Your metal casting quality depends on one key choice: the right ceramic porous filter maker.

A poor filter does more than ruin your casting. It leads to rejected batches. You waste materials. Client trust breaks down. India’s foundry sector keeps growing, and dozens of suppliers say they have the best filters.

Good filters and average filters? That gap separates top foundries from those that struggle.

You need pure molten aluminum. You filter high-heat alloys. You remove tiny bits of contamination. Your filter maker choice changes your output and product quality.

We looked at India’s top ceramic porous filter manufacturers. We checked their technical skills, material focus, and track records. Some companies bring 35+ years of aluminum filter know-how. Others use new dust-free molten metal tech.

This guide shows you seven makers changing India’s metal casting business. Plus, you’ll see exactly what procurement teams should check before picking a supplier.

Jagannath Company – 35+ Years Aluminium Filtration Specialist

Jagannath Company built its reputation over three decades. They solve aluminum extrusion problems that other suppliers can’t handle. They’ve served over 250 aluminium extrusion industries across India since they started. Their focus? Precise metallurgy backed by I.I.T.-trained engineers.

Their technical team includes certified metallurgical engineers. These experts understand how aluminum alloys behave at the molecular level. This isn’t just marketing talk. You’re working with magnesium master alloy ingots at 80% magnesium composition? One percentage point error destroys your entire batch.

Products Beyond Standard Filtration

Most manufacturers stick to one product type. Jagannath offers foundry chemicals engineered for aluminium extrusion work. Their magnesium master alloy ingots maintain tight tolerances. The boron grain refiner boosts mechanical properties. It controls grain size during solidification.

Tattvam Vyapaar Private Limited – Multi-Material High-Temperature Filter Solutions

Three years ago, Tattvam Vyapaar Private Limited jumped into India’s ceramic porous filter market. CEO Rameshgiri Gosai leads the company from Ahmedabad, Gujarat. They chose a different path than old-school manufacturers. Rather than focus on one material, they mastered three filter types. Each one works for different metal casting temperatures and alloy mixes.

