Choosing the right industrial filter matters. It affects your system’s efficiency, cost, and reliability. I recommend you evaluate your process needs carefully before buying.

Key Considerations for Choosing an Industrial Filter

Type and Properties of Fluids: Are you filtering liquids or gases? Check viscosity, temperature, pH, and chemical makeup. Abrasive or corrosive fluids need resistant materials. I suggest PTFE or polypropylene for these cases.

Understanding Contaminant Profile: Know what you need to remove. Is it solid particles, oil, bacteria, or chemicals? Size matters too. Particle size is measured in microns. Beach sand is 300–600 microns. Fine dust is under 10 microns. Filters range from 0.2 microns (for pharmaceuticals or microelectronics) to 1000 microns (for heavy industries).

Matching Micron Rating & Efficiency: The micron rating shows the smallest particle a filter can catch. Higher efficiency filters give you purer results. But they clog faster. They also use more energy because of higher pressure drop.

Considering Sector-Specific Needs: Each industry has different needs. Pharmaceutical and food sectors need ultra-fine filtration. This ensures safety and purity. Construction and mining focus on removing bulk particles. They need tough materials.

Based on my experience, this approach works. It helps you find the right balance of efficiency, compliance, and cost for your operation.

Step 1: Identify What Needs to Be Filtered

Before you select an industrial filter, define what you need to remove from your process. The right choice depends on three factors: the type of medium, the specific contaminants, and any industry regulations.

Define the Medium

Liquids: Common examples include water, oils, chemicals, and slurries. Check properties like viscosity, temperature, pH, and chemical reactivity. For corrosive or abrasive fluids, I recommend materials like PTFE or polypropylene. They resist damage and last longer.

Gases/Air: Think about particulates, oil vapors, and moisture. ISO 8573-1 standards classify acceptable levels for compressed air. These standards cover solids, water, and oil.

Solids/Particulates: Applications often involve removing dust, sand, fibers, or fine powders. The required filter depends on particulate size. Some industries need to capture particles as small as bacteria or smoke. Others need filters for large debris.

Determine the Contaminant Type

Solid particulates: These range from millimeter-sized fibers to sub-micron dust, metal shavings, or cement particles. Mining, chemical, and cleanroom applications all have different contaminant profiles.

Oils and emulsions: Hydraulic systems and food manufacturing often require filters that capture trace oils and emulsified liquids.

Microorganisms/bacteria: Industries like pharmaceuticals, biotech, and semiconductors demand absolute-rated filters. ULPA filters capture particles down to 0.12 microns. They ensure sterilization and purity.

Chemicals: Solvents, acids, and organic chemicals may need specialty filters. I suggest Activated Carbon for effective removal.

Water/moisture: This is critical in compressed air. Removing excess moisture prevents equipment corrosion. It also maintains product integrity.

Consider Industry-Specific Standards

Pharmaceutical: FDA and cGMP regulations require sterile, particulate-free environments. Absolute-rated membrane filters are the norm.

Food and beverage: These industries must meet strict contamination limits. Filters and housings should meet FDA/EC standards.

Mining/heavy industry: I suggest focusing on durability and high load capacity. Filters must remove large solids and resist abrasion.

Electronics/semiconductors: Ultrafine particulate and vapor removal is needed. This avoids defects.

