Australian aluminum foundries need ceramic filters that handle extreme heat. These filters must deliver consistent quality during high-volume production runs.

A premium ceramic filter does more than just clean molten metal efficiently. It stops defects before they happen. Scrap rates drop. Your castings maintain the structural integrity that Australian manufacturing demands.

Running a specialty casting shop in Melbourne? Managing a large aluminum facility in Queensland? Your choice of high-temperature ceramic filtration company affects your profits and reputation.

We looked at the market and found six top providers. These companies get what Australian aluminum casting requires. They understand everything from sourcing raw materials to helping you after installation.

Each company has its own strengths. Some create custom filtration systems for unique needs. Others ship fast across Australia. A few have developed their own technologies that push molten metal purity to new levels.

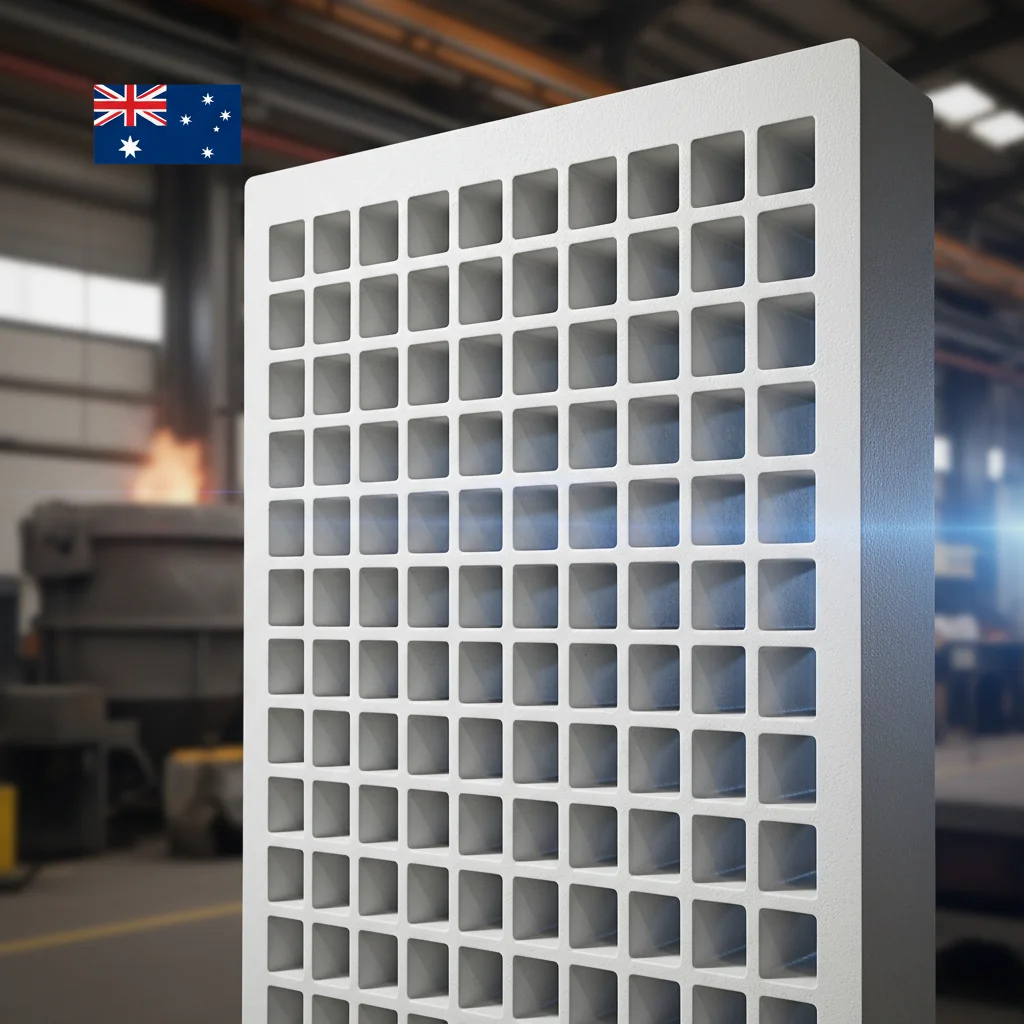

M-Kube (Australia-Based Ceramic Filter Specialist)

M-Kube runs ISO-certified factories in Australia. They’ve built their name on Ceramic filters that meet ASTM and ISO standards. This isn’t some reseller selling imported products—it’s a real manufacturer with deep technical know-how.

