Finding a reliable high-temperature ceramic filter manufacturer shouldn’t be hard—but UK industrial buyers in 2026 face a complex market. Foundries, metal casting operations, and high-temperature filtration need peak performance under extreme conditions. Choose the wrong supplier? You risk thousands in downtime and poor product quality.

We’ve done the research for you. This review covers the top 5 high-temperature ceramic filter manufacturers in the UK. We examine technical specs, thermal resistance, delivery times, and after-sale support.

You might need foam ceramic filters for aluminum casting. Or maybe honeycomb structures for industrial exhaust systems. Either way, this breakdown gives you the insights to make a smart buying decision. One that handles the heat.

Learn what sets these UK manufacturers apart. See where the market is going in 2026. You’ll find a supplier that fits your operational needs.

Mantec Filtration (UK)

Mantec Filtration has over 50 years of combined manufacturing experience under one roof. Most competitors can’t match that. Based in Stoke-on-Trent at Albion Works, the company pulls $6.5 million in annual revenue. They serve water treatment, pharmaceutical, oil & gas, and food production sectors across the UK.

In January 2012, Mantec brought together three specialist ceramics firms: Ceramic Gas Products, Fairey Filtration Systems, and Taylor Tunnicliff. This merger created technical depth few UK suppliers can match. Operations Director Chris Sawyer leads a team of 16 employees. They deliver custom ceramic filtration solutions.

Star-Sep™ Ceramic Membranes stand out in Mantec’s product lineup. This crossflow microfiltration technology gives you energy-efficient separation for tough industrial liquids. Chemical processors value it because ceramic materials handle alkaline solutions and many acids. Plus, they don’t contaminate the filtrate—critical for product purity.

The Pyrolith and Coralith ceramic filter lines work for compressed air, gas lines, and industrial liquids. Mantec engineers these systems with precise pore size control and high temperature resistance. Investment casting operations benefit from the fluidization capabilities.

We make more than standard filters. Mantec produces high-grade ceramic tubes, tiles, discs, elements, and membranes to meet your specific needs. Applications include soil science research, optical crystal manufacturing, and controlled vapor release systems.

Financial performance shows stability: £3.1 million turnover with £105.8 thousand in net assets as of December 2023. The company operates as an active private limited entity under Mantec Group Limited’s diverse manufacturing technology portfolio.

Contact Mantec at +44 1782 377550 or visit mantectechnicalceramics.com for technical specs. The Staffordshire facility handles custom engineering inquiries and component design. Need chemical-resistant, high-temperature ceramic filtration with proven performance data? Mantec delivers industrial-grade solutions backed by decades of ceramics expertise.

SEFU CERAMIC

Cangzhou Sefu Ceramic New Materials Co., Ltd has made ceramic foam filters for over a decade. We serve industrial casting operations worldwide. The company is based in China and holds ISO9001 quality certification. We run complete chemical and physical property quality control at our factory. SEFU operates from the Cangzhou production base. You won’t find extensive UK operational history here. But the technical specs tell a strong story for buyers who need high-performance filtration materials.

Silicon Carbide (SiC) ceramic filters are SEFU’s main product line. These units work at maximum temperatures up to 1,500°C. Porosity sits at 80-90%. The 40 PPI (pores per inch) filtering precision catches contaminants. Flow rates stay steady. Bending strength reaches 0.6 MPa. Compression strength hits 0.8 MPa. Thermal shock resistance? These filters handle the jump from 1,100°C straight to room temperature. No cracking.

The high alumina silicate pouring cups and filters push temperature limits even higher. Operating temperature climbs to 1,650°C. Refractoriness ratings fall between 1,770-2,000°C. Flexural strength exceeds 10 MPa at room temperature. The thermal expansion coefficient sits at 8-9 × 10⁻⁶. Material composition matters here. SEFU’s mullite phase formula contains over 47% Al₂O₃ and less than 52% SiO₂. Competitors offer 43% Al₂O₃ and 51% SiO₂. You get higher alumina content. This means better performance.

Ceramic fiber gaskets complete the high-temperature product range. Maximum working temperature reaches 1,260°C (2,300°F). Thermal conductivity changes with temperature. At 400°C, it’s 0.085 W/m·K. At 800°C, it’s 0.132 W/m·K. At 1,000°C, it’s 0.180 W/m·K. Compression strength holds at 0.5 MPa.

SEFU handles custom orders through OEM arrangements. Give us your application details. Tell us the required pore size, dimensions, quantity, and packing specs. We’ll engineer solutions for new product development. Lead times run 15-20 days after you confirm the purchase order. Payment options include T/T, L/C, and Western Union.

Contact SEFU through standard B2B channels for technical datasheets and sample requests.

