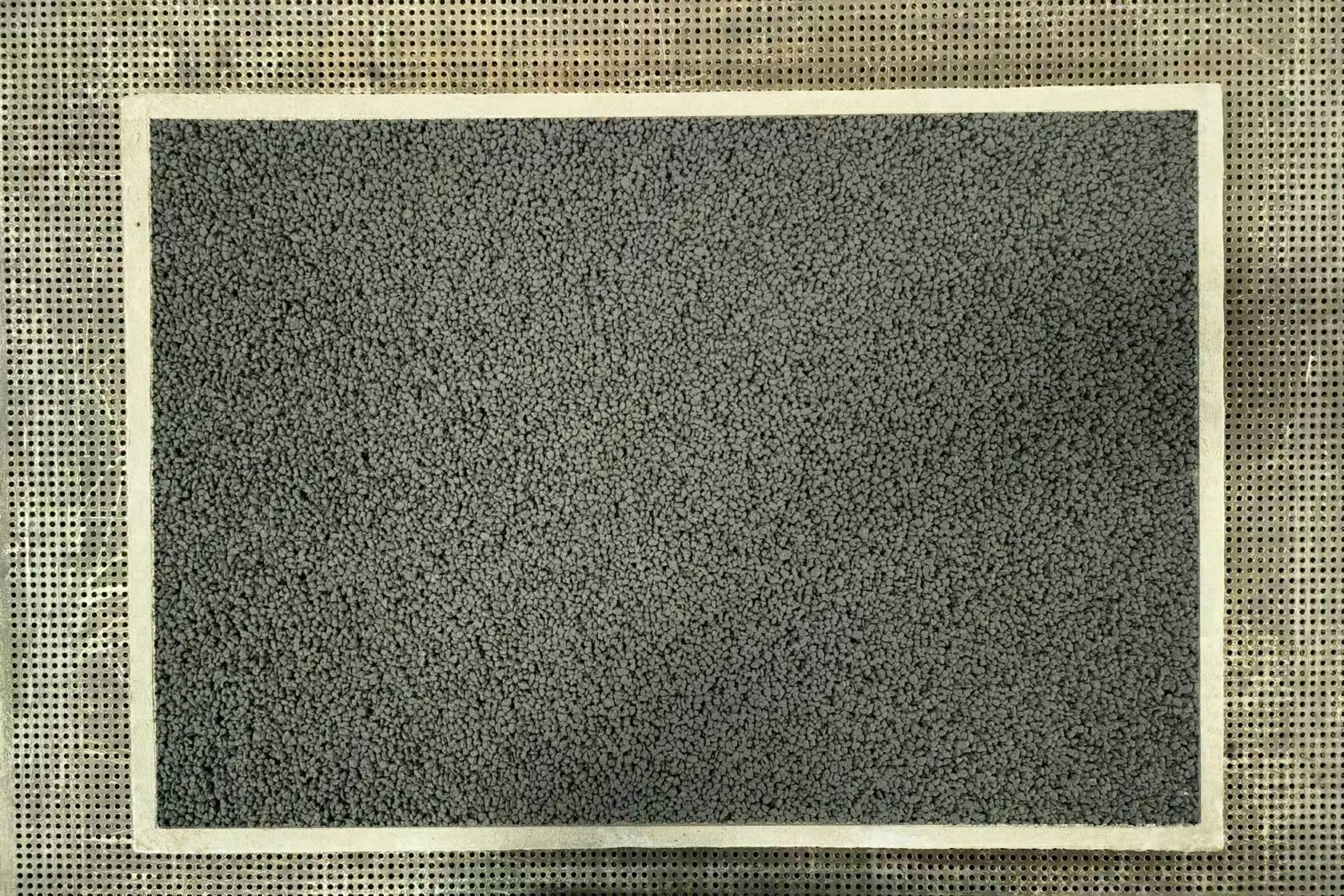

FM-04 Alumina Ceramic Foam Filters: Superior Aluminum Casting Filtration Solutions

The FM-04 alumina ceramic foam filter is a high-performance molten aluminum filtration technology, designed for aluminum foundries to eliminate inclusions and improve casting quality. Made from premium aluminum oxide (Al₂O₃), this ceramic foam filter ensures cleaner metal flow, reduced defects, and higher production yields in aluminum casting filtration applications.