Their catalog covers three main materials. High-temperature ceramic filtration starts with Alumina foam filters. These work for aluminum, copper, and precision non-ferrous metals. silicon carbide types handle Ductile Iron, grey iron, and copper alloys. Zirconia filters work for steel casting where heat goes past 1650°C.

Material Performance Data

M-Kube’s Silicon carbide filters come in four types. SSIC gives you 380 MPa flexural strength and runs at 1600°C. RBSiC operates at 1380°C but keeps 250 MPa strength. NBSiC and RSIC sit between these two. Each type uses 80-99% silicon carbide by weight. Densities range from 2.65 to 3.10 g/cm³.

Their alumina filters have 0.35 to 0.50 g/cm³ bulk density. You get over 1.0 MPa compressive strength. They operate at 1350-1800°C and handle thermal shock well.

Pore Size Selection

Pick 10-15 PPI for high-flow jobs and large castings. Go with 20-30 PPI if you care more about stopping defects than speed. M-Kube makes 10, 20, 30, 40, and 50 PPI options. Custom setups? They do those too. Standard sizes include 50×50 mm, 75×75 mm, and 100×100 mm squares. Rounds or custom shapes are available.

Your filter area needs to be 2-4 times your gating system cross-section. Too small? The filter blocks metal flow and causes turbulence.

M-Kube ships across Australia with technical support. Call them at +61-478-594-746 or email info@mkube.com.au. Each batch comes with material composition reports, size accuracy data, and thermal shock test results.

FoundryMax

FoundryMax builds Ceramic honeycomb structures that changed how foundries handle molten aluminum. Their filters don’t just catch inclusions—they pull them out of the metal stream before defects form.

The honeycomb design creates thousands of tiny channels. Molten aluminum flows through these paths. Non-metallic particles stick to the ceramic walls. This goes beyond basic mechanical filtration. The structure’s shape creates turbulence patterns. These patterns force inclusions into contact with absorption surfaces.

Automated Production Lines

FoundryMax runs automated systems that produce filters with repeatable precision. Traditional hand-formed ceramics vary batch to batch. Automated lines eliminate that problem. Each filter keeps the same pore structure, wall thickness, and thermal properties.

Australian foundries run 24/7 production. They need filters that perform the same at 6 AM or midnight. Manual production can’t deliver that consistency.

Thermal Performance

These high-temperature ceramic filtration products resist heat and chemical attack. Aluminum alloys at 700-750°C corrode many materials. FoundryMax’s honeycomb ceramics hold their structure and absorption capacity throughout the pour.

The filters fit standard foundry filter boxes. No custom modifications needed. You swap them into existing setups. No retooling. No redesigning your gating systems.

FoundryMax hasn’t set up direct Australian distribution yet. Orders take longer to arrive. Still, their ceramic honeycomb technology offers a different approach to melt cleanliness. Some specialty foundries find it worth the wait.

Sefunm.com (Australia-Focused Filtration Solutions)

Sefunm ships high-temperature ceramic filtration products from their Hebei Province factory to Australian aluminum foundries. These foundries can’t afford casting defects. The Foam ceramic filters handle temperatures up to 1700°C. That’s hot enough for steel and extreme aluminum work.

Three material types cover different heat ranges. alumina ceramic foam filters operate at 1580°C. These work for standard Aluminum Alloy casting. The open-pore structure traps oxides, slag, and metal particles. Your molten aluminum flows clean. Surface quality gets better. Defects drop.

zirconia ceramic foam filters push the limit to 1700°C. Steel foundries use these. Specialty alloys at high temperatures need this heat resistance. The zirconium oxide stays stable where other ceramics fail.

silicon carbide filters sit between these two. They offer strong heat transfer and strength. Iron castings and automotive parts benefit from these.

