Industrial ceramic filter materials separate and retain particles in gases and liquids. I find the core materials—alumina (Al₂O₃), silicon carbide (SiC), titania (TiO₂), and zirconia (ZrO₂)—bring unique traits to each filter design. These include thermal resistance, chemical stability, and mechanical strength.

Industrial ceramic filter materials stand out for good reasons. They have advanced chemistry, customizable pore structure, and adaptability. I believe these qualities make them perfect for modern industrial, environmental, and technological filtration challenges. Their thermal and chemical resistance, high mechanical strength, tunable porosity, and innovative design options keep them in high demand for critical process applications.

Alumina (Al₂O₃) – Properties, Performance & Applications

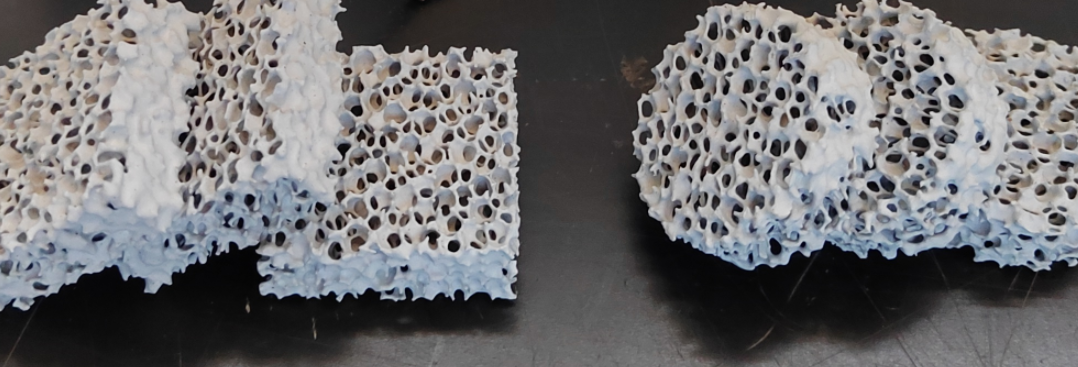

I recommend Alumina (Al₂O₃) as a top choice for industrial ceramic filter materials. It offers high-temperature resistance, chemical inertness, and mechanical strength. Its open-cell porous structure performs well in tough environments.

Major Industrial Applications of Alumina Ceramic Filters

- Metal Filtration: Used often in aluminum, copper alloy, and iron casting. Foam filters install in gating systems. They trap inclusions and reduce gas content.

- Catalyst Carriers: I’ve seen it support chemical reactions well. Its chemical inertness and stable structure help.

- Thermal Insulation: Used in kilns, furnaces, and high-temperature reactors. Its low thermal conductivity and heat resistance make it ideal.

- Wear-Resistant Parts: It forms heavy-duty tools, tiles, guides, and discs. These parts endure harsh wear.

- Electronics: Acts as a substrate and insulator. Its dielectric and electrical properties support this.

- Environmental and Energy: I suggest it for catalytic converters, solar energy systems, and special filtration. Examples include battery production and 3D printing powders.

Filtration Performance & Real-World Case

Example from Aluminum Foundries:

Alumina foam filters (e.g., AC2323 type, 85% Al₂O₃) are placed before the casting mold. Results:

– Big drop in inclusion content in molten metal. After filtration, it usually falls to <50 ppm.

– Better mechanical properties in cast products. I’ve noticed a clear rise in tensile strength and elongation.

– Steady flow and minimal clogging. This allows for high throughput production.

– Over 30% lower rework rates. This raises efficiency and cuts casting costs.

I like its versatility and light weight makes filter installation and change-out easier. It serves many industries: metalworking, electronics, environmental clean-up, and catalytic processing. It delivers superior filtration through interconnected pores, handles extreme heat and thermal shocks well. It resists corrosion from chemicals and oxidizing agents.

Typical Physical Properties of Alumina Ceramic Filters

| Property | Foam Alumina | Bulk Alumina |

|---|---|---|

| Main Composition | 85% Al₂O₃ | 99% Al₂O₃ |

| Porosity | 80–90% | <2% |

| Density | ≤0.5 g/cm³ | 3.75–3.95 g/cm³ |

| Compression Strength | ≥1.0 MPa | 2,000–4,000 MPa |

| Max Temperature | 1200°C (foam type) | up to 1500°C |

My evaluation: Alumina (Al₂O₃) sets the benchmark for ceramic filter materials. Based on my experience, the alumina ceramic brings strong strength, thermal stability, chemical inertness, and efficient filtration. I see it as the go-to solution for the toughest industrial filtration jobs.