Quantitative & Practical Details

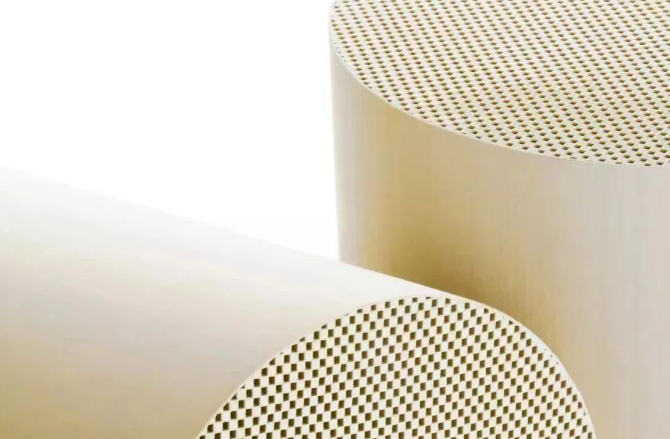

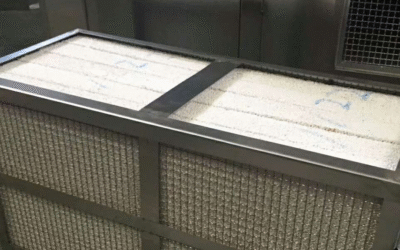

Filter materials: Options include cellulose, polypropylene, activated carbon, ceramic, stainless steel, fiberglass. Choose based on compatibility, dirt-holding capacity, and temperature resistance.

Nominal vs. absolute rating: Nominal covers 75–80% of specified particles. Absolute is ≥99% effective.

Beta ratio: This indicates efficiency. A beta of 2000 at 5 microns (Beta5 ≥ 2000) means 1 out of 2000 particles at that size will pass through.

Cleanroom standards: For ISO 5 (class 100), a HEPA filter is essential. Class 10 (ISO 4) needs ULPA.

Step 2: Determine Filtration Requirements

I recommend starting with clear filtration needs. This ensures your system runs well and your product stays high quality. Here’s my approach:

Identify Particle Size & Removal Needs

Micron Ratings: Filters sort by particle size. We measure this in microns (µm). Here are the main options:

25 microns: Removes sand and large debris. I suggest this for first or second-stage filtration in general use. It offers over 85% efficiency.

10 microns: Captures fine sand and silt. This gives you over 90% efficiency. It works well for clarity in oils and chemicals. Note: it won’t remove bacteria.

5 microns: Gets rid of mold spores and some bacteria. Food and beverage industries use this often. You’ll need to replace it more often.

1 micron: Removes fine bacteria and protozoa. I recommend this for pharmaceuticals and electronics. It’s a must for these fields.

Match Filter Efficiency to Application

Nominal Filters: These remove 50–80% of target particle size in one pass.

Example: A 50-micron nominal filter clears most particles above 50 microns. But it won’t catch all of them.

Absolute Filters: These capture 90–98% of particles at their rated size. I suggest these for strict contaminant limits.

Step 3: Select the Filter Type: Finding the Right Filter for Your Industrial Process

I recommend choosing the right filter type to ensure efficiency and reliability. It also helps you save money over time. Here are the main industrial filter types. I’ll explain how they work and which applications suit them best.

Bag Filters for High Particulate Loads

- Typical uses: Wastewater treatment, chemical processing, food & beverage.

- Materials: Polypropylene, nylon, or polyester.

- Micron range: 1 to 400 µm.

- Bag sizes: #1 (8″ x 25″), #2 (8″ x 31″), #3 (8″ x 36″).

- Flow rates: Up to 1,000 GPM (depends on filter size and setup).

- Advantages: You can change them easily. They cause minimal downtime. They handle high solid loads well.

High-Flow Filters for Large-Volume Systems

- Applications: Cooling water circuits, desalination plants, large-scale manufacturing.

- Construction: Large-diameter cartridges or modular housings.

- Media: Polypropylene, cellulose.

- Flow rates: 500–2,000+ GPM.

- Cartridge lengths: 40″ or 60″.

- Benefits: These filters support fast filtration. They handle big system demands well.

Depth Filters for Varied Particulate Sizes

- Best for: Pre-filtration in pharmaceuticals, paints, resins.

- Materials: Cellulose, glass fiber, polypropylene.

- Micron range: 0.5 to 100 µm.

- Key features: They hold a lot of dirt. They work well in multi-stage systems where particle sizes vary.