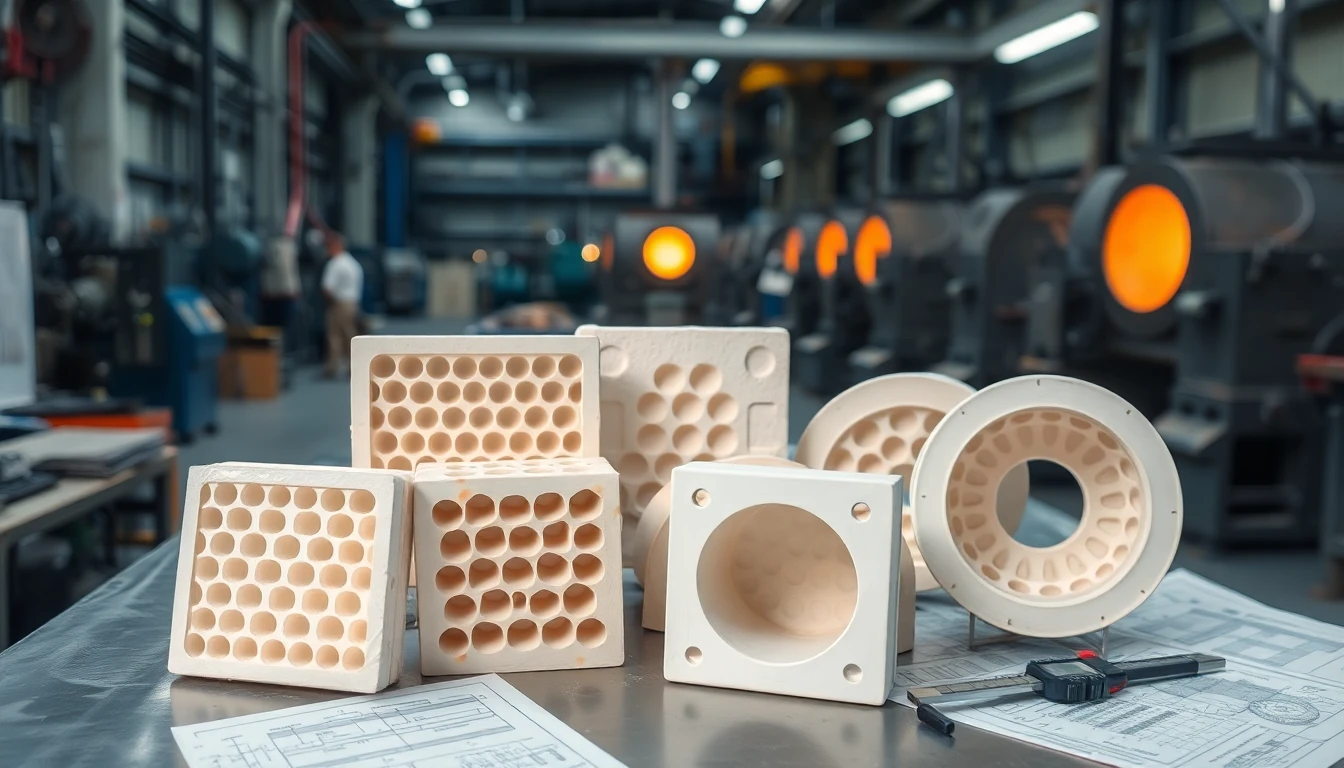

Three-Material Filter System for Different Casting Demands

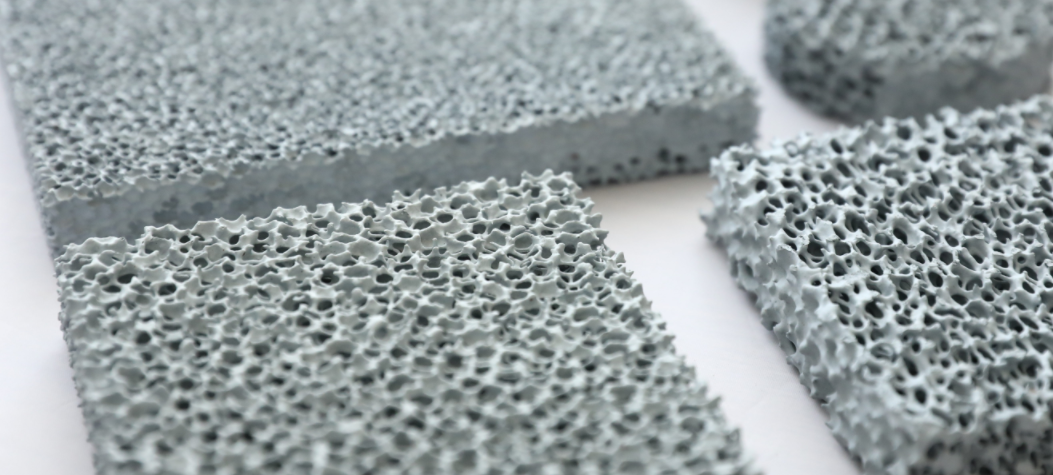

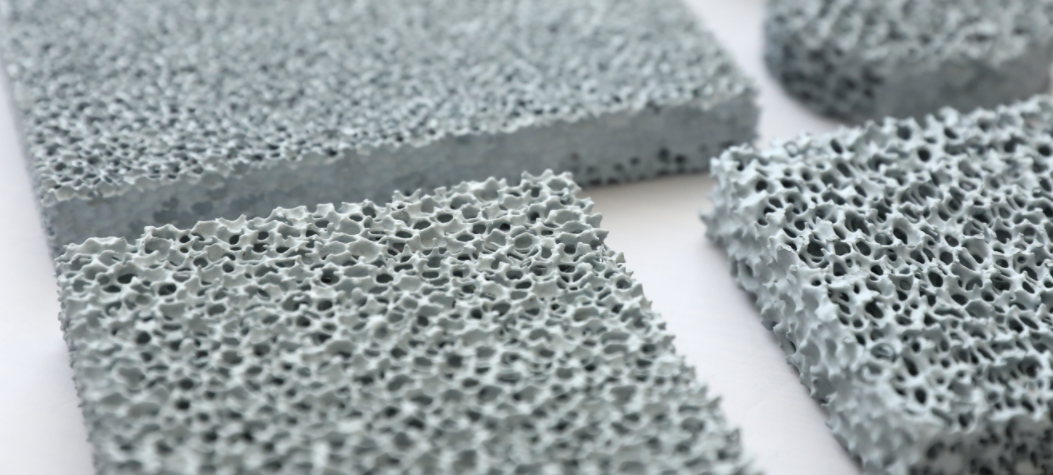

Their silicon carbide (SiC) filters work well for iron and steel casting. Chemical stability is what matters here. The grey foam structure offers 10, 20, or 30 PPI pore densities. You can pick 15 mm or 22 mm thickness. These filters cost ₹5 per piece. No hidden charges. You get solid heat resistance. Plus, they handle aggressive molten metal flow.

Need extreme heat resistance? Check out their zirconia filters. These survive temperatures up to 1700°C. The yellow foam structure traps dirt in high-temperature steel casting. Standard ceramics can’t do this. Square sizes go from 40×40 mm to 200×200 mm. Round ones span 30 mm to 150 mm diameter.

The alumina ceramic line works for general foundry metals. White filters come in seven thickness options from 7 mm to 22 mm. Pore sizes run 1.7 mm to 3.75 mm. Small square filters start at 25×25 mm. Large rounds reach 150 mm diameter. Price drops to ₹2 per piece. You need to order 500 units minimum.

Contact details: Their Ahmedabad office can help you pick the right material. Tell them your alloy type and working temperatures. They export to international foundries that need multi-material filters from one Indian supplier.

SS Khardekar India Pvt Ltd – Lanik VUKOPOR Exclusive Distributor

SS Khardekar India Pvt Ltd (SSKIPL) is the sole distributor for Lanik VUKOPOR® ceramic foam filters in India. They teamed up with Czech Republic’s Keramtech s.r.o. in 2014. This isn’t a side gig. They focus on one thing: bringing European filtration technology to Indian foundries.

