Who We Are - Filter Manufacturer

With over 20 years of deep expertise in metal casting filtration technology, Foundry Max has grown from a small workshop to an internationally recognized filter manufacturer and global supplier of premium ceramic foam filters and refractory materials for the foundry industry.

Driven by innovation and quality, our state-of-the-art manufacturing facility in China, equipped with advanced production lines, is dedicated to offering the foundry industry advanced filtration solutions and Maximized Foundry Materials, eliminating metal casting defects and boosting yields for foundries worldwide, ultimately improving casting quality and reducing production costs.

Mission Statement

Our mission is to empower foundries globally with advanced filtration technology to achieve superior casting quality, enhance efficiency and reduce waste in metal casting processes, while providing exceptional technical support and customized solutions.

Vision Statement

To be the global leader in foundry filtration technology, setting the benchmark for casting quality improvement and driving the development of the entire foundry industry through continuous innovation, technical excellence, and sustainable production practices.

Core Values

Technical Excellence: We continuously improve our products and processes, pursue advancements in ceramic formulations and filter designs, invest heavily in R&D, and allocate 8% of our revenue to R&D to meet the ever-evolving industry needs and challenges.

Quality without Compromise: Our ISO-certified manufacturing processes ensure consistent, reliable performance in every filter we produce, with rigorous testing at every production stage.

Customer-Focused Innovation: We work closely with foundries worldwide to understand their unique challenges and develop customized solutions to address specific casting issues and production requirements.

Global Responsibility: We are committed to sustainable manufacturing practices that minimize environmental impact while maximizing resource efficiency and product performance.

Collaborative Partnership: We work closely with our customers as a technology partner, providing not only products but also comprehensive filtration expertise and ongoing support.

Countries Served

In-depth Experience

Experienced staff

%

Customer Satisfaction

What We Do

FoundryMax specializes in the design, development, and manufacture of high-temperature casting filters and refractories for the global metal casting industry. In addition to our products, we are committed to providing high-performance filtration solutions. We offer comprehensive filtration system design services, including gating system optimization, filter placement analysis, and custom filter designs for specific applications.

Our technology is widely used in a variety of casting processes, including sand casting, investment casting, lost foam casting, gravity casting, and die casting. Our engineering team works closely with customers to analyze their current casting challenges, recommend appropriate filtration technology, and provide ongoing support to maximize filtration efficiency.

Business Model

Foundry Max operates on a consultative technical partnership model designed to deliver maximum value to our customers. Rather than simply selling products, we collaborate closely with foundries to understand their specific challenges and production requirements. This process begins with detailed analysis of current casting defects, process parameters, and quality objectives.