Zirconia (ZrO₂) – High-Performance Ceramic Filters for Extreme Applications

I recommend Zirconia (ZrO₂) as a top-tier industrial ceramic filter material. It performs well in extreme temperatures and tough conditions.

Performance Advantages and Filtration Efficiency

-

High-temperature resistance: This material maintains its integrity in molten steel and high-alloy casting. Operating temperatures often exceed 1500°C in these applications.

-

Removal of non-metallic inclusions: The filters deliver superior casting quality. They filter out impurities and reduce gas content in the metal stream.

-

Reduces casting defects: Zirconia promotes smooth flow and consistent metal distribution. This leads to fewer welds, cracks, and inclusions in your final product.

-

Strong and durable: High strength enables repeated handling. You get consistent performance during production.

-

Thermal shock tolerance: I’ve seen these filters perform reliably during rapid temperature changes in demanding foundry cycles.

-

Chemical stability: Zirconia remains inert in aggressive foundry and metallurgical environments. This includes exposure to molten steel, nickel, and cobalt alloys.

Applications and Industry Examples

Steel and Alloy Foundries: I suggest using these filters for all grades of steel. This includes unalloyed to stainless and high-alloy steels. They work in both ingot casting and investment casting processes.

Superalloy Casting for Aerospace and Automotive: Zirconia filters are crucial in casting nickel- and cobalt-based superalloys for demanding sectors. Turbine blade producers report increased casting yield. They also see lower defect rates. The metallurgical quality improves thanks to zirconia’s filtration precision.

Automotive and Precision Components: Zirconia filters reduce surface defects in the production of engine parts, valves, and critical safety elements. They also reduce inclusion-related rejects. This leads to less downstream machining. Your end products become more reliable.

High-Temperature Gas Filtration and Catalytic Applications: The chemical process industry and environmental protection fields use these filters. Zirconia supports reliable, high-efficiency filtration even at elevated process temperatures.

Comparative Performance—Why Choose Zirconia?

Based on my experience, here’s why I recommend zirconia:

- Higher operating temperature capacity than alumina or SiC filters

- Better corrosion and thermal shock resistance

- Best for critical applications where casting purity is essential

Zirconia Ceramic Filter Properties Overview

| Property | Typical Value |

|---|---|

| ZrO₂ Content | 85–90% |

| Porosity | 80–90% |

| Pore Density | 10–40 PPI |

| Max. Operating Temperature | 1700°C |

| Bulk Density | 0.8–1.5 g/cm³ |

| Compressive Strength | ≥1.5 MPa |

| Thermal Shock Resistance | ≥6 cycles at 1100°C |

| Available Sizes | 40–600 mm |

| Color | Yellow |

| Certifications | ISO 9001:2015, REACH, RoHS |

My evaluation: I believe Zirconia (ZrO₂) ceramic filters set the industry standard for high-temperature filtration. They excel in defect control and critical process reliability. In my experience, if your application demands the best in thermal, chemical, and structural performance—for high-value alloys and steel—zirconia is the proven choice. I recommend it for your most demanding applications.

Titania (TiO₂) – High Chemical and Photocatalytic Performance for Industrial Filtration

I recommend Titania (TiO₂) for industrial ceramic filters. It offers strong chemical resistance, thermal stability, and unique photocatalytic properties.

Key Properties and Technical Data

Operating Temperature: Stable up to 800°C; effective filtration up to 300°C

Chemical Resistance: Performs across the full pH range (0–14)

Mechanical Strength:

- Flexural strength: 50–100 MPa

- Compressive strength: 1000 MPa

- Hardness: 9.3–10.3 GPa

- Modulus of elasticity: 230–290 GPa

- Density: 3.84–4.23 g/cm³

- Fracture toughness: 2–3 MPa·m½

Electrical Properties:

- Dielectric strength: 8–10 MV/m

- Dielectric constant: 20–100

- Volume resistivity: 10¹⁰–10¹⁴ Ω·m

Hydrophilicity: Strong water affinity boosts filtration rates and flux

Advanced Functional Advantages

Photocatalytic Activity:

- Enables “self-cleaning” under UV light. It breaks down organic contaminants.

- Reduces maintenance. Extends membrane life.

High Flux and Rejection Efficiency:

- Multilayer TiO₂ nanofiltration membranes filter ions and organics selectively.

- Composites like TiO₂–Al₂O₃ and TiO₂–ZrO₂ membranes create smaller pore sizes. They achieve high rejection rates.

Controlled Microstructure:

- Maintains consistent homogeneity.

- We fabricate membranes on supports such as mullite, alumina, or α-Al₂O₃. This enhances durability and performance.

