Manufacturing professionals often mix up Investment casting and ceramic casting. This makes sense—both methods create precise metal parts using disposable molds. But they differ in three key ways: shell makeup, temperature limits, and cost.

What is the difference between investment casting and ceramic casting? This question matters for your project. The answer affects quality, timeline, and budget.

Pick the wrong method and you face problems. Turbine blades that need to handle 1,500°C might fail. Jewelry parts lose their fine details. Tolerances slip. Materials get wasted. Prototypes don’t work.

This comparison shows how traditional investment casting differs from Advanced ceramic shell processes. We look at mold formation techniques and real-world uses. You’ll learn which method fits your material needs, production volume, and performance specs. Process costs, accuracy data, and industry examples help you choose with confidence.

What Is Investment Casting? (Lost-Wax Casting Process)

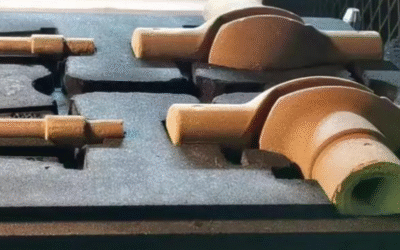

Investment casting creates metal parts through a 7-11 step process. It starts with wax and ends with finished parts. The name comes from the ceramic “investment” that covers wax patterns before you pour the metal.

The core workflow has three phases:

Phase 1: Pattern Creation

– Aluminum or steel molds inject liquid wax at 60°C

– You get tolerances below 0.1mm with surface finish of Ra 1.6-3.2μm

– Release agents help eject cooled wax patterns

– Workers attach multiple patterns (10-100 pieces) to a central wax tree using adhesive

Phase 2: Shell Building

– The wax tree dips 7-9 times into silica-based ceramic slurry

– Each layer adds 0.5-1mm thickness with zircon flour and colloidal silica binder

– Refractory sand (0.1-0.3mm grit) coats the wet slurry between dips

– Each layer needs 2-4 hours to dry

– This creates a final shell 5-10mm thick

– The shell strength exceeds 20 MPa after baking at 1100°C for 2-4 hours

Phase 3: Metal casting– Steam dewaxing at 120°C recovers 90-95% of wax for reuse- Molten metal pours at 1100-1500°C (bronze at 1200°C, steel at 1450-1550°C)- Controlled cooling manages metal shrinkage: 2.1% for steel, 1.2% for aluminum- Water quench breaks the shell and leaves clean metal parts

This process delivers ±0.05-0.13mm tolerances for parts under 100mm. Surface finishes reach Ra 0.8-3.2μm. That’s much smoother than Sand casting‘s 6.3-12.5μm. Material use reaches 90-95%. Parts range from 5 grams to 250 kilograms.

What Is Ceramic Shell Casting?

Ceramic shell casting is a type of investment casting. It uses special heat-resistant materials to build very thin, strong molds. The shells are 4.8-15.9mm thick. Some parts have cross-sections as thin as 1.3mm. This method works great for casting superalloys and heat-resistant materials. You get extreme precision with this process.

How We Build the Shell

The ceramic shell forms through repeated dipping and coating cycles:

We use premium heat-resistant materials:- Slurry base: Fine-grain zircon (ZrSiO₄), aluminum oxide (Al₂O₃), and fused silica. These mix with colloidal binders.- Stucco coating: Each dip gets coarser ceramic sands applied on top.- Layer count: We apply 5-10+ coats. This builds a self-supporting shell. No backup materials needed.

Firing gives the shell controlled properties:

– Baking at 980-1,000°C (1,800°F) hardens the ceramic.

– Heat treatment removes volatile binders and organic residues.

– Controlled micro-cracking forms during firing. These tiny fractures let gas escape during metal pouring. But they prevent metal leakage.

– The fired shell gets strong enough for dewaxing. Yet it stays weak enough to break away clean after casting.

Top Performance Features

Ceramic shell casting gives you tolerances of ±0.1mm for the first 25mm. After that, it’s ±0.003mm per extra millimeter. Surface finish reaches 24μm (75-150μin) RMS. That’s much smoother than regular shell methods.

The thin walls handle extreme heat:

– They withstand pour temperatures over 1,500°C. This works for nickel-based and cobalt superalloys.

