Facility managers struggle with one main issue. Balancing maintenance costs against safety keeps them up at night. Let’s be real. Swap your Industrial ceramic filters too soon, and you waste money. It feels like throwing cash away. But wait too long? You invite trouble. You risk compliance fines and equipment failure. High-grease environments could even catch fire. That gamble isn’t worth it.

No universal “expiration date” exists. Take a steakhouse running smokers 12 hours a day. Compare that to a cool data center. The wear and tear differs. So, generic guesses don’t work. You need a schedule that fits your specific reality. We break down replacement timelines by industry in this guide. You will see the physical warning signs to watch. Plus, we show you how to get full value from every filter without dropping safety standards.

Replacement Frequency Guidelines

industrial ceramic filter replacement schedules change based on your facility type and daily operations. Know these industry timelines to keep air quality high and avoid wasting money on early filter changes.

Food Service Operations

Restaurants and eating establishments need filter replacement every 1-2 months under normal conditions. This baseline schedule shifts based on several key factors:

-

High customer volume speeds up filter wear

-

Barbecue and grilling create smoke that demands more frequent changes

-

Commercial kitchens running 12+ hours need new filters at least once a month

Grease, smoke, and steam from commercial cooking equipment saturate Ceramic filters fast. Wait too long and you create fire hazards and ventilation problems. These issues affect food safety and worker comfort.

Retail and Commercial Spaces

Retail stores and small businesses usually follow a 3-month replacement cycle. This longer timeline works because retail spaces create fewer airborne contaminants than food service or industrial operations.

High foot traffic areas need closer attention. Stores near busy streets or in dusty climates should replace filters every two months. Customer flow brings outdoor pollutants, dust, and particles inside. These build up faster than in low-traffic locations.

Heavy Industrial Environments

Large manufacturing and industrial facilities face the toughest filtration needs. These operations need weekly filter replacements as a baseline standard.

Industries that generate smoke, soot, dust, and airborne particles must change filters even more often. Metalworking shops, chemical processing plants, and heavy manufacturing operations often replace filters twice a week. Some implement continuous monitoring systems.

Weekly replacement costs are small compared to equipment damage, product contamination, or worker health issues from poor filtration.

Specialized Facility Requirements

Data centers and electronics facilities operate on daily replacement schedules as needed. Even tiny particles interfere with sensitive computer components and electronics equipment. These facilities can’t risk downtime or equipment failure from contaminated air.

Medical facilities use sophisticated alarm-based replacement systems instead of fixed schedules. Hospitals, urgent care centers, and emergency rooms use HVAC monitoring that signals when filters need changing. This prevents virus, bacteria, and airborne pathogen spread throughout critical care areas. Air quality has a direct impact on patient outcomes in these environments.

Key Factors Affecting Replacement Schedule

Filter replacement timing varies based on your operation. Multiple factors work together to affect this. You can create a maintenance schedule that protects equipment and controls costs by understanding these factors.

Operating Environment and Particle Load

Your facility’s air quality sets how fast ceramic filters reach capacity. Manufacturing plants produce metal dust, chemical vapors, or combustion particles. These fill filters much faster than standard office buildings.

High-particle environments create the fastest filter breakdown:

-

Welding and metalworking shops make fine metal particles. These embed deep into ceramic pores.

-

Chemical processing facilities expose filters to harsh compounds. These weaken filter structure.

-

Woodworking operations create sawdust loads. These clog filter surfaces fast.

-

Automotive paint booths saturate filters with sticky overspray residue.

Data centers face unique challenges. They look “clean” but aren’t. Computer equipment creates static electricity. This attracts tiny dust particles. These small bits build up inside sensitive electronic parts. Equipment failures follow. Even small particle buildup means you need to inspect filters each day in server rooms with critical infrastructure.

Medical facilities work under strict contamination control standards. Airborne bacteria, viruses, and pharmaceutical particles need special filtration approaches. Hospitals use HVAC monitoring systems. These measure air quality all the time. Automated alarms trigger replacement based on actual contamination levels, not calendar dates.

