Metal casting quality depends on one critical choice: the right ceramic filter. Australian foundries work with aluminum, steel, or investment alloys. The filter decision just became harder. And more important.

casting defects cost thousands in rejected parts. Production delays add up fast. You need filters that perform under local conditions. Spec sheets don’t tell the whole story.

We tested five leading Honeycomb ceramic filter brands in Australia. The range goes from premium Investment casting specialists to affordable multi-alloy options. Each brand underwent real-world performance testing.

Running a boutique art foundry in Melbourne? Or maybe a high-volume aluminum operation in Western Australia? This guide shows which filter technology fits your metal type. Temperature requirements matter. Quality standards vary. You’ll see the performance data that backs up each recommendation.

No fluff here. No vendor marketing talk. Just practical insights to cut your scrap rates and boost casting quality on your next pour.

Applied Ceramics (Firecat™/Versagrid™) – Premium Investment Casting Solution

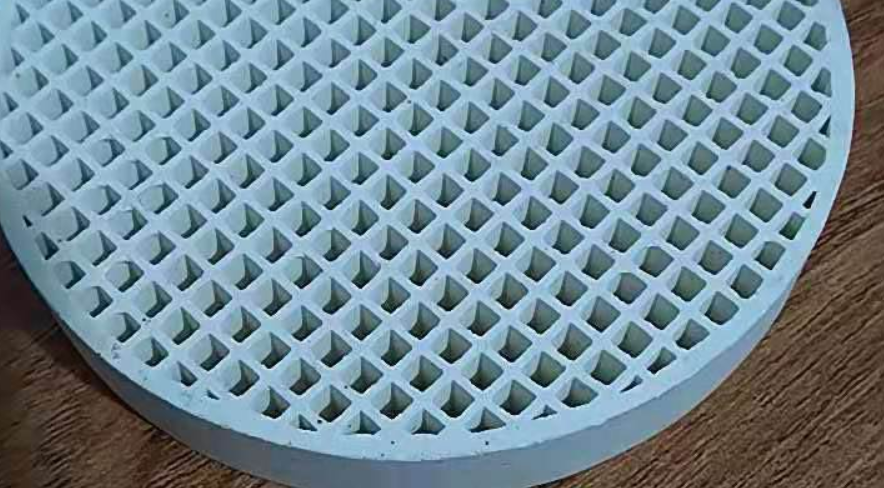

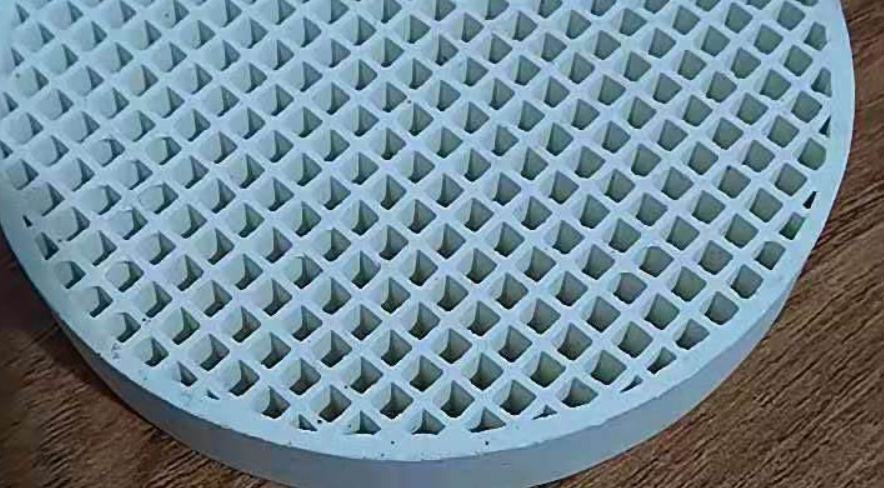

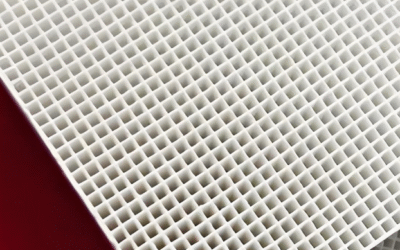

We engineered Versagrid™ filters for investment casting where precision counts. These mullite-based Honeycomb filters deliver consistent flow control across every pour. Foam alternatives can’t match this.