– Preheated shells stop thermal shock. This matters for heat-resistant stainless steels.

– Most cast weights stay under 125kg. But there’s no strict upper limit.

This precision fits aerospace turbine blades perfectly. High-temperature engine parts benefit too. Complex superalloy components work well with this method. Traditional investment casting shells can’t match the heat resistance or size control you get here.

Core Process Differences: Mold Formation & Shell Building

Both methods build disposable molds. But the formation techniques differ. Investment casting creates shells through cold dipping cycles. Ceramic shell casting uses premium refractory materials. It’s a specialized variant. Traditional shell molding takes a different path. It cures sand-resin mixtures on heated metal patterns.

Investment Casting: Cold Dip & Dry Cycles

The shell forms through 5-10+ repeated immersions in liquid ceramic slurry. Each cycle follows this rhythm:

-

Dip the wax tree into fine-grain zircon or alumina slurry

-

Apply stucco coating with coarser ceramic sand while wet

-

Air dry 2-4 hours between layers (no heat during building)

-

Build thickness step by step: Each coat adds 0.5-1mm, reaching final shell of 5-15mm

Standard investment uses ordinary silica-based refractories. The advanced ceramic variant switches to zirconia (ZrO₂) and aluminum oxide (Al₂O₃) slurries. This upgrade pushes heat resistance past 1,500°C. That’s key for superalloy casting.

The critical dewaxing step removes patterns through:

– Steam autoclave at 150-200°C (precise temp control prevents cracks)

– Flash dewaxing for rapid wax evacuation

– 90-95% wax recovery for reuse

Temperature precision matters here. Too hot? Shells crack. Too cool? Wax residue remains.

Ceramic Shell Casting: Same Dip Method, Different Materials

This is investment casting with enhanced materials. The core difference sits in slurry composition:

-

Premium refractories: No ordinary silica allowed

-

Zircon sand (ZrSiO₄) base mixed with colloidal silica binders

-

Alumina (Al₂O₃) alternatives for extreme temperature resistance

-

Thinner final shells: 4.8-15.9mm versus standard investment’s 5-15mm range

The dipping process stays the same. The firing temperature hits 980-1,000°C to harden ceramic. This creates controlled micro-cracks. These tiny fractures vent gases during metal pouring. But they seal against leakage.

Dewaxing uses the same autoclave methods as standard investment. The material upgrade delivers pour temperatures exceeding 1,500°C. That’s essential for nickel-based superalloys in turbine blades.

Side-by-Side Shell Comparison

|

Formation Aspect |

Investment Casting |

Ceramic Shell Variant |

|---|---|---|

|

Build method |

Cold dip cycles |

Cold dip cycles |

|

Layer count |

5-10+ coats |

5-10+ coats |

|

Base materials |

Standard silica refractories |

Zircon/alumina |

|

Final thickness |

5-15mm typical |

4.8-15.9mm (thinner) |

|

Drying time/layer |

2-4 hours air dry |

2-4 hours air dry |

|

Dewaxing temp |

150-200°C autoclave |

150-200°C autoclave |

|

Max pour temp |

1,100-1,500°C |

Over 1,500°C |

The formation workflow stays the same. Material selection drives the performance gap between standard and ceramic variants.

Precision, Surface Finish & Dimensional Accuracy Comparison

Manufacturing precision separates basic prototypes from flight-ready aerospace parts. Investment casting and ceramic shell casting differ in three key areas: dimensional tolerances, surface texture, and post-processing needs.

Dimensional Control: Where Each Method Excels

Investment casting gives you tolerances of ±0.05-0.13mm for parts under 100mm in size. This fits the CT4-CT6 grade range for most uses. The standard process works for Aluminum Alloy brackets, bronze fittings, and stainless steel pump housings. No secondary machining needed.

Ceramic shell casting tightens this control. You get ±0.1mm for the first 25mm, then ±0.003mm per additional millimeter. This hits CT3-CT5 grade precision. Turbine blade root sections need this accuracy. A 0.15mm deviation in blade attachment points? That causes vibration failures at 12,000 RPM.

Critical dimension stability relies on shrinkage compensation. Steel shrinks 2.1% during cooling. Aluminum contracts 1.2%. Ceramic shell methods use 0.25-0.5mm machining allowances on functional surfaces. This covers material contraction. Plus, it allows final grinding to exact specs.