Main Industrial Applications and Performance Examples

Municipal and Industrial Wastewater: Removes organic matter, chloride ions, and oil pollutants from harsh effluents.

Pre-filtration for Reverse Osmosis: Works well as pre-filters. It resists fouling and maintains high permeate flux.

Additional Uses: Environmental cleanup. Outdoor filter elements (UV resistant). Biomedical and dental ceramics (biocompatible). White, opaque glaze additives for technical ceramics

Practical Considerations: Cost and Scalability

Costs: More expensive than alumina. This is due to advanced fabrication and functional benefits. The higher initial cost makes sense. It offers longer operational life and less downtime. The self-cleaning properties reduce maintenance.

Silicon Carbide (SiC) – Built for Extreme Conditions & Top Performance

I’ve worked with many industrial filter materials. Silicon Carbide (SiC) is one of the best ceramic filter options available. It offers great heat resistance, strength, and chemical durability.

Core Properties & Technical Data

Maximum Operating Temperature:

- Foam filter types reach 1600°C

- Industrial gas filtration membranes handle 800°C

- It can handle direct contact with molten metals and high-temperature process streams

Chemical Resistance:

- Stable and inert across pH 0–14

- Resists strong acids, alkalis, and oxidizers like ozone and hydroxyl radicals

- Stands up to corrosive industrial gases and liquids

Performance Advantages & Unique Surfaces

Hydrophilic, Oil-Repelling Surface:

- Contact angle as low as 0.3° creates strong water affinity

- Enables ultra-fast flux and effective oil–water separation

- Anti-fouling properties allow rapid cleaning after backwash

Electrical & Thermal Conductivity: Good conductivity opens uses in heating, sensing, and energy recycling systems

Form Factors:

- Open-cell foam ceramics work well for metal filtration

- Tubes, planar membranes, and multi-channel/honeycomb monoliths suit industrial water, gas, or chemical separation

- High-purity sintered modules provide great durability and chemical resistance

Industrial Applications & Case Studies

- Common in aluminum, copper, and iron alloy foundries

- Catches non-metallic inclusions

- Increases casting purity

- Reduces defects and porosity in cast products

High-Temperature Industrial Gas Filtration:

- Power plants use SiC honeycomb filters for flue gas cleaning (over 1000°C)

- Traps fine particles, heavy metals, and acid gases

- Reduces emissions at a lower cost

Water and Wastewater Treatment: I recommend SiC for tough process waters (high-salinity, corrosive, oil-containing) and chemical plant effluents. Pure SiC membranes stay stable and efficient for over a decade in harsh environments.

Chemical and Petrochemical Processing: SiC resists catalyst poisons and solvents. This makes it ideal for catalyst supports, reaction filters, and process fluid purification

Major Silicon Carbide Filter Types

- Foam ceramic filters (foundries, casting)

- Tubular or planar ceramic membranes (wastewater, ultrapure water, chemical processing)

- Honeycomb/monolithic supports (gas, energy applications)

- Catalyst supports (chemical, petrochemical industries)

Application Industries

Users of SiC filter technology include:

– Foundries and metal casting plants

– Chemical manufacturing

– Power generation (flue gas cleaning)

– Water and wastewater treatment

– Oil & gas operations

– Mining, electronics, food & beverage, and aerospace sectors

My evaluation: Based on field data and real industrial practice, I believe Silicon Carbide (SiC) filter materials offer top performance for high-temperature, high-corrosion, and long-life filtration needs. Do you need maximum durability, ultra-high flux, and reliability in harsh process environments? I suggest choosing SiC. It provides great long-term value and technical results.

Silica (SiO₂) – Nano-Engineered Filters for Better Thermal Shock and Strength

I recommend Silica (SiO₂) for industrial ceramic filter work. It offers low density, high mechanical strength, and strong resistance to thermal shock. This material gives you solid structure and good fluid flow at the same time.

Boron Nitride (BN) – High-Performance, Non-Wetting Ceramic Filters for Extreme Environments

Boron Nitride (BN) excels in industrial ceramic filtration. It offers unique thermal, electrical, and chemical properties. I recommend BN when you need high purity, non-reactivity, and durability in harsh conditions.

Purity Grades and Material Types

- Hot-Pressed BN (HPBN): ≥99% purity, standard for machining and insulation.

- High-Purity BN: ≥99.5% or ≥99.6%, optimized for thermal and electrical reliability.

- Pyrolytic BN (PBN): ≥99.99% purity; made by CVD for ultra-smooth, binder-free dense ceramics.