The company runs a manufacturing unit at Gat No. 994/1, Sanaswadi, near Pune. Their Lanik India facility is at Gat No 399, Balaji Warehousing, Lonikand. Both sites do one job: make VUKOPOR filters that fit India’s varied casting needs.

VUKOPOR Filter Technical Performance

VUKOPOR filters use Al2O3 or SiC materials. The open-cell pore structure catches solid bits in molten metal flow. Standard sizes like 150x150x22 mm S10 work for high-volume production. They ship 2,016 pieces per order under HS code 69039090.

These filters handle non-ferrous alloys, aluminum, and steel casting. You run sand casting? Investment casting? Continuous casting for bars, rods, or tubes? VUKOPOR works for all three.

The performance data shows real cost savings. Casting yield goes up. Waste and rejections drop. Machining costs fall. Surfaces come out smoother. Your molds and equipment last longer. Less erosion damage. Energy use drops through uniform solidification. You need fewer refining agents. Mechanical properties get better. Defects become rare.

Complete Foundry Supply Range

SSKIPL stocks more than filters. They carry feeding solutions: insulating sleeves, exothermic sleeves, high-density sleeves, and hot tops. Their coating line has mold and core coatings, Korestick, and mold sealing rope. Need slag coagulant? Inoculants? FeSiMg? Tundish boards? Chromite sand chilling compound? They stock it all.

Get their catalog: Contact their Pune facility for VUKOPOR filter specs. Ask about bulk pricing on foundry materials. They offer technical help for matching filters to your specific alloy and casting method.