Surface Roughness: The Texture Gap

Standard investment casting produces Ra 1.6-3.2μm surface finish. That’s 3-5 times smoother than sand casting’s 6.3-12.5μm. Run your finger across the metal. You can feel the difference. Most valve bodies and marine hardware ship at this quality.

Ceramic shell casting achieves Ra 0.8-1.6μm straight from the mold. This mirror-like finish matches the Rq/Ra ratio of 1.22 ± 0.02 found in precision manufacturing. Medical implants benefit most. Hip joint parts need Ra below 1.0μm to prevent tissue irritation.

Surface texture affects more than looks. Roughness valleys (Rvk) trap dirt in hydraulic systems. Peak heights (Rpk) create wear points in sliding contacts. Ceramic shells produce Mr1 values below 10% (minimal peaks) and Mr2 above 90% (shallow valleys). This profile cuts friction. It also extends part lifespan.

Post-Processing: Time and Cost Reality

Investment casting parts often ship as-cast for non-critical uses. Decorative railings, art sculptures, and general industrial fittings need no finishing. You save 2-4 hours per part batch.

Ceramic shell castings need selective machining. Turbine blade platforms get ground to 54.3 HRC ± 0.6 hardness. Bearing journals need Ra 0.8μm for oil film stability. Post-grinding cuts radial runout. It also converts stress from compression to helpful tension.

The machining allowance strategy matters. DMLS gear studies show 0.1mm shrinkage prediction accuracy. Use 0.25mm stock on simple holes. Use 0.5mm allowances on complex profiles with heat treatment. This prevents under-sizing. That saves expensive superalloy parts from scrap.

Both methods beat sand casting for dimensional accuracy. Ceramic shell casting wins for extreme precision needs. Investment casting offers the best mix of cost and quality for medium-tolerance uses.

Material Compatibility & High-Temperature Alloy Casting

Your metal choice decides which casting method works for production. Standard investment casting works with aluminum, bronze, and stainless steel at 1,100-1,500°C pour temperatures. Ceramic shell casting goes beyond this limit. It handles superalloys that melt above 1,500°C.

Standard Investment Casting: Aluminum to Moderate-Temperature Steels

Regular investment shells handle these materials:

Aluminum alloys lead in affordable production:

– NASA 398 aluminum-silicon alloy (6-18% Si): Gravity casting at standard temps, works up to 232-400°C (450-750°F)

– A360 alloy: Strong at high temps for exact parts

– A383/A384 alloys: Better hot-crack resistance than A380, works for complex shapes

– 300-series aluminum: Costs under $0.90/lb to cast, perfect for investment work

These alloys stop performing well at medium heat. The 12-25% silicon types lose strength above 260-371°C (500-700°F). Particle strengthening keeps them stable.

Minimum wall thickness stays at 4.8mm (3/16 inch) for all high-alloy castings. Don’t make sudden thickness changes. They create shrinkage problems.

Ceramic Shell Casting: Superalloy Territory

Premium heat-resistant shells handle extreme-temperature materials that standard investment can’t:

Nickel-based superalloys fight oxidation and creep:

– Inconel 600: Hot working at 1,260-1,010°C (2,300-1,850°F), light work to 871°C (1,600°F)

– Pour temps run 200-300°C hotter than standard shell limits

Cobalt-based alloys stay hard at red heat:

– High-temp types: Stellite 21, 25, 31, 188, 250

– Anti-corrosion types: Stellite 21, 209, 306

– Keep strength where nickel alloys get soft

Iron-chromium-nickel heat-resistant grades (HA/HE/HD/HC series):

– HA (Fe-Cr-Ni): Non-stop service to 1,093°C (2,000°F)

– HC: Welding needs 204-427°C (400-800°F) preheat, 843°C (1,550°F) post-weld heat treatment

– HD: Expands 20% more than HC, matters for size planning

– HE: Fights high-sulfur gases (300-500 grains/100 ft³), runs at extreme temps

ASTM A297 heat-resistant grades give structural strength:

– HU/HW/HX alloys: Stress-rupture strength 60,000-65,000 psi at high temperature

– Chrome-moly types (9Cr-1Mo, 2¼Cr-½Mo, 3Cr-1Mo-V): Work above 425°C (800°F)