Pleated Depth & Membrane Filters for Fine Filtration

- Typical applications: Sterile processes in pharmaceuticals, biotech, electronics.

- Pleated depth filters: 0.2 to 10 µm, up to 99.98% removal efficiency.

- Membrane filters: PTFE, PVDF, or nylon media, 0.1 to 0.45 µm absolute filtration.

- Considerations: These filters excel at catching ultra-fine particles and microbes. But larger debris can clog them quickly. I suggest you use them after pre-filtration stages.

Strainers and Duplex Strainers for Continuous Flow

- Applications: Oil & gas, power plants, HVAC—where downtime isn’t an option.

- Types: Y-type, T-type, basket strainers.

- Sizes: DN15 to DN600.

- Pressure rating: Up to 40 bar.

- Duplex strainers: You can clean or replace one chamber while the other keeps running. You don’t need to shut down the process.

Based on my experience, I recommend selecting your filter type based on three factors: your process size, contaminant load, and need for continuous flow. This prevents expensive downtime. It also extends your filter system‘s lifespan. Review your application needs first. Then match them to each filter’s technical strengths before you buy.

Step 4: Choose Filter Media

I recommend picking the right Filter Media. It affects your industrial filter performance, maintenance costs, and reliability. Below, I’ve gathered key data, application tips, and practical advice to help you match media to your system needs.

Overview of Common Industrial Filter Media and Their Performance

| Media Type | Max Temp (°C) | Chemical Resistance | Abrasion Resistance | Typical Efficiency (micron) | Key Use Cases |

|---|---|---|---|---|---|

| Polypropylene (PP) | 100 | Good (many chemicals) | Fair | 5; 99%+ | Water/chemical, pre-filtration |

| PTFE | 250 | Exceptional | Good | 0.3; 99.5% | Aggressive chemicals, pharma |

| Stainless Steel | 500 | Excellent | Excellent | Mesh size dependent | Abrasive slurries, high temp flows |

| Spunbond Polyester | 104 | Good | Good | 0.3; 99% | Abrasives, moist dust |

| 80/20 Cellulose/PE | 80 | Moderate | Moderate | 0.3; 99.9% | Generic dust collection |

| Activated Carbon | 80–120 | Inert | Fair | 3; 70% | Odor/chemical removal |

Key Factors in Industrial Filter Media Selection

Corrosion & Chemical Compatibility: I suggest you select PTFE or stainless steel if you’re filtering corrosive chemicals or acidic/alkaline slurries. For food or water applications with mild conditions, polypropylene gives you good resistance at a lower cost.

Temperature Resistance: Match media max temperature to your process conditions:

- Polypropylene: up to 100°C

- Spunbond Polyester: -26°C to 104°C

- PTFE: up to 250°C (short periods)

- Stainless Steel: 300–500°C, based on alloy

Filtration Efficiency & Particle Removal:

- Polypropylene and polyester filters reach 99%+ at 5 or 1 micron.

- PTFE achieves 99.5% at 0.3 micron for microelectronics/pharma.

- 80/20 Cellulose/Polyester blends achieve 99.9% at 0.3 micron (MERV 13 rating).

- I like stainless steel mesh for its durability. You can reuse and backwash it, which lowers costs.

Application-Specific Media Selection Examples

Food & Beverage: I recommend polyethersulfone or PTFE membranes for sterile final filtration down to 0.2 microns.

Dust Collection: Use 80/20 cellulose/Polyester blends for general dust. Pick spunbond polyester for strong abrasion or moist dust.

Chemical Processing Plants: Go with stainless steel or PTFE mesh for streams with aggressive solvents, frequent CIP (clean-in-place), and harsh cleaning chemicals. These materials resist damage. They support repeated cycles. This lowers your total ownership cost.

Air/Oil Mist Filtration: Coalescing media provide 99.97% removal at 0.3 microns. They capture both fine particulates and oil mists.

