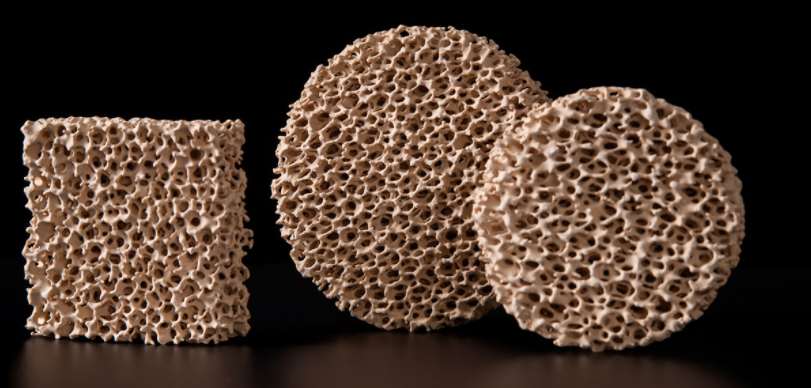

porous ceramic materials matter a lot in applications that need high heat transfer and good thermal control. These materials have a special structure with connected or closed pores. This gives them useful properties: low weight, large surface area, and strong resistance to heat shock. They also provide better heat insulation.

Three factors control thermal conductivity in porous ceramics: porosity, pore size, and wall thickness. Porosity in these materials ranges from 2.3% up to 99%. Pore sizes vary from 3 nm to several millimeters (3 mm). This wide range helps you control how the material performs.

Based on my experience, porous ceramics lead the way in new material solutions. They balance strength, light weight, and excellent heat control. This makes them perfect for today’s most challenging uses.

Beryllium Oxide (BeO) Porous Ceramic: Top Thermal Conductivity and Real-World Uses

High Thermal Conductivity and Structure

Beryllium Oxide (BeO) stands out among porous ceramic materials. It has very high thermal conductivity. At room temperature, bulk BeO achieves 240–330 W/m·K. Sintered BeO reaches about 285 W/m·K. Monolayer BeO measures 266 W/m·K at 300 K.

Among electrical insulators, BeO comes second to diamond. Let me give you some context. Aluminum nitride (AlN) offers 180 W/m·K. Alumina provides just 30 W/m·K. Copper reaches 400 W/m·K.

BeO has a hexagonal (wurtzite-type) crystal structure. This structure features strong covalent bonds. It also enables excellent phonon transport. The structure boosts heat conduction. It keeps the material stable at high temperatures.

Full Material Properties

Electrical Insulation:

BeO works well as an electrical insulator. Here are the key properties:

- Dielectric constant: 6.9 ± 0.4 at 10 GHz

- Dielectric strength: 10–20 kV/mm

- Volume resistivity: 10¹¹ Ω·cm (at 300°C)

- Very low dielectric loss (≤4×10⁻⁴ at 1 MHz)

- Wide bandgap blocks unwanted currents

Mechanical & Chemical Performance:

- Bending strength: ≥190 MPa

- Density: ≥2.85 g/cm³

- Thermal expansion: 7.98×10⁻⁶ 1/K (25°C–500°C)

- Grain size: 12–30 μm

- Melting point: ~2,530°C (high thermal stability)

- Thermal shock resistance: Strong. It can handle rapid temperature changes without cracking.

- Stable against most acids, bases, and molten metals. It reacts at high temperatures with water vapor.

Key Advantages and Disadvantages

Advantages

– Fast, efficient heat removal for high-density electronics

– Excellent electrical insulation at high voltage and frequency

– Lightweight: One-quarter lighter than alumina. About 10% lighter than aluminum nitride.

– Chemical and mechanical stability work well in tough environments

– Good for miniaturization: Works great for compact, high-performance electronics

Disadvantages

– High toxicity risk: Fine dust and fumes during handling are hazardous. You must use strict safety controls.