Pore Selection Matches Your Alloy Grade

High-grade aluminum alloys need finer pores. You catch smaller dirt particles this way. Product quality matters more than flow speed. Standard-grade alloys run faster with larger pores. The coarser structure stops clogging. Bigger particles get removed easier.

Sefunm makes these filters using organic foam coating. This method creates the same pore structures every time. No performance changes. No failures mid-pour.

The packaging system protects zirconia filters during ocean freight to Australia. The containers handle rough shipping. The ceramic structure stays intact.

Contact them at info@sefunm.com or call +86-13785803358. They ship related products too—fiberglass casting filters, Investment casting filters, and auto pouring ladle systems. Check www.sefunm.com for specs on each filter type.

Sefunm delivered zirconia filters to Vietnam in August 2023. Malaysia received alumina filters for precise casting in May 2025. Australian foundries get the same global shipping network.

Foseco (Molten Metal Systems – Global Leader)

Vesuvius plc just paid £92.7 million to buy Morgan advanced Materials’ crucible business. This shows where high-temperature ceramic filtration markets are going. Foseco, their foundry division, doesn’t make small bets. They’ve been doing this since 1932.

The deal has two parts. £20 million cash bought the non-Indian operations. The other part used a share swap. Foseco India Limited gave 1,150,800 new shares for 75% of Morganite Crucible India Limited. Those shares were worth £55.8 million based on August 2025 prices. The deal closes by mid-November 2025.

Revenue Structure and Market Position

Morgan’s crucible business made £42 million in 2024. EBITDA reached £8 million. Aluminum producers account for half that revenue. Copper alloys and precious metals make up most of the rest. India brings in about 20% of total sales.

This acquisition lifts Foseco’s non-ferrous market share from 21% to 27%. That’s a smart move. Australian aluminum foundries are the type of customers this combined operation wants.

Manufacturing Synergies

Vesuvius plans to boost EBITDA by at least 50%. They’ll do this through better manufacturing and lower overhead costs. They run low-cost plants near customer sites around the world. Morgan adds manufacturing sites in Pune and Puducherry, plus an R&D center. Foseco gains technical experts who already work at customer facilities.

The product range grows too. Feeding systems, sand mold coatings, ceramic filters, gating systems, metal treatment chemicals, refractory linings, flow control equipment—all available from one source now. Australian foundries can get more solutions from a single supplier.

Vesuvius holds 64% of Foseco India Limited, which trades on public markets. Morgan owns about 15%. Retail investors hold the rest. After buying 75% of MCIL, FIL must offer to buy remaining shares under Indian securities law.

This deal strengthens Foseco’s filter technology. It also shortens their Australian supply chains. Large-scale aluminum casting operations get proven materials backed by global R&D and local technical support.

Almatis (High-Purity Alumina Raw Material Supplier)

Almatis doesn’t sell filters to your foundry. They sell the raw material that keeps those filters working at 1600°C. No cracking. No dissolving into your aluminum melt.

This German company makes calcined alumina powders. ceramic filter makers buy them by the ton. Australian foundries won’t contact Almatis themselves. But here’s what matters: their alumina purity controls how long your high-temperature ceramic filtration system lasts. Three pours or three hundred pours—it depends on this material.

Material Grades That Matter

Two product lines run ceramic filter making. XLS SG series gives you 99.8% aluminum oxide purity. Sodium oxide stays under 0.03%. ULS SG series goes higher—purity past 99.9%. Sodium oxide drops to 0.01% or less.

Why does sodium content matter? It moves during firing. High sodium creates weak spots in the ceramic. Molten aluminum hits those spots at 750°C. They fail.

CL 2500 ULS SG has the specs most filter makers need. Fires at 1540°C for one hour. Shrinkage: 17%. Green density: 2.22 g/cm³. After firing: 3.91 g/cm³. Crystal size: 1.7 micrometers. Surface area: 0.95 m²/g.

CT 1200 XLS SG fits budget filter work. Fires at 1670°C. Shrinkage: 16%. Green density matches CL 2500. Fired density matches too. Crystal size: 1.7 micrometers. Surface area: 0.9 m²/g.

