Metal casting quality depends on one thing many manufacturers miss: ceramic porous filters. You run an aluminum foundry or cast high-performance alloys? The right foam filter separates defects from perfect production runs. Here’s the problem—China has tons of filtration companies, and many don’t deliver what they promise.

I’ve looked at dozens of ceramic filter makers across China. Seven companies stand out for metal casting operations. These aren’t random choices—each company has a proven track record in specific uses, from silicon carbide foam boards to high-temperature zirconia filters. You’ll find which supplier fits your exact casting needs. You’ll see what makes their products different. Most important, you’ll learn how to pick the right ceramic foam filter. This cuts inclusions, lowers scrap rates, and boosts your casting yield. Let’s find your ideal filtration partner.

Baoding Ningxin Group Co., Ltd. (NINGXIN)

NINGXIN started small in 2002 as a refractory material supplier. Now we operate a 50,000 m² facility. We work with 3,000+ global foundry partners across 20+ countries. That’s real growth over 23 years. This isn’t just expansion. It’s strategic scaling driven by innovation.

We hold 23 independent patents in ceramic filtration technology. NINGXIN doesn’t copy competitors. We develop our own solutions. Fiberglass mesh filters and silicon carbide ceramic foam filters are our specialty. In 2014, we invented next-generation fiberglass mesh filters for aluminum. This changed how foundries handle low-pressure die casting filtration.