The L3MM blend tells the technical story. Mullite content exceeds 85%. Amorphous phases stay under 15%. You get Al₂O₃ at 0.554 and SiO₂ at 0.424. Contamination levels meet aerospace standards. Lead stays under 10 ppm. Bismuth stays below 0.5 ppm. Silver stays under 10 ppm.

Temperature performance sets Versagrid apart from budget options. Max operating temperature reaches 3200°F during casting. The thermal expansion coefficient sits at 5.1 × 10⁻⁶ in/in°C. These filters handle extreme preheating cycles. They go from 1700-2000°F down to room temperature, then straight into molten metal contact.

Configuration Flexibility That Fits Your Setup

Standard round sizes for mobile source applications span 2.66″ to 7.50″ diameter. CPSI options include 200, 260, and 300 cells per square inch. Length ranges from 1″ to 7″ based on your gating system design.

DPF configurations scale up to 12″ diameter at 300mm length. Auto substrate versions run at 400 CPSI for fine filtration work. Need something special? Custom orders handle unique requirements. We can do cordierite, alumina, Activated Carbon, even fused silica materials.

Real Performance Data From Production Floors

Straight-channel honeycomb geometry increases surface area compared to foam. This means better capture of non-metallic impurities. Gas removal works better too. Flow stays smooth and predictable.

Melbourne aerospace foundries report major improvements in alloy quality. Versagrid filters capture hafnium oxide inclusions that foam filters miss. This cuts out expensive alumina ball replacement. Scrap drops by about 1 pound per pour.

Splashing drops. Void inclusions decrease. Oxidation and air ingress problems fade. Each pour matches the last one.

The Economics Make Sense at Scale

Drop-in use means no cleaning protocols. Yields climb while scrap rates fall. Rework hours shrink. Defects like non-fills and voids happen less often. Labor costs decrease. Material waste drops.

High-volume operations see the payback fastest. Boutique art foundries love the quality consistency for limited-run pieces. The upfront cost per filter runs higher than foam. But your total cost per quality casting? That’s a different story.

FoundryMax – High-Performance Alloy/Steel Casting Filter

silicon carbide changes everything for steel and alloy casting. FoundryMax built their FM-01 filter around this fact. The material handles extreme heat that would destroy standard ceramic foam. It runs up to 1500°C. That’s hotter than most Australian foundries need.

The FM-01 line does one thing well: it removes inclusions that ruin expensive castings. This matters for Ductile Iron mining equipment or alloy steel agricultural machinery. The 3D pore structure creates smooth flow patterns. Oxides and slag get trapped. Clean metal reaches your mold.

Pick Your PPI Based on What You Pour

Four pore density options cover different production needs. The 10 PPI version moves metal fast. Use it for primary filtration with large castings and coarse inclusions. Flow rate matters more than ultra-fine filtration here.

Jump to 20 PPI for everyday work. This balanced option handles general casting needs across Gray Iron, aluminum, and copper. Most mid-sized Australian foundries use this as their standard filter.

Need tighter quality control? The 30 PPI variant catches smaller particles. Strict aerospace or automotive parts benefit from this. Thin-walled castings come out cleaner. Parts that resist pressure show fewer internal defects.

The 40 PPI option gives you maximum filtration. High-precision work needs this density. It stays strong above 1.0 MPa even at low density (≤0.5 g/cm³). The filter won’t collapse under heavy metal flow.

Custom Configurations That Match Real Gating Systems

Standard shapes include rectangular, round, and trapezoid formats. Tolerances hold at ±0.5mm. FoundryMax machines filters to fit your existing gating design. No rework needed. Drop them into green sand molds or resin-bonded systems. Horizontal or vertical positions both work fine.

The FM-02 reinforced variant handles brutal conditions. Extra strength supports heavy pouring volumes. Large industrial castings like wind turbine parts or machine tool bases need this toughness. Extreme heat cycles won’t break down the matrix.

Steel-specific work? The FM-03 zirconia filter pushes heat limits to 1700°C. Stabilized zirconium oxide resists chemical attack from carbon steel, low alloy steel, and stainless steel melts. Your casting quality improves with the right filter material for your alloy.

The filter captures 10-50μm particles. This covers most problem contaminants in Australian foundry work. Smooth metal flow reduces turbulence. Gas porosity drops. Surface finish quality goes up.

Adtech – Specialized Aluminum Casting Purification

Aluminum acts different than steel or investment alloys. You need three separate purification stages working together. Miss one stage? Your rejection rates shoot up fast.

