Malaysia’s factories need filters that handle extreme heat without breaking down. This separates capable suppliers from the rest.

Managing a foundry with molten metal at 1,600°C? Running chemical plants that need constant high-heat filtration? The wrong ceramic filter supplier costs you thousands in downtime. Your product quality suffers too.

We analyzed Malaysia’s top high-temperature porous ceramic filtration companies. Five providers stood out. They’ve proven themselves in real industrial settings.

You’ll find companies that deliver what you need:- Specialized foundry foam filters– Advanced hot gas filtration systems- Technical specs that match your operation- Local support you can count on- Real reliability

Plus, we cover critical buying factors. Most buyers miss these until problems hit.

FoundryMax – Foundry Ceramic Foam Filters

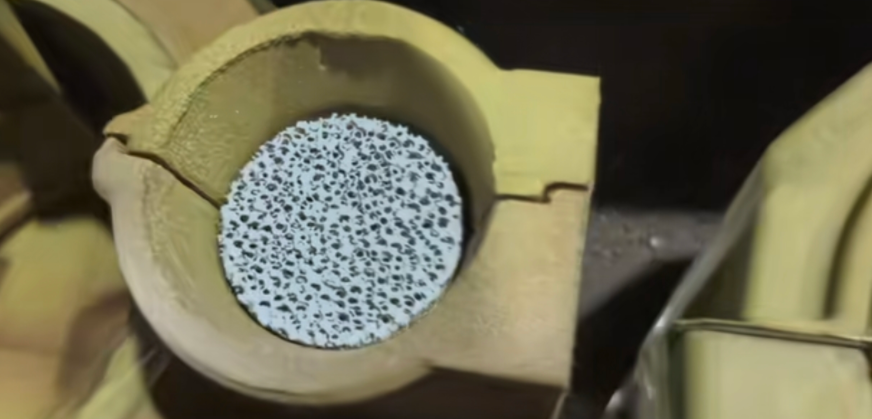

The company offers six porosity grades (PPI: pores per inch). Each grade matches specific casting needs. Their 30 PPI filters deliver 85% filtration rates. They capture 40-micron inclusions—perfect for automotive foundries and aerospace foundries. Step up to 50 PPI. You’re filtering 10-micron particles at 92% efficiency. Precision housing manufacturers running thin-wall castings often pick the 60 PPI option. This achieves 95% filtration by trapping contaminants as small as 5 microns.

Each filter maintains 80–90% porosity despite its fine pore structure. The open design lets molten metal flow without restriction. A 12×12-inch filter (305x305mm) with 50mm thickness handles 50–156 kg/min. It maintains 80% effective filtration area. Scale up to their 26×26-inch units (660x660mm). You’re processing 276–830 kg/min at 90% efficiency.

Built for Thermal Punishment

FoundryMax filters endure 6 thermal shock cycles at 1,100°C without cracking. Their rupture modulus measures 5.5 MPa at 816°C. That’s strong enough to handle turbulent metal flow during high-volume pours. The compressive strength ranges from 0.8–1.0 MPa. Bending strength values of 0.6–1.0 MPa back this up, depending on material makeup.

The company stocks eight standard sizes from 7×7 inches to 26×26 inches. Available in 25mm, 50mm, or 75mm thickness (±2mm tolerance). Each filter features a precision 17.5±1.5° bevel angle for proper gating system integration. Custom shapes—square, rectangular, round, or trapezoidal—ship within standard lead times.

Their CFF-Al20 model dominates aluminum casting operations. This high-purity alumina formula comes in 10, 20, or 30 PPI options. The CFF-SiC30, reinforced with silicon carbide, handles aggressive molten metal chemistry. Standard alumina filters break down too fast in these conditions.

Attaquant Enterprises – Industrial High-Temperature Filtration Systems

Attaquant Enterprises works in four markets: China, Egypt, Dubai, and Malaysia. We take a different approach to filtration. We don’t chase extreme temperature ratings. Our systems focus on process integration.

Our filters capture contaminants. But they do more than that. They fit into complete multi-stage thermal-filtration workflows. These combine heat exchangers, membrane tech, and automated controls.

Our ceramic-based filters use outside-to-inside flow patterns. Liquid passes through porous walls. These walls are made from sintered stainless steel 316L, PTFE, PVDF, or polypropylene. The material depends on your chemical setup. Solid particles get trapped. The clean stream keeps flowing. This isn’t new technology. But our automation approach changes the cost picture.

Built-In Intelligence That Cuts Labor Costs

Our systems use sensor-based real-time monitoring. These connect through IoT networks. You track filter performance from anywhere. Smart cycle management triggers automated backwashing or ultrasonic cleaning. This happens before pressure spikes. Predictive maintenance alerts warn you days before a filter fails. You don’t need technicians watching gauges. No more guessing about filter changes.