SKJ Group – Custom Advanced Ceramic Filter Maker

SKJ Group started in 2019 with one clear goal: build ceramic porous filters that adapt to each foundry’s unique casting needs. No generic off-the-shelf products. They operate from the USA with a global presence. Their precision ceramic engineering serves metal casting operations that need exact specs.

Premium Cordierite Engineering

They use premium-grade cordierite as their main material. The chemical makeup stays tight: Al₂O₃ at 35.2% ± 1.5%, SiO₂ at 50.9% ± 1.5%, and MgO at 13.9% ± 1.5%. This precision counts during molten metal filtering at extreme heat. Cordierite costs less than silicon carbide. Its lower melting point gets balanced by better cost value. You get thermal shock resistance without breaking your budget.

Need something else? They work with alumina, zirconia, and silicon carbide for special casting work. Each material choice depends on your metal type and heat levels.

Honeycomb Structure Tech

The honeycomb design gives you maximum surface area. Cell densities run from 50 to 600 CPSI (cells per square inch). This structure traps soot and fine particles that hurt casting quality. Thin-wall design cuts backpressure. Plus, it keeps filtration working well. The light build makes handling easier during filter changes.

Their diesel particulate filter (DPF) honeycomb ceramics work beyond auto applications. Foundries use them for exhaust gas filtering in power plants. The high porosity gives you excellent strength. Temperature changes? The thermal shock resistance handles sudden heat shifts without cracking.

Beyond Metal Casting

Foundry filtration drives their business. But SKJ products serve many industrial sectors. Chemical plants use their filters in high-temp environments needing heat protection. Aerospace and electronics industries pick them for applications needing structural strength at extreme heat. Environmental protection systems use their air and water purification filters. The same honeycomb tech that cleans molten aluminum also works as catalyst support in chemical reactions.

Contact SKJ Group for custom filter specs matched to your alloy makeup and casting process. Their engineering team designs solutions for your specific application—not catalog items changed to “sort of” fit your needs.

Flotuff – India’s Largest Industrial Ceramics Producer

Flotuff started in 1989 in Panchkula, Haryana. That’s 36 years making ceramics. They run India’s largest industrial ceramics production facility. The numbers prove it. Their ceramic porous filter line goes far past basic foam filters. They built multi-channel membrane systems. These span 5 kD to 1.2 µm filtration range.

Alpha Alumina Membrane Technology

The base material is α-Al2O3 (alpha alumina). This supports the membrane. Their MF membranes use α-Al2O3, ZrO2, or TiO2. UF membranes flip that order: TiO2, ZrO2, then α-Al2O3. Why does this help metal casting? These membranes resist pH 0-14. So aggressive molten metal filtration won’t break down the membrane. Steam sterilization works at ≥121°C. Elements stretch to 1500mm. That beats most competitors.

Flotuff makes twelve different multi-channel setups. The 1/6 type has one 6.0mm channel. Length runs 1000-1200mm. Filter surface is 0.019-0.023 m² per element. Want more flow? The 85/3.3 setup packs 85 channels at 3.3mm each. Element diameter is 52.0mm. That gives you about 1.0 m² filter surface in 1200mm length. The 61/4 type offers 1.03-1.29 m². It uses 61 channels at 4.0mm diameter.

Pore sizes cover microfiltration at 1.2, 0.8, 0.4, 0.2, and 0.1 µm. Ultrafiltration drops to 0.05 µm. Then you get molecular weight cutoffs: 150 kD, 100 kD, 25 kD, 15 kD, 5 kD, 1 kD. Metal casting foundries pick the larger microfiltration sizes. Chemical plants and biotech need the ultrafiltration options.

Beyond Casting Filters

Flotuff’s products include other ceramic items. High purity alumina crucibles work for lab melting. Ceramic ferrules deliver exact components. Their wear resistant tiles come in three types: standard alumina, white alumina, and alumina wear resistant lining tiles. Zirconia crucibles take extreme heat. Cordierite saggers handle thermal shock. Foundries use these for heat treatment.