Chemical Resistance Data

Almatis tests every batch. Iron oxide, silicon dioxide, calcium oxide, boron trioxide—all checked. All stay below 0.03%. Most hit 0.02%.

Their tabular alumina products (T60 and T64) deliver bulk gravity over 3.50 g/cm³. Porosity: below 5%. Water absorption: under 1.5%. These numbers mean ceramic filters handle thermal shock better than fused grain types.

Almatis sells worldwide using standard specs. BET analysis and laser size testing keep each batch the same. Australian ceramic filter makers get the same material quality as European buyers.

FoundryFiltration.com (Export-Focused Ceramic Filter Provider)

FoundryFiltration.com ships high-temperature ceramic filters worldwide. Our ISO 9001:2015 certified facilities meet REACH and RoHS standards. Australian foundries get three different material systems. Each one fits specific metal types and temperature needs.

Silicon Carbide Filters for Iron and Non-Ferrous Work

SiC foam filters mix 50-60% silicon carbide, 20-30% alumina, and over 10% magnesium oxide. Porosity: 80-90%. Bulk density: 0.36-0.5 g/cm³. Strength hits 2.0 MPa at room temperature. Maximum operating temperature: 1500°C.

A 50×50×22 mm filter handles 35 kg of ductile iron. Or 70 kg of grey iron. Flow rates hit 3 kg/s for ductile. 4.5 kg/s for grey. Scale up to 150×150×22 mm? Ductile capacity jumps to 450 kg. Grey capacity reaches 900 kg. Flow rates climb to 36 kg/s for ductile and 54 kg/s for grey.

These filters pass thermal shock tests. 1200°C down to room temperature. Six cycles. PPI options: 8, 10, 15, 20, 25, and 30. The structure straightens metal flow. It screens particles. Plus, it pulls out impurities.

Zirconia Filters Push Temperature Limits

Zirconia foam filters pack 85-90% zirconium oxide, 5-10% alumina, under 4% silica, and 4-5% magnesia. They handle up to 1700°C. Hot enough for steel and extreme aluminum jobs. Strength: 1.5 MPa minimum. Bulk density: 0.8-1.5 g/cm³.

A 100×100×22 mm zirconia filter processes 100 kg total. Pouring rates: 14-20 kg/s. The 75×75×22 mm size takes 60 kg at 7-12 kg/s. Smallest standard size—50×50×22 mm—filters 30 kg at 3-5 kg/s. These work for steel, aluminum, copper, and other non-ferrous metals. The structure creates smooth flow. Also removes inclusions.

Aluminum-Specific Ceramic Plates

Aluminum filter plates use mullite-corundum construction. Density: 0.3-0.45 g/cm³. Heat resistance goes beyond 1500°C. Bending strength: over 0.5 MPa. They pass five thermal shock cycles at 750°C.

Standard size: 305 mm (12 inches) with ±3 mm tolerance. Thickness: 50 mm ±1 mm. PPI ranges from 10 to 40. The tiny pore structure traps microscopic particles. The ceramic stands up to molten aluminum.

Quality Control Standards

We keep tight dimensional tolerances. Filters 100 mm or larger stay within -2.5 to +0.5 mm. Pore density variance: ±3 PPI. No crack longer than 10 mm passes inspection. Each batch includes composition reports. Plus thermal testing data.

Key Selection Criteria for Australian Aluminum Foundries

Start with compliance, not performance specs. Australian facilities casting 50 tonnes or more non-ferrous metal per year fall under ERA 29 (Environmental Relevant Activity) regulations. Miss these standards? Your operation stops. No exceptions.

Location rules come first. Your foundry can’t sit within 100 metres of any watercourse, wetland, or spring. Category A or B sensitive areas? Off limits. Kindergartens, schools, universities, medical centres, hospitals, protected areas, public parks—stay outside their boundaries. Check zoning before you invest in high-temperature ceramic filtration systems.