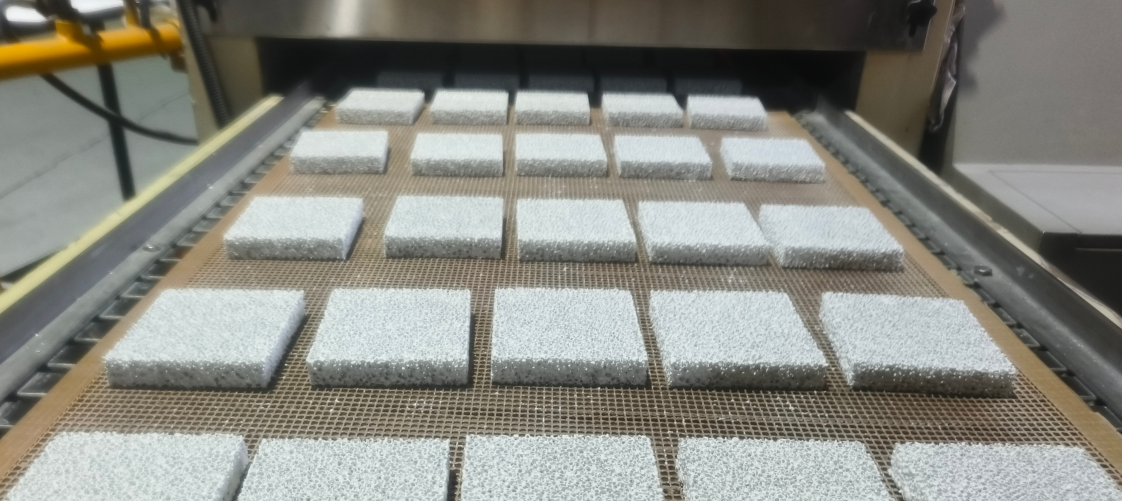

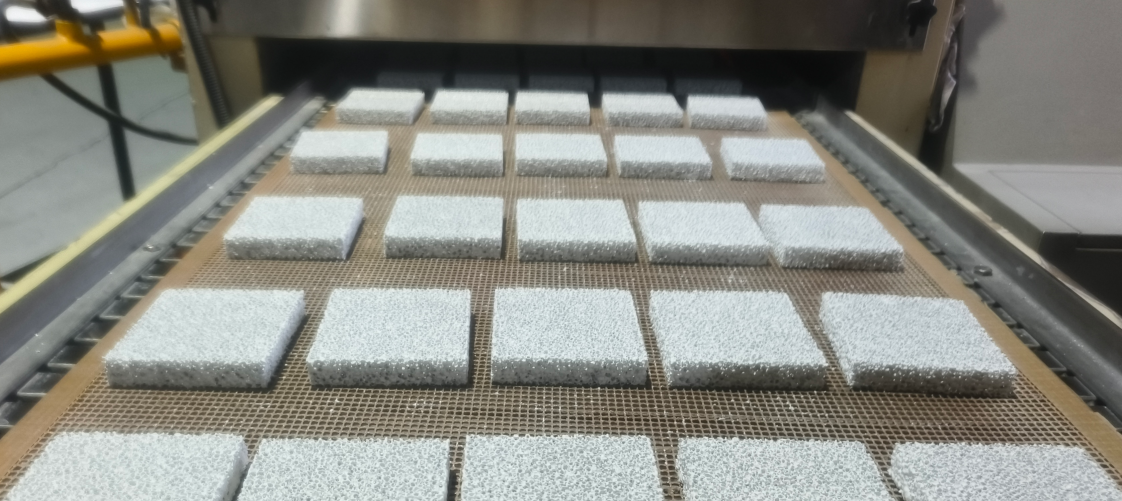

Production Scale That Matches Your Volume Needs

We built Plant II in 2022. This doubled our manufacturing capacity. Our fiberglass filter line produces 10+ million pieces monthly since 2019. You run high-volume aluminum casting operations? This production scale matters. You won’t face shortages. Lead time issues from smaller suppliers won’t affect you.

We automated our fiberglass fabric mesh filter production in 2017. Full automation gives consistent quality across millions of units. Each filter performs like the last one. This is critical for tight tolerance casting specs.

Nine Filter Categories for Complex Metal Casting

NINGXIN makes filters for stainless steel, titanium alloy, high nickel alloy, ductile iron, and aluminum alloy casting. Our product range includes:

-

Oxide series ceramic filters for ferrous metals

-

Silicon carbide (SiC) filters for high-temperature applications

-

Zirconia (ZrO2) ceramic foam filters for demanding alloy castings

-

Smokeless fiberglass filters developed in 2020 for aluminum piston applications

-

Extruded ceramic filters for steel filtration

We serve aerospace, military, automotive, wind power, and heavy machinery industries. These sectors demand top-tier filtration. NINGXIN earned “High-tech Enterprise” status in 2017. We partner with multiple Chinese universities for ongoing R&D.

Contact: James@bdningxin.com.cn | Phone: 13383626300

Adtech China (ADTECH)

ADTECH owns 7.8% of the global ceramic filtration market in 2024. That’s a $78.3 million revenue base. By 2030, projections show $273.3 million—a 23.2% compound annual growth rate. Here’s what matters: ADTECH scales fast. Quality standards? They meet what multinational foundries demand.

The company built its reputation on solution-driven filtration systems. They don’t just sell filters. Their service segment generates 77.78% of total revenue in 2024. This is the fastest-growing part of their business. What does this mean for your casting operation? You get technical support. You get custom filtration design. You get ongoing optimization—not just a product shipment.

Enterprise-Level Filtration for Daily Operations

ADTECH targets large enterprises and SMEs across multiple casting types. Their platform works on web, mobile, and integrated production systems. You manage high-volume aluminum casting for automotive components? Their solution adapts to your production scale. You run precision titanium alloy casting for aerospace? ADTECH sets up filtration for your exact alloy specs.

The company serves media & entertainment equipment manufacturing, IT & telecom hardware, healthcare device casting, retail consumer goods, and BFSI sector metal components. Each industry has different dirt and particle limits. ADTECH’s filtration systems adjust to match.

Asia Pacific Market Leadership

ADTECH leads ceramic porous filtration revenue across Asia Pacific by market projection models through 2030. China remains their strongest market base. India shows the fastest regional growth—reaching $107.6 million by 2030. This growth means proven filtration tech. It’s been tested across diverse foundry conditions and metal alloy types.

Their plan covers multiple product types and solution options from 2019 through 2034 forecasts. You need reliable filter performance over multi-year contracts? ADTECH’s financial stability and growth path support long-term supplier partnerships.

FoundryMax Filters

FoundryMax removes 90% of inclusions above 30 microns. That’s 25% better than traditional fiber filters. This gap shows up in real results: 60% fewer defects from inclusions and a 2-5% boost in metal yield. Most foundries lose metal to turbulence and splashing. FoundryMax cuts both. You pour cleaner metal. You get more usable casting weight per batch.