The self-cleaning cartridge systems handle timing on their own. No manual work needed. Petrochemical and chemical processing plants run 24/7. Clogged filters mean downtime. That costs thousands per hour. Our hybrid control systems keep filtration going. Automated cleaning runs in parallel stages.

Multi-Stage Process Integration

We design five-stage workflows: pre-treatment, settling, sand or membrane filtration, heat exchanger integration, and final polish through sparkle filters. The heat exchanger sits in a specific spot. This controls heat management before filtration stages that need stable temperatures.

Our nanofiber membrane tech works in multiple filter types. These include hollow fiber, tubular, and leaf element designs. Pore sizes range from 0.01 to 0.1 microns. Pharma companies use these for final polishing. Food and beverage plants use the same membranes. They get better water purity and taste properties.

Contact us at +91 8788482769 or marketing@attaquant.in for custom engineering design and process help.

Glosfume – G3 Ceramic Hot Gas Filter Elements (1000°C)

Most filtration tech melts at these temperatures. Glosfume’s G3 filters don’t. Their ceramic elements run at 1000°C. They push to 1100°C during demanding processes. Over 2000 installations across 90 countries prove this works. These aren’t test units. They solve real filtration problems. Standard equipment can’t survive these environments.

The material composition makes the difference. Glosfume uses high-temperature fibres. These form a micro-porous structure. The material won’t burn. Acids and alkalis can’t corrode it. This setup catches 99.99% of sub-micron particles—both PM10 and PM2.5. Particle capture is just the start. The G3 system cuts dioxins and NOx emissions by 80%. Heavy metal levels drop too.

After filtration, particle emissions measure below 1 mg/m³. That’s clean enough to skip reaction towers and cyclones. Your process chain gets shorter. Equipment costs drop.

Five Sizes, One Reverse-Jet System

Glosfume stocks five standard lengths: 500mm, 1000mm, 1250mm, 3000mm, and 5000mm. Each size uses the same reverse jet pulse cleaning system. Compressed air blasts buildup off the filter surface. Performance stays steady. You don’t need manual work during operation.

The filters stay stable up to 1000°C during operation. Glosfume’s testing shows no breakdown at 1100°C. The ceramic melts at 1200°C. This gives you a safety buffer for temperature spikes.

Biomass boilers, wood-fired systems, and coal furnaces run these filters up to 900°C for dedusting. Aluminium foundries use them for spark and fire resistance. Steel mills, chemical plants, and waste-to-energy facilities depend on G3 elements. They handle hot flue gas loaded with sparks and particles. Filtration hits 99% in these uses.

The system runs stable to 650°C with no performance loss. Longer service life compared to bag filters cuts both CAPEX and OPEX. This happens over the equipment’s lifetime.

Alalloycasting – Foundry Porous Ceramic Filters

Alalloycasting offers thirteen pore size options. You get 1, 5, 10, 20, 30, 50, 80, 100, 120, 150, 200, 250, and 300 μm. Each size works for different metals and casting needs. Their 10 μm pore size filter hits 1 μm accuracy for liquids. Gas filtration reaches 0.5 μm accuracy with the same pore size. That’s much finer than the pore size itself.

The key? Their twisted microporous channel design. Molten metal can’t flow straight through. It twists through connected paths. This builds a 3D maze. Inertial collision traps particles. Here’s how it works: capture efficiency goes up with particle size squared. It goes down with faster flow or thicker fluid. The diffusion and interception systems add two more trap layers. Single-pass removal hits over 95% for hot dust particles.

Material Mix Built for Extreme Heat

These filters use six materials: aluminum silicate, clay, corundum, quartz, silicon carbide, and diatomaceous earth. This mix handles -40°C to 1600°C without breaking. Normal working temps reach 800°C. Hot dust cleaning pushes this to 1350°C. The low thermal expansion rate stops cracks during temp changes. Thermal shock resistance keeps the ceramic whole even with cold metal on hot surfaces.

Porosity varies by filter type. Standard Porous Ceramic reaches 60% porosity. Their foam ceramic filters hit 80-90% porosity—same as FoundryMax’s numbers. The 3D network structure traps particles and does more. It makes particles travel longer through the filter. This cuts cleaning frequency. Backflush resistance is lower than old-style filters. Pore shapes stay the same even after long use.

Chemical Resistance for All Conditions

Alalloycasting filters handle strong acids—sulfuric, nitric, and hydrochloric. They resist strong bases like sodium hydroxide. Organic solvents can’t damage the ceramic core. The material is non-toxic and odorless. No foreign matter gets in during production. So they work in sterile processing areas.