Operational Intensity and Running Hours

Equipment runtime affects filter lifespan. A facility running 8-hour shifts has different replacement needs than 24/7 operations.

Extended operation schedules compress maintenance cycles:

-

Round-the-clock manufacturing plants cycle through filters 3x faster than single-shift facilities

-

Restaurant exhaust systems running 12+ hours each day build up grease and smoke faster than operations that only serve lunch

-

Seasonal businesses experience irregular filter wear. This demands flexible scheduling.

Peak production periods stress filtration systems beyond normal capacity. Holiday retail rushes, agricultural processing seasons, and manufacturing surge periods all speed up filter contamination. Smart facility managers stock extra filters before these predictable high-demand windows.

System Design and Cleaning Mechanisms

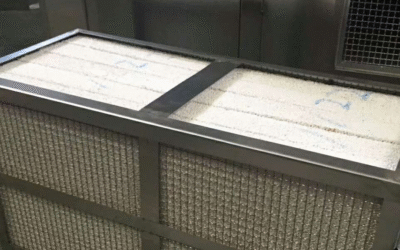

Back pulse cleaning systems extend filter life. They also add mechanical stress. These automated cleaning cycles blast compressed air through filters. This removes built-up particles. The thermal expansion and contraction creates small cracks in ceramic material over time.

Cleaning frequency affects overall durability:

-

Aggressive pulse cleaning schedules (every 15-30 minutes) can cut total filter lifespan by 20-30%

-

Gentle cleaning intervals (every 2-4 hours) preserve filter strength longer

-

Pulse pressure settings must balance cleaning power against material stress

Filter airflow changes throughout the service life. New ceramic filters allow maximum airflow with minimal resistance. Dust cake builds on filter surfaces. Airflow restriction increases even with regular cleaning. You can monitor pressure differential across filters. This shows you once cleaning no longer restores good performance.

Combined Stress Factors

Industrial filters face many challenges at once. These speed up wear. Mechanical vibration from nearby equipment adds stress beyond normal demands. Temperature changes from process heating and cooling cycles cause ceramic material to expand and contract. Chemical exposures from industrial processes can react with filter materials. This reduces structural strength.

Unexpected events create the harshest conditions. Equipment malfunctions generate excessive smoke. Chemical spills produce corrosive vapors. Sudden pressure surges from system failures damage filters beyond normal wear patterns. These incidents often need immediate unscheduled replacements. Previous maintenance timing doesn’t matter.

Track these combined factors through detailed maintenance logs. Record actual operating conditions, cleaning cycles, and system performance metrics. This reveals your facility’s unique replacement patterns. You get optimized timing specific to your operation instead of generic schedules.

Signs That Mean You Need a New Filter Right Now

Ceramic filters show clear warning signs before they fail completely. Spot these signs early. You’ll avoid equipment damage, production stops, and safety problems.

Performance Problems

Flow rate collapse is your first major warning. Your flow drops more than 20% from baseline? The filter system is blocked at a critical level. You can’t keep running at this reduced capacity.

Pressure changes tell you the same thing. Check the pressure drop across your filter regularly. Readings jump 10-15 psi above normal? Severe clogging has happened. The filter is about to fail. This pressure spike makes your system work harder. Energy costs go up. Equipment wears faster.

Your back pulse cleaning system shows filter condition through how it acts. Cleaning cycles run more than 2-3 times per day? The filter is near end of life. The problem grows worse if these frequent bursts don’t improve flow or pressure. The filter has soaked up all the contamination it can take.

Physical Damage and Structure Problems

Visual checks catch problems that sensors don’t see. Cracks, chips, or surface damage to the ceramic body kill filtration power right away. These flaws break down structure strength. Replace damaged filters the moment you see them. Don’t wait for scheduled maintenance.

Strange vibration or noise from filter housings and pipes means serious trouble inside. These sounds often mean filter collapse or heavy fouling in the housing. Structure failure inside creates safety risks beyond just poor filtering.