Alloy-Specific Filter Requirements

Standard casting alloys follow the Aluminum Association system. This is the recognized global standard. Your filter choice changes based on alloy series. The 1xx.x series handles pure aluminum at 99.00% or greater purity. Al-Cu alloys in the 2xx.x series need different filtration than Al-Si mixes in the 4xx.x series. The 3xx.x series combines silicon with copper and magnesium. Al-Mg alloys fill the 5xx.x category.

Engine piston heads demand special alloys. Integral engine uses can’t work with standard grades. Colour anodizing works with alloys that respond to treatment. Match your ceramic filter porosity to your alloy needs. Finer particles need tighter pore structures. High-volume standard alloys run better through coarser filters that resist clogging.

Critical Safety Integration

Moisture causes molten metal explosions. This is the top hazard in aluminum foundries. Your filtration system sits in the metal flow path. Damp scrap, water-contaminated materials, ingots with moisture in shrinkage cavities, wet fluxes—all create serious risks. Oxidized or rusted materials bring water molecules. Even rust on tool surfaces introduces moisture.

Lead contamination exposure requires engineering controls. Install extractor hoods above furnaces. Add dust extraction for any buffing, discing, grinding, or cutting of lead-containing castings. Your ceramic filter supplier needs to understand these environmental systems. Filters that generate too much dust during handling create compliance problems.

Australian Aluminum Casting Industry Applications

Australia’s aluminum casting sector moves $12 billion worth of metal through foundries every year. That number hits $21.15 billion by 2033 if current growth holds. Mining equipment eats up most of this capacity. Mill liners wear out fast. Construction comes next. Then transport. Energy infrastructure rounds out the big four.

High-temperature ceramic filter companies serve these uses in distinct ways. Mill liners need maximum strength. Surface finish matters less. Transport parts flip that priority. A truck suspension part with defects fails inspection. An aerospace bracket with oxide streaks gets scrapped before it leaves the shop.

Mining Equipment Drives Filter Demand

Rio Tinto runs the biggest operation. Their $3.15 billion revenue beats everyone else in Australian aluminum smelting. Alcoa brings in $479.8 million. CSR adds $449 million more. These producers make primary ingots and castings under one roof.

Mill liners represent the toughest casting job. Ore crushers spin these parts at high speed. Rock impacts create massive stress. The aluminum alloy must stay uniform throughout. One weak spot means total failure. Ceramic filters remove the particles that create those weak spots.

Australia dug 100 million tonnes of bauxite in 2022. Exports hit 39.8 million tonnes. Production climbs to 110 million tonnes by 2027. Every tonne going through refineries needs equipment. That equipment wears out. Casting replacements drive steady filter use.

Infrastructure and Transport Push Quality Standards

Renewable energy projects changed what foundries cast. Wind turbine parts require aerospace-grade purity. Grid transmission hardware can’t have defects. Electric vehicle parts follow auto specs that ban visible defects.

Australia exported 85% of its aluminum production in 2025-26. Overseas buyers demand certification. AS 1874-2000 compliance isn’t optional anymore. Neither is AS/NZS 1734 for sheet and plate specs. Your ceramic filter choice affects whether castings pass these standards.

The transport sector keeps raising standards. Lightweight parts replace steel in trucks. Aluminum suspension parts cut fuel use. But they must match steel’s reliability. Ceramic filtration delivers the purity levels that make this swap work.

Conclusion

Finding the right high-temperature ceramic filtration partner for Australian aluminum casting goes beyond product specs. You need a supplier who gets your foundry’s unique challenges. They should understand your delivery timelines and quality standards.

Local support matters to some operations. M-Kube and Sefunm.com offer that. Others need proven global expertise—that’s where Foseco comes in. Custom solutions? Check out FoundryMax and FoundryFiltration.com. Each company on this list brings clear benefits to your molten metal filtration process.

The Australian aluminum industry needs reliability. Consistency counts. So does innovation. Start by checking your specific casting needs: filter pore size, production volume, and aluminum alloy complexity. Reach out to 2-3 suppliers for samples. Get technical consultations. Test their filters in real production conditions. The proof isn’t in the sales pitch—it’s in the pour.

Your next breakthrough in casting quality could be one filter change away. Don’t let poor filtration hold back your foundry’s potential.