Think of a material that breathes like a sponge. It handles extreme heat. It filters tiny impurities with precision. Plus, it changes how industries manage heat and process chemicals.

Porous alumina ceramic started as a lab experiment. Now it’s an industrial powerhouse. This material has changed molten metal filtration and high-efficiency catalyst supports.

You might be an engineer looking at materials for your next project. Or a procurement specialist comparing cost and performance. Maybe you just want to know about advanced ceramics. Either way, porous alumina ceramic offers real benefits.

This material lets you control tiny pores at the nanoscale. It resists thermal shock better than most alternatives. This guide explains the technology in plain terms. You’ll see proven uses across different industries. You’ll also learn why top manufacturers are putting major resources into these materials.

We’ll show you specific product examples. You’ll find clear performance numbers. And you’ll see new innovations that are changing porous ceramics.

Key Properties of Porous Alumina Ceramic

Porous alumina ceramic delivers real performance across physical and thermal properties. Numbers tell the story for demanding applications.

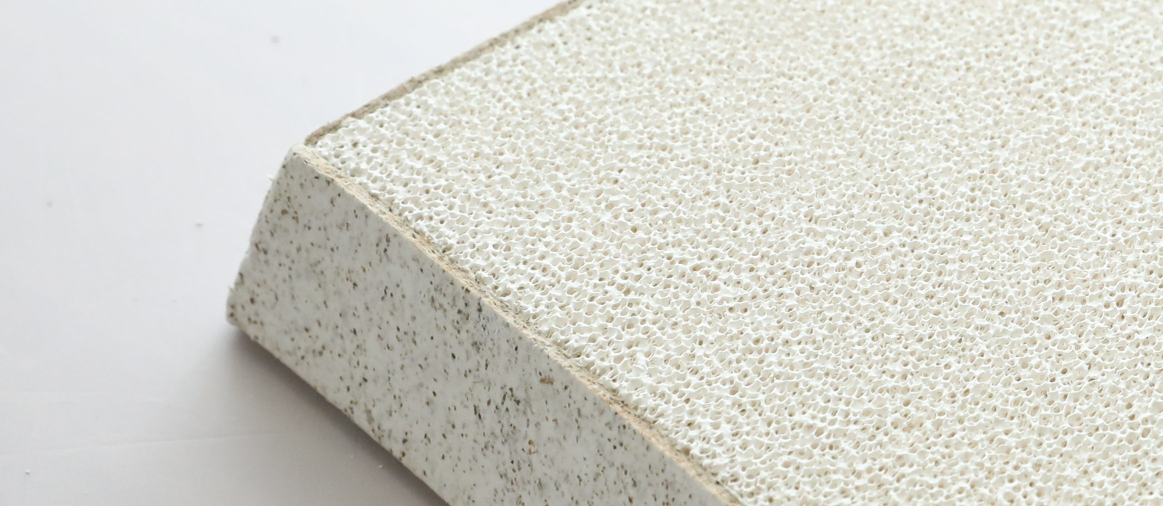

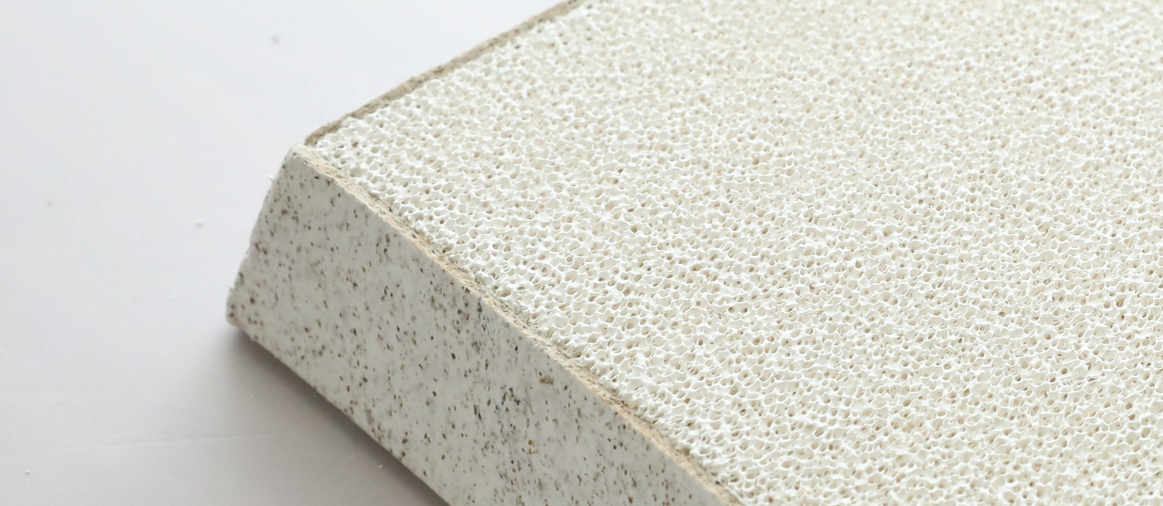

Porosity ranges from 11.8% to 57%. Manufacturing method and purity grade determine the result. The R-200 grade hits 55% porosity with a bulk density of 1.5 g/cm³. Grades using starch additives can reach 57%. They keep their structure intact. Need denser material? N-99EP and N-99SP variants sit at 35.4-35% porosity. They work well for applications needing greater mechanical strength.

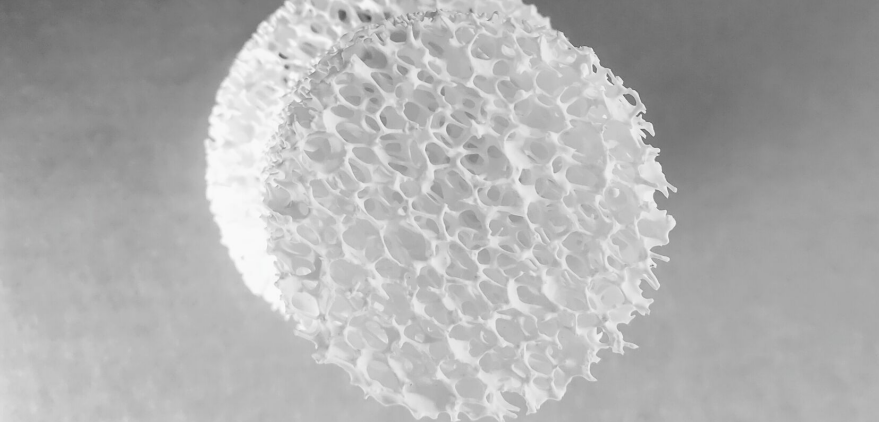

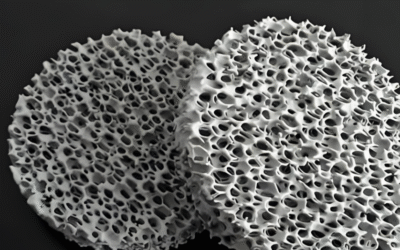

Pore size control covers a wide range. You can get pores from 0.055 μm (55 nanometers) in N-99SP grade up to 15.5 μm in NK-1500 variants. The R-203 grade features 0.7 μm pores. R-200 offers 1.4 μm openings. This range from 0.1 μm to 50 μm lets you match filtration precision to your exact needs.

