Ever wonder why some castings come out flawless while others end up as expensive scrap? The difference often comes down to one hidden factor most foundries overlook—filtration quality.

Gray and ductile iron make up three-quarters of all U.S. castings. Yet many operations still treat filters as an afterthought. They should view them as a precision tool instead.

The right ceramic foam or honeycomb filter can slash your rework time by half. It can eliminate porosity defects too. But here’s the catch most operators miss.

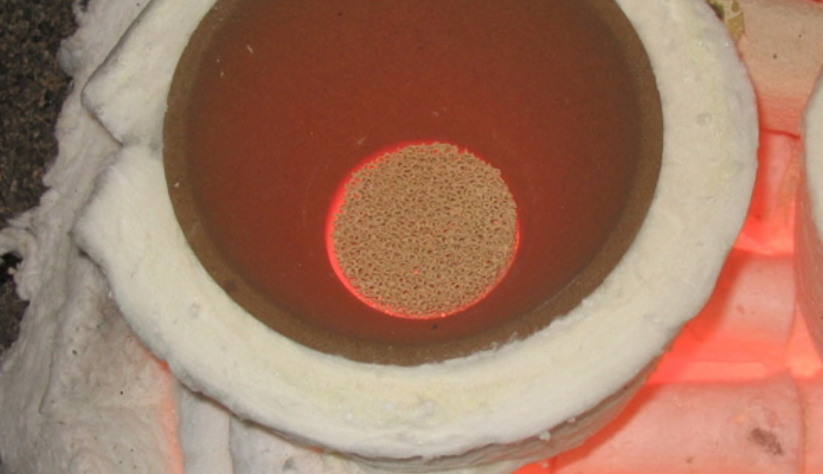

Iron Casting

Gray and ductile iron castings make up 75% of all ferrous and nonferrous castings by weight in the U.S. under SIC codes 3321 and 3322. Automotive, machinery, construction, and infrastructure industries rely on these castings. Component reliability affects operational safety and performance.

Filtration Technology Portfolio:

Iron foundries use three main filter types—ceramic foam filters, pressed filters, and honeycomb filters. Each filter handles high heat and captures maximum impurities. Applied Ceramics, SF Foundry, Foseco, and ICP make customizable solutions. Pore densities vary (measured in cells per square inch, cpsi) to match your process needs.

Measurable Performance Gains:

Advanced filtration systems deliver real improvements:

– 50%–70% reduction in casting upgrading time

– Less welding material consumed

– Better surface finish and machinability

– Lower foundry scrap rates and fewer process defects

– Less porosity with more reliable components

Specialized Solutions by Provider:

Foseco’s STELEX ULTRA and PrO filters manage turbulence and trap inclusions through finer filtration. Industrial Ceramic Products offers customizable filters (shape, size, pore density) for diverse iron casting processes. Applied Ceramics honeycomb structures maximize surface area for molten iron interaction. This achieves better impurity removal.

Filters go at the ingate or within the running system. Size depends on alloy type, casting dimensions, temperature, and expected impurity loads. Modern filter technologies feature ultra-low friability and precise dimensional tolerances. This makes filtration systems essential for top-tier foundry production.

Barnes International, Inc.

Barnes International started in 1907 in Rockford, Illinois. We’ve built over a century of know-how in coolant filtration systems and grinding filters. Our 160,000 sq. ft. ISO-certified facility serves multiple industries. You’ll find our systems in automotive, aerospace, agriculture, and machine tool sectors. Flow capacities range from 10 GPM to 20,000 GPM.

Technology Growth:

We introduced magnetic separators in the 1950s. These removed metallic sludge. The 1980s brought patented immersed drum filters. We also launched the Series 30 filter line.

Today’s product range includes gravity, vacuum, and pressure filtration systems. You get deep bed gravity fabric filters with magnetic drum pre-cleaners. Plus, we offer chip filters made through our alliance with Mosnic, Japan. All systems work with permanent and disposable filter media. Precision reaches micron-level accuracy.

Casting Industry Uses:

-

Cold rolling of steel

-

Steel strip cleaning operations

-

Steel and cast iron grinding, honing, and polishing

-

Fines removal from cast iron machining systems

-

Water-soluble coolant filtration for grinding, lapping processes

Carpenter Brothers, Inc.