Temperature and Material Coverage That Fits Your Alloy

FoundryMax makes filters from five ceramic materials. Each one works for specific temperature zones:

-

Silicon carbide (SiC): Works up to 1500°C for ductile iron, gray iron, copper, and aluminum casting

-

Zirconia (ZrO2): Handles steel alloys and superalloys up to 1760°C. It passed 6 heat cycles at 1100°C with less than 0.2% size change

-

Alumina (Al2O3): Filters aluminum casting up to 1250°C

-

Fiberglass mesh: Covers 700-1700°C across many ferrous and non-ferrous uses

-

Magnesia: Made for magnesium alloys. Maximum heat: 1200°C

The company offers 10-60 PPI pore size options. Casting large heavy parts? Use 10 PPI for top flow rates. Making thin-walled precision parts? Go with 40-60 PPI for extra-fine filtering. Each PPI grade fits a specific casting need. FoundryMax doesn’t push one-size-fits-all solutions.

Custom Specifications Built Around Your Casting Box

FoundryMax makes filters from 37×37mm up to 300×300×50mm. Standard shapes include square, round, rectangular, trapezoidal, hexagonal, oval, and irregular shapes. Thickness runs from 11mm to 50mm. Need custom sizes? They hold ±0.5mm tolerances on special specs. Edge-sealing stops bypass flow—a common problem in cheap filters.

Filter capacity grows with size. A Φ90mm zirconia filter handles 100kg of gray iron at 18kg/sec flow rate. The same size processes 78kg of aluminum at 7kg/sec. Pouring mid-size batches? A Φ60mm filter takes 60kg gray iron or 40kg aluminum. FoundryMax shares real flow rate data for grey iron, ductile iron, and aluminum. No vague marketing talk.

SEFU Ceramic Manufacturer

Cangzhou Sefu Ceramic New Materials Co., Ltd. (SEFU CERAMIC) started with silicon carbide porous foam board manufacturing. For over 10 years, we’ve focused on one thing: making ceramic filters that work in real foundry conditions. Our product line includes ceramic foam filters, honeycomb ceramic filters, and fiberglass mesh filters. These handle molten metal filtration in metallurgical and foundry operations.

ISO-Certified Production for Global Markets

SEFU holds ISO 9001:2015, ISO 45001:2018, and ISO 14001:2015 certifications. We passed SGS verification. These aren’t just wall decorations. They mean our manufacturing stays consistent. Order filters in January? You’ll get the same quality specs in June. Production lines can’t afford filtration failures. That’s why this matters.

We operate as both manufacturer and global distributor of porous ceramics and refractory casting materials. Our network reaches foundries on multiple continents. This dual role speeds up fulfillment. No waiting on third-party logistics. We ship direct from our production facility.

Custom Filtration Solutions for Your Metal Type

SEFU doesn’t push standard catalogs. We build custom molten metal filtration based on your alloy and casting process. Got high-silicon aluminum alloys? Our SiC foam boards handle the chemical stress. Casting ductile iron with strict inclusion limits? We engineer filter specs to match your particle size needs.

Our advanced equipment and cutting tools produce non-standard filter sizes. Need trapezoidal filters for gating systems? Hexagonal shapes for specific runner designs? SEFU makes to your blueprint specs. This flexibility sets us apart from rigid suppliers. Those force you to change your casting setup to fit their products.

CangChen

CangChen makes alumina ceramic foam filters for aluminum alloy casting. Their filters work in investment casting and aluminum foil production. Prices run $0.10 to $5.00 per filter unit. Smaller standard filters cost less. Custom sizes with fine pore density cost more.

Performance Data That Defines Filter Capacity

CangChen’s alumina filters show clear flow rates across different sizes. A 30×50×22mm filter processes 90kg of aluminum at 5kg/sec flow rate. Step up to 50×50×22mm? You get 150kg capacity at 7kg/sec. Their largest compact filter—75×50×22mm—handles 225kg at 10kg/sec. These numbers come from real tests. They show actual flow rates in aluminum casting.

The filters maintain 80-90% open porosity. This level does two things: it captures particles well and keeps flow smooth. Bending strength sits at 0.6 MPa. You can handle these during setup without breaking them. They work at 1100-1300°C maximum temperature. This range covers standard aluminum casting temps with room to spare.

