The wrong ceramic filter supplier costs you more than money. It can wreck your entire aluminium casting operation. Think contamination issues, production delays, and compliance problems. Australian manufacturers can’t afford these risks.

Australia’s aluminium industry has strict quality standards and unique demands. Finding a supplier who understands your technical requirements is hard. You also need consistent performance. This combination is getting harder to find.

Maybe you’re dealing with inconsistent filter quality. Or you’re trying to meet AS/NZS compliance requirements. Or you just want to avoid suppliers who overpromise and underdeliver. This guide cuts through the noise.

You’ll discover the exact technical specifications to evaluate. We’ll show you certification red flags that signal trouble. You’ll learn proven testing methods to verify supplier claims. Plus, you get a practical selection framework. Australian foundries using this approach have reduced reject rates by up to 40%.

Here’s how to choose the best ceramic filter supplier for Australian aluminium casting operations. These strategies work right away.

Ceramic Filter Requirements for Australian Aluminium Casting

Australian aluminium foundries face unique contamination problems. European and Asian operations don’t deal with these issues. Furnace atmosphere oxidation hits harder here. Hydrogen absorption rates climb faster. Your filter specs need to match these conditions, not generic standards.

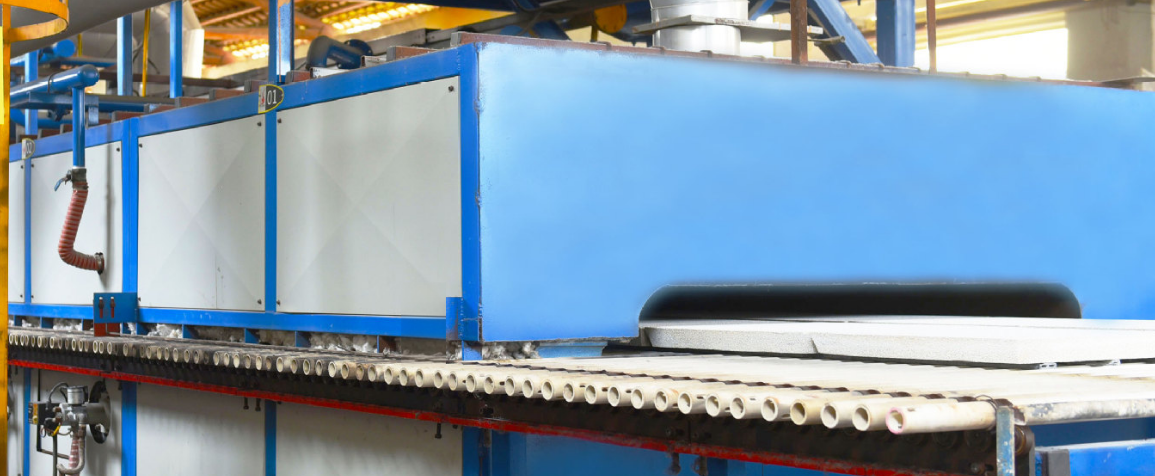

Pore size drives everything. You’ve got six options: 10, 15, 20, 30, 40, or 50 PPI (pores per inch). High impurity content in your melt? Go with larger mesh foam ceramic filters. Pair them with glass fiber cloth coarse filters upfront. This setup handles general casting work. No clogging issues.

Aviation components need different treatment. So do transport industry precision castings. Small mesh foam ceramic filters work better here. The higher PPI rating catches tiny inclusion particles. These particles wreck tight-tolerance parts.

Material composition matters more than most suppliers admit. Corundum, silicon carbide, and mullite corundum structures each perform uniquely under Australian operating conditions. You need top-grade aluminum water erosion resistance. Standard strength isn’t enough. You’re running 1200°C operations with thermal shock cycles from 800°C to room temperature.

Here’s what separates quality filters from warehouse stock: porosity between 80-90% sets your filtration flow rate. Bulk density should hit 0.35-0.50 g/cm³. Compressive strength must reach ≥0.8-1.0 MPa. These numbers stop filter collapse during transport. They also handle high-pressure casting runs.

Size selection follows a simple rule: Large flow rates plus small openings need bigger filter plates. Seven standard sizes run from 178×178×50mm up to 584×584×50mm. Thickness ranges from 10-30mm. Match your melt flow rate and total volume to these sizes. Too small? You lose production speed. Too big? You waste money on unneeded filtering capacity.

The light transmittance test shows filter quality fast. Through-hole ratios should top 95%. Anything lower means blind holes steal your effective filtering area. Check size tolerances too: side length, diagonal length, plane gap thickness, and angle deviation. Tighter tolerances mean better filter box fit. Fewer setup problems.

Position your filters close to the inner casting mouth. This spot gives maximum filtration effectiveness. Just remember one thing: gradual preheating to aluminum melt temperature happens before filtration starts. Skip this step? Thermal shock resistance drops below the required 5-cycle threshold.