Mechanical specs fit tough foundry work. Working pressure goes to 6 MPa. Differential pressure capacity reaches 1 MPa. Surface hardness stays high with special coatings. Sintering strength stops slag from falling during pours.

These filters handle grey iron, Ductile Iron, copper, bronze, and Aluminum Alloy work. Starting pressure head is 100-150mm. Aluminum liquid flows through? Operating pressure head drops to 75-100mm. The adsorption effect pulls sodium and potassium from aluminum liquid—vital for alloy quality.

Light pass-through (through-hole ratio) measures ≥95%. Filter plate flatness is precise on every unit. Size specs meet exact limits. These aren’t sales talk. They’re production rules that decide if your casting runs work or fail.

Filken – Ceramic Water Filter Systems (Industrial Grade)

Filken skips extreme temperature specs. Their ceramic water filtration systems solve a different problem: high-volume Water Purification. Flow rate and capacity beat heat resistance here. Malaysian offices, hotels, restaurants, and schools want clean, chlorine-free water at scale. Filken’s systems push out 16,000 gallons (60,567 liters) per filter cycle. That’s enough for hundreds of people each day.

The tech mixes Ceramic filters with Activated Carbon and Filken’s Ultra-D membrane. This membrane? It’s the sole outdoor-rated Ultra-D material in Southeast Asia. The pore structure sits at 3,000 times smaller than a human hair’s diameter. It grabs particles standard filters can’t catch. The four-stage premium filtration strips out sediment, chlorine, bacteria, chemicals, heavy metals, and lead. You get odorless, chlorine-free water that tastes clean.

Commercial-Scale Performance Numbers

Flow rate reaches 2.5 GPM (9.46 liters per minute) at 60 psi. The system runs across 30-125 psi working pressure. Buildings see water pressure shift between floors or during busy hours. This flexibility handles that. A cafe hits morning rush? A hotel kitchen preps lunch? Flow stays solid.

Their S2300 indoor dispenser shows Filken’s approach to commercial ceramic filtration. The unit pumps out 30 liters per hour of filtered water. The 0.9-liter cold tank holds chilled water. Compact size—180 x 514 x 407 mm—slides under counters or into service areas. 13.5 kg net weight means no structural reinforcement needed. 2,400-watt power draw runs heating and cooling without blowing standard commercial circuits.

Filken made these systems to last in busy spots. Quality materials cut down maintenance needs. Downtime drains money in commercial spaces. Fewer filter swaps mean less disruption. The ceramic cartridge holds its flow rate longer than throwaway options. Your water stays steady during peak hours.

Key Factors for Choosing High-Temperature Porous Ceramic Filters in the Malaysian Market

Malaysia’s industrial buyers throw money away on ceramic filters. The problem? These filters don’t match actual temperature needs. A spec sheet’s temperature rating won’t help you. It must align with your process conditions.

Your equipment sets the filtration standards. Automotive exhaust systems run 800°C Honeycomb ceramic carriers. These meet Malaysia’s upcoming emission standards. They mirror China’s National VI regulations. Diesel engines need high-porosity carbon soot filters. These filters handle temperatures above 800°C. Chemical plants work another way. Their Ceramic filter media operates at 400–815°C. You get 0.08 µm precision and 20 MPa differential pressure. Going with sintered metal fiber filters? You’re at 1,000°C.

Match Filter Capacity to Real Operating Loads

The global porous ceramic market reached USD 6.33 billion in 2021. By 2029, it climbs to USD 15.17 billion—a 10.9% CAGR. China’s honeycomb ceramic segment grew from RMB 2.86 billion in 2014 to RMB 5.5 billion in 2019. That’s 13.97% annual growth. Malaysia’s industrial growth shows similar trends. Your filter choice impacts upfront costs. It also affects long-term replacement budgets.

Commercial vehicle honeycomb ceramics measure 1–2 liters in volume. Prices range from RMB 5–7.5 per liter. Calculate your fleet size. Factor in replacement cycles. The 2024 market shows billions in combined replacement and new installation demand. Environmental protection sectors use ceramic fiber filters rated 180–600°C. Waste incineration does too. The thermal power and steel flue gas treatment market hit RMB 239–325 billion capacity between 2021–2025.

Know Your Failure Thresholds Before They Hit

Filters fail two ways. Pore blockage cuts carbon particle filtration below 90% efficiency. Thermal shock cracks wreck cordierite carriers. Don’t wait for failure. Track maximum backpressure above 37 kPa. Replace at 5.5–7.5 kPa differential. Monitor particle size shifts. Service life typically runs five years in controlled settings.

Watch your PM particle capture rate. Performance below 90% means replacement time. SOF filtration decline backs this up. Monitor pressure differential. Set alerts at 0.025–0.60 MPa thresholds. Imported ceramic filters from Mott or Pall cost more upfront. But they handle 1,000°C without fail. Local cordierite options give you lower backpressure. Plus, they cost less at the start.