They work with atech innovations on ceramic membrane chains. This partnership brings you filterability testing, on-site pilot testing, and custom pressure vessel build. Flotuff holds Indian Green Building Council membership. Their Haryana plant ships all over India. Pricing stays competitive. Technical support comes from engineers with two decades in ceramics.

Contact Flotuff at Plot No. 198, Phase 1, Industrial Area, Panchkula-134113, Haryana. Ask about custom multi-channel membrane specs for your filtration needs. Their team designs solutions with you. Not just catalog orders.

Lanik (via SS Khardekar Partnership) – Dust-Free Molten Metal Filtration Technology

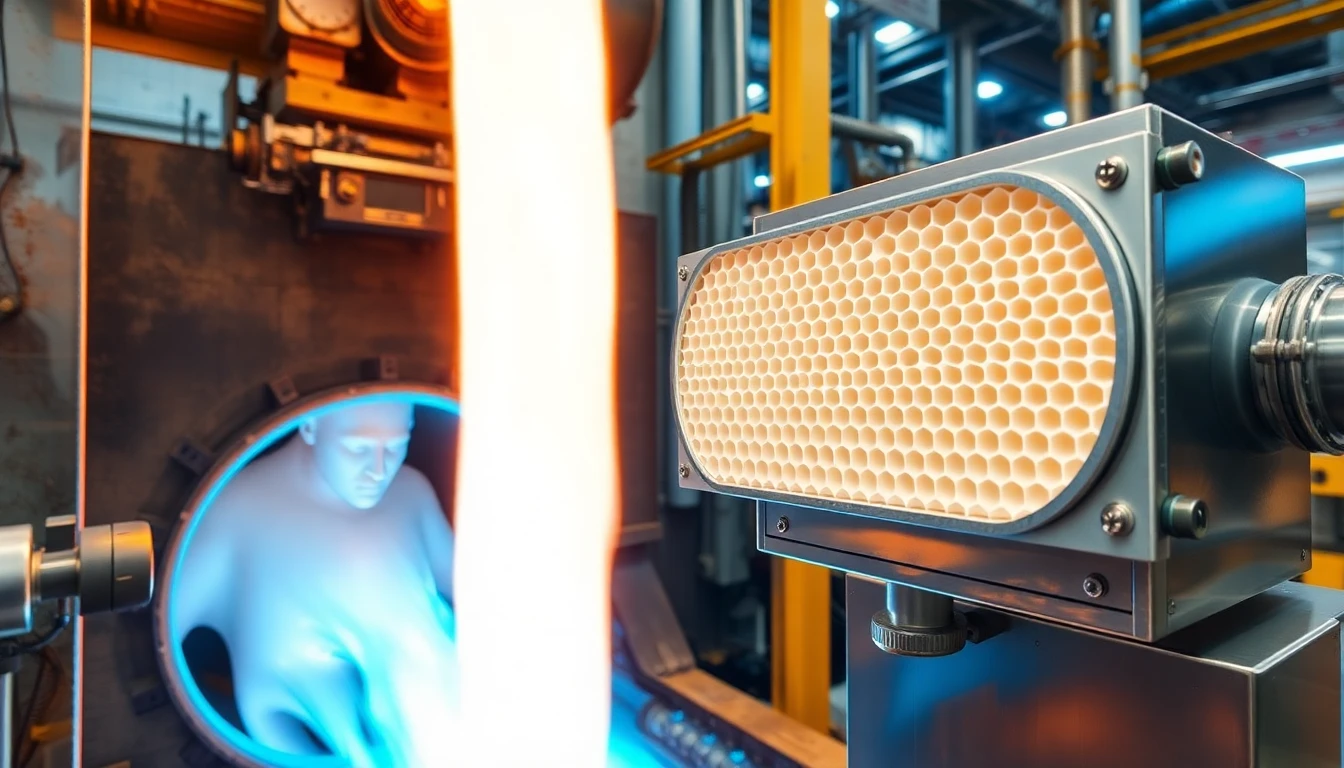

Dust-free molten metal? It’s real now. Lanik’s VUKOPOR® technology comes to India through SS Khardekar. It catches every non-metallic impurity before your casting fails. The filter turns wild, choppy flow into smooth, even movement.