Key Benefits

Superior inclusion removal – Captures large and microscopic impurities in molten aluminum

Optimized flow control – Promotes laminar flow for better mold filling

Reduces oxidation – Minimizes air entrapment and oxide formation

Excellent thermal stability – Withstands extreme heat without cracking

Universal compatibility – Works with gravity casting, sand casting, and lost foam casting

Custom designs – Available in various sizes for different gating systems

Enhanced filtration – Can be used with fiberglass mesh filter for maximum efficiency

Why Choose FM-04 Alumina Filters?

Proven molten aluminum filtration technology – Reliable and efficient

High-purity aluminum oxide filter – Durable and long-lasting

Improves casting quality – Smoother surfaces, stronger mechanical properties

Boosts productivity – Higher yields, lower scrap rates

Precision-engineered Filtration Solutions for Your Aluminum Casting Process

Contact our expert technical team today for customized filtration solutions tailored to your aluminum casting needs. We’ll recommend the most suitable alumina ceramic foam filter based on your aluminum casting type, production process, and quality requirements, providing detailed technical specifications and a quote. Partner with us for a small trial and experience the improved quality firsthand.

Technical Specifications

| Main Material | Alumina | |

| Working Temperature (℃) | ≤1200 | |

| Pore Size (PPi) | 10~50 | |

| Porosity (%) | 80~90 | |

| Compressive Strength (Mpa) | ≥0.8 | |

| Density (g/cm3) | ≤0.5 | |

| Thermal Stability(1100℃/times) | 6 | |

| Composition | AI2O3 (%) | 60~70 |

| SiO2 (%) | 15~25 | |

| SiC (%) | / | |

| ZrO2 (%) | / | |

| Others (%) | 10~15 | |

Superior Filtration Efficiency

Removes >90% of inclusions larger than 20μm, delivering superior filtration performance

Thermal Shock Resistance

Withstands rapid temperature changes exceeding 1000°C without structural failure

Mechanical Property Improvement

Aluminum castings produced using our filters show 15-25% improvement in tensile strength

Improved Production Yield

Acceptable castings 5-8% increasing after aluminum filtration, saving foundries material and costs.

What Can We Offer?