Final Recommendations

Pick filter media that fits your operating environment and filtration goals. For corrosive, high-temperature, or abrasive settings, I suggest you invest in premium options like PTFE or stainless steel. For general, non-aggressive dust or water applications, polypropylene, cellulose, or polyester blends give you reliable, cost-effective performance.

Based on my experience, matching your filter media choice with process specifics ensures compliance and performance. It also gives you cost savings and easier maintenance.

Step 5: Evaluate System Fit and Installation

Selecting an industrial filter goes beyond filtration efficiency. You must ensure the filter fits your physical system, piping, and installation constraints. Skip this step and you risk downtime, leaks, or equipment damage. Here’s how I recommend approaching system fit and installation:

Assess Physical Configuration and Space Requirements

Choose a filter housing that suits your available installation space and process setup.

Compact cartridge or single-bag filters work best for tight spaces. Large-scale operations may require multi-bag filter vessels. These need more floor area (e.g., 60″x20″x20″). I suggest horizontal filter placements for maintenance access in low-ceilinged pump stations. Vertical placements make efficient use of floor area in crowded plants.

Confirm Inlet/Outlet Configuration

Piping Alignment: Filter connections must match your plant’s pipe size, threading, and orientation.

Standard connections include: in-line, side-in/side-out, or top-in/bottom-out.

Retrofitting older systems may require adapters or rework. Ensure the filter’s 2″ NPT inlet (or other specification) aligns with your system. Mismatches invite leaks and increased pressure drops. This leads to operational issues and extra costs.

Choose Proper Gaskets and O-Rings

Fluid Compatibility & Durability: The right sealing material prevents leaks and extends system life.

- Nitrile (Buna-N): Good for petroleum-based fluids and up to 100°C. Typical life is 1–2 years.

- Viton: Resistant to acids and hydrocarbons, works up to 200°C. It costs about twice as much but can last several years in harsh conditions.

- EPDM: Best for water and steam. It degrades with oil exposure.

- Silicone: Common in food plants for FDA compliance and easy cleaning. Service life varies depending on cleaning regime.

- I recommend checking O-ring sizing (AS568 standards) for proper sealing. This reduces bypass risk.

Design for Maintenance and Safety

Maintenance Access: Horizontal cartridges and tool-free closure systems can cut downtime for filter changes by more than 50%. In my experience, horizontal setups reduce safety risks tied to confined entry in wastewater plants.

Checklist Before Install:

- Measure installation space (height, width, depth)

- Confirm pipe specs (size, thread, orientation)

- Check housing material matches pressure and temperature needs

- Match gaskets and O-rings to chemical, temperature, and regulatory requirements

- Ensure maintenance access (I prefer tool-free or quick-release closures)

- Test-fit components before full-scale installation. This guarantees seal integrity and operational fit.

I suggest following these steps. You’ll prevent expensive mistakes and ensure your industrial filter installation is safe, compliant, and efficient.

Step 6: Assess Maintenance and Operating Costs for Industrial Filters

You need to understand and manage maintenance and operating costs. This will help minimize your filtration system’s total cost of ownership. The choices you make here affect plant uptime, energy use, and long-term savings.

Key Maintenance Cost Factors

Filter Replacement Frequency & Cost:

Fine micron filters—like HEPA or ULPA—often need replacement every 6–12 months. Each filter can cost 3–8 million VND. Coarse prefilters need more frequent changes, usually every 3 months. They cost a few hundred thousand VND per unit. Pharmaceutical plants have demanding settings. Their maintenance cycles are much shorter. Costs rise compared to food or electronics production lines.

Energy Use & Pressure Drop:

Pressure drop across the filter impacts your HVAC or process system energy usage. High-efficiency filters boost initial pressure drop. This drives up energy bills. In some cases, it shortens equipment life. Budget filters may seem like a bargain. But you replace them 3–4 times as often. This creates more labor and disposal costs.