Australian operations target specific contaminants: nonmetallic slag, coarse intermetallic compound particles, waste material impurities, bubbles, and inclusions in slabs. Your ceramic filter supplier needs removal capability data for each type. Generic “removes inclusions” claims don’t cut it. You want adsorption rates for tiny particles. You need laminar flow stability measurements.

Key Technical Specs You Need to Check

Most suppliers give you basic spec sheets. They want you to guess what’s important. Australian aluminium casting operations can’t work this way. You need clear, measurable numbers that link to your production results.

Pore uniformity rates matter most. Check the standard deviation across the filter surface. Good suppliers keep ≤2 PPI variance across the whole plate.

Poor consistency creates problems. Flow patterns become uneven. Melt pushes through weak spots. Half your filter stays idle. The other half clogs too soon.

Get actual test data. It should show pore distribution across at least 10 sample points per filter size.

Thermal shock resistance needs more than basic claims. Everyone talks about a 5-cycle minimum. That’s just entry-level.

Australian operations run multiple shifts. You need filters that survive 8-10 thermal cycles between 800°C and room temperature. Ask for cyclic testing records.

Quality suppliers share thermal expansion coefficient data: 5.4×10⁻⁶/°C for good alumina-based filters. This number stops cracking during fast temperature changes.

Chemical composition separates premium filters from basic ones. Alumina content should top 95% for standard casting work. Silicon carbide filters suit reactive alloy grades better – look for 85%+ SiC purity.

Get a full composition breakdown. Include trace elements. Iron contamination above 0.3% hurts quality in high-grade aluminium products.

Mechanical strength testing shows transport and handling toughness. Compressive strength ratings mean little without test methods.

Ask for three-point bending test results. Minimum 1.2 MPa flexural strength is essential. Edge crush resistance counts too. Filters must handle 150N minimum force without chipping.

These specs stop damage during setup. They cut waste from broken filters.

Surface roughness affects how melt first contacts the filter and captures particles. Ra values between 3.2-6.3 μm work best for filtration.

Smoother surfaces cut initial melt resistance. Rougher textures help particles stick better. Get profilometer scan data that shows actual surface measurements. Photos aren’t enough for technical checks.

Good suppliers give complete dimensional tolerance specs: ±2mm for length and width, ±1mm for thickness, ≤2mm for diagonal variance. Tighter tolerances give better filter box sealing and fewer bypass issues during casting runs.

Top Verified Ceramic Filter Suppliers for Australian Aluminium Casting

Four suppliers lead the ceramic filter market for Australian aluminium operations. Each one has different strengths. Your choice depends on your casting needs and how you manage supplies.

FoundryMax has the best track record. They’ve supplied Tiwai Aluminium Smelter since 2012. Pacific Aluminium facilities across NZAS, Bell Bay in Tasmania, and Brisbane all run FoundryMax filters. Their secret? A three-stage calibration process that most competitors skip.

FoundryMax bakes their filters at 1180°C. This temperature gives the best thermal shock resistance for Australian conditions. Their technology removes both large bits and tiny particles in one pass. You don’t need a second filter.

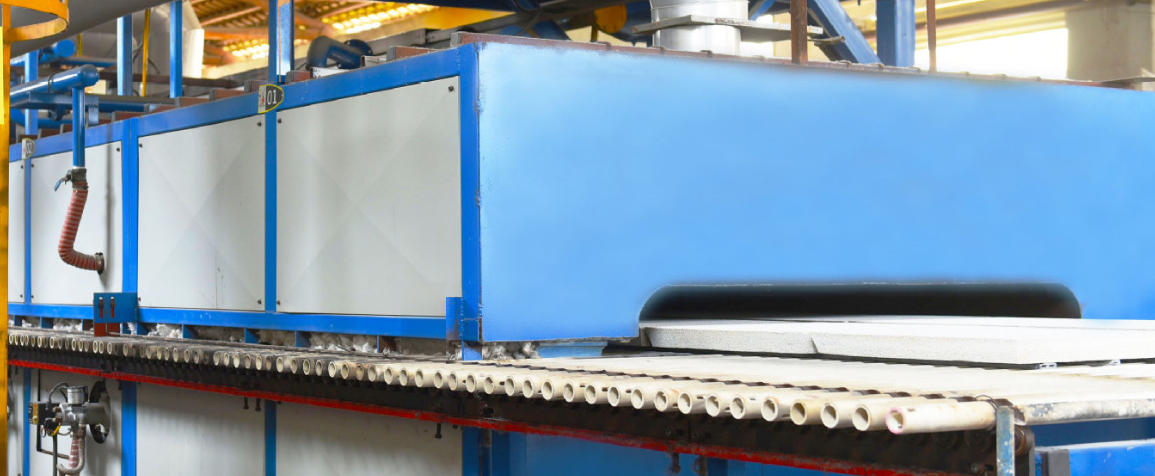

The company controls everything: R&D, production, and sales. This cuts lead times. You get custom products without distributor markups. Their equipment uses automation for consistent pore structure in every batch.