– Higher price than most alternatives. It costs more than alumina and AlN.

Industrial and High-Tech Uses

I recommend BeO for these applications:

- Power Electronics: High-performance heat sinks and substrates in microelectronics. Think transistors, amplifiers, and microwave devices.

- RF and Microwave Devices: Core component in electronic substrates for power modules and hybrid circuits.

- Aerospace and Defense: Light and strong. It handles both electrical and thermal loads in harsh environments.

- Medical Equipment: Critical in high-power X-ray tubes. Both insulation and heat removal matter here.

- Semiconductor Devices: Laser diode mounts and advanced packaging for density and reliability.

- Nuclear Reactors: Neutron moderator rods. BeO has low neutron absorption.

- Advanced Ceramics: Small electronic components and packaging for next-generation devices.

Conclusion:

Beryllium oxide porous ceramics deliver top heat removal and electrical insulation. The cost is higher. Handling requires strict safety measures. For tough applications that justify the expense and safety investment, I recommend BeO as the best solution.

Aluminum Nitride (AlN) Porous Ceramic: High Thermal Conductivity and Optimal Electronic Performance

Aluminum Nitride (AlN) is a standout material in porous ceramics. It offers exceptional thermal conductivity and stable electrical insulation. Few beryllium-based ceramics beat its heat transfer ability. I recommend AlN as one of the best choices for thermal management in semiconductors, power electronics, and optoelectronic devices.

Advantages and Disadvantages

Advantages

- Non-toxic option: AlN is safe for all stages of fabrication and use. This includes consumer electronics.

- Superior thermal conductivity: 5× higher than alumina. Far better than most Industrial Ceramics.

- Reliable strength: High compressive and flexural strength ensures durability.

- Excellent insulation: Handles demanding high-frequency, high-voltage designs.

- Flexible processing: Produced as thick plates, thin films, and complex substrate geometries.

- Resistant to molten salts: Reliable in high-temperature industrial and electronic environments.

Disadvantages

- Cost: High-purity and advanced processed AlN are much more expensive than alumina. Price increases fast with purity.

- Moisture sensitivity: Fine powders and uncoated surfaces may hydrolyze over time.

- Corrosive vulnerability: Long exposure to mineral acids and alkalis can degrade the material.

Major Applications and Typical Use Cases

- Semiconductor substrates: Power modules, RF circuits, and microwave devices benefit from AlN’s heat management and electrical stability.

- LED Heat Spreaders: Essential for high-power and high-brightness LED mounting. Keeps chips cool to maximize lifespan.

- High-Frequency Electronics: Baseplates, insulators, and packaging for fast, power-dense microchips.

- Other Uses: Laser diode mounts, optoelectronic components, advanced circuit boards, and IC packaging.

Key Properties of Aluminum Nitride (AlN)

| Property | Value/Range |

|---|---|

| Thermal Conductivity | 170–230 W/m·K (standard), up to 321 (single crystal) |

| CTE | 4.5 × 10⁻⁶ /K |

| Dielectric Strength | 14–15 kV/mm |

| Electrical Resistivity | >10¹³–10¹⁴ Ω·cm |

| Density | 3.32 g/cm³ |

| Flexural Strength | 350 MPa |

| Compressive Strength | 3000 MPa |

| Hardness | 10 GPa |

| Non-toxic | Yes |

AlN enables reliable, scalable design for today’s most advanced electronics and thermal management systems. I recommend AlN as a top candidate for those focused on performance, safety, and processing flexibility—right after beryllium ceramics.

Silicon Carbide (SiC) Porous Ceramics: High Thermal Conductivity and Superior High-Temperature Stability

I recommend silicon carbide (SiC) porous ceramics for their strong heat transfer ability. They also offer excellent mechanical strength and chemical resistance. Engineers choose them for heat transfer and durability at high temperatures.