Three-Temperature Filter Range

VUKOPOR® A works with aluminum and non-ferrous alloys up to 1350°C. The Al2O3 structure traps alumina bits through its even ceramic build. Filter clogs? Gone. Pour at 1200°C—the alumina stays solid without breaking apart.

Need more heat? VUKOPOR® S goes to 1480°C for cast iron, bronze, brass, and copper alloys. The silicon carbide base forms 3D connected cells. Choppy metal flow goes in. Smooth flow comes out. New impurities don’t form during pouring like they do with metal gratings.

Steel and heavy iron need VUKOPOR® HTX. It handles 1700°C. Sand casting, investment casting, continuous casting—this filter line works with all three.

How It Works

The open-cell pore network traps what you don’t want. Slag bits, impurities, oxides—they stick inside the ceramic structure. Quick priming starts the filtering right after pre-heating. Old-style filters create choppy flow that makes new defects. VUKOPOR turns that mess into clean, smooth movement.

Running low-pressure die casting? Try the reusable “corks” with ceramic pipes and heat sleeves. No more buying one-shot filters that drain your budget.

Metal flows better. Casting problems drop. Your finished surfaces need less machine work. SS Khardekar keeps the full VUKOPOR range at their Raigad factory. Horizontal or vertical filter bowls with gaskets fit your current gating systems.

Contact SS Khardekar for VUKOPOR specs that match your alloy temperatures and casting needs.

FoundryMax Supplier – High-Porosity Aluminum Casting Purification

FoundryMax FM-04 filters pack 86.8% porosity by volume into their alumina ceramic foam structure. That’s 80–90% open space built to trap what ruins aluminum castings. The honeycomb channels create maximum contact area between molten metal and ceramic walls. Inclusions over 20μm get caught—90% removal rate guaranteed.

The 15–25% Strength Jump You Get From Clean Metal

Sodium and potassium dirt destroys aerospace aluminum alloys. FM-04 filters strip these out during pouring. The result? Tensile strength jumps 15–25% compared to unfiltered castings. Aviation and high-tech transport jobs need this boost. Fewer bits of dirt mean better mechanical properties. Your alloy performs the way the spec sheet promises.

Key Selection Criteria for Metal Casting Buyers

Procurement teams waste millions on the wrong filter supplier. A qualified vendor versus an average one? The difference shows up in three places: rejected batches, long lead times, and hidden rework costs that kill your margins.

Your selection process needs structure. Not gut feeling. Not the supplier who answered first.

Match Supplier Experience to Your Alloy Complexity

Aluminum casting for automotive parts? High-temperature steel for aerospace turbine housings is different. Check the supplier’s client list on their website. Look for your exact industry—defense, automotive, aerospace, nuclear. Generic “industrial casting” experience won’t work with exotic alloys that melt above 1500°C.

A supplier serving automotive clients for 15 years gets aluminum’s thermal behavior. They know how magnesium content affects grain structure. They’ve fixed porosity problems in die-cast aluminum engine blocks. This knowledge doesn’t come from a steel foundry overnight.

Process Diversity Cuts Your Vendor Count

Single-process suppliers lock you in. You need sand casting for prototypes. Die casting for production runs. Investment casting for complex shapes. Three suppliers mean three quality systems. Three payment terms. Three technical contacts.

Pick a vendor offering multiple casting processes under one roof. Part complexity changes? They switch from gravity casting (tolerances ±0.5-1mm) to pressure die casting (tolerances ±0.05-0.1mm). No need to hunt for a new supplier. Die casting handles high-volume thin walls under 3mm. Gravity casting works for low-medium runs with larger parts.