Trends and Localization Challenges in High-Temperature Ceramic Filtration Technology

The global porous ceramic market jumped from USD 6.33 billion in 2021 to a projected USD 15.17 billion by 2029. That’s a 10.9% CAGR. Malaysia’s industrial sector sits right in this growth wave. But here’s the problem: local manufacturing? Almost zero. You’re buying from China or waiting weeks for European shipments.

New materials push temperature limits higher. Silicon carbide (SiC) and aluminum oxide-based composites now handle processes above 1000°C. Graphene-ceramic composite membranes run at 300°C for 1,000 hours without breaking down. Aluminum nitride ceramics offer 5 times higher thermal conductivity than standard alumina. Their expansion coefficient matches silicon perfectly. This matters for semiconductor substrate applications. These aren’t lab tests. They’re ready for production. They’re changing high-temperature porous ceramic filtration companies across Asia.

Why Malaysia Lacks Local Production

Three factors block local manufacturing: technical gaps, high costs, and scattered market demand. Malaysia has no unified high-temperature testing standards. International specs like JIS Z 8122:2013 stop at 250°C. Anything hotter needs custom aging tests. That’s expensive upfront R&D. Most local firms can’t afford it.

Raw material processing happens elsewhere. China controls the manufacturing hubs for ceramic precursors. Asia-Pacific’s closeness to these processing centers cuts innovation cycles by months. Malaysian operations? They import finished filters. The cost structure breaks down at small volumes. Local production doesn’t make sense.

Price pressure kills competitiveness too. High-performance Filter media costs jump fast. Small and medium businesses can’t justify the capital spend. Import tariffs add another layer. Buyers pay higher costs. Domestic manufacturing stays frozen.

China Dominance Creates Real Risks

Relying on Chinese suppliers worked—until it didn’t. 2025 U.S. tariffs hit ceramic components and raw materials hard. Costs spiked across the board. Malaysian buyers depending on cross-border chains saw delivery delays stretch from weeks to months. Price swings became normal.

Quality problems show up at extreme temperatures. PTFE chain breakage at high heat changes micropore structures. Nobody saw this coming until filters failed mid-process. High-temperature dust bonding makes cleaning tough. Pulse-jet systems that worked at 650°C failed above 900°C. Filter makers issued updates. But damage hit foundries and chemical plants hard.

China’s Zhongcai Technology HT-F series offers solid value: 1,500 Pa pressure drop, -50°C to 300°C range, Class A fire resistance. Pricing beats Western competitors. But international brands like Pall’s T-Rex filters guarantee 99.9% efficiency at 450°C with proven regeneration stability. They cost more. Yet downtime from filter failure costs far more than the price difference.

Regional Warehousing Makes Economic Sense

Regional distribution centers in Malaysia shift the equation. Closeness to Asia-Pacific’s ceramic manufacturing bases speeds up innovation cycles. Time-to-market drops. Custom configurations don’t need months of shipping delays.

Industrial processing growth drives demand. Air quality rules get tighter. Water reclamation projects grow. These need high-throughput, low-maintenance filtration systems. Local stock of critical sizes and specs means you’re not waiting on container ships for a failed filter.

Modular production lines combined with additive manufacturing enable local customization without huge capital spending. Tariff exposure drops. Chain disruptions hurt less. You stock Pall T-Rex all-metal washable elements that handle -20°C to 450°C. Or Zhongcai HT-F filters with 180 Pa resistance. Either way, lead times drop from 8 weeks to 48 hours.

Malaysia sits between raw material suppliers and end-use markets. This creates opportunity. The infrastructure isn’t built yet. But the business case gets stronger every quarter.

Conclusion

Malaysia has strong options for high-temperature ceramic filters. These work for foundry, industrial, and water treatment needs. Looking for foundry Foam Filters? Check FoundryMax and Alalloycasting. Need industrial hot gas filters that handle 1000°C+? Attaquant and Glosfume have you covered. For industrial water cleaning, Filken delivers. The 5 best high-temperature porous ceramic filtration companies in Malaysia give you proven results and solid technical know-how.

Pick your supplier based on three things. First, make sure the temperature specs match what you need. Second, check their technical support. Third, look at total ownership costs, not just the starting price. Global filtration standards now blend with local market needs. This creates real opportunities for manufacturers ready to invest in quality filters.

Ready to upgrade your filtration system? Contact these suppliers with your exact temperature needs, flow rates, and application details. The right ceramic filter partner does more than sell products. They build solutions that cut downtime and boost product quality. You’ll see clear ROI within 12-18 months. Pick the right partner. Your production efficiency relies on it.