Key Performance Data and Thermal Conductivity

Dense SiC ceramics:

Thermal conductivity: 120–270 W/m·K (most dense grades: 160–200 W/m·K at room temperature, theoretical maximum up to 270 W/m·K)

Porous SiC ceramics:

- At 10–15% porosity (e.g., NSiC): ~12 W/m·K

- Argon/nitrogen-sintered: 3.3–19.8 W/m·K (depends on porosity)

- At 20–30% porosity: 7–30 W/m·K

- Observation: Thermal conductivity falls fast as porosity increases. Dense material shows above 100 W/m·K. Higher porosity drops it below 20 W/m·K.

Mechanical and Chemical Properties

- Flexural strength (porous grades): 8–33 MPa

- Compressive strength: up to 19.4 MPa (at 30% porosity)

- Hardness (dense): 25–28 GPa

- Modulus of elasticity: 220–400 GPa

- Coefficient of thermal expansion: ~3.9–4.6 × 10⁻⁶/K

- Working temperature range: Up to 1380–1500°C. It keeps mechanical strength even at high temperatures.

Major SiC Porous Ceramic Types and Example Grades

| SiC Type | Density (g/cm³) | Porosity (%) | Thermal Conductivity (W/m·K) | Flexural Strength (MPa) | Max Use Temp (°C) |

|---|---|---|---|---|---|

| Dense SSiC | 3.1 | 0 | 110 | 390 | 1600 |

| CVD-SiC | 3.18 | 0 | 120–200 | — | 1500+ |

| Nitride-bonded (CarSIK-NG) | 2.85 | 10–15 | 12 | 200 | 1470 |

| Mullite-bonded (CarSIK 70 ZA) | 2.1 | 25 | 7 | 30 | 1400 |

| Porous (lab) SiC | ~1.7–2.4 | 21–51 | 3.3–19.8 | 8–33 | — |

Common Industrial Uses

- Heat Exchangers: I’ve seen SiC tubing work well in waste incinerators and chemical lines. It delivers high heat transfer and lasts at temperatures up to 1500°C.

- Mechanical Seals and Pump Parts: SiC stands out for hardness and corrosion resistance. Pumps use it for harsh or hot fluids.

- Filtration Systems: Nitride-bonded, open-pore SiC filters hot gases. It captures particles in industrial exhaust.

- Heat Sinks & Electronic Substrates: High-power electronics need fast heat removal. SiC handles thermal management well.

- Burners and Radiant Tubes: Special SiC grades (CarSIK-G, CarSIK-Z) support stable combustion in industrial heating.

Advantages and Challenges

Advantages

- Excellent thermal shock resistance: SiC handles fast temperature changes. Cracking risk stays low.

- Chemical inertness: It resists acids, alkalis, and oxidizing gases. This holds true even above 1000°C.

- Strong mechanical durability: SiC performs well long-term. It works in abrasive, corrosive, or high-heat settings.

Limitations

- High-purity porous SiC is hard to produce: You need special process control. Impurities and uniform porosity require careful attention.

- Brittle fracture risk: Like most ceramics, SiC can crack. Sharp impact or severe bending can cause fractures.

Based on my experience, SiC porous ceramics balance high heat transfer, stability, and toughness. Metals or plastics can’t work in these conditions. I recommend SiC for any system that needs reliable heat removal and extreme service. It performs best in demanding industrial and high-tech settings.

Hexagonal Boron Nitride (h-BN): Direction-Dependent Heat Conductivity for Advanced Heat Management

Hexagonal boron nitride (h-BN) has exceptional thermal conductivity that varies by direction. This property makes it unique among porous ceramics and electrical insulators. I find it works best for spreading heat across flat surfaces.