Material Compatibility Matrix Matters

|

Metal Type |

Critical Checks |

|---|---|

|

Aluminum |

Aerospace/automotive focus; verify die casting for high-volume; check corrosion resistance specs |

|

Steel/Iron |

Confirm ferrous and non-ferrous handling; avoids split orders across vendors |

|

High-Temp Alloys |

Nuclear and aerospace certifications needed; request full alloy compatibility list |

A supplier claiming “we cast everything” means they’re average at most materials. Aluminum price swings drive material costs up. Steel casting hits $30 billion by 2026. Your supplier needs deep expertise in your specific metal. Not basic knowledge across twenty alloys.

Quality Inspection Depth Reveals Real Capability

Ask about their NDT (non-destructive testing) setup. Radiography? Ultrasonic testing? Penetrant inspection? These methods catch 90%+ of internal defects before parts ship. Visual checks spot surface porosity and cracks. Dimensional checks use calipers and CMMs for tight tolerances.

Qualified suppliers cut scrap rates 15-25% through systematic inspection. That’s not marketing. That’s fewer rejected batches. Lower total cost per good part.

Cost Breakdown Beyond Unit Price

Die casting tooling runs $50,000 to $500,000. Your supplier quoting the lowest per-piece price but charging high tool costs? You lose money at volume. Break down these areas:

|

Cost Dimension |

What to Verify |

|---|---|

|

Initial Investment |

Tool costs, material pricing stability, aluminum price swings |

|

Operational Life |

Design reviews that extend part lifespan; integrated machining cuts handling 20-30% |

|

Defect Prevention |

NDT capabilities that eliminate rework; proven scrap reduction record |

Integrated machining services cut your handling steps by 20-30%. One supplier does casting plus finish machining. Fewer touchpoints mean fewer quality problems. Faster delivery too.

Service Benchmarks That Predict Performance

Custom cycles matter. Value-added design review during quoting? That saves you from making problems later. Sample parts in 2-4 weeks show quick production capacity.

Technical support depth separates leaders from followers. Do they have metal engineers? Alloy-specific know-how? Certifications like ISO 9001 or AS9100 for aerospace work?

Delivery chain stability shows in their history. Nearshoring cuts lead times 20-40% versus distant suppliers. Financial stability prevents mid-project supplier failures that stop your production line.

Five Questions Before You Sign

-

Show me three projects matching my alloy and product complexity

-

What certifications and testing gear do you keep in-house?

-

Do you offer extra services—design optimization, integrated machining, heat treatment?

-

Prove your financial stability and work history over five years

-

How do you align on my priority: quality, cost reduction, or delivery speed?

The global metal casting market grows from $161 billion in 2025 to $263 billion by 2035. That’s 5% yearly growth driven by automotive demand—40%+ of market share goes to EV parts and lightweight structures. Ceramic porous filter makers supporting this growth invest in aluminum expertise. That’s where volume sits.

Your filter choice affects everything downstream. Pick suppliers who prove capability through certifications, testing setup, and records in your exact application. Not vendors selling generic solutions to anyone who calls.

Conclusion

India’s metal casting industry has grown and matured. The right ceramic porous filter manufacturer makes a real difference to your production efficiency and casting quality. Jagannath Company brings 35+ years of aluminium filtration expertise. Flotuff offers massive production capacity. Each manufacturer has distinct strengths.

The smart move? Don’t settle for generic solutions. Running high-volume aluminum casting operations? Need specialized multi-material filtration? The 7 best ceramic porous filter manufacturers in India’s metal casting industry profiled here have proven track records and real results.

Map out your specific requirements first. List your filtration grade needs. Check your production volume. Note material compatibility. Set your budget constraints. Then reach out to 2-3 manufacturers whose capabilities match what you need. Request technical specifications. Ask for samples. Get case studies from similar applications in your industry.

The right filtration partner does more than supply filters. They help you cut rejection rates. They reduce machining costs. They deliver superior castings every time. Your next foundry breakthrough might be just one supplier conversation away.

Ready to upgrade your metal casting quality? Contact these manufacturers today.