Since 1917, Carpenter Brothers has supplied North American foundries with filters and metal expertise. Founders Everett and Milton Carpenter started by selling bonded molding sand. The company made it through hard economic times. It grew into a complete filtration provider. Today, four metal experts with over 100 years of combined experience help iron and non-iron operations across the country.

Complete Filter Range:

-

Pressed ceramic filters – Control molten metal flow and stop non-metal bits from getting through

-

Ceramic foam filters – Make runner systems simpler and filter better for steel, iron, aluminum, magnesium, and brass casting

-

Cloth filters and wire mesh filters – Custom sizes for your specific runner setup

Real-World Results:

A Midwest iron foundry uses ceramic foam filters for automotive engine block production. The partnership cut down casting defects. It also improved surface finish on key parts.

Technical Support Across Casting Stages:

The experts help with melting, molding, core making, casting, shakeout, finishing, surface prep, and environmental rules. They guide you on filter placement and choice. This cuts defects and keeps metal clean.

Steel Casting

Ceramic foam filters lead the steel foundry world. They give you steady flow rates and better turbulence control. Zirconia-based ceramic foam filters like STELEX ZR ULTRA from Foseco resist breakdown during pouring. This cuts casting flaws. Carbon-bonded filters (STELEX PrO) work best for low-carbon steel and steel alloy jobs. Place these at the ingate to remove more inclusions. This helps most during reoxidation problems.

Integrated Filtration Systems:

KALPUR units absorb turbulence while filtering molten steel. They also feed metal during solidification. This dual role cuts shrinkage defects. HOLLOTEX CFU devices use spin force to catch larger inclusions first. Built-in ceramic filters finish the cleaning. Big ferrous casting shops use this two-stage method.

Proven Cost Reductions:

Northeast Filter and SF-Foundry build custom solutions for steel makers. Their ISO9001-certified systems cut post-casting operations by 50%–70%. You’ll get better machinability and surface finish. This means lower processing costs downstream. Steady filtration methods also make scrap diagnosis easier. You can tell metal problems from mold problems right away.

Foseco

Foseco runs as the Foundry Division of Vesuvius plc. The company started in 1932 in Birmingham, UK. Eric Weiss and Dr Kossy Strauss founded Foundry Services Ltd. They wanted to support casting operations worldwide. The company created new technologies that became industry standards. These include insulating feeding systems, ceramic foam filters, and rotary degassing for aluminum melts.

Advanced Filter Technologies:

Foseco makes filters from carbon-bonded alumina, silicon carbide, zirconia, and graphite. These filters work for steel, iron, and non-ferrous alloys. STELEX Optiflow3D filters use 3D printing with carbon-bonded alumina ceramic. They have low density and thermal capacity. So they work well for iron and all steel grades. STELEX ZR ULTRA gives you steady performance. It breaks apart less, which matters for tough steel jobs.

Aluminum Casting

Aluminum and aluminum alloy castings make up about 11% of total U.S. casting production by weight. This makes aluminum the top nonferrous casting metal. The industry operates under SIC codes 3363 (Aluminum Die-Castings) and 3365 (Aluminum Foundries). HVAC, compressor, energy, defense, and aerospace sectors rely on these castings. They need them for critical airflow control and structural parts.

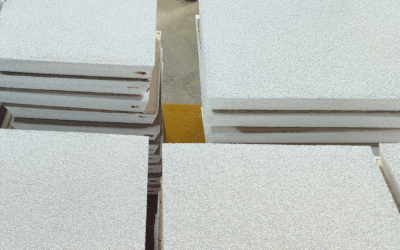

Core Filtration Technologies:

Three main filter types are used in aluminum foundries:

-

Ceramic foam filters – Remove inclusions and reduce trapped gas through controlled pore structures

-

Silica mesh filters and fiberglass mesh filters – Promote smooth flow during pouring

-

High-efficiency baghouse filters – Capture airborne particles during high-temperature processing

Place filters in the gate system to maximize impurity removal. You get cleaner metal this way. Plus, you’ll see fewer scrap parts and lower inclusion defects.

Advanced Filter Engineering:

FOSECO’s SIVEX FC filters use phosphate-free binders. This stops phosphorus contamination during melting and recycling. The KALPUR direct pour technology combines feeder insulation with foam filtration. It controls metal stream velocity while feeding during solidification. This dual function cuts shrinkage defects in vertical parted molding operations.