In-Plane vs. Cross-Plane Thermal Conductivity: Key Values & Anisotropy

In-plane thermal conductivity:

- Bulk high-quality single crystals: 220–420 W/(m·K) at room temperature

- Monoisotopic 10B h-BN: 585 ± 80 W/(m·K)

- Monolayer: up to 751 W/(m·K); Theoretical for nanoribbons exceeds 2000 W/(m·K)

Cross-plane (out-of-plane):

- Bulk: < 8–16 W/(m·K), sometimes as low as 0.3 W/(m·K)

Anisotropy Ratio: Often more than 30–70× (in-plane vs. cross-plane); can be >100:1 in the best materials

Thermal Conductivity by Thickness

- Few-layer (5–11 layers): 250–360 W/(m·K), close to bulk performance

- Monolayer: Up to 751 W/(m·K)

- Polycrystalline h-BN: Drops to 20–52 W/(m·K) (in-plane); cross-plane under 1 W/(m·K)

Industrial Applications and Use Cases

- Heat spreaders in electronics: h-BN’s in-plane conductivity spreads heat sideways in chips and microelectronics. This reduces device temperature rise by more than 20 K. I’ve seen this boost performance and reliability.

- Thermal interface materials: Used for rapid heat flow across microelectronic layers. This works well where vertical transfer is less critical.

- High-temp furnace and crucible linings: Remains insulating and inert up to 800 °C and beyond.

- Composite filler for polymers: Provides high thermal conductivity retention while preserving electrical insulation.

- 2D electronics: Essential as an insulating, passivating, flat substrate for graphene and other 2D heterostructures. I suggest using it at the atomic level.

Advantages and Disadvantages in Engineering Practice

Advantages:

– h-BN has one of the highest in-plane thermal conductivities among ceramics and insulators. Diamond or cubic boron arsenide are the few materials that beat it. – Excellent for heat-spreading roles without electrical current leakage. – Stable against oxidation at high temperatures. – Isotopic manipulation allows further performance tuning. – Machinable to precision shapes. This is unusual among advanced ceramics materials.

Disadvantages:

– Cross-plane heat transfer is very poor. You must plan orientation carefully in device design.

– High cost, for single-crystal, isotopically pure, or thin forms.

– Performance drops with atomic-scale defects, stacking faults, or contamination.

– Polycrystalline forms have much lower thermal conductivity.

Personal Evaluation and Summary

I see h-BN porous ceramics as a frontier material for heat management. This is true when you need precise in-plane thermal conductivity and electrical insulation at the same time. I’ve noticed their use in microelectronics, LED cooling, and as advanced substrate materials is rising. The purest grades face cost hurdles. But I recommend h-BN for next-generation thermal control systems. It outclasses all conventional ceramics for lateral heat spreading when cross-plane heat flow can be minimized.

Titanium Diboride (TiB₂): High Heat Transfer and Extreme Performance

Titanium diboride (TiB₂) has a great mix of high heat transfer, strength, and electrical properties. I rank it as one of the best porous ceramics for tough, high-heat jobs.

Key Heat and Physical Properties of Titanium Diboride

Heat Transfer:

- Pure, high-density TiB₂: up to 95 W/m·K

- Typical commercial TiB₂ (varied density, more porous): 58–70 W/m·K

- Porous or composite TiB₂: 25–47 W/m·K

- Some reports cite values up to 120 W/m·K depending on processing

Maximum Service Temperature: 1270 °C

Heat Shock Resistance: Survives rapid temperature swings up to 110 °C

Density: 4.5 g/cm³ (high density ensures better heat properties)

Heat Expansion: About 8.0–8.1 µm/m·K; increases with temperature

Specific Heat Capacity: 870 J/kg·K

Heat Spread Rate: Around 15 mm²/s

Grain Size Effect: Best heat transfer requires <10 µm grain size. Microcracks above ~15 µm grains cut heat transfer

Mechanical and Electrical Features

Vickers Hardness: Up to 66 GPa (at low load)

Strength-to-Weight Ratios:

- Axial stiffness/weight: 35

- Bending stiffness/weight: 49

- Axial strength/weight: 17

- Bending strength/weight: 21

Electrical Power:

