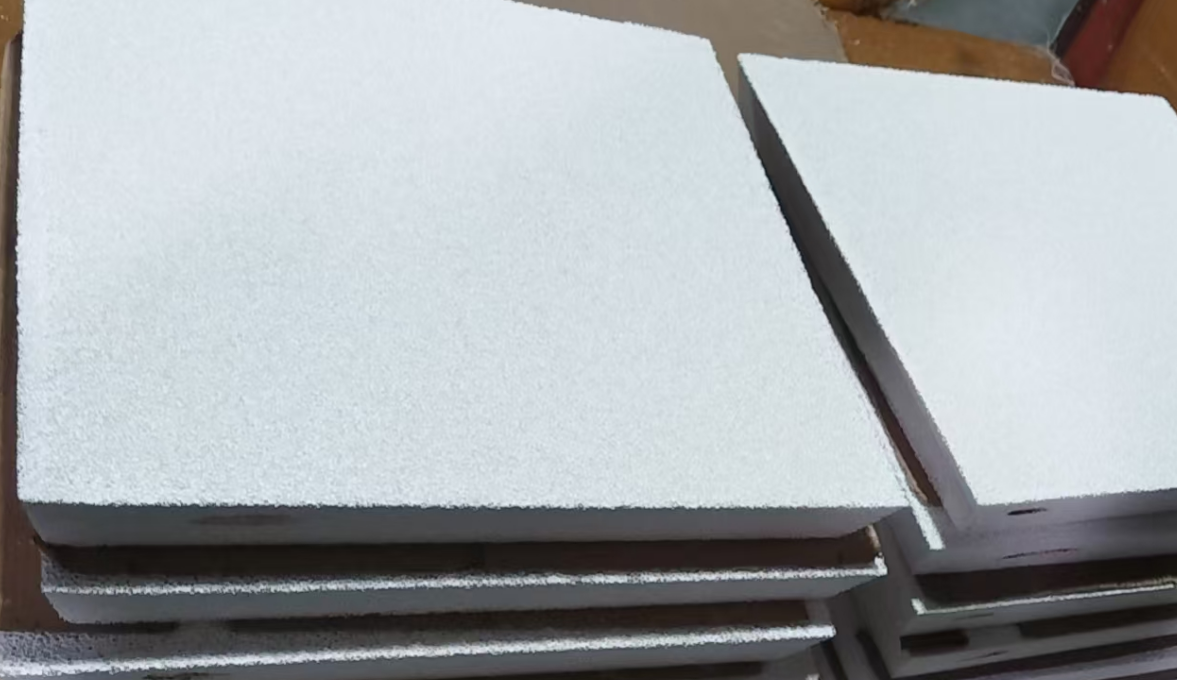

M-Kube Alumina Foam Filter – High-Temperature Ceramic Filtration for Metal Casting

I recommend the M-Kube Alumina Foam Filter for tough molten metal filtration jobs in Australian foundries. It works well for the wider casting industry too. This filter uses premium alumina ceramic (Al₂O₃). It removes impurities with high purity and efficiency. You can use it for ferrous and non-ferrous metal castings. You can get custom shapes, sizes, or purity levels.

Key Applications in Industry

- Molten aluminum, copper-based alloys, and ferrous metals (grey iron, ductile iron, steel alloys)

- High-temperature gas filtration

- Chemical processing: catalyst carriers, chemical fillings

Performance Benefits & Real-World Results

It removes large and fine impurities from molten metals, promotes laminar flow and cuts down turbulence. This reduces casting defects and supports better-quality castings.

Chemical and thermal stability keeps the filter strong in harsh foundry conditions.

Summary Table of Core Technical Specifications & Material Performance

| Property | Value/Detail |

|---|---|

| Alumina (Al₂O₃) Content | ~85% |

| Maximum Temperature | ≤1200°C |

| Porosity | 80–90% |

| Compression Strength | ≥1.0 MPa (RT) |

| Volume Density | ≤0.5 g/cm³ |

| Thermal Shock Resistance | 800°C to Room Temp x 5 cycles |

| Custom Options | Yes, on request |

Based on my experience, the M-Kube Alumina Foam Filter leads the Australian industrial ceramic filter market. It offers strong performance. You get flexible customization. I like how it delivers clear benefits for advanced foundry operations.

Southern Cross Pottery Carbon Ceramic Filter

Advanced Filtration Technology & Performance

The Southern Cross Pottery Carbon Ceramic Filter uses a micro-porous ceramic wall with 0.2 micron pore size. It also has an activated coconut shell carbon core. I like how this design provides excellent water purification:

- Removes up to 99.99% of bacteria, cysts, and suspended solids

- Particle removal: 100% efficiency at 0.9 microns (absolute), >98% at 0.2 microns, >90% at 0.05 microns

- Turbidity reduced to below 0.07 NTU

- The activated carbon core absorbs chlorine, fluoride, ammonia, organic chemicals, odors, and tastes

The ceramic contains silver. This creates a strong anti-bacterial barrier. It stops bacteria from growing inside the filter and in stored water. You don’t need chemical sterilization.