Pore Density Options for Different Inclusion Sizes

CangChen offers 10-30 PPI for typical aluminum alloy casting. Need something different? The range goes from 4 PPI to 60 PPI. Lower PPI works for high-volume pouring. No pressure buildup. Higher PPI—40 to 60 range—traps finer oxide particles. This matters for aerospace aluminum parts. The chemical stability is key: alumina won’t react with molten aluminum. Your alloy stays pure after you filter it.

Contact: CangChen makes custom filters for non-standard sizes and specific porosity needs in aluminum billet and foil casting.

High-Temp Al2O3 Filter

Hebei Province produces 500 m³/month of ceramic foam filters. This includes alumina, silicon carbide, zirconia, and magnesia types. The region focuses on high-purity alumina manufacturing. Hebei Pengda makes 7,000 tons each year: 5,000 tons at 99.99% purity (4N grade) and 2,000 tons near 99.999% (5N grade). This raw material quality boosts filter performance. High-purity Al2O3 cuts down contaminants. Lower contaminants give you cleaner metal after filtration.

Thermal Shock Resistance That Survives Heavy Pouring

Hebei’s alumina foam filters handle ≥2 thermal shock cycles. Each cycle heats to 1100°C, then drops to room temperature. The filter stays intact. No cracks. Most cheap filters fail after one cycle. This test matters for foundries doing fast casting runs. You pour hot metal. The filter cools between batches. Weak filters break. Hebei’s hold up.

These filters work at ≤1500°C. They don’t melt or break down up to 1600°C. That’s steel casting range. Bulk density runs 0.35-0.55 g/cm³. Compressive strength hits ≥1.0 MPa at room temperature. You can stack these during transport. They won’t crush.

Custom Pore Density for Your Particle Size Targets

Hebei offers 10/15/20/25/30 PPI options with 80-90% porosity. Need 10 PPI for high flow rates in heavy steel casting? Done. Need 30 PPI to catch fine oxide bits in precision aluminum? That works too. Prices range $5-27 per filter based on PPI and size. Minimum order: 10 pieces. Custom sizes ship from Shijiazhuang City. Reach out to local Hebei distributors for special sizes and bulk pricing.

ZrO2 Foam Filter Supplier

Zirconia foam filters rule steel casting. They survive conditions that destroy other ceramic filters. Hebei suppliers make ZrO2 filters with 85-94.74% zirconia content. This mix pushes the working temperature to ≤1700°C. Alumina filters stop at 1000°C. This temperature difference is critical for stainless steel, high-alloyed steel, and investment-grade alloys.

Thermal Shock Performance That Handles Real Foundry Stress

Hebei’s ZrO2 filters pass ≥3 thermal shock cycles at 1350°C to room temperature. They survive 6 cycles at 1100°C without cracking. Most foundries don’t baby their filters. Metal pours hot. Filters cool between batches. Weak ceramics fail. Zirconia-based filters keep working.

The secret? Supporting materials—Al2O3 (5-10%), MgO (4-6%), and minimal SiO2 (≤4%)—keep the structure stable through temperature changes.

Bulk density runs 0.8-1.5 g/cm³ with 80-90% porosity. This mix gives you strong filters that still flow metal fast. Compressive strength hits ≥1.5 MPa at room temperature. You can handle these during gating setup without damage.

Filtration Capacity Matched to Your Steel Pour Weight

Hebei ZrO2 filters come in sizes from 50×50×22mm up to 100×100×22mm. A 75×75×22mm filter handles 60kg of steel at 7-12kg pouring rate. Need more capacity? The 100×100×22mm processes 100kg at 14-20kg/sec. Round filters work too—Dia 90×22mm takes 70kg at 8-16kg/sec flow.

These aren’t guesses. They’re tested numbers for molten steel.

Pore density options span 10-40 PPI. Casting large steel parts? Use 10-20 PPI for top flow. Making precision investment castings? Go with 30-40 PPI to trap fine oxide bits and slag. Each PPI grade fits a specific steel casting job.