- High, ranging 1.1–4.5 × 10⁵ S/m

- Handles both heat and electrical flow in key roles

How Structure, Mix, and Making Affect Performance

Porosity and Grain Size:

- High density and fine grains drive performance

- Porous or coarse-grain materials drop heat transfer to 25–63 W/m·K

Dopants and Blends:

- Chromium-doped or B₄C/SiC composite TiB₂: As low as 33 W/m·K

- Add-ins may boost toughness but cut heat transfer

Making Methods: Hot pressing, spark plasma sintering, and chemical vapor deposit boost density and grain control. These raise production costs but give better material quality

Industrial Uses and Case Studies

Cutting Tools: Popular as a WC-Co replacement; works for non-ferrous metal machining and wear-resistant parts

Molten Metal Handling & Electrolysis: Crucibles, stir bars, and lining for aluminum/copper smelting. Works as cathodes due to chemical stability and strong electrical/heat flow

Armor and Aerospace Parts: High-performance armor plates and inserts. Wear protection for parts facing friction and heat

Pump Seals and Tubes: Top ceramics makers pick it for wear-resistant pump seals and thermocouple protection tubes

Pros and Cons

Pros of TiB₂ Porous Ceramics

– High heat transfer even in porous form, beats most borides/carbides

– Great hardness and rust resistance at high temperatures

– Strong electrical flow for jobs needing both heat and electrical transport

Cons – Hard to process and compress; you need advanced sintering to get top performance – Heat transfer trails silicon carbide or non-Porous alumina single crystals – High production cost; quality varies with impurities, grain size, and porosity

My View and Industry Trends

I think TiB₂ is a top Porous Ceramic for combined high heat and electrical flow. You need extreme hardness and rust resistance? This material works. I recommend it for special metal processing, advanced wear parts, and harsh environment jobs.

The big challenge? Processing is complex and costs run high. But for key systems in cutting, chemical, or aerospace industries, the performance is worth it. Based on my experience, keeping high density and fine grains is a must. This unlocks TiB₂’s full heat potential. Advanced hot pressing or spark plasma sintering is now the norm for high-end products.

Need a heat conductor with real toughness and durability under high heat? I suggest you put TiB₂ on your shortlist.

Magnesium Oxide (MgO): Efficient Heat Management in Porous Ceramics

Magnesium oxide (MgO) ceramic excels at heat transfer, electrical insulation, and staying stable at high temps. It doesn’t beat aluminum nitride or silicon carbide in raw performance. But I find MgO a smart pick for many high-heat uses. Why? It balances good conductivity with reasonable cost.

Thermal Conductivity and Temperature Behavior

Typical thermal conductivity:

- 28–35 W/m·K at room temperature

- Spherical MgO: 40–60 W/m·K (after processing)

- Literature/expert reports: Up to 53 W/m·K at room temp, 42 W/m·K at 273 K

- At 400 K: ~29–33 W/m·K

- High temperatures: Drops to 8 W/m·K at 1300 K for 93% dense, polycrystalline MgO

Thermal trend: Conductivity falls fast above 750 K. Porosity cuts thermal conductivity even more

Comparison Table:

| Material | Thermal Conductivity (W/m·K) | Melting Point (°C) | Density (g/cm³) | Electrical Resistivity (Ω·cm) |

|---|---|---|---|---|

| Magnesium Oxide | 40–60 | 2800–2852 | 3.58 | >10¹⁴ / 10¹⁵ |

| Aluminum Nitride | 140–180 | ~2200 | ~3.3 | 10⁹–10¹¹ |

| Silicon Carbide | 120–270 | ~2730 | ~3.2 | 10⁷–10⁹ |

Application Scenarios and Case Data

Thermal insulation: Common in refractory bricks and kiln furniture, works as lining in high-temp furnaces and crucibles

Electronics:

- Provides heat isolation and insulation in cartridge heaters

- Serves as a key additive for polymer composites and electronic encapsulants

- Spherical MgO powder improves heat removal in power electronics. It also forms thermal pads for EV and battery modules.