- Commercial Grades: HBN uses boron oxide binder and works up to 550–850°C. HBR uses calcium borate binder and works up to 1600°C. HBC/HBT is binder-free and supports up to 3000°C in vacuum.

Industrial Applications

Furnace Crucibles & Melt Handling: BN’s non-wetting nature stops molten metals or glass from sticking. Many advanced metallurgy facilities use it.

High-Temperature Insulators: BN works well for heat shields, infrared windows, and thermal-shock resistant parts.

Electronics & Semiconductors: I’ve seen BN used as ultra-clean insulators in high-vacuum, high-temperature semiconductor and aerospace setups.

Microwave, Sputtering, and Heat Sinks: BN’s dielectric and thermal qualities suit demanding components in electronics and energy sectors.

Composite/Hybrid Ceramics: Adding BN to silicon nitride or alumina boosts thermal shock resistance. This improves reliability and lifespan in harsh industrial filter and lining applications.

Example: BN Filter Material Properties

| Property | Typical Value (High-Purity BN) |

|---|---|

| Purity | ≥99.6% |

| Density | 1.6 g/cm³ |

| Bending Strength | 18 MPa |

| Compressive Strength | 45 MPa |

| Thermal Conductivity | 35–751 W/m·K |

| Max. Operating Temp | up to 3000°C (vacuum, by grade) |

| Electrical Resistivity | Very high |

| Hardness (Mohs) | ~4 |

| Machinability | Excellent |

| Non-wetting | Outstanding |

Distinct Advantages and Evaluation

BN performs at extreme temperatures in both vacuum and controlled-atmosphere processing. it resists chemical attack from acids, molten metals, and slags. It outperforms typical ceramic filter materials. Molten substances don’t affect BN. It won’t wet, clog, or stick. This maximizes filter service life and reliability. BN is easy to machine. You can create intricate custom filter geometries and components for high-spec processes.

Aluminum Nitride (AlN) – High-Thermal Conductivity Ceramic Filters for Advanced Industrial Filtration

I find Aluminum Nitride (AlN) to be a premium ceramic filter material. It offers great thermal conductivity, strong electrical insulation, and solid mechanical strength.

Core Advantages and Industrial Comparisons

- Non-toxic (I suggest it as a safe alternative to beryllium oxide)

- Superior thermal conductivity

- No other advanced filter ceramic except BeO offers better heat dissipation

- High-temperature endurance is great

- Thermal shock resistance is excellent

- Surface oxidation at 700°C in air may affect performance

- Protective coatings are often used

- Machining requires specialized diamond tooling

- Grades like Shapal Hi-M Soft allow easier shaping for complex geometries

Performance Summary and Evaluation

I recommend Aluminum Nitride (AlN) for rapid heat dissipation and reliable electrical insulation. You get both in one material. Based on my experience, power electronics, lasers, aerospace, and advanced filtration systems prove its value. The price is higher than alumina. But the performance leap is huge for miniaturized and high-density devices. Your process demands the best in thermal management and insulation? AlN is unmatched in the industrial ceramic filter field.

Beryllium Oxide (BeO) – Top Heat Transfer and Electrical Protection for Extreme Filters

I recommend Beryllium Oxide (BeO) as a leading industrial ceramic filter material. It offers great heat transfer, strong electrical insulation, chemical resistance, and mechanical strength.

Key Physical and Performance Properties

Thermal Conductivity: BeO delivers up to 330 W/(m·K) in high-purity grades (B-99, ≥99%). This beats alumina (~30 W/m·K), silicon (~150 W/m·K), and aluminum nitride (AlN, ~170 W/m·K). It allows fast, efficient heat removal in compact and high-power electronics.

Electrical Insulation:

- Resistivity >10¹⁴ Ω·cm at room and high temperatures.

- Dielectric constant ≈ 6.7; loss tangent tanδ ≈ 0.0003. This is ideal for reducing signal loss in RF and microwave filters.

- It works well in high-voltage, high-frequency, and harsh industrial settings.

High-Temperature Stability: BeO stays stable up to 1,800°C in inert or vacuum processing. It works up to 1,650°C in oxidation. Melting point: Around 2,575°C. Perfect for ultra-high-temperature filter parts.

Chemical Durability: BeO resists most acids, alkalis, and molten metals under normal use. It stays stable in tough chemical filtration. But avoid water vapor above 1,000°C.

Density and Weight:

- ~3.02 g/cm³. Lighter than most ceramics.

- I like this for aerospace, defense, and lightweight electronic assemblies.

Mechanical Strength: High Young’s modulus gives resistance to thermal shock and mechanical stress. It keeps its shape and structure during rapid heating and cooling cycles.