Longevity, Maintenance & Durability

- Filter lifespan: Up to 2,000 litres of purified water (I suggest you replace it every 6 months for best results)

- Usage period: 6–12 months, depending on water quality

- Handcrafted ceramic housing: Fired at 1305°C for strong durability

- Glazed interior: Easy to maintain and clean

You don’t need power, and there’s no water waste or chemicals. This gravity-fed filter is efficient and cost-effective. It’s also eco-friendly.

Health, Practical Benefits & Recognition

- Keeps beneficial minerals—filtered water retains natural minerals

- Military, aid agencies, missionaries, and disaster relief teams use this filter. They trust it for safe, reliable water even in tough environments

- Works with municipal, tank, or alternative water supplies. It doesn’t lose efficiency

British Berkefeld (Doulton) Ultra Fluoride Filter

Top Performance for Fluoride & Heavy Metals Removal

I recommend the British Berkefeld (Doulton) Ultra Fluoride Filter for cleaner water in Australia. It removes up to 98.9% of fluoride. This includes both natural and added types. I find this makes it one of the best ceramic fluoride filters you can buy.

This filter also removes many other harmful substances:

– Sediment, silt, dirt, bugs, cysts, and bacteria

– Chlorine and chloramine

– Heavy metals: arsenic, barium, chromium, lead, selenium, mercury

– Herbicides and pesticides

– Pharmaceuticals

– Giardia cysts

– Microplastics

Based on my experience, this filter helps protect your health. It cuts down exposure to industrial and farm pollutants.

This ceramic filter works with many popular gravity systems:

– Fits these brands: Filteroo Steel/Ceramic, Berkey, Phoenix, Purewell, Newton, Southern Cross Pottery, ProOne. It fits most systems with holes larger than 12.5 mm.

Why I Suggest the British Berkefeld (Doulton) Ultra Fluoride

I suggest this filter based on test data and what users say.

It performs well for fluoride removal. I find it valuable for Australian homes and offices. It reduces heavy metals, pesticides, pharmaceuticals, and microplastics. At the same time, it keeps beneficial minerals.

The certifications are strong. It fits many systems. Maintenance is easy. Based on my research, it is a practical and smart choice among industrial ceramic filters.

TFIFiltration Porous Ceramic Filter Cartridge

Key Features and Technical Details

I recommend the TFIFiltration Porous Ceramic Filter Cartridge for its porosity up to 40%. It works well in tough industrial settings. The cartridge keeps a rigid, self-supported cylindrical shape. This shape holds up even during heavy use. You can choose from standard thicknesses: 10 mm, 15 mm, and 20 mm. These sizes fit various industrial setups.

Filtration Precision: Ranges from 0.2, 1, 5, 10, 25, 50, to 100 microns. You get both fine and coarse filtration. This helps meet different operational needs.

Material and Structural Capabilities:

– High chemical resistance: Handles both acidic and alkaline fluids

– Max. working temperature: Up to 950°C

– Max. working pressure: 0.6 MPa

– Precision: As fine as 0.2 microns

– Shape options: Mostly cylindrical

– Color options: White (common), brown, grey

You can clean and reuse these cartridges. This cuts lifecycle costs in busy operations. Based on my experience, the sintered ceramic structure provides great burst and tensile strength. The filter stays stable under high temperatures and pressures.

Industrial Uses and Real-World Examples

I suggest the TFIFiltration cartridge for tough settings. It works well in chemical processing, pharmaceuticals, petrochemicals, electronics, and the food industry. The cartridge resists harsh chemicals. It also delivers high purity. This makes it ideal for air, gas, and liquid filtration. You can use it for steam filters, solvent filters, catalyst filters, and vent filtration.

Waters Co BIO 1000 Bio Ceramic Filter

I recommend the Waters Co BIO 1000 Bio Ceramic Filter for its 15-stage filtration system. It offers excellent water purification in Australia. You can use it at home or in industrial settings.

Key Features & Technical Specifications

Filtration Stages: 15 stages. These include submicron pre-filtration, silver ionised carbon, ion exchange resin, coral minerals, bio-ceramic, far infrared diskettes, and magnets.

Contaminant Removal Rate: Removes up to 99% of sediment, bacteria, cysts, chlorine, chemicals, heavy metals, fluoride, odours, and microplastics.

Filtration Fineness: Filters down to 0.1 microns. It targets microplastics and ultra-fine particles.

Capacity & Dimensions:

- Maximum filtered water: Up to 15,000 litres or 5 years per filter kit. This depends on usage and water quality.