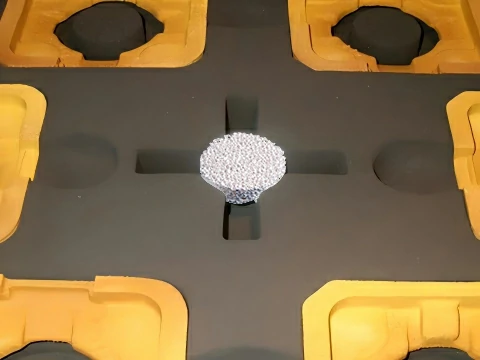

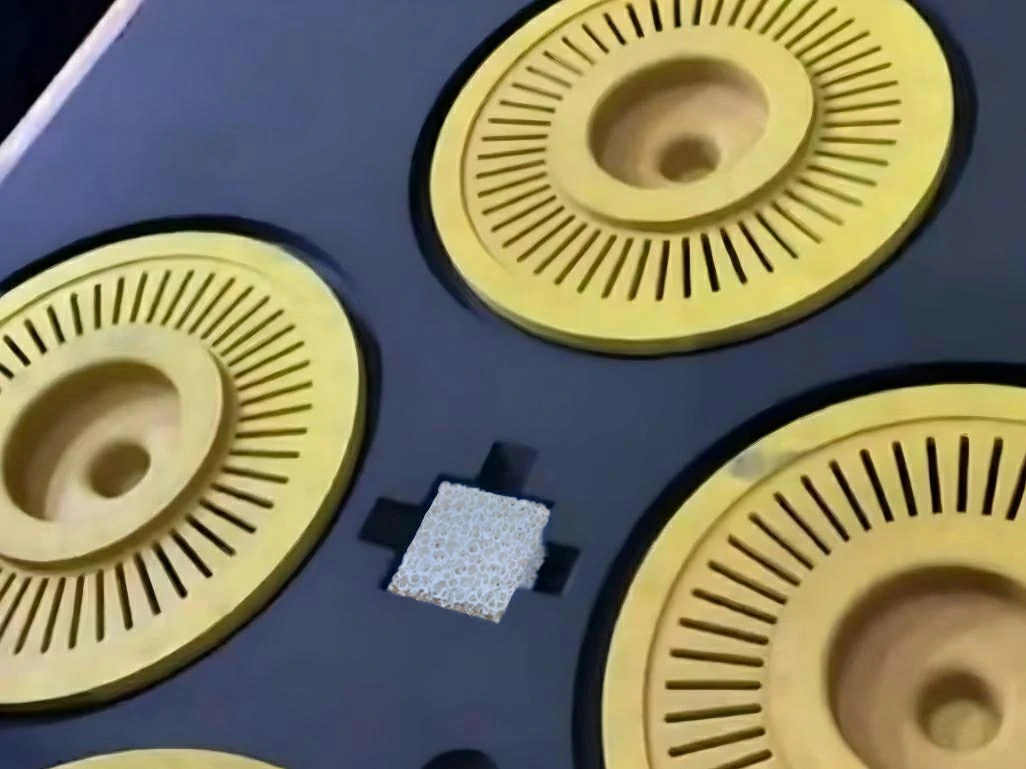

Custom Size: Available in sizes from 40×40 mm to 500×500 mm, with diameters and thicknesses customizable to suit the customer’s filter tank dimensions.

Pore Size Options: Available in 10, 20, 30, and 40 PPI (pores per inch), tailored to casting quality requirements and the properties of the molten aluminum.

Custom Shape: In addition to standard round and square shapes, special shapes are available.

Custom Surface Treatment: Special surface coatings can be applied to enhance filter performance.

Edge Treatment: Standard or enhanced edge seals are available for specialized applications.

Advanced Alumina Ceramic Filtration Technology for Aluminum Casting

Our high-performance alumina ceramic foam filters effectively remove inclusions from molten aluminum, ensuring smoother metal flow, superior surface finish, and significantly improved mechanical properties in your final aluminum castings.

Alumina Ceramic Foam Filter Applications in Aluminum Casting Industry

Alumina ceramic foam filters address various filtration challenges in aluminum castings across a wide range of manufacturing industries, including automotive, aerospace, industrial equipment, energy, and marine applications.

Our FM-04 alumina filter is designed to be compatible with all standard gating system designs, including horizontal, vertical, and bottom-fill configurations. Our filter sizes allow for easy integration into existing flow systems.

Frequently Asked Questions

How do alumina ceramic foam filters improve the quality of aluminum castings?

Our alumina filters improve the quality of aluminum castings through three key functions:

first, mechanical retention, physically intercepting inclusions larger than the pore size;

second, deep filtration, capturing tiny particles through chemical adsorption and surface forces;

Finally, laminar flow promotion, reducing turbulence in the molten aluminum and preventing gas entrapment and oxidation.

These three functions collectively reduce inclusions and pores in the casting, significantly improving its density, strength, and surface quality.

What are the advantages of alumina ceramic foam filters compared to glass fiber filter materials?

Alumina ceramic foam filters offer significant advantages over glass fiber:

1. They offer higher temperature resistance, making them suitable for various high-temperature aluminum castings.

2. They offer greater chemical stability, preventing the introduction of impurities.

3. Their three-dimensional network structure provides a larger effective filtration area.

4. Their superior mechanical strength ensures safe operation.

5. Their longer service life and more stable filtration performance allow them to process larger volumes of molten aluminum.

How do I choose the right filter?

Choosing the right filter requires considering the following factors:

- The casting quality requirements determine whether to use a ceramic filter or a glass fiber filter.

- The molten aluminum flow rate and gating system design determine the filter size.

- The alloy type, some alloys may require special filter materials.

- The casting process and temperature.

Our technical team will recommend the most suitable model and specifications based on the detailed process parameters and quality requirements you provide, and can also provide small-batch testing to verify the results.

What preparations are required before using the alumina casting filter?

Key preparations before use include:

1. Storage in a dry environment (humidity <50%);

2. Preheating to at least 400°C before use to avoid thermal shock;

3. Checking the seal after installation to prevent molten aluminum from bypassing; and

4. Ensure the filter is securely supported to prevent displacement due to the impact of the molten aluminum.

For detailed installation instructions, please contact our technical support team for advice specific to your specific equipment.

How does alumina ceramic foam filter installation location affect performance?

Installation location is crucial. Ideally, it’s between the pouring cup and the sprue, allowing for filtering before the metal enters the mold cavity. For low-pressure casting, it should be installed between the riser tube and the mold. The installation angle should be horizontal or slightly tilted (no more than 5°). Ensure a complete seal around the filter to prevent molten aluminum from flowing around. Accessibility for replacement should also be considered.

We can provide installation location design recommendations tailored to your specific equipment to maximize filtration effectiveness.

More Foundry Filters

As a filter manufacturer with decades of experience in the foundry industry, we produce and supply a wide range of molten metal filter materials.

Request your foundry filter today and experience the profound impact that the right molten metal filtration product can have on casting quality!

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China