Shell Refractoriness Gap: The Key Separator

Pour temperature decides if shells survive:

|

Temperature Range |

Shell Type Required |

Application Example |

|---|---|---|

|

1,200-1,400°C |

Standard investment |

HE alloy post-weld heat at 649-704°C (1,200-1,300°F) |

|

1,500-1,700°C |

Ceramic shell required |

CA40 annealing at 843-899°C (1,550-1,650°F), HC post-heat 843°C |

|

Above 1,500°C |

Advanced ceramic required |

Cobalt/nickel superalloy casting |

HA alloy’s 1,093°C service limit sits close to standard shell’s top range. Cobalt and nickel superalloys need shells rated beyond 1,500°C. Regular investment shells break down here. Ceramic shells use zircon and alumina to handle these extremes.

Welding heat cycles show the challenge:

– HA needs 232-288°C (450-550°F) preheat

– HE needs no pre/post heat with E312-15 electrodes

– HC needs 843°C post-weld soak for stress relief

Standard investment casting covers 80% of industrial metal work. Ceramic shell casting handles the other 20%—where heat, stress, and rust meet. Your material spec picks the process. Superalloys require ceramic shells. Regular alloys work fine with standard investment.

Cost Analysis: Tooling, Materials & Production Economics

Investment casting and ceramic shell processes show a 4-7× price gap. Raw materials eat up 62.3% of total production costs in both methods. Ceramic variants need premium refractories. This pushes material spending 15-25% higher than standard investment shells.

Tooling & Pattern Development Costs

Wax pattern tooling hits your budget first:

– Aluminum molds for investment casting: $800-$3,500 per cavity (simple shapes)

– Steel tooling for high-volume runs: $5,000-$25,000 (complex turbine blade dies)

– Tools last 50,000-100,000+ wax injections before you replace them

– Ceramic shell casting uses the same pattern tools—no extra cost here

Small runs (under 500 parts) cost $15-$45 per part for tooling. Orders above 10,000 units drop this to $0.80-$2.50 per piece. Machinery prices climbed 85% since 1994. A sharp 13.6% jump in 2022 came from disrupted supplies and steel shortages.

Material Cost Structure: The Shell Premium

Standard investment shells run $4.50-$8.00 per kilogram for silica-based slurries. Ceramic shells need $12-$22 per kilogram for zircon (ZrSiO₄) and alumina (Al₂O₃) refractories. A 5kg turbine blade shell uses:

– Standard investment: $22.50-$40 in materials

– Ceramic shell: $60-$110 in premium refractories

Input costs will rise 5.5% over the next 12 months—the steepest climb since Q2 2022. Energy prices vary by region. Midwest facilities pay 9.2¢/kWh. California pays 18.7¢/kWh. Dewaxing autoclave cycles use 15-25 kWh per batch. That’s $1.38-$4.68 per run based on where you operate.

Total Production Economics

Trade uncertainty tops planning worries at 76.2% of manufacturers (up 20 points from Q4 2024). Tariffs create headwinds. Still, revenue growth sits at 4.2% for 2025. Product prices will probably rise 3.6% over the next 12 months—up from 2.3% in Q4 2024.

Per-part cost comparison (100-unit run):

– Standard investment casting: $45-$120 (aluminum to stainless steel)

– Ceramic shell casting: $180-$650 (superalloy parts with tight tolerances)

The ceramic premium gives you heat resistance above 1,500°C and CT3-CT5 accuracy. Standard investment saves 80% on costs for pour temps below 1,400°C. Your material specs and tolerance needs decide which option makes sense—not just the sticker price.

Advantages & Limitations: Which Method Fits Your Needs?

Both processes make precision metal parts. But real-world operations set them apart. Your production volume, budget, and performance needs pick the winner for you.

Investment Casting: The Versatile Workhorse

Advantages:

– Cost efficiency wins: Material costs hit $4.50-$8.00/kg for standard silica slurries. That’s 60% cheaper than ceramic options.

– Works with many materials: Handles aluminum, bronze, 300-series stainless steel, and moderate-temp alloys. Pour temperatures range 1,100-1,500°C.

– Scales for production: Tooling costs drop to $0.80-$2.50 per part above 10,000 units. High-volume runs become cost-effective.