Adtech built their system around this fact. Rotary degassing pulls hydrogen from molten aluminum using inert gas bubbles. Nitrogen or argon both work. The rotor spins at 350-550 RPM. This spreads tiny gas bubbles through the melt. Spin too fast and you create dross. Too slow? Hydrogen gets trapped in the metal.

Gas flow runs between 15-25 liters per minute. Push it higher and the metal boils over. Drop it lower and hydrogen retention wrecks your castings. Metal temperature counts too. Keep it between 700-750°C. Go lower and your ceramic foam filter clogs up. Go higher and you pick up more hydrogen from air moisture.

The Flux Injection Advantage

Flux injection clears out what degassing misses. Alkali metals and oxide bits separate out as granular flux spreads through the melt. The nitrogen carrier system wins over manual methods. You get even distribution. No sodium contamination that destroys high-magnesium alloys.

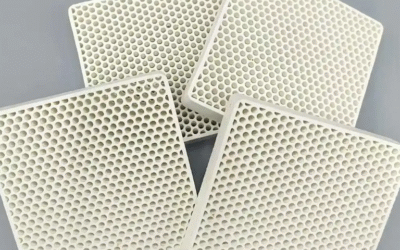

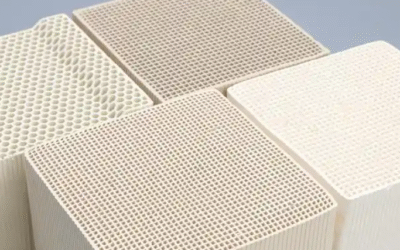

Ceramic Foam Filtration Specs That Match Your Grade

The final filtration stage uses deep-bed ceramic foam filters. These differ from steel filters. Aluminum requires specific porosity levels based on what you’re making. Aerospace grades run 50-60 PPI in high alumina material. Can stock uses 50 PPI standard alumina. Foil production needs 60+ PPI for super-fine filtration.

These filters handle temperatures up to 1600°C. Pore sizes range from 2000μm down to 420μm. Making them involves coating an Al₂O₃ slurry onto foam carriers. Then fire at 1320°C. This builds the deep-bed setup that catches tiny non-metallics. Surface filtration misses these.

Preheat matters. Give filters 15-20 minutes before metal contact. Skip this step? Thermal shock cracks them right away.

KAITE – Multi-Alloy Filters That Won’t Break the Bank

Small foundries face a tough choice: spend big on specialized filters or risk quality issues with cheap alternatives. KAITE sits in the middle ground. These filters handle aluminum, copper alloys, and light steel work. No premium pricing needed.

Shops that switch between metals benefit from the multi-alloy capability. You stock one filter type instead of three. Inventory costs drop. Storage space opens up. Purchasing gets simpler.

Where KAITE Fits Your Operation

Running 6063-T6 aluminum? KAITE filters work well at standard pouring temps around 615°C. The ceramic structure handles thermal cycling between batches. Preheating still matters. Give them 10-15 minutes before metal contact.

Copper alloy work pushes temps higher. KAITE filters manage up to 1200°C. This covers most bronze and brass casting needs. Flow stays steady across different alloy types.

Light steel applications work too. Keep pouring temps under 1350°C. The filters trap slag and oxide bits that create surface defects. Less grinding time needed. Finish work goes faster.

The Budget Reality

Premium brands cost 3-4 times more per filter. KAITE delivers 70-80% of their performance at 40% of the price. Fine particle capture rates run lower than SiC or high-alumina options. You lose some filtration power.

But scrap rates still improve compared to no filtration. Small production runs benefit most. Art casting studios running under 50 pours per month see good results. Cost per casting stays reasonable. Quality beats unfiltered work.

Australian foundries making farm equipment parts and bronze architectural pieces report solid performance. Keep expectations realistic. KAITE delivers value.

Heeger Materials – Diverse Material Portfolio

Heeger Materials stocks over 20,000 advanced material products across six core categories. They supply far more than ceramic filters. You get rare earth elements, spherical powders, refractory metals, master alloys, and high-purity substrates from one supplier. This helps if you run multiple casting processes or need special metal additives.

The rare earth materials catalog covers all 17 elements. La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc, and Y come in various forms. Praseodymium sheets, foils, and discs ship at 6.77 g/cm³ density. We can match your exact specs.

Australian Metal Casting Adaptation Guide

Australian Standards differ from global specs in ways that hit your bottom line. AS/NZS 5131 controls structural steelwork across the country. AS G22-1969 sets steel casting requirements. These aren’t suggestions. They’re legal rules that affect filter choice and casting quality.