Measurable Industry Impact:

Advanced filtration systems deliver real improvements:

– Higher-quality castings with consistent mechanical properties

– Reduced scrap rates through better inclusion control

– Lower defect rates in pressure-tight applications

– Increased profit from reduced rework and material waste

– Compliance with environmental regulations for particle emissions

Foundries match filter media to specific alloy types. They also consider casting dimensions and expected contamination levels. Disposable filters provide cost-effective operation. They maintain casting integrity across production runs.

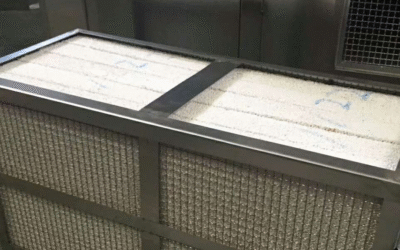

Pyrotek

Pyrotek focuses on advanced filtration tech for aluminum production. We serve both primary and secondary operations worldwide. Our Cartridge Filter Systems (PCF) give you high filtration efficiency for top-tier uses. You’ll find PCF systems in canstock production, fine foil making, lithographic sheet lines, and electronics casting. The system uses Pyrotek Bonded Particle Filter (BPF®) media with alumina granules. This packs a large surface area into a small space. You can use finer filter grades. Your operation runs more efficiently.

Bonded Particle Filter Range:

BPF® filters handle aluminum gravity casting, high-pressure die casting, low-pressure die casting, and high-performance sand foundries. Pure silicon carbide gives you great strength. Plus, you get long life, chemical resistance, and good heat transfer. We offer these types: vertical gate filters, box filters, pump filters, dosing tube filters, stalk tube filters, and crucible baffle filters. Foundries using BPF® filters cut down on scrap from inclusions. Metal flows better. Castings get stronger. Surface finishing gets easier.

Premium Aluminum Uses:

SIVEX Ceramic Foam Filters (CFF) work well for beverage cans and aircraft alloys. These filters use phosphate bonding and pure alumina. You get high surface area and steady performance. Sizes go from 17.8 to 66 cm (7 to 26 inches). Filter grades range from 10 to 100 PPI. Setup and care are easy. Blue preheat dots help you change alloys faster.

Complete Solution Range:

Pyrotek also make Deep Bed Filters, Filter Box Systems, Vertical Gate Filter Systems, and Rigid Glasweve® Filters for sand and permanent mold casting. Our products boost melt quality across different casting methods. Global tech support teams visit aluminum foundries and casthouses. You get complete filtration solutions built for your exact production setup.

Foundry Max

Foundry Max makes filtration systems for metal casting. We serve aluminum, iron, steel, copper, and alloy foundries worldwide. Our filters remove non-metallic bits, catch slag, and stop refractory particles from molten metal. This means better casting quality. Plus, you get stronger mechanical properties and faster production.

Product Portfolio:

-

Ceramic foam filters – Work with aluminum, iron, and steel casting. Zirconia-based options resist heat up to 1700°C.

-

Fiberglass filtration mesh – Handles extreme heat where standard filters break down.

-

Filter caps and socks – Give you precise control of metal flow during pouring.

-

Custom filter solutions – Designed for investment casting and special foundry needs.

Customization Options:

You get adjustable pore sizes (measured in PPI). Match them to your filtration needs. Standard and custom sizes fit any foundry layout. We’re ISO-certified, so quality stays the same across all batches.

Industry-Specific Applications:

Aluminum operations use our filters to reduce oxide buildup. Surface finish on final castings gets better. Iron foundries remove inclusions that create defects. Steel casting needs high-temp filters to keep purity under extreme heat. Copper and alloy foundries face unique chemical and heat challenges. Our specialized filters handle them.

Technical Support and Resources:

We provide technical data sheets, application guides, webinars, and training on filter selection. Our team partners with aerospace, automotive, and industrial foundries across the globe. We work with major casting equipment makers to create integrated filtration solutions. Industry awards recognize our innovation. We attend conferences regularly to show new filtration tech.