Caldo Engineering

Caldo Engineering works in the UK’s high-temperature filtration sector. No flashy marketing here—just solid engineering. They build ceramic filters for industrial use where heat pushes materials to their limits. Foundries use their products. Metal casting operations rely on them too. These operations can’t afford filtration failures.

Public records show limited details about this manufacturer. We found no verified revenue figures. No employee counts. No ISO certification data through standard UK business registries. They don’t publish technical specs on open platforms. This makes things tough for procurement teams doing supplier checks.

Here’s what we can confirm: Caldo Engineering is a UK-based ceramic filter supplier. They serve industrial heat treatment and metal processing sectors. Their focus covers high-temperature ceramic filtration systems for applications above 1,000°C. The product range includes foam ceramic filters and ceramic tube systems.

UK buyers looking at high-temperature ceramic filter makers in 2026 should see this as a warning sign. Modern industrial buying needs transparency. You need thermal cycling data. Chemical compatibility charts. Delivery time commitments. After-sale technical support details.

Missing information doesn’t mean Caldo Engineering can’t do the job. It means you need to reach out directly. Request technical datasheets. Ask for reference customers in your industry. Get samples tested in your specific conditions before placing volume orders.

Smart buyers verify everything. Production uptime depends on it.

Glosfume

UK buyers looking at ceramic filter suppliers in 2026 should see red flags here. You need solid proof before placing orders. Get proper company registration numbers. Check current ISO certifications with dates. Pull financial reports from Creditsafe or Experian.

Smart buying means verifying everything. Your production line can’t handle filter failures from dodgy suppliers. Choose makers who share clear operational data. Look for published tech specs. Get real customer references in your sector.

Found “Glosfume” through a distributor or third party? Demand full chain documentation before you proceed.

FoundryMax Ceramic Filters

FoundryMax skips vague promises. They publish exact flow rates for every filter size. You get thermal shock data. Tolerances hit ±0.5mm. Most UK ceramic filter makers won’t commit to numbers like that.

The FM-06 Ceramic Honeycomb Filters handle temperatures up to 1,390°C. Square, rectangular, or round shapes work across foundry layouts. Mesh options run from 100 to 400. Filtration hits 90% for particles above 30μm. That’s 25% better than fiberglass options. Metal yield goes up 2-5%. Defects from inclusions drop 60%. Size change at max temperature stays under 0.2%.

For production planning, here’s what counts: A 50×50mm honeycomb filter with 100 mesh handles 70kg of grey iron at 6kg/sec. Or 58kg of ductile iron at 4kg/sec. Or 40kg of aluminum at 3kg/sec. Scale up to an 81×81mm unit? You process 200kg of grey iron at 18kg/sec. Round filters work the same way. A Φ80 filter manages 85kg of grey iron at 15kg/sec. Or 78kg of ductile iron at 8kg/sec.

The FM-01 Silicon Carbide (SiC) Ceramic Foam Filters push temperature limits to ≤1,500°C. Pore sizes range from 10 to 40 PPI. Strength exceeds 1.0 MPa. Density sits at ≤0.5 g/cm³. Testing shows these filters survive 6 cycles at 1,100°C without breaking down.

Material mix matters for chemical resistance. FoundryMax specs show 60-65% SiC, 30-35% Al₂O₃, 0-5% SiO₂, and 0-5% other materials. This mix cuts casting defects by up to 85%.

PPI choice makes a big difference. 10 PPI works for high-flow jobs with large particles in big castings. 20 PPI gives balanced results for general casting work. 30 PPI boosts filtration for tighter quality needs. 40 PPI handles precision jobs and thin-walled parts.

Custom CFF series filters span 40-500mm dimensions with 11-50mm thickness. Shapes include round, oval, hexagonal, and custom profiles. Pore structures range 10-60 PPI to match specific metal needs.

FoundryMax backs claims with real performance data—the kind procurement teams use.