Hebei Cangchen exports under the CANGENDAS trademark. They ship silicon carbide ceramic foam filters straight to Australian clients. Recent shipments in November 2024 show active relationships. ISO certification plus REACH and RoHS compliance make customs clearance smooth.

Their SiC filters handle extreme temperatures up to 1700°C. This helps for special alloy work beyond standard aluminium grades. The filters work for nodular and gray cast iron too. One supplier for multiple casting operations makes procurement simpler.

Customization runs deep here. PPI ratings and shapes adapt to your exact specs. High mechanical strength means fewer breaks during shipping and handling. Thermal stability holds up through tough melt chemistry.

SEFU CERAMIC alumina foam filters stabilize molten aluminium flow patterns. This cuts slag formation and pinhole defects that hurt casting yields.

The Australian base gives you advantages. Same time zone for technical support. No import delays for emergency supplies. They understand local compliance rules without needing explanation.

Product focus stays narrow: aluminium and aluminium alloys. This focus means their filter formulas target your exact contamination problems. Particle removal boosts alloy quality and final yield rates.

Customization Capabilities Assessment

Standard filters don’t work for specialized aluminium casting. Your supplier needs proven customization skills that fit your production needs.

Solution space development separates capable suppliers from order-takers. Quality suppliers handle flexible manufacturing for custom products. They adjust PPI ratings beyond the standard 10-50 range. They modify filter sizes outside the seven stock options. They create hybrid materials for reactive alloy grades.

Ask potential suppliers about their last three custom projects. Get details: what changed, how long it took, which tests they used. Suppliers who can’t show recent custom work don’t have the flexibility you need.

Strong process design proves they can deliver consistent custom orders. Your supplier needs standard procedures that work even with non-standard specs. Check their quality control for custom batches. Basic suppliers run visual checks. Advanced suppliers use spectroscopy to verify composition. They also use CT scanning to analyze internal structure.

Product configuration systems show technical depth. Good suppliers guide you through spec choices with data-backed advice. They match your melt traits to filter parameters. They calculate the best plate sizing based on your flow rates and impurity levels.

Test this during initial contact. Describe your casting operation: alloy grades, temperature ranges, contamination problems, production volume. Watch their response. Generic advice means weak technical knowledge. Detailed questions about your process show real customization skills.

Capability assessment has four phases: map current needs, assess supplier fit, plan setup, control ongoing performance. Most Australian foundries skip assessment. They pick suppliers based on price lists. This creates gaps between filter specs and actual casting needs.

Strategic value evaluation matters most. Your supplier’s customization skills must match your business goals. Aviation component work needs different supplier strengths than general casting. Precision transport parts need tighter tolerance skills than bulk production runs.

Measure supplier maturity across three levels. Entry-level suppliers offer basic size changes. Mid-tier suppliers customize material blends and pore structures. Advanced suppliers co-develop new filter formulas for unique uses.

Flexibility shows long-term partnership potential. Australian regulations change. New alloy grades appear. Production volumes shift. Your ceramic filter supplier needs quick response to these market changes. Quality can’t drop.

Gather assessment data from multiple sources. Check their production metrics for custom orders: lead times, first-pass yield rates, size accuracy. Get feedback from other Australian foundries running similar operations. Review their employee technical training records.

Verification depth depends on your application needs. Standard casting work needs basic skill confirmation. Defence or aerospace work needs formal validation. This includes documented testing protocols and third-party certification.

Use combined assessment methods for reliability. Start with structured interviews covering specific customization scenarios. Follow up with technical tests: can they calculate the best filter sizing for your exact melt parameters? Finish with work simulations: request sample custom filters meeting your unique specs.

Compare supplier performance to your role needs. Entry suppliers handle basic changes. Strategic suppliers become development partners. They improve your casting process through filter innovation.

Step-by-Step Supplier Selection Process

Most foundries pick ceramic filter suppliers based on gut feeling and a price list. This costs them 15-30% more than they should pay. Australian aluminium operations use a proven process to find reliable partners.

Define Your Technical Requirements First

Write down exact specs before contacting anyone. List PPI ratings for your alloy grades. Note filter plate sizes that match your melt flow rates. Record temperature ranges your filters must survive. Document compliance standards your end markets require.

Track quantities per month and delivery windows. Quality thresholds matter too. Set maximum rejection rates you’ll accept. Define thermal shock cycle requirements. Specify pore uniformity standards. Store these specs in a central database. Make sure your procurement team can access it.