– Good precision: CT4-CT6 tolerances (±0.05-0.13mm) work for 80% of industrial uses. No extra machining needed.

– Faster lead times: Standard materials and proven processes cut shell building cycles by 15-20% compared to ceramic methods.

Limitations:

– Temperature limit blocks high-temp alloys: Standard shells fail above 1,500°C. You can’t cast nickel-based Inconel or cobalt Stellite.

– Surface needs work: Ra 1.6-3.2μm finish needs polishing for medical implants or aerospace seals.

– Thicker walls needed: Minimum 4.8mm sections restrict design options in lightweight aerospace parts.

– Small batches cost more: Batches under 500 parts run $15-$45 each in tooling costs.

Pick investment casting for:

– Pour temperatures below 1,400°C (aluminum alloys, bronze, standard stainless grades)

– Production runs over 1,000 units per year. Scale makes tooling worth it.

– Tolerances of ±0.1mm that meet your needs (valve bodies, pump housings, marine hardware)

– Tight budgets that need 60-80% cost savings over top precision

– Parts weighing 5-250kg with standard shapes

Ceramic Shell Casting: The High-Performance Specialist

Advantages:

– Handles extreme heat: Zircon/alumina materials survive pour temps above 1,500°C. Required for turbine blade superalloys.

– Better size control: CT3-CT5 grade tolerances (±0.1mm base + 0.003mm/mm) stop turbine vibration problems.

– Mirror-like finish: Ra 0.8-1.6μm surfaces skip post-polishing on medical implants.

– Thinner walls possible: Shell strength allows 1.3mm cross-sections for weight-critical aerospace parts.

– Smart micro-cracking: Built-in gas venting stops porosity defects in complex cooling channels.

Limitations:

– Higher material costs: Refractory slurries cost $12-$22/kg. A 5kg shell runs $60-$110 versus standard’s $22.50-$40.

– Longer production time: Strict quality checks add 15-22 worker-hours per shell tree. That’s 3-4 hours more than standard.

– Needs skilled labor: Special training for advanced materials raises labor rates 25-40% in skilled markets.

– High cost floor: Per-part costs of $180-$650 make runs under 100 units too expensive.

– Energy costs vary by region: Preheating shells in high-cost areas (California at 18.7¢/kWh) adds $2.80-$4.68 per batch versus Midwest plants.

Pick ceramic shell casting for:

– Superalloy specs require it: Inconel 600, Stellite 21/25, HA/HC/HE iron-chromium-nickel grades

– Operating temps above 1,093°C continuous service (turbine blades, combustion chambers)

– Tolerances under ±0.1mm to prevent failures (blade root attachments, bearing journals)

– Surface finish needs of Ra < 1.0μm for biocompatibility or fluid flow

– Part shapes needing thin walls under 2mm for heat efficiency or weight cuts

Direct Method Comparison

|

Decision Factor |

Investment Casting |

Ceramic Shell Casting |

|---|---|---|

|

Material cost/kg |

$4.50-$8.00 |

$12-$22 |

|

Max pour temp |

1,500°C |

Above 1,500°C |

|

Tolerance grade |

CT4-CT6 (±0.05-0.13mm) |

CT3-CT5 (±0.1mm + 0.003mm/mm) |

|

Surface finish |

Ra 1.6-3.2μm |

Ra 0.8-1.6μm |

|

Min wall thickness |

4.8mm |

1.3mm |

|

Cost per part (100 units) |

$45-$120 |

$180-$650 |

|

Break-even volume |

500+ units |

50-100 units |

|

Best applications |

General industrial, medium-temp alloys |

Aerospace, superalloys, precision |

The 1,500°C mark splits these two apart. Standard investment casting fits cost-focused projects with moderate performance needs. Ceramic shell casting dominates the high-temperature, high-precision space where failure costs more than production premiums. Your material specs make the choice—not your preference.

Industrial Applications & Real-World Use Cases

GE Aviation makes LEAP engine blades from single-crystal nickel superalloys. They use ceramic shell investment casting. These blades run at 1,500°C without stopping. The process cuts fuel use by 30% versus older engines. IIoT sensors watch casting equipment in real time. This drops downtime by 25% at Airbus plants.