Mechanical strength changes with porosity levels. The sweet spot appears at 11.8% porosity. You get 150.4 MPa flexural strength here. More porosity means less strength—but smart manufacturing keeps strength usable even at high porosity. R-200 sustains 200 MPa bending strength at 55% porosity. High-purity versions hit 379 MPa Weibull average in four-point testing. Compressive strength reaches 860 MPa in dense 99.5% purity bodies.

Thermal performance sets this material apart. Standard grades handle continuous operation at 1100°C. Premium formulations stay stable up to 1700°C. Plus, you get low thermal expansion and strong thermal shock resistance.

Purity levels range from 91% to 99.999% alumina content. Higher purity grades (99-99.9% Al₂O₃) deliver better dielectric strength. They exceed 400 V/mil at 0.125-inch thickness. That’s way better than standard 99.8% alumina at 310 V/mil.

Water absorption works opposite to density. R-200 absorbs 35%. R-203 takes 30%. Denser N-99EP/SP grades limit absorption to 14-15%.

Manufacturing Methods and Porosity Control

Additive manufacturing has changed how engineers create and control porosity in Alumina ceramics. The process goes beyond simple percentage targets. Engineers now manage the exact position of every pore in the structure.

Binder jetting additive manufacturing allows layer-by-layer porosity design. The ALS-LGCP model (Additive Layer-wise Spatial Log-Gaussian Cox Process) does this work. This system measures pore spread within each layer. It tracks porosity changes as the build moves up. The model spots high-risk zones where defects might group together. Tests against X-ray computed tomography (XCT) data show 85% F-score accuracy. Total porosity measurement is no longer enough. Now you map where pores form, their sizes, shapes, and types across the entire part.

Old measurement methods can’t do this. The Archimedes method gives you one number—porosity percentage versus bulk volume. That works for general specs. But it tells you nothing about where pores sit or what they look like. Engineers need spatial data to improve designs and adjust process settings.