Major Industrial Applications of BeO Ceramic Filters

-

High-Power Electronics: Heat removal substrates for power semiconductors, laser parts, and RF modules.

-

Microwave and Communication: Electrical insulators in microwave packaging, radar, and satellite communication.

-

Aerospace and Defense: High-performance thermal interface modules and lightweight thermal control units.

-

High-Temperature Systems: Used in lasers, vacuum tube insulators, nuclear energy filters, and high-purity crucibles for advanced process industries.

-

Sensor and EMC Systems: High-purity BeO ceramics for stable, quick performance in sensor housings and electromagnetic compatibility solutions.

I suggest BeO where rapid heat removal and electrical isolation are critical. This is true for RF, high-frequency, and high-power filtration challenges. Does your application demand industrial ceramics with the highest thermal performance, chemical reliability, and precise electrical insulation? Then BeO is worth the higher cost and strict handling. Based on my experience, BeO pays off in maximum performance and reliability.

Magnesium Aluminate Spinel (MgAl₂O₄) – Advanced Ceramic Filter Material for Chemical and Thermal Endurance

I recommend Magnesium Aluminate Spinel (MgAl₂O₄) as a top-tier ceramic filter material. It offers excellent chemical stability, heat resistance, and mechanical strength. I suggest using it for processes that need to stand up against harsh chemicals and extreme heat.

| Property | MgAl₂O₄ Spinel | Magnesia (MgO) | Alumina (Al₂O₃) |

|---|---|---|---|

| Density (g/cm³) | 3.58–3.64 | ~3.58 | ~3.98 |

| Melting Point (°C) | 2130–2135 | ~2800 | ~2050 |

| Chemical Resistance | Excellent | Good | Excellent |

| Optical Transparency | Possible (dense) | No | Yes (dense) |

| Particle Size (nano) | <50 nm | Variable | Variable |

This allows MgAl₂O₄ to work well in high-temperature filtration. It goes well above standard alumina’s limits. You can get both dense and porous ceramics. This means you can match the filter to your specific industrial needs.

Filtration Performance & Industrial Endurance

Chemical Resistance: This material lasts a long time when exposed to acids and bases. The filters resist breakdown under harsh chemical attack. For alloy melt filtration (like magnesium refining), spinels beat magnesia alone. They offer higher stability, better long-term performance, and lower contamination risk during continuous casting.

Mechanical Strength: Periclase–MgAl₂O₄ foam filters (with 30 wt% fused MgO) have a cold compressive strength of 0.68 MPa. This meets industrial filter needs.

Yttrium Aluminum Garnet (YAG) – Advanced Ceramic Filter Material for Laser and Optical Applications

I believe Yttrium Aluminum Garnet (YAG) represents the next generation of industrial ceramic filter materials. It excels in sectors that need top optical and thermal performance. YAG combines broad transmission range, high thermal conductivity, and strong mechanical strength. This makes it unique among industrial ceramic filters.

Manufacturing Scalability and Processing Advantages

- Polycrystalline YAG Ceramics: These now match single crystal YAG in transparency. They can be produced in large substrate sizes up to 6 inches. This opens new possibilities for industrial-scale optical filtering.

- Production Techniques: I recommend advanced methods like liquid phase epitaxy (LPE), sol–gel with centrifugal spinning, heat/tube collapse, and melt-in-tube. These allow precise control over purity and dopant profiles. They deliver high mass productivity. They increase yields. They reduce contamination risk.

- Process Efficiency: Polycrystalline ceramics simplify grinding and scalability. This makes them attractive for cost-effective mass production of industrial ceramic filters.

Comparative Table: Single Crystal vs. Polycrystalline YAG

| Property | Single Crystal YAG | Polycrystalline YAG |

|---|---|---|

| Max Substrate Size | Limited | Up to 6 inches |

| Transparency | Excellent | Equivalent |

| Mass Productivity | Low | High |

| Dopant Distribution | Often Uneven | Even |

| Mechanical Toughness | Lower | Higher |

| Ease of Bonding | Challenging | Easy |

| Production Yield | Lower | Higher |

| Slope Laser Efficiency (Sample) | — | Up to 37% |

How to Compare and Choose Industrial Ceramic Filter Materials

I recommend you look closely at thermal stability, chemical resistance, mechanical durability, filtration performance, fouling resistance, and cost efficiency when comparing industrial ceramic filter materials. In my experience, the best choice matches material properties to your specific industrial process needs.

Custom solutions exist. Many industrial operations benefit from composite ceramic filters. These combine chemical, thermal, and mechanical stress resistance. I suggest exploring custom options for complex filtration challenges.