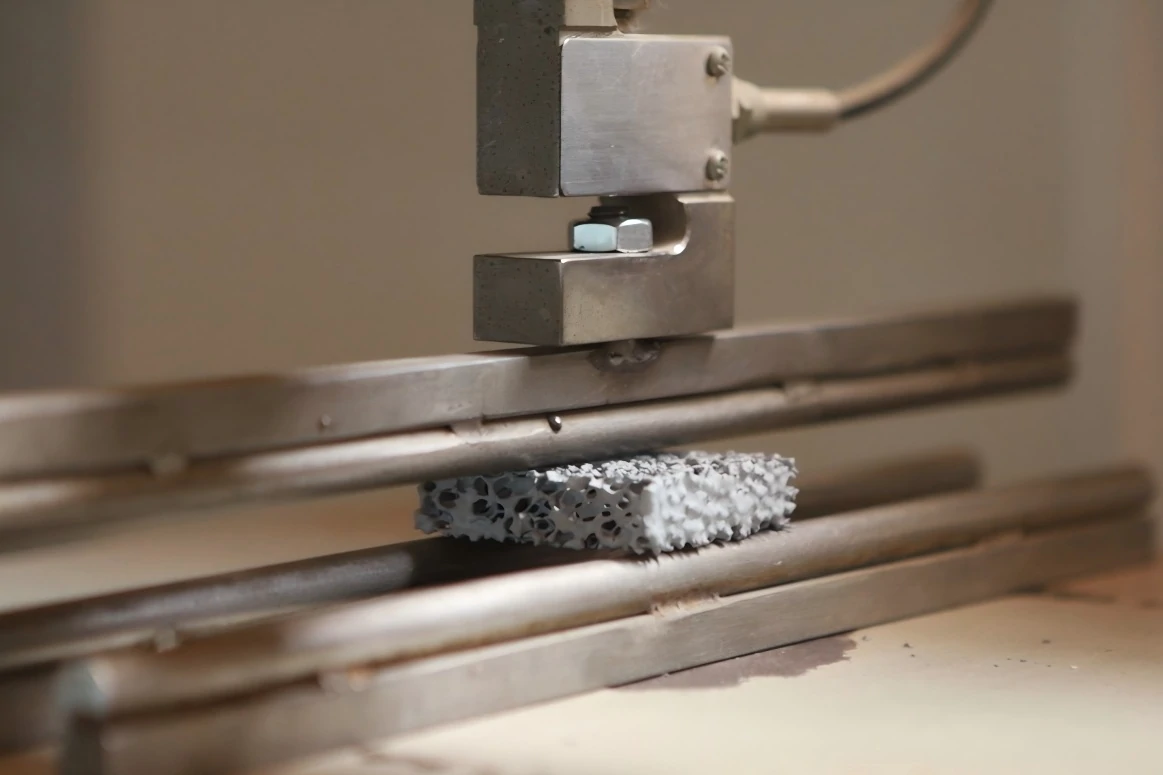

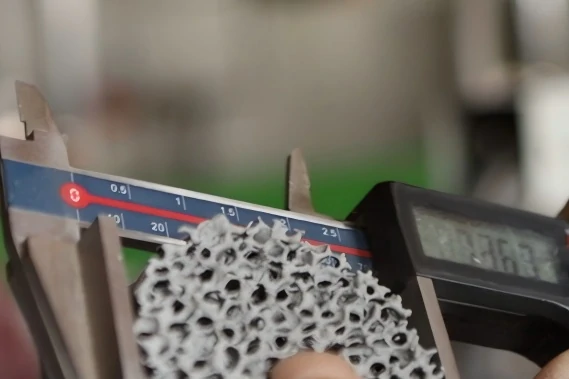

To ensure quality, we use advanced analytical and measurement technologies, including ultra-high-temperature laser confocal microscopes, powder comprehensive property testers, intelligent sand strength testers, laser particle size distribution analyzers, and room-temperature flexural testers. These tools allow us to verify filter performance, ensuring internal structure verification and identifying any deviations before products leave the factory, providing critical data for continuous product improvement.

Ultra-high Temperature Laser Confocal Microscopy

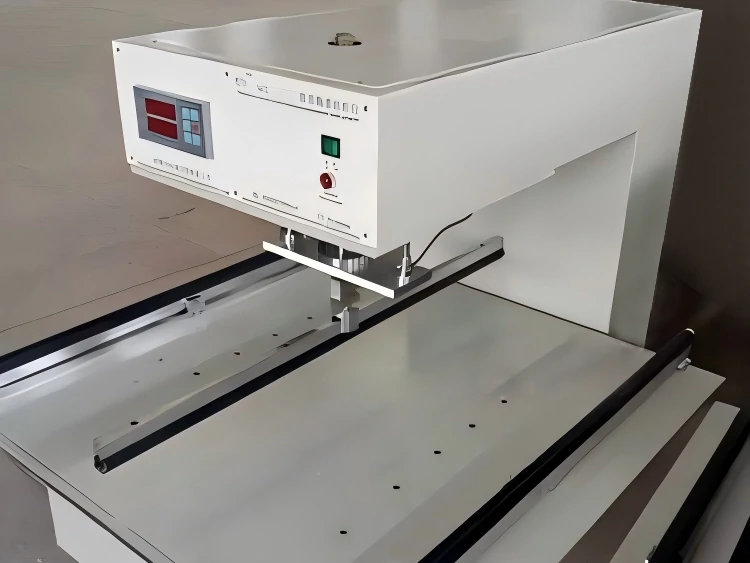

Room Temperature Flexural Tester

Laser Imaging Particle Size and shape analyzer

Powder Comprehensive Properties Tester

Metal Powder Flowability Tester

High Temperature Muffle Furnace

FoundryMax: 20 Years of Experience Helps You Solve Casting Defects!

FoundryMax History

Company Timeline

Foundry Max was established with a small production facility focusing on aluminum casting filters, starting with just one production line and serving primarily local foundries.

Expanded product range to include silicon carbide filters for iron castings, marking our entry into high-temperature filtration applications.

Opened our first international sales office to support growing export demand, particularly from European automotive foundries.

Added production line, tripling manufacturing capacity and adding advanced testing laboratories for product development.

Launched zirconia-based filter technology for steel casting applications after three years of intensive research and development.

Introduced automated production line, significantly improving production consistency and capacity for higher volume products.

Upgraded to ISO 9001:2015 certified company, establishing formal quality management systems

Established joint research initiative with leading metallurgical university to advance ceramic filter technology for ultra-high temperature applications.

Added ISO 14001 and ISO 45001 certifications, demonstrating commitment to environmental and safety standards.

Opened advanced R&D center focused on next-generation filtration materials and innovative filter designs for challenging casting applications.

Completed expansion of our main production facility, incorporating state-of-the-art environmental controls and energy efficiency measures.

Foundry Max now operates multiple production facilities with distribution in over 50 countries, continuing to lead the industry in metal filtration innovation and technical support.