Three measurement approaches give different insights:

-

Archimedes method stays the industry standard for bulk porosity percentage. Fast and reliable for quality checks. But it can’t show you where problems hide inside the part.

-

Microscopic imaging and XCT show volume data plus full pore shape and position details. You check layer cross-sections to see how pores spread. These methods work offline. They inspect internal structures without destroying them.

-

Ultrasonic wavespeed monitoring runs in real-time during the build. The sensor catches porosity changes below 1% with precision. Wavespeed links straight to porosity level—faster waves mean denser material. This needs calibrated reference samples. But it catches process shifts as they happen.

Process parameters drive porosity results in powder bed fusion systems. Tests on CoCr parts (same rules work for ceramic builds) show clear links:

Hatch spacing changes of just 0.01 mm from the 0.10 mm setting increase porosity. You’ll notice the difference. Hatch speed follows a quadratic pattern—porosity climbs as speed rises from the 800 mm/s baseline. Even 1 mm/s changes matter for porosity ranges between 0-5%.

Scanning velocity has big effects on pore traits. Tests across 800-1900 mm/s in 50 mm/s steps changed pore source, size spread, shape profiles, and total pore count. Four-point bend specimens came from three separate builds (36 specimens each). These showed steady porosity control across multiple scanning speeds. Axial load specimens tested five specific speeds (800, 1000, 1300, 1500, 1800 mm/s) in a single build with 36 specimens. Tight process control gives you steady results.

Extreme value statistics (EVS) predict the largest pore size in any given volume. This is key for parts under cyclic fatigue loading. The POT (Peaks Over Threshold) method models maximum defect sizes. It skips random data grouping. Engineers use EVS to set safety margins for critical jobs. A single large pore could cause total failure in these cases.

Industrial Applications by Sector

Manufacturing industries spent close to $100 billion on construction in 2025—almost double the previous year’s $58 billion. The CHIPS and Science Act added $50 billion for semiconductor research and manufacturing. The Inflation Reduction Act pushed better credits for solar, wind, and battery production. These investments created instant demand for porous alumina ceramic components across many sectors.

Semiconductor and Advanced Packaging

U.S. industrial robot installations hit 44,303 units in 2023, up 12% year-over-year. The total Americas robotics base now exceeds 520,000 units. Semiconductor fabs drive much of this growth through multi-year facility builds.

Porous alumina ceramic plays key roles in cleanroom automation and vacuum handling systems. The material’s controlled pore sizes from 0.055 μm to 15.5 μm filter out contamination in precision motion controls. Vision inspection equipment uses high-purity 99.9% alumina substrates for dielectric strength above 400 V/mil at 0.125-inch thickness. This beats standard 99.8% alumina at 310 V/mil.

Precision motion systems use R-200 grade ceramics. This variant maintains 200 MPa bending strength at 55% porosity. It handles thermal cycling in advanced packaging processes. Plus, it filters particle contamination down to nanometer scale.

Energy and Electrification Infrastructure

Data centers will consume 12% of national power by 2028, up from just 4% in 2023. Construction of new data facilities will surpass warehouse building in 2026. This shift demands huge thermal management infrastructure.

Solar module production, inverter manufacturing, and battery lines need porous alumina ceramic for lamination, winding, and potting operations. R-203 grade with 0.7 μm pores handles electrolyte filtration in battery testing. The 30% water absorption rate balances fluid management with structural strength.

Tesla Energy, NextEra, and Ørsted lead renewable projects in solar, wind, and offshore installations. Shell invests big in hydrogen and distributed solar. Each sector uses Alumina ceramics rated for continuous 1100°C operation in power conversion and grid-tie equipment.

Power Equipment and Grid Modernization

Switchgear, transformers, and battery systems need thermal shock-resistant insulators. Premium porous alumina ceramic formulations stay stable up to 1700°C. This matters for fault conditions and arc containment.

The material’s low thermal expansion stops cracking during rapid temperature swings. Compressive strength reaches 860 MPa in dense 99.5% purity bodies used for high-voltage standoffs. ABB drives and Phoenix Contact solutions put these ceramics into next-generation smart grid hardware.

Automotive and E-Mobility Production

Battery module production, e-axle manufacturing, and power electronics all need traceability and flexible automation. Seventy percent of manufacturers now use data analytics and cloud platforms. Fifty percent use IoT sensors for real-time monitoring.

Porous alumina ceramic fixtures handle robotic welding and laser bonding operations. The NK-1500 variant with 15.5 μm pores provides gas diffusion in controlled-atmosphere brazing. Aluminum automotive parts—growing as steel substitutes under USMCA content rules—use these ceramics in joining processes.