Industrial use: Stays stable up to its melting point. It almost never breaks down or reacts.

Advantages and Drawbacks in Engineering Practice

Advantages

– Solid heat transfer among porous ceramics

– Strong insulation at high temps and high frequency

– Very stable: Holds up to 2800+ °C without breaking down

– Affordable and easy to source for most uses

Disadvantages

– Heat transfer is weaker than dense aluminum nitride or silicon carbide

– Breaks easily under heavy mechanical stress

– Large, pure single crystals cost a lot and are tough to get

Personal Assessment and Value

I rank MgO high for heat insulation and moderate heat transfer in hot environments. Its price and reliability make it my go-to for tasks like insulating heaters, packaging electronics, and lining furnaces. If you need extreme conductivity, denser or non-porous ceramics still win. But for heat and electrical insulation on a budget and at high operating temps, MgO has no equal.

Comparison Table: Thermal Conductivity and Key Properties of Porous Ceramic Materials

I’ve prepared a comparison of the top six porous ceramics. I focus on thermal conductivity, electrical insulating abilities, density, and specialized notes. These properties will help you select materials for high-performance heat management, insulation, and demanding industrial uses.

| Material | Thermal Conductivity (W/m·K) | Electrical Insulation | Density (g/cm³) | Additional Notes |

|---|---|---|---|---|

| Beryllium Oxide | 184–300 | Yes | ~3.0 | Highest among ceramics, rivals some metals; strict handling due to toxicity |

| Aluminum Nitride | 140–230 | Yes | 3.26 | High-purity grades up to 200 W/m·K; safe and preferred for most electronics |

| Silicon Carbide | 120–180 | No | 3.21 | Strong, wear-resistant; electrical conductor, not an insulator |

| Hexagonal Boron Nitride (h-BN) | 120–250 (in-plane) | Yes | 2.1–2.3 | Extreme anisotropy; in-plane much higher than cross-plane; machinable |

| Titanium Diboride | 60–70 | Moderate | ~4.5 | High heat/electric flow, ultra-hard; challenging processing |

| Magnesium Oxide | 40–60 | Yes | 3.58 | Good insulator at high temperature; affordable, stable under heat |

Comparison Highlights

Beryllium oxide has thermal conductivity that beats most ceramics. It even approaches metallic levels. I recommend it for top-tier electronics and defense. But you must handle it with extreme care due to toxicity.

Aluminum nitride offers high, reliable thermal conductivity and electrical insulation. This makes it ideal for power modules, LED substrates, and microelectronics. It’s safer than BeO. However, it costs more than general ceramics.

Silicon carbide works best where high thermal conductivity pairs with strength, hardness, and chemical resistance. But it’s not suitable if you need electrical insulation.

Hexagonal boron nitride leads for in-plane heat conduction. It’s perfect for lateral heat spreading in electronics. But cross-plane conductivity is poor. You need strong directional use with precise orientation.

Titanium diboride fits applications needing a mix of thermal and electrical conduction, toughness, and chemical resistance. Its processing is more complex. It also costs more.

Magnesium oxide is my go-to for heat and electrical insulation at a reasonable price. It’s not the best conductor. But it’s reliable in refractory and insulation roles.

Summary

I’ve worked with Advanced Ceramics for years. I’ve learned something important. Choosing the right material goes beyond spec sheet numbers.

These six materials each solve real problems. They just do it in different ways. BeO has the best conductivity numbers. But I often see AlN win in real use. Why? It’s safer to handle. SiC works best where you need toughness.

Here’s what matters most: match the material to your actual needs. Don’t just chase the highest thermal conductivity.

I suggest you start with your operating conditions. Look at the tradeoffs clearly. Test before you commit. This approach works. It has never failed me.