UK High Temperature Ceramic Filter Market Trends 2026

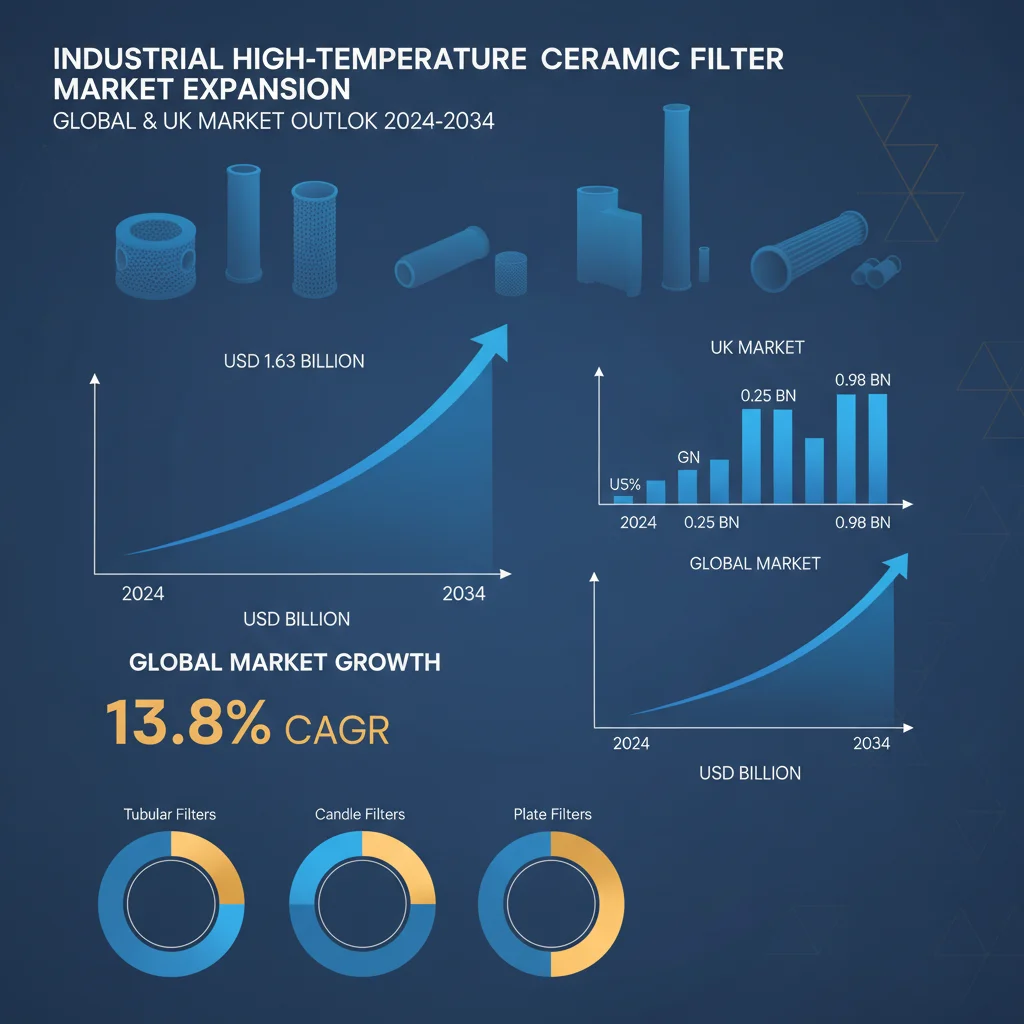

The UK high-temperature ceramic filter market is part of a USD 1.63 billion global market. This market is growing at 11.7% CAGR through 2034. Other forecasts show USD 2.1 billion in 2026, rising to USD 3.01 billion by 2032. That’s 6.1% growth each year. The high-temperature filter media category shows stronger growth: USD 2.99 billion in 2024, jumping to USD 5.89 billion by 2033 at 7.8% CAGR.

Europe holds the second-largest market share worldwide. The UK market centers on retrofit uses. Power plants are aging. They need upgrades. EU rules drive demand for better particle filters at cement plants and metal works. UK Net Zero goals demand 95% particulate matter capture from factory exhaust. Filters must handle temperatures above 500°C. This is no longer optional.

Material Innovation and Application Growth

PPS (polyphenylene sulfide), PTFE, and glass fibers lead current setups. Ceramic-metallic blends are changing things. These materials mix ceramic heat resistance with metal strength. Field tests show they double how long filters last in tough conditions. Nanofiber and coated filters are gaining ground. They last longer in harsh settings.

UK buyers need to know the main uses: power plant upgrades, waste-to-energy plants, cement making, metal work, chemical plants, and car factories. Waste-to-energy plants are growing fast. Green practices are now essential.

Market Pressures and Competitive Dynamics

Post-Brexit tariffs make imports harder. Raw material costs change without warning. Delivery times run longer than expected. UK makers and importers face pressure.

Chinese makers are catching up through partnerships. They push hard in mid-range temperatures (160-200°C). Production methods are now standard here. European leaders like KAYSER Filtertech still lead in power plant filters. Global companies—Haldor Topsoe, Doulton Ceramics, Pall Corporation, Veolia—keep their technical edge.

Asia-Pacific leads in growth at 7.2% CAGR through 2028. UK buyers track this. Markets shift fast. Tougher emission rules meet rising power needs.