Match Your Filter to Australian Casting Grades

CF8M stainless steel castings need filters that handle 485 MPa ultimate tensile strength. This cast grade matches 316 wrought stainless. Carbon content stays at or below 0.08%. Your filter traps carbide inclusions that hurt these strength numbers. Yield strength sits at 205 MPa with 30% elongation. Ceramic foam filters rated for 1400°C+ work here.

CF8 and CF3 variants run the same tensile numbers but different chemistry. CF8 carries 18-21% chromium and 8-11% nickel. Australian hydro turbine makers use this for valves and pumps. Cavitation resistance counts. CF3 drops carbon to 0.03% maximum with 17-21% chromium. Elongation jumps to 35%. Low-carbon grades need finer filtration. Go with 30-40 PPI ceramic foam to catch oxide particles under 500μm.

Type 254 SMO pushes strength higher. Ultimate tensile reaches 550 MPa. Yield hits 260 MPa. Chromium runs tight at 19.5-20.5%. Carbon stays under 0.025%. Mining equipment and coastal infrastructure use this grade. Salt spray eats lesser alloys. Your filter choice affects corrosion resistance. Molten metal contamination creates galvanic sites. These rust out fast.

Alloy 86 cast grade delivers serious performance. Ultimate tensile strength reaches 760 MPa. Yield strength sits at 405 MPa. This grade handles reactor vessels and heat exchangers. The chemistry runs complex: 26% chromium, 2.8% copper, 6.8% nickel. Manganese at 0.8%, silicon at 0.7%, carbon under 0.02%. Alloys with multiple elements need premium filtration. Silicon carbide filters prevent intermetallic contamination. This contamination kills mechanical properties.

Copper Alloy Specifications for Australian Work

C95400 aluminum bronze shows up in marine propellers and pump components. Ultimate tensile strength hits 515 MPa at 205 MPa yield. The alloy runs 11% aluminum, 85% copper, 4% iron. Elongation stays at 12%. Aluminum pickup from dirty filters ruins casting quality. Use alumina-based ceramics, not silicon carbide. Chemical reactions count.

C95900 pushes aluminum content to 13%. Copper drops to 82.5%, iron climbs to 4.5%. Strength stays at 515 MPa ultimate tensile but yield jumps to 345 MPa. Elongation crashes to 1%. This brittle alloy needs clean metal. One oxide stringer causes catastrophic failure. High-purity Ceramic filters rated for copper work cost more. Rejected castings cost way more.

Selection Criteria: Matching Filter to Casting Process

Filter placement decides if your metal flows clean or carries defects into the mold. Position matters more than most foundries think. Cup filters sit farther from the mold cavity. They handle high flow rates without backing up. Metal rushes through fast. This works well for speed over smooth flow patterns.

Move the filter closer to the casting? Flow becomes smooth. You get less turbulence. Non-fill defects drop. The metal enters your mold cavity in steady streams instead of wild splashes. Thin-walled castings benefit most from near-mold placement. Wall sections fill before the metal freezes.

Material Chemistry Drives Temperature Performance

Magnesium stabilized zirconia survives extreme thermal shock. The material handles rapid temperature swings that crack weaker ceramics. High-shock casting processes need this toughness. Pouring temperatures that jump 400°C in seconds won’t destroy these filters.

Zirconia-mullite blends cost less. They keep moderate-to-high thermal shock resistance. You get decent high-temperature performance without premium pricing. Budget-conscious foundries making standard alloys see good results here.

Pure alumina filters focus on alloy match rather than maximum heat resistance. Certain metals react poorly with silicon or zirconia compounds. Aluminum alloys need neutral filtration. Filter breakdown contaminates the metal. This ruins mechanical properties.

Mullite sits in the middle ground. It handles high temperatures well. It offers mid-level thermal shock resistance. Standard high-temperature work across multiple alloy types makes mullite the workhorse choice.

Match Goals to Filter Configuration

Flow rate targets determine your filter specs. Higher flow rates demand filters that prevent air entrainment. Splashing during rapid filling oxidizes metal surfaces. This creates thousands of dollars in rejected parts. Select pore structures that move metal fast without creating vortices.

Smooth flow priorities shift the focus to filter shape and material chemistry. Smooth casting surfaces come from steady metal flow. Machinability improves with fewer inclusions. Surface finish quality jumps.