Investment Casting

Investment casting needs very pure metal for detailed parts with tight tolerances. Ceramic foam filters, honeycomb filters, and fiberglass mesh filters handle the main filtration work. These filters remove slag, oxides, and non-metal particles before metal flows into shell molds. Pure metal gives you better surface finish and stronger parts.

Top Filtration Providers:

Applied Ceramics, Foundry Filtration, Industrial Ceramic Products (ICP), Blasch Precision Ceramics, Dynatec Sales, GBC Advanced Materials, Ransom & Randolph, and Vesuvius serve this industry. They make reticulated ceramic foam filters, 3D ceramic foam filters, and custom-shaped filters for shell molds, pouring cups, in-line systems, and gate placement.

Strong Filter Materials:

Filters use zirconia (ZrO2), alumina, and silicon carbide ceramics. These materials handle thermal shock at very high temperatures. Pore sizes go from 10 PPI to 100 PPI. Pick the grade that fits your alloy type and casting details.

Product Uses:

Ceramic foam filters work with aluminum, steel, and superalloys for aerospace turbine blades. Honeycomb ceramic filters have straight channels. This design gives you faster flow rates and better filtration. Fiberglass mesh filters suit aluminum and non-ferrous metals. Custom-shaped filters match specific mold shapes.

Real Performance Results:

Aerospace makers produce very pure turbine blades with complex shapes using ceramic foam filtration. Auto and machinery companies see lower scrap rates and higher output. Better filtration means fewer defects. Production costs go down. The market keeps growing in aerospace, auto, and industrial areas. New tech like 3D printing and better ceramics makes filtration work even better.

Carpenter Brothers, Inc.

Carpenter Brothers supplies filters and foundry gear to metal casting shops across North America. We’re based in Milwaukee and keep four metallurgists on staff. They bring real technical know-how to each customer call. Our warehouses cover the continental U.S. Filters and casting supplies reach you fast—truck, plane, or rail—right on your schedule.

Product Categories for Metal Casting:

We stock products for all casting stages:

-

Metals & Alloys – Raw materials for different casting methods

-

Melting & Melt Quality – Crucibles, ladles, and analysis tools

-

Molding & Core Making – Binders, sand systems, and core materials

-

Casting & Shakeout – Gear that separates castings from molds

-

Finishing & Surface Prep – Grinding and polishing tools

-

Environmental Compliance – Dust control and emission filters

Complete Technical Support:

Our sales and engineering team helps you solve problems. They spot quality issues. They suggest process fixes. They pick the right filters for your metal type. This hands-on help creates lasting partnerships with foundries. Steel, iron, aluminum, magnesium, brass, copper—we work with them all.

Why Foundries Choose Carpenter Brothers:

Better inclusion control means higher casting quality. Cleaner runner systems boost your efficiency. Custom filters fit your exact gating design. Steady logistics prevent production delays. We’ve spent over a century in foundry work. That experience shapes every recommendation and shipment.

Ductile Casting

Ductile iron now holds equal market share with gray iron. It’s becoming the top casting type. This creates demand for filters that handle ductile’s unique metal properties and pouring needs.

Filtration Challenges Solved:

Large ductile iron castings had filtration problems. Chill issues, small filter capacity, and weak structures stopped effective cleaning. FOSECO’s STELEX PrO carbon aluminium oxide ceramic foam filters solved these issues. You get cleaner castings. Surface finish improves too. Foundries save major costs in fettling and cleaning work.

Parted Molding Solutions:

SUPER SEDEX silicon carbide ceramic foam filters give you steady metal flow and strong filtration. The pouring times stay consistent. This makes them perfect for DISAMATIC and other parted molding systems. Flow stays predictable across all production runs.

Filter System Options:

ASK Chemicals’ UDICELL Filters with Exactfill Housing Systems come in Round, Tee, Elbow, Iron, and Steel types. The 10 PPI pore size works well for ductile iron. Installation is quick. Operating costs stay low.

Deep-Bed Filtration Performance:

SELEE’s ceramic foam filters use deep-bed filtration. This traps fluid slag in the foam network. The design cuts scrap and machining needs. You get multiple sizes, thicknesses, and pore sizes for different ductile iron jobs.