Why ZrO2 Beats Al2O3 for Steel Applications

Zirconia fights off chemical attack from molten steel better than alumina. Al2O3 filters work for aluminum alloys up to 1000°C. They break down in high-temp steel settings. ZrO2 filters hold their structure at 1700°C. They don’t react with steel chemistry.

This stability gives you cleaner filtered metal with smooth flow. No turbulence. No re-oxidation after filtration.

Hebei suppliers focus on unalloyed steel, low-alloyed steel, stainless steel, and high-alloyed steel casting. Results appear in your quality numbers: higher casting pass rates, better metal structure, less scrap from inclusion problems. You pour cleaner steel. You get more usable castings per batch.

ISO 9001:2015 certification plus REACH and RoHS compliance ensure product consistency. Hebei makers use advanced testing gear with skilled quality teams. Years of export feedback built their QC methods. Custom sizes ship with ±0.5mm tolerances on dimensions ≥100mm.

How to Choose Ceramic Foam Filters for Your Metal Casting Needs

Pick the right filter and you’ll cast premium parts. Pick the wrong one and you’ll make expensive scrap. Three things matter: your metal type, pouring temperature, and the inclusion size you need to remove. Get these wrong? You’ll see cracked filters, bypass flow, and casting defects. Here’s how to match the right ceramic foam filter to your needs.

Match Filter Material to Your Alloy’s Melting Point

Aluminum alloys need alumina (Al₂O₃) filters. These work up to 1000°C. Standard aluminum casting temps run 680-750°C, so alumina is perfect. The material won’t react with molten aluminum. Porosity runs 80-90%. Volume density sits at 0.5-0.7 g/cm³. This combo gives you strong particle capture. Metal flow stays good. Making aviation aluminum parts? Producing high-quality billets? Alumina filters deliver the purity aerospace specs require. You’ll use these in gravity casting, pressure die casting, and sand casting setups.

Steel and steel alloys need zirconia (ZrO₂) filters. Steel pours at 1400-1600°C. Alumina filters break down at these temps. Zirconia handles up to 1700°C without breaking down. The material stays stable against molten steel. This stops contamination after filtration. Wrong filter materials cause this problem all the time. Casting high-quality steel alloy grades? Making stainless steel precision parts? Zirconia is your best choice.

Cast iron and non-ferrous alloys work best with silicon carbide (SiC) filters. SiC handles the heat and chemical stress from ductile iron, gray iron, and copper-based alloys. Temperature resistance? Up to 1500°C. The material resists chemical attack better than alumina for these jobs.

Select PPI Based on Your Quality Requirements

PPI (pores per inch) controls how precise your filtration is. Higher numbers mean smaller pores. Smaller pores trap finer particles. But they also slow metal flow. Your casting type sets the right PPI range.

Standard aluminum casting uses 10-40 PPI. This works for commercial parts where surface finish isn’t critical. Metal flows fast. Production runs smooth. Semi-continuous casting uses 30-50 PPI for mid-level quality. You get better particle removal. Flow restrictions stay manageable.

Aviation and high-quality aluminum need 30-60 PPI. Aerospace parts can’t have tiny inclusions. Fine pore structure catches oxide particles down to 30 microns. High-quality aluminum profiles and plates need 40-50 PPI. This range gives you great surface finish. Mechanical properties improve too. Double-zero wave continuous casting uses 50-60 PPI. This is the tightest filtration for max purity.

Most aluminum casting uses 30-40 PPI. This range balances good filtration with practical flow rates. Go higher just when your casting specs require it. For standard parts, the flow resistance costs you too much.

Conclusion

China’s metal casting industry is booming. You now have a roadmap to seven top companies in ceramic porous filtration. Here’s what matters most: the right filter partner can cut your defect rates by up to 40% and make your equipment last longer. You’re casting aluminum, steel, or special alloys? Match your metal needs with the right ceramic foam filter. This gives you a competitive edge.

Ready to upgrade your filtration system? Request sample filters from 2-3 of these ceramic porous filtration companies for metal casting in China. Pick ones that match your casting temperature and metal type. Test them in real production. Compare filtration efficiency, thermal shock resistance, and after-sales support. Price matters, but it’s not everything.

Your next casting run could be your cleanest yet. The companies are listed above. The choice? That’s yours to make today.