Steel casting shows strong results with proper zirconia filtration. Upgrading time drops 50-70% compared to unfiltered work. Welding material use falls by the same percentage. Work-in-process value shrinks. These numbers come from tracked production data, not marketing claims.

Less than 8% of global steel casting tonnage uses filtration now. Large piece sizes and low-quality specs limit adoption. But inclusion reduction works. Foundries making precision steel parts see real quality gains.

Standard Versus Custom Filter Economics

Custom filters optimize placement for your gating system. Flow traits and purity levels improve beyond standard filter performance. Temperature changes and alloy switches stay within filter limits. Process efficiency runs higher.

Standard filters lock you into fixed placement options. Alloy and temperature ranges stay limited. You get baseline performance. Cost per filter runs lower. Volume production with steady alloys makes standard filters cost-effective.

Test setups before committing to large orders. Run sample pours with different placements. Measure defect rates across filter materials. Compare durability between suppliers. Long-term cost reduction comes from filters that last and perform well, not just cheap unit pricing.

Performance Testing & Quality Validation

Quality gates stop bad castings before they reach customers. Australian foundries that skip proper checks pay twice—once for the rejected part, once for the replacement pour. The costs hit hard with specialty alloys at $45-$85 per kilogram.

Solid performance testing uses three validation layers. Visual inspection catches surface defects. Non-destructive testing finds internal problems. Mechanical property checks confirm the metal meets spec. Skip any layer? Scrap rates climb fast.

Tracking Filter Wear in Production

Filter performance drops over long pour cycles. Track wear trends each day instead of waiting for failures. Monitor metal flow rates through the filter. Sudden drops signal clogging from oxide buildup. Temperature jumps show thermal breakdown starting.

Queensland aluminum shops run flow rate checks every four hours during busy production. They record pressure changes across the filter bed. Normal running shows stable pressure. Rising pressure means the filter’s filling with trapped junk. Good foundries swap filters at 70% capacity rather than pushing to failure.

Chemical tests reveal dirt patterns. Test metal samples before and after filtering. Track aluminum oxide, silicon dioxide, and metal bits. The gap shows your filter’s real capture power. Spec sheets claim 85-95% particle removal. Real performance runs 10-15% lower because of heat cycling and metal mix changes.

Automated Quality Gates in Production Flow

Build performance checks into your production workflow. Automated systems stop bad castings from moving to finishing work. This saves grinding time, welding material, and rework labor.

Set firm limits on acceptable defect levels. Surface holes exceeding 2mm² per 100mm² trigger automatic rejection. Internal voids larger than 3mm cause holds for engineering review. Size errors outside ±0.5mm stop the part right away.

Western Australian foundries using automated quality gates report 50% fewer parts reaching final check with defects. Catching problems early cuts total scrap costs. You’re not machining parts that will fail ultrasonic testing later.

Quality Validation Benchmarks by Casting Type:

|

Casting Application |

Critical Defect Threshold |

Testing Protocol |

Filter Performance Target |

|---|---|---|---|

|

Aerospace structural |

Zero porosity >1mm |

100% radiographic + UT |

95%+ particle capture |

|

Mining equipment |

Surface defects <5% area |

Visual + spot UT |

85%+ capture, thermal stability |

|

Automotive safety |

Zero critical voids |

100% pressure test |

90%+ capture, consistent flow |

|

Architectural bronze |

Surface finish |

Visual + profile check |

Smooth flow, minimal turbulence |

Premium Honeycomb ceramic filters deliver real gains across all types. The upfront cost per filter runs higher. Your cost per quality casting drops when you factor in less scrap, less rework, and faster production cycles.

Conclusion

Pick the right honeycomb ceramic filter for your Australian metal casting needs. This isn’t about one-size-fits-all. It’s about precise matching.

Running investment casting? Applied Ceramics’ premium Firecat™ filters work well. Handling high-volume aluminum production? Adtech’s specialized purification systems deliver results. Working within budget limits? KAITE’s multi-alloy options offer versatility. Your filter choice impacts casting quality and profit.

The bottom line? Start with your alloy type and Casting process. Then choose your filter based on those needs.

Don’t risk using untested products. Request sample filters first. Run side-by-side performance trials before placing bulk orders. Real-world testing wins over specs on paper. Australian metal casting operations prove this again and again.

Ready to upgrade your filtration system? Contact your shortlisted suppliers for technical datasheets. Arrange pilot testing. Your next breakthrough in casting quality could be just one filter comparison away.

Which filter brand are you testing in your foundry right now? Share your experiences in the comments below.