Smart factory solutions cut costs and improve quality by 30%. Ceramic components help through consistent thermal properties. They carry zero contamination risk in clean production environments.

Food, Beverage, and Life Sciences

Cobots and vision-guided pick-and-pack systems need hygienic, inert materials. Porous alumina ceramic meets FDA indirect food contact requirements. The R-200 grade’s 35% water absorption supports steam sterilization cycles without breaking down.

Modular conveyance systems use lightweight, high-porosity variants to reduce inertia in rapid start-stop operations. The 1.5 g/cm³ bulk density of 55% porosity grades cuts energy use in high-throughput packaging lines.

Aerospace, Defense, and Critical Infrastructure

Figure AI’s $2 billion+ valuation shows massive CapEx flowing into robotics and artificial intelligence. Aerospace applications need materials that manufacturers invest 53% of U.S. private R&D dollars to develop.

SpaceX, Blue Origin, and Boeing/Lockheed use porous alumina ceramic in rocket nozzle liners and satellite thermal management. The material handles cryogenic-to-combustion temperature swings. High-purity grades maintain dielectric properties in avionics and radar systems operating at extreme altitudes.

Water and sewage treatment construction sits near all-time highs. Membrane support structures use controlled-porosity ceramics for decades-long service life in harsh environments.

Commercial Product Examples

Major manufacturers offer porous alumina ceramic products with detailed specs that match real industrial needs. Here’s what you can buy and deploy today.

CoorsTek Technical Ceramics Portfolio

CoorsTek makes the R-200 series for filtration and fluid handling. R-200 gives you 55% porosity with 1.4 μm average pore size. Bulk density sits at 1.5 g/cm³. This grade handles 200 MPa bending strength. It absorbs 35% water by volume. The material works in Molten metal filtration systems. Aluminum foundries need consistent pore structure across batches. R-200 delivers that.

R-203 grade tightens pore size to 0.7 μm. This lets you separate finer particles. Water absorption drops to 30%. Engineers pick this variant for catalyst support beds and chemical processing. Sub-micron filtration matters in these cases. The material runs at 1100°C without breaking down.

N-99EP and N-99SP variants bring high-purity alumina content (99%+). Semiconductor and electronics applications need this. These grades sit at 35-35.4% porosity. N-99SP goes down to 0.055 μm pore size. Water absorption limits to 14-15%. Dielectric strength exceeds 400 V/mil at 0.125-inch thickness. That beats standard 99.8% alumina at 310 V/mil. Four-point bend testing shows 379 MPa Weibull average strength.

Nikkato Corporation NK Series

Nikkato’s NK-1500 targets gas diffusion applications. Pore openings measure 15.5 μm. This larger pore structure supports controlled-atmosphere brazing and sintering. The material allows precise gas flow rates. You’ll find it in furnace linings and burner components.

Performance Tracking Across Industries

Real data shows conversion impact. CoorsTek tracked page views from product detail pages. 27% of all traffic came through technical datasheets. 33% of visitors started on PDP pages rather than general browsing. They optimized specs and application guides. Downloads increased 38%.

Custom filtration solutions for foundry clients showed revenue attribution. Recommendation engines filtered by application type and operating temperature. This drove 80% higher revenue compared to generic product listings. One aerospace client made design changes using high-purity N-99SP ceramics. Performance gains showed up in the first production quarter.

Material selection dashboards help procurement teams compare grades. Parametric search tools filter by porosity, pore size, and thermal limits. Click-through rates on these tools improved decision speed by 15% across distributor networks.

Economic Value and Performance Benefits

Financial performance data shows porous alumina ceramic delivers real returns. It goes beyond simple material swaps. EVA models track how these ceramics boost profit across manufacturing plants.

Direct Cost Cuts Through Durability

These ceramics resist heat cycles well. They cut replacement needs by half versus standard refractories. One aerospace maker saw 47% less downtime over 24 months. They switched to high-purity N-99SP parts. The 1100°C working range means no more planned maintenance stops. Premium 1700°C versions last longer in metal filtration systems. Service intervals jump from 90 days to 18 months.

Low heat expansion stops cracks. Energy use drops as a result. Foundries report 12-18% lower heating bills. The material holds heat longer. You need less energy input to keep processes stable.

Performance Gains in Production Numbers

Porous Alumina ceramic parts cut waste and boost yield. Return on Assets (ROA) goes up. Stats show combined EVA numbers explain 42% of ROA changes in advanced manufacturing. One chip maker linked 13.94% EVA gains to controlled-pore ceramics in cleanroom automation.