Measured Industry Benefits:

Ceramic foam filtration brings real gains to ductile iron foundries:

– Fewer impurities in finished castings

– Lower scrap from inclusion defects

– Better surface finish requiring less cleanup

– Higher production efficiency through fewer rejects

– Stronger mechanical properties in final parts

SF-Foundry and Baoding Ningxin Group give you complete technical support with their filters. Both companies build custom solutions. They base this on your casting size, alloy mix, and production volume.

Foundry Max

Foundry Max makes filters for metal casting. You get systems for aluminum, iron, steel, and copper casting. Their filters include ceramic foam, fiberglass mesh, and honeycomb ceramic types. These handle temps up to 1700°C. They hold ISO9001:2015 certification for quality.

Industry Applications:

-

Automotive casting – Ceramic foam filters for aluminum engine parts

-

Aerospace manufacturing – Zirconia filters for high-temp steel melts

-

Heavy machinery – Fiberglass mesh for iron casting

-

Copper alloy work – Custom ceramic and fiberglass options

Complete Service Package:

Our technical teams offer on-site visits, process help, and custom filter design. Monitoring systems connect to your current foundry setup. Training helps your operators get the best filter results.

Innovation Pipeline:

New work includes better coating methods and smart monitoring tools. R&D teams develop green materials. We’re also expanding high-temp options. You’ll find us at international shows, sharing new filter tech.

Contact: Call +86 153 6977 0013 or email through the official website for specs and custom solutions.

Comparison Matrix

Seven global leaders drive industrial filtration for different casting needs. These companies offer specialized tech, strong regional presence, and solid track records in metal production.

Market Size & Growth Trajectory:

The industrial filtration market hit $36.03 billion in 2024. Experts predict growth to $53.81 billion by 2033. This growth comes from higher quality standards in automotive casting, aerospace manufacturing, and precision metal work.

Leading Companies by Casting Application:

|

Company |

Primary Casting Focus |

Core Technologies |

Geographic Coverage |

Key Differentiators |

|---|---|---|---|---|

|

3M (Solventum, post-2024) |

Foundry casting, electronics making |

Membrane filters, depth filters, predictive maintenance systems |

North America, Europe, Asia Pacific, Latin America, MEA |

Smart filtration with IoT connection, industrial focus after 2024 spin-off |

|

Donaldson Company |

Heavy-duty casting, dust control, cleanroom work |

Dust collectors, compressed air filters, hydraulic filtration, process filters |

U.S., Europe, global partners |

High-power dust and air control, cleanroom-ready solutions |

|

Mann + Hummel |

Engine casting, automotive work |

IoT-enabled dust collectors, HEPA filters, ultrafiltration membranes |

Global with IoT hubs in Singapore |

Digital labs (since 2016), real-time monitoring tools |

|

Pall Corporation |

Chemicals, pharmaceuticals, investment casting |

Industrial cartridges, liquid/gas filters |

North America, global operations |

Advanced cartridge tech for high-flow processing |

|

Parker Hannifin |

Cement, CNC machining, coal/oil-fired boilers |

PEACH® depth matrix coalescing filters, dust collectors |

Worldwide installations |

3D depth coalescing tech for oil mist capture |

|

Alfa Laval |

Marine, oil & gas, food processing |

Centrifugal separators, decanters, pressure filters |

Global manufacturing network |

Solid-liquid separation with heat transfer |

|

Filtration Group |

Food & beverage, HVAC, life sciences |

Process liquid filters, gas filtration, clean air systems |

Local market branches worldwide |

Niche market focus, branch-driven innovation |

Selection Criteria for Casting Operations:

Pick your filtration partner based on three factors:

-

Filtration capacity – Match flow rates and volume to your production size

-

Precision needs – Coarse, medium, or fine filtration for your metal type

-

Customization level – Standard systems or custom-built solutions

Technology Innovation Trends:

IoT and predictive maintenance lead today’s developments. Mann + Hummel runs digital hubs for connected filter tracking. 3M’s Solventum division (launched in 2024) targets industrial scale. Parker Hannifin’s PEACH® depth matrix catches oil mist through 3D coalescing structures.

Regional Manufacturing Support:

Major casting centers get local support in U.S., Canada, Mexico, UK, Germany, France, China, Australia, Japan, India, South Korea, Brazil, South Africa, Saudi Arabia, and UAE. This network means fast parts delivery and on-site help.