I recommend premium filters. They cost more upfront but save money over time. You get fewer replacements and better energy efficiency. Over a 5-year period, energy and operational costs can represent 15–25% of a filtration system’s total ownership cost.

Maintenance Access & Uptime:

Smart system design is crucial. Duplex or multi-cartridge filters allow maintenance without stopping production. This cuts the risk of expensive downtime. I suggest routine checks. Pressure monitoring every 3–6 months improves predictive maintenance. You can avoid sudden failures.

Maintenance and Operating Cost Examples

Vacuum filtration systems:

- 40–60% of the 5-year total cost goes to maintenance and operation.

- Purchase accounts for another 40–60%, energy for 15–25%, media changes for 10–20%, and repairs for 10–15%.

Screen Filters:

- Initial investment: $0.02–$0.12 per 1,000 gallons filtered.

- Ongoing expense is electricity, with minimal other maintenance.

Fiber Media Filters: Regular media replacement drives the highest costs—up to $2.09 per 1,000 gallons as production volume increases.

Medium-Scale Factory Reference Tasks:

- Filter pressure check: 3–6 months, 500,000–1,000,000 VND

- Prefilter replacement: every 3 months, 300,000–700,000 VND

- HEPA filter change: every 6–12 months, 3,000,000–8,000,000 VND

- FFU (Fan Filter Unit) maintenance: every 6 months, 1,500,000–3,000,000 VND

- Full system cleaning: 1–2 times per year, 2,000,000–5,000,000 VND

Practical Cost-Saving Strategies

I recommend preventive maintenance and modular filter setups. They can cut costs by 10–20%. This works well in systems that aren’t too complex.

Full-service maintenance contracts often deliver 20–30% savings over one-off service calls. This is true in regulated industries such as GMP/ISO plants.

Filter media surface area and quality determine how often you need replacements. Larger, high-quality filters can reduce total maintenance work and costs.

Key Takeaways

Regular inspections and predictive maintenance are essential to prevent unplanned system downtime, while an energy-efficient filter design further reduces operational expenses over the system’s lifetime. It’s important to note that delayed or improper maintenance can lead to unexpected disruptions and additional repair costs. Therefore, I strongly recommend prioritizing routine checks and timely replacements to ensure reliable and cost-effective operation

Based on my experience, you should weigh these factors before purchasing. This can help you lower overall costs, improve efficiency, and protect your equipment investment over the long term.

Step 7: Ensure Compliance and Future Scalability

Choosing an industrial filter isn’t just about performance today. You need filters that meet strict rules and can grow with your processes.

Meeting Industrial Filter Compliance Requirements

Regulatory Standards: industrial filters must meet EPA, OSHA, NFPA, and local regulations. For example, the EPA’s MACT rules require at least 99% particulate capture in metal fabrication. They also require up to 99.9% mercury removal in boiler operations. air filtration systems often need to meet UL 900 and ASHRAE MERV ratings. Most industrial air systems need a minimum MERV 8.

Certifications: Your industry may require ISO, API, NACE, and NSF approvals. Pharmaceutical, food, and beverage plants must follow FDA and NSF standards. You need ISO performance documentation for each audit cycle.

Facility Permitting: Industrial facility permits (such as Title V) set clear filtration performance limits. They also set inspection frequencies and reporting requirements. Modifying your filtration system can trigger permit revision and compliance reviews. These can take 6–12 months.

Auditing: I recommend you plan for inspections. Metal fabrication needs them each month. Food and pharmaceutical production needs them every three months. Keep documentation of every inspection, audit, and staff training event.

Careful attention to industrial filtration compliance and future scalability saves costs. It prevents production delays. You stay ready for audits or rule changes.

Summary

I’ve gone through these steps with you. Now I see that picking industrial filters isn’t just about specs on paper. It’s about knowing what you need in real life.

Take your time with each choice. The right filter does three things. It protects your equipment. It meets regulations. It saves you money over time.

I suggest you talk to experts if you need help. Your operation needs filtration that works well.