- Reservoir: 10 litres, made from hand-blown blue silica glass.

- Physical size: 485 mm height × 305 mm diameter; weight: 6.4 kg.

Replacement & Warranty:

- Filter kit lifespan: 36–60 months for typical municipal water.

- Warranty: Lifetime coverage.

Cost Efficiency: Each litre of purified water costs about 3 cents.

Filtration and Remineralisation Technology

- Submicron pre-filter: Traps sediment, bacteria, rust, and high-level copper particles.

- Activated silver ionised carbon: Absorbs chlorine, THMs, pesticides, and heavy metals. It adds trace minerals for freshness and taste.

- Ion exchange resin: Removes up to 99% fluoride. No activated alumina is used.

- Coral mineral and silica sand filtration: Adds over 60 trace minerals. This boosts alkaline levels in a safe way.

- Bio-ceramic & far infrared stages: Keep water fresh. They prevent bacterial growth. They balance pH to a light alkaline level.

- Magnets & organic germanium: These claim to boost water “energy” and bioavailability. Research on these effects continues.

Based on my experience, this model uses strong ceramic technology with good mineralization and alkalization. It leads among industrial ceramic filters in Australia. I like it for those who want strong purification with little ongoing effort.

Clean & Clear Ceramic Water Filter Cartridge

I recommend the Clean & Clear Ceramic Water Filter Cartridge for large-scale and industrial water filtration in Australia. It combines strong construction, effective contaminant removal, and easy servicing. This section reviews its advantages for high-capacity environments and commercial water quality systems.

Filtration Performance & Capacity

Particle Filtration: This filter captures particles as small as 20–30 microns. It offers strong protection against dust, sediment, and large contaminants in municipal and industrial water supplies.

High Filtration Area: Models such as the CC150 feature an 150 ft² effective filtration area.

Flow Rate & Turnover: The system supports up to 150 gallons per minute (GPM). A single unit can process 72,000 gallons in 8 hours or 90,000 gallons in 10 hours.

Consistent Performance: The cartridge surface delivers consistent blocking. It minimizes bypass. It maximizes filtration across the surface area.

I’ve seen this filter used in commercial pool systems, industrial water purification, and high-demand residential setups. You can incorporate it into multi-stage water systems with chrome taps (ceramic disc operation). This gives you direct access to filtered water.

Australian Ceramic Foam Filter (AlAlloyCasting)

Advanced Ceramic Foam Filter Technology for Aluminum Casting

The Australian Ceramic Foam Filter (AlAlloyCasting) is built for precise aluminum and aluminum alloy purification. I recommend it for foundries and industrial casting operations. This filter combines corundum and silicon carbide. The materials form through advanced ceramic methods. You get a filter with excellent mechanical strength. It offers thermal stability up to 1350°C. It performs well in tough environments.

Performance & Industrial Benefits

Three-dimensional mesh design: This design maximizes surface area. The filter captures both large and tiny inclusions. I find this feature very useful.

Effective impurity removal: It removes up to 95% of fine particles from molten aluminum. You get cleaner metal. Casting defects decrease.

Improves flow and reduces turbulence: The filter stabilizes the laminar flow of molten aluminum. Turbulence decreases. Slag is eliminated. The casting process runs smoothly.

No contamination risks: The ceramic foam does not add slag or unwanted substances. Your melt stays pure.

Consistent quality: Automated processes produce these filters. Dimensions are precise. Performance is repeatable. I trust this consistency.

Application Areas

- Primary aluminum ingot production

- Aluminum rod, plate, and coil manufacturing

- Aerospace and automotive castings: Use it for precision parts. Examples include jet turbine engine fan blades, automotive transmission cases, and wheel hubs.

- Electronics industry: It filters materials for computer hard disks, printing PS board bases, and high-grade can materials.

Installation, Usage & Flow Rates

Installation:

- Always install in a CFF (ceramic foam filter) filter box.

- Preheat the filter plate to at least 260°C before pouring metal. This step is critical.

- Seal the filter with a ceramic fiber gasket. This prevents leaks.

- Maintain a stable hydraulic head. This ensures optimal filtration flow.

Typical filtration flow rates by size:

| Filter Size | Flow Rate (kg/min) |

|---|---|

| 7″ | 22–56 |

| 9″ | 25–80 |

| 12″ | 50–156 |

| 15″ | 85–252 |

| 17″ | 110–335 |

| 20″ | 160–478 |

| 23″ | 210–640 |

| 26″ | 276–830 |

Ceramic Foam Filter for Tiwai Aluminium

The Ceramic Foam Filter for Tiwai Aluminium works well for high-end aluminium alloy casting. It made of High-grade alumina (Al₂O₃) ceramic. It has great strength, resists erosion, and handles thermal shock well.