Founding Story

FOUNDRY MAX was founded by a team of experienced metallurgical engineers, starting with a small team of four engineers and a modest 500-square-meter workshop. We developed our first ceramic filters, specifically designed for the unique challenges of local iron foundries. These early filters demonstrated remarkable effectiveness in reducing casting defects, quickly attracting attention from foundries struggling with high scrap rates.

What distinguished our approach from the beginning was our commitment to both technical excellence and practical application. Rather than simply manufacturing products, we worked directly in customer foundries to understand their specific challenges and optimize our filters for real-world conditions. This hands-on, problem-solving approach became the foundation of our business philosophy and remains central to our operations today.

Growth Journey

FoundryMax has grown from a small domestic supplier to a global leader in foundry filtration technology with over 200 staff across multiple facilities. This growth has been marked by strategic expansion, with an emphasis on technical capabilities and customer support rather than simply expanding production.

Early growth was driven by word of mouth, with initial aluminum foundry customers experiencing significant quality improvements and sharing their results within the industry. As our reputation for technical excellence spread, we began to receive inquiries from iron foundries who faced similar challenges but required different filter performance. This led to our first expansion into silicon carbide filters, which required significant investment in high temperature ceramic expertise and equipment.

International expansion naturally began as export inquiries increased, ultimately leading to the opening of our first Indian sales office. As we entered new markets, we encountered a variety of foundry challenges, which advanced our technical understanding and product capabilities.

We’ve focused on deepening our technical capabilities through advanced R&D initiatives and strategic partnerships with leading universities and research institutions. This has accelerated our development of next-generation filtration technologies designed to meet the increasingly stringent requirements of industries like automotive and aerospace.

Throughout this journey, we’ve maintained our commitment to personal customer relationships, ensuring that even as we’ve grown, we’ve kept our focus on solving the specific challenges faced by each customer.

Facility Overview

Our main production facility is equipped with advanced equipment specifically designed for ceramic filter manufacturing, operating at industry-leading efficiency. These include:

Automated Foam Processing Lines

Density control to ±0.5% and dimensional accuracy to 0.3 mm produces uniform substrates for all filter types.

Computer-controlled Ceramic Slurry Systems

Maintain precise viscosity and particle distribution, ensuring consistent impregnation quality.

Advanced Impregnation Systems

Two automated production lines with precise pressure cycling ensure a fully porous filter structure.

High-temperature Kilns

Computer-controlled tunnel kilns precisely follow complex firing curves, maintaining temperature uniformity of ±3°C throughout the firing chamber.

Quality Control Equipment

Automated compression testing stations and filter pore analysis equipment verify filter performance parameters for each production batch.

FoundryMax’s facility layout optimizes production flow, with raw materials entering at one end and finished products exiting at the other end after carefully sequenced processing stations. This linear layout minimizes material handling and the risk of cross-contamination while maintaining efficient production.

Our manufacturing environment is equipped with advanced dust collection and air purification systems to maintain a cleanroom-like environment in key processing areas. Dedicated lighting systems are installed throughout the production area to facilitate visual inspection and quality verification at each stage.

The entire facility follows our comprehensive management system, which covers ISO 9001, ISO 14001 and ISO 45001 standards, ensuring that best practices are always followed in all aspects of operations.

Raw Material Handling

High-Temperature Processing

Performance Testing

Quality Control Activities

Expertise, Experience

Our team has deep expertise in the following key areas:

- Metal flow dynamics and gating system optimization

- Inclusion analysis and defect prevention strategies

- High temperature ceramic performance characteristics

- Quality system implementation of key components

- Compliance with international standards in major markets

Continuous Development

We maintain our technological edge through ongoing education:

- Annual technical seminars with international experts

- Regular participation in important foundry and ceramic industry conferences

- Internal knowledge sharing program with weekly technical demonstrations

- Partnerships with universities for ongoing research collaboration

- Comprehensive training program for new technicians

Our Team

Foundry Max consists of three main functional departments – Technology, Production and Business – designed to maximize technical expertise while ensuring responsive customer support.

We regularly form cross-functional project teams to meet specific customer needs or development initiatives, drawing on appropriate expertise from across the organization to ensure a comprehensive solution.

Technical

Technology encompasses R&D, Application Engineering and Quality Assurance. This structure ensures that technological innovations are quickly translated into practical solutions while maintaining consistent quality standards across all product lines.

Production

Production manages all aspects of production, from raw material sourcing to manufacturing and logistics. Production includes specialized departments including Material Processing, Filter Manufacturing and Supply Chain Management.

Meet Our Foreign Trade Department

Kerry

Head of Global Sales

Kerry leads Foundry Max’s global sales team and has 20 years of technical sales experience in the foundry and metallurgical industries. Her approach emphasizes building consultative partnerships rather than transactional relationships, focusing on creating long-term value for customers. Under her leadership, customer retention rates have reached 92%, with an average relationship duration of more than 8 years.

Jane

Sales Manager

Jones

Sales Manager

Sherily

Marketing Manager

Kira

Logistics & Supply Chain Manager

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China