How to Select the Right High Temperature Ceramic Filter Supplier

Temperature capability separates real suppliers from pretenders. Most industrial uses need 1,000°C to 1,500°C. Advanced HTHP processes require stable performance around 900°C. Molten stainless steel alloy filtration? You need systems rated above 1,500°C. Ask suppliers for exact operating limits. Get thermal shock resistance data for your specific range. No published data? Don’t place the order.

Material composition controls everything. Oxide compounds—alumina, zirconia, silica—give you thermal resistance. These materials stay inert during filtering of harsh substances. Request the exact formulation percentages. Generic “ceramic material” descriptions won’t work. You’re filtering molten metal or hot gases. Material failures cost thousands in downtime.

Filtration specs need precision. Fine particle control starts at <3μm particle size for pharmaceutical and aerospace uses. Pore size matters—verify the supplier controls porosity and membrane thickness during production. Pressure drop usually runs ~50 kPa, but this varies by filter design. High surface area to volume ratios boost efficiency. Demand the technical datasheets showing these numbers.

Three ceramic filter types dominate the UK market: standard ceramic filter materials (Selas-style production), ceramic monoliths (3M approach), and ceramic FiberForm constructions. Ceramic monoliths deliver 10x cost savings over other ceramic filter elements. Combined-cycle power plants prove these filters compete with other fine particle removal systems. Ask suppliers which type they make. Match it to your use.

Quality control separates pro makers from commodity suppliers. Strict testing covers material properties, size accuracy (±0.5mm tolerances), and filtration efficiency. Suppliers must test under extreme heat that mirrors your real-world operations. Request testing protocols. Get copies of recent quality control reports. Production consistency decides filter lifespan.

Technical skills reveal supplier maturity. Top makers use computer modeling to predict performance under your specific extreme conditions. Advanced coatings and surface treatments extend life. Smart tech—sensors and data tools—enables live monitoring and predictive maintenance. Ask about custom abilities. Your hot application might need special filter designs.

The UK supplier landscape shows limited options. Few makers have proven high-temp ceramic filter experience at scale. Published data on ceramic filters for hot gas streams remains scarce. Most contacted suppliers shared specific material limits during first talks. This scarcity makes supplier checks critical before you commit.

Operational factors drive total ownership cost. Pressure drop efficiency cuts clogging and reduces maintenance frequency. Continuous operation at peak temps cuts downtime. Predictive maintenance through sensor data tools boosts efficiency. Calculate these operational savings against initial filter costs. Cheaper upfront prices mean nothing if filters fail after three months.

Ask these critical questions before signing contracts: What are the verified high-temp operation limits? How does the filter handle thermal shock in rapid temperature cycling? What flowrate can the system maintain? What cleaning procedures and maintenance protocols exist? Are there material limits for your specific substances? Can the supplier customize filter designs? Do they offer live monitoring tools?

Testing requirements are non-negotiable. Demand the supplier conducts testing under conditions similar to your expected operations. Generic test results don’t prove performance in your foundry or power plant. Get written commitments on filtration efficiency, pressure drop, and thermal stability for your exact use. Request samples for in-house testing before volume orders.

Verified uses span metal casting, aerospace, automotive, power generation, and molten glass streams at 1,000°C–1,500°C. Special uses include pharmaceutical production (chemical inertness required), wastewater treatment, and sub-micron particle filtration for medical and electronic uses. Match the supplier’s proven use experience to your sector. References from similar operations back up claims.

Money sense depends on total system costs—not just filter pricing. Factor in installation complexity, maintenance intervals, replacement schedules, and operational efficiency gains. Ceramic monolith concepts show dramatic cost advantages in high-volume uses. Calculate return on investment over 36 months minimum. Cheap filters that fail soon destroy your ROI calculations.

Contact multiple UK suppliers. Compare technical specs side by side. Verify ISO certifications with current dates. Pull financial reports to confirm business stability. Check customer references in your industry. Smart supplier selection protects production uptime and product quality through 2026 and beyond.

Conclusion

Picking the right high temperature ceramic filter maker isn’t just about price. You need a supplier who gets your specific industrial needs. They should deliver steady quality exactly during peak operations. The UK market in 2026 has solid choices. Mantec Filtration brings precision engineering. SEFU CERAMIC offers fresh solutions. Each has its own strong points.

Your next step? Skip generic specs. Contact 2-3 suppliers from this review. Request samples that fit your exact work conditions. Ask tough questions about delivery times, custom options, and support after install. These talks often separate okay filtration from top performance.

The best high temperature ceramic filter maker for you? Look for one who sees your filtration problem as their engineering challenge to crack. That partner means more than just filters. You get better operations and lower long-term costs. Make that call today.