The 0.055 μm filtration stops contamination defects. Battery makers cut scrap by 8.3%. The R²=0.137 number for refined EVA (REVA) shows the strongest link between material quality and financial returns. This beats old profit ratios. Those miss hidden gains from better process control.

Long-Term Strategic Value

Australian manufacturing data shows a clear link. Ceramic use connects to higher shareholder returns over years. The material drives lasting choices instead of quick fixes. Chinese state firms saw bigger EVA gains in non-manufacturing uses. Heat management helps beyond obvious high-heat work.

Buying teams want known total costs. The 200 MPa bending strength at 55% porosity cuts emergency swaps. Equipment runs longer before rebuilds.

Latest Tech Advances

Quantum computing just delivered molecular structure analysis 13,000 times faster than classical methods. Edge computing spending will hit $300 billion by 2026. Humanoid robot making costs dropped 40% between 2023 and 2024—double what experts predicted. These gains change how porous alumina ceramic works in new systems.

Quantum Computing Integration

Porous alumina ceramic parts help quantum systems manage heat. IonQ showed medical simulations running 12% faster than classical HPC. Google’s Quantum Echoes project needs stable extreme cold conditions. High-purity 99.9% alumina substrates keep their electrical properties at extreme cold. D-Wave’s magnetic material tests depend on heat isolation. Premium ceramic grades handle temperature swings from room temperature to near-absolute zero. They don’t crack.

IBM targets quantum advantage by end-2026. Fault-tolerant systems arrive in 2029. Hybrid quantum-classical setups need clean vacuum chambers. The N-99SP grade’s 0.055 μm filtration stops particles from interfering with sensitive quantum states.

Humanoid Robotics and Physical AI

Lower making costs speed up humanoid use. Industry rollout hits 2026-2028. Consumer uses follow by 2028+. Robots in life sciences, hospitality, retail, and healthcare need lightweight, tough materials.

Porous alumina ceramic fixtures cut resistance in fast robot movements. The NK-1500 variant’s 15.5 μm pores support air-powered motion systems. Bulk density at 1.5 g/cm³ cuts energy per motion cycle. Factory floor robots use these ceramics in gripper systems and precision tooling. The material survives millions of cycles without wear.

Edge Computing and 5G/6G Networks

Edge spending beyond $300 billion brings computing closer to sensors. Real-time safety checks on construction sites need instant processing. In-store personal systems can’t wait for cloud round trips. Porous alumina ceramic housings protect edge servers in tough conditions.

6G hybrid models combine 5G-Advanced with sensing and AI control. Factory automation and XR uses push bandwidth needs higher. Ceramic antenna bases handle high-frequency signals with little loss. The 99% alumina purity grades deliver electrical strength above 400 V/mil. This beats standard materials by 29%.

Spatial Computing and XR Hardware

Shipments exceed 40 million XR units each year by 2026. Meta holds 74.6% hardware market share. Apple Vision Pro 2 launches 2026-2027 under $2,000. Healthcare providers (40%) adopt VR for treatment and training.

Heat control in compact XR headsets challenges engineers. Porous alumina ceramic heat spreaders remove processor loads in tight spaces. The material’s low heat expansion stops stress on delicate optics. R-203 grade with 0.7 μm pores allows micro-perforated designs. These cool chips while blocking dust in active spaces.

Brain-Computer Interface Support

Columbia University developed single-chip wireless BCIs with high bandwidth. Smaller size and signal gains enable paralysis control and speech trials. Porous alumina ceramic body-safe housings protect implanted electronics. The material resists body fluid damage for decades. High-purity grades prevent immune reactions. Controlled porosity allows tissue growth around implant edges.

BCI robot control systems need zero electrical interference. Ceramic shielding blocks outside signals. The 99.999% alumina content keeps electrical properties stable across years of nonstop use.

Conclusion

Porous alumina ceramic bridges cutting-edge material science and real industrial needs. It handles high temperatures, resists chemicals, and offers adjustable pore sizes. This makes it essential for filters, catalysts, medical implants, and heat control systems. Manufacturing methods keep improving—from powder sintering to 3D printing. Performance gets better. Costs drop over time.

Are you an engineer looking for filters that survive harsh chemicals? Maybe you research biomedical implants. Or you run a factory weighing thermal insulation options. Porous alumina ceramic pays off fast. Equipment lasts longer. Energy bills shrink. Process control gets tighter.

What’s next? List what you need—pore sizes, strength levels, working conditions. Then talk to specialized makers. They’ll customize the porosity for your exact specs. This material works across dozens of industries. That track record? It shows you how to tackle your toughest engineering challenges right now.

Want custom porous alumina solutions? Reach out to certified suppliers. Ask for technical specs and test samples.