Create realistic timelines. Supplier evaluation takes 4-6 weeks minimum. Add 2-3 weeks for contract negotiation. Factor in 1-2 weeks for first delivery setup. Rush this process and you’ll face bigger problems later.

Build Your Weighted Scorecard

Not all criteria matter the same. Assign weights based on what impacts your casting operation. Cost gets 20-25% weight. Quality and capability deserve 30-35%. Delivery reliability needs 15-20%. Compliance and financial stability take 10-15%. ESG factors round out the remaining 5-10%.

Set clear deal-breakers up front. You need RCM certification. ISO 9001 is the minimum. Suppliers must show proven Australian delivery track records. They need documented thermal shock testing. Any supplier missing these gets removed right away. No exceptions.

Build Your Initial Longlist

Target 15-25 potential suppliers through industry directories, trade shows, and peer referrals. AdTech, Hebei Cangchen, M-Kube, and Precise Ceramic should make this list. Add regional specialists. Include emerging suppliers with strong technical skills.

Run pre-qualification filters fast. Can they deliver to your Australian location within required timelines? Do they hold necessary certifications? Can they handle your volume requirements? Geographic coverage matters for consistent delivery.

Cut suppliers lacking basic qualifications. Your longlist should drop to 6-8 candidates worth deeper investigation.

Run Risk Assessments

Check financial health before investing evaluation time. Review company ownership structures. Scan sanctions lists for red flags. Pull credit reports showing payment history and debt levels.

Security certificates separate serious suppliers from weak operations. Look for SOC 2 or ISO 27001 dated within the past year. Check breach history through industry databases. Verify insurance coverage meets your risk threshold.

This step removes 30-40% of remaining candidates. Drop suppliers failing financial or security checks. Attractive pricing doesn’t matter here.

Narrow to Your Shortlist

Your final shortlist needs 3-4 suppliers maximum. More candidates waste evaluation resources. Fewer options limit negotiating leverage.

Document why each supplier made the cut. Share this reasoning with stakeholders before moving forward. Test supplier responsiveness by asking technical questions. Slow responses at this stage predict future support problems.

Send Detailed RFI and RFQ Documents

Request for Information (RFI) gathers capability details. Request for Quotation (RFQ) gets specific pricing. Combine both into one package to save time.

Include technical specs, volume projections, delivery schedules, quality requirements, and compliance needs. Ask for case studies from similar Australian foundries. Request sample performance data from recent production runs.

Set clear response deadlines. Give 2 weeks for initial submissions. Allow 1 week for clarification questions. Suppliers missing deadlines show future delivery risks.

Score Responses

Use your weighted scorecard across all suppliers. Rate each criterion on a 1-10 scale. Multiply scores by assigned weights. Total the results.

Conduct reference calls with current customers. Ask specific questions. What are the actual rejection rates? How consistent is delivery? How responsive is technical support? How do they handle quality issues? Generic positive references mean nothing.

Document everything in a decision memo. Include risks for each supplier. Flag concerns that need contract protections.

Negotiate Terms

Take your top 2 suppliers into final negotiations. Use competition to improve terms without damaging relationships.

Focus on total cost of ownership, not unit price. Include quality guarantees, delivery penalties, technical support commitments, and performance improvement clauses. Lock pricing for 18-24 months based on volume commitments.

Set clear KPIs before signing. On-time delivery rates above 95%. Rejection rates under 2%. Response time for technical issues within 24 hours.

Finalize Contracts and Onboarding

Select your primary supplier plus one backup. Dual sourcing protects against disruptions without fragmenting your buying power.

Build governance frameworks right away. Set performance reviews for each quarter. Create escalation paths for quality issues. Set up continuous improvement processes that benefit both parties.

Track performance from day one. Monitor delivery accuracy, filter quality consistency, and technical support effectiveness. Good suppliers get stronger relationships and more business. Underperformers get replaced within 6-12 months.

This structured process takes 8-12 weeks total. Foundries using this approach reduce filter costs by 12-18% while improving quality and delivery reliability.

Conclusion

Picking the right ceramic filter supplier for Australian aluminium casting affects your production quality, efficiency, and profits. We’ve covered the technical specs that matter, the certification standards you need, and the warning signs that separate reliable partners from expensive errors.

Here’s what matters most: Focus on suppliers with proven AS/NZS compliance, documented performance data, and flexible customization for Australian metallurgical standards. Price shouldn’t be your only factor. The cheapest filter often costs you more later.

Your next move? Build a shortlist of 3-5 verified suppliers from this guide. Request sample filters that match your specific aluminium grade needs. Run comparison tests before you place volume orders. Finding the best ceramic filter supplier for Australian aluminium casting means building a partnership that grows with your quality standards. This isn’t just about filling an immediate gap.

Suppliers who take time to understand your casting challenges—not just sell products—those are the ones you want.