Aerospace: Turbine Blades That Define Performance

Rolls-Royce builds Trent XWB turbine blades with directional solidification investment casting. The low-pressure turbine parts use titanium aluminide (TiAl) alloys. Ceramic shell methods cast these alloys. This material cuts component weight by 20%. The lighter weight boosts thrust by 15%. No extra engine mass needed.

Critical aerospace casting specs include:

– Temperature resistance: Nickel superalloys stay strong above 1,500°C during flight

– Dimensional accuracy: Blade root fits within ±0.1mm to stop high-RPM vibration failures

– Surface quality: Ra 0.8-1.6μm finishes cut aerodynamic drag. They also stop crack start points

– Defect control: Porosity under 0.5% keeps fatigue strength above 900 MPa for 20,000+ flight cycles

Ceramic shell casting meets these tough demands. Standard investment methods break down at 1,500°C+ pour temps. You need these high temps for Inconel 718 and similar aerospace-grade superalloys.

Automotive: Turbochargers & High-Temperature Engine Components

BorgWarner casts turbocharger housings from Inconel 718. They use ceramic shell processes. The material handles 1,000°C exhaust gas temps in Volkswagen and Audi turbocharged engines. Investment casting creates the complex internal shapes needed for best gas flow. This design boosts engine efficiency by 15-20% versus standard aspirated types.

Ford EcoBoost exhaust manifolds show investment casting’s weight benefits:- Silicon-molybdenum (SiMo) cast iron replaces heavier traditional iron- Component weight drops 40% while keeping thermal shock resistance- Lower mass cuts tailpipe emissions by 10%- Audi facilities use IIoT quality control systems that cut casting defects by 15%

Auto manufacturing saw a 42% jump in robot orders during Q1 2025. The $580.7 million in automation investments targets welding and casting operations. Collaborative robots (cobots) now handle 11.6% of industrial robot work. This automation trend improves casting quality. Plus, it speeds up production cycles.

Medical Devices: Biocompatible Implants & Surgical Precision

Orthopedic makers cast hip and knee joint parts from cobalt-chromium-molybdenum (CoCrMo) alloys. Investment casting keeps porosity under 1%. This stops implant failure. The process gives fatigue strength over 600 MPa. These properties support the 2+ million joint replacement procedures done worldwide each year.

Medical-grade casting requirements include:

– Material purity: CoCrMo composition must meet ASTM F75 standards for biocompatibility

– Surface finish: Ra values under 1.0μm stop tissue irritation and bacterial adhesion

– Sterilization resistance: Parts handle repeated autoclave cycles at 135°C without size changes

– Tolerance control: ±0.05mm accuracy ensures proper fit in modular implant systems

Surgical instrument makers use 316L stainless steel Investment casting for forceps, retractors, and specialty tools. The process creates complex shapes with built-in features. No need for extra build steps. Cobots now do over 20% of life sciences build tasks. This includes post-casting inspection and packaging work.

Art & Jewelry: Where Precision Meets Aesthetics

Bronze sculptors still use the lost-wax investment casting method from thousands of years ago. Modern foundries cast huge sculptures over 10 meters tall. They use 88% copper-12% tin alloys. The process copies fine details from original clay or wax models. Surface finishes reach Ra 3.2μm without polishing. Smooth enough to show artist toolmarks and texture.

Investment casting dominates precision jewelry production:

– Platinum and gold alloys flow into micro-detailed molds

– Feature resolution under 0.1mm captures intricate filigree and stone settings

– First-pass quality yields top 95% for experienced casting houses

– Wax pattern printing now uses 25-micron resolution 3D printers for complex designs

The jewelry industry gains from investment casting’s ability to make identical pieces. A single master pattern creates hundreds of wax copies. Each casting matches the original within 0.05mm. This consistency matters for wedding ring sets, branded collections, and limited-edition art pieces.

Conclusion

Your project needs determine which casting method works best. Both methods use the lost-wax foundation. Ceramic shell casting handles high heat better and keeps tighter dimensions. This makes it ideal for aerospace and heavy industrial parts. Traditional investment casting costs less and works great for detailed parts that need smooth surfaces.

Know what is the difference between investment casting and ceramic casting. This helps you pick the right method based on precision needs, material types, and budget. Working with high-temperature metals? Need tight tolerances? Ceramic shell technology is worth the extra cost. Got complex shapes in standard metals with medium production runs? Conventional investment casting gives you great value.