Thermal imaging and ultrasonic checks find hidden damage during routine maintenance. Micro-cracks show up in ceramic material from heat cycling and mechanical stress. These tiny fractures get bigger over time. Temperature spikes or heat problems in the filter zone prove these failures are growing. High-heat industrial use faces extra risk from loss of heat resistance.

Loss of Filtering Power

Particle counters downstream measure what truly counts—actual filtering results. More particles breaking through proves the filter no longer traps contaminants well. Visual check of filtered gas or liquid shows the same issue. Contaminants pass through the filter into your final product or exhaust.

Failed tests give solid proof of filter failure. Bubble point tests and pressure decay tests measure filter performance clearly. These standard tests remove all doubt. Failed results mean you must replace the filter now.

Lab analysis of filtered media measures efficiency loss precisely. Removal efficiency drops below 90% for target particles? The filter can’t meet performance standards. This limit varies by industry and use, but the rule stays the same—measured results determine replacement timing.

Chemical and Environmental Harm

Chemical attack leaves visible marks on ceramic surfaces. Look for color changes, etching, or erosion patterns. Harsh gases and liquids react with filter materials. This chemical breakdown weakens structure strength and creates paths for contamination.

Too much ash or dust buildup that won’t respond to standard cleaning means the filter’s useful life is over. Compressed air pulses, chemical washing, or heat treatment can’t restore the filter surface? You need a replacement.

Steam or moisture breaking through in hot gas filtering systems means seal failure or damaged filter strength. This moisture harms sensitive equipment downstream. It also proves the filter can’t maintain needed separation barriers.

System-Level Warnings

Automated monitoring systems set off alarms for good cause. Pressure sensors and flow monitoring systems shut down operations if readings go past safe limits. These shutdowns need quick inspection. Replacement comes next in most cases.

Compliance alarms in regulated settings carry legal force. Emissions above limits and particle counts past permitted levels need fast filter replacement plus full system check. Environmental violations create legal problems beyond operational issues.

Unusual events—sudden temperature spikes, pressure surges, or chemical spills—damage filter structure even without visible harm. Replace filters exposed to these conditions. Hidden damage from extreme events causes surprise failures down the road.

Strange odors or contamination in filtered output shows filter bypass or total failure. This contamination affects product quality and worker safety. Manufacturer service bulletins or recall notices for specific filter models beat all other replacement schedules. Follow this safety guidance right away.

Maintenance to Extend Lifespan

Good care routines add months—sometimes years—to your ceramic filter investment. Performance stays strong too.

Establish a Cleaning Protocol

Clean the surface often. This stops buildup before it gets deep into the pores. Back pulse cleaning works best with pressure readings. Don’t use fixed time schedules. Set your system to start cleaning cycles at 3-5 psi above baseline. This stops over-cleaning. The ceramic won’t get stressed. Dirt stays under control.

Manual cleaning helps in busy work areas. Pull filters every three months. Check them and clean deep. Use compressed air at 40-60 psi. Blow debris off the outside. Never go past what the maker says. Too much pressure makes tiny cracks. Filters wear out faster.

Monitor Operating Conditions

Control temperature to protect the ceramic. Keep temps in the rated range. Big swings make the material expand and contract. Cracks form. Put sensors before and after the filter. You’ll spot heat issues fast.

Track pressure all the time. This one number tells you about filter health better than anything else. Use digital gauges that save data. Pressure goes up slowly? That’s normal aging. Sharp jumps? You have system trouble. Fix it now.

Handle Filters Right

Rough handling breaks more filters than regular use. Show your crew how to handle them right. Hold filters at the mount points only. Never grab the body in the middle. Stress builds up there. Keep spare filters in boxes. Put them away from busy walkways. Accidents happen less.

Write down every task you do. Note cleaning cycles, pressure numbers, what you see, and odd things. These notes show how your setup wears. You can guess the best time to swap filters. Performance won’t drop.