I’ve seen it used in aviation, automotive, and electronics industries. The filter uses careful engineering and strong materials. This means it delivers excellent filtration for quality metal products.

Key Sizes, Shapes & Pore Options

Standard Sizes: 7×7in, 9×9in, 12×12in, 15×15in, 17×17in, 20×20in, 23×23in, 25×25in, 26×26in

Thickness: 50 ± 2 mm

Available Shapes: Square, rectangular, round, trapezoidal, plus custom sizes

Mesh/Pore Density (PPI): 10–90 PPI; choose your PPI based on filtration needs. Sample pore density:

- 20 PPI: ~18–22 window pores (captures 80 μm inclusions at 78% efficiency)

- 30 PPI: ~28–32 pores (captures 40 μm at 85%)

- 40 PPI: ~38–42 pores (20 μm at 88%)

- 50 PPI: ~48–52 pores (10 μm at 92%)

- 60 PPI: ~58–62 pores (5 μm at 95%)

Application & Case Example

Best for: High-purity aluminium alloy casting. Continuous and semi-continuous casting. Production of rods, ingots, coils. Aerospace, automotive, and precision electronics

I recommend the Ceramic Foam Filter for Tiwai Aluminium if you want top filtration standards and better alloy quality. Based on my experience, the proven data, durability, and process fit make it a benchmark solution in modern aluminium production.

Adtech Ceramic Filter

The Adtech Ceramic Filter works well for industrial casting and molten metal filtration in Australia. I like its strong build, high porosity, and how it fits demanding aluminum alloy manufacturing.

Technical Specs & Key Features

Standard Sizes: You can get sizes from 178×178×50 mm up to 584×584×50 mm (this covers 7–26 inch range).

Custom sizes and shapes are made to fit your unique foundry needs.

Pore Size Options: You can select porosity between PPI 10 and PPI 60. Higher PPI gives you finer filtration. This means cleaner metal.

Mechanical & Thermal Performance:

- High compressive strength keeps it durable during handling and operation.

- It handles rapid thermal cycling during preheating and casting.

- It stays effective over repeated use.

Physical Configuration:

- Most filters come in square shapes. Custom profiles are available.

- Flatness and size tolerances ensure proper seal and fit in filter boxes.

Application Cases & Practical Value

- Used across Australian aluminum smelters, die-casting plants, and large foundries.

- Filters fit in automated or manual filter boxes. This gives you precise, safe filtration.

- Customers like easy cleaning, low resistance, and proven impurity capture during tough production runs.

Comparison Table of the Best Industrial Ceramic Filters in Australia

This table compares top industrial ceramic filter products in Australia. I’ve included sales data, average prices, core technical features, and cartridge lifespan. This helps you pick the right filter for tough water or metal processing work.

| Product Name | Avg. Rating | Sales Volume | Price Range (AUD) | Key Features | Cartridge Life | Supplier/Brand |

|---|---|---|---|---|---|---|

| 10PPI Silicon Carbide Foam Filter | — | 50,000/month | $1.5/filter | High porosity, foundry use | — | Guangzhou Chemxin Env. Material Co., Ltd. |

| High-Strength Ceramic Water Filter | — | 325/month | $0.85–1.0/filter | 5–8 stages, direct drinking | — | Pingxiang Bestn Chemical Packing Co., Ltd. |

| Alumina Ceramic Foam Filter | — | 150/month | $0.1–8.0/filter | Wear-resistant, 5–80 PPI | — | Pingxiang Bestn Chemical Packing Co., Ltd. |

| Elite Series 5Q Wellness System | — | — | $3,995/system | 5-stage, marine-grade steel | 12+ months | Great Water Filters AU |

| Generic Whole House System | — | — | $4,500/system | 3-stage, plastic/powdercoated | 6 months | Market average |

| MCC Ceramic Filter Candle | — | — | — | High flow rate, less E. coli removal | — | Madhyapur Clay Craft |

| Puro Filter Candle | — | — | — | Highest E. coli, coliform removal | — | Puro |

| Surya Filter Candle | — | — | — | Moderate bacteria removal | — | Surya |

Example Use Cases

- Foundry sector: Many foundries now use silicon carbide and alumina foam filters. They improve molten metal quality. High sales show how essential these are.

- Homes and offices: I see more people choosing multi-stage ceramic or hybrid filters like Elite 5Q. They protect the whole house. They last longer and cost less over time.

- Industrial casting: Factories use custom, high PPI ceramic filters. These resist wear and remove impurities with precision. They’re key for top-quality metal products.

Based on my experience, most Australian suppliers help industrial buyers with technical advice, product demos, and maintenance plans. You might need custom filters for foundries, high-flow water systems, or specialized industrial processes. These channels offer reliable products with expert support. I suggest you contact them directly to discuss your specific needs.