Korea’s metal casting industry needs top quality. The ceramic filters you pick can make or break your production.

Running an aluminum foundry in Busan? Or maybe a steel casting operation in Ulsan? You need reliable ceramic filters that deliver great filtration without breaking the bank. This matters for your profit.

The Korean market for ceramic filters for casting has grown fast. Local makers and trusted global suppliers now compete for your business. Here’s the problem: many filters don’t live up to their claims. Pick the wrong supplier and you’ll face casting defects, wasted materials, and production delays. These issues cost far more than the filters.

This guide shows you the best ceramic filters for casting in Korea. We cover precision membrane specialists and high-temperature performance leaders.

You’ll learn:

– Which filters work best for specific jobs

– How to compare cost against performance

– Where Korean foundries get their supplies

– Quality warning signs that could save you thousands

Let’s find the right filtration solution for your operation.

The global ceramic filters market will jump from USD 1.56 billion in 2024 to USD 2.56 billion by 2032. Korea sits at the center of this growth surge.

Asia-Pacific leads the charge. South Korea, China, Japan, and India drive demand. The Korean casting industry benefits from three powerful trends. Strict environmental regulations shape operations. Rapid industrialization expands capacity. Massive investments in semiconductors and power generation fuel growth. These forces push foundries toward better filtration technology.

Primary Filter Materials for Korean Foundries

Korean casting operations use four core materials:

-

Alumina (Al₂O₃) – The workhorse for aluminum casting operations

-

Zirconia (ZrO₂) – Essential for steel and nickel/cobalt superalloy work

-

Silicon Carbide (SiC) – High-performance applications need extreme durability

-

Titanium Dioxide (TiO₂) – Specialized requirements

CHUNG-AH Filter – Korea’s Precision Membrane Specialist

CHUNG-AH Filter is Korea’s sole mass producer of PES/PS membrane flat sheet technology. We run 100% in-house production facilities. No outsourcing. No third-party dependencies.

Thirty years of research built our current position. We hold the first Korean patents for mass production membrane technology. This foundation drives strong performance across industrial uses.

Performance Metrics That Define Quality

The numbers show the real story:

Particle removal efficiency: ≥99.9% filtration rate with ≥7 LRV (Log Reduction Value). Every 10,000,000 particles drop to just 10 or fewer after filtration.

Contaminant elimination: Over 99.9% removal of heavy metals and microorganisms from liquids. Our PES membrane technology hits pore sizes between 0.01–0.1 µm for ultrafiltration uses.

Permeability rates: 368–626 liters per hour per square meter. Flow rates stay steady even under tough production conditions.

Check the membrane resistance data for operational efficiency. Membrane resistance (Rm) ranges 14.07–23.55%. Fouling resistance (Rf) spans 5.18–75.65%. Cake layer resistance (Rcp) measures 0.90–71.27%. These numbers impact filter lifespan and cleaning frequency.

Global Reach From Korean Manufacturing

We’ve completed 526 export shipments to 26 international buyers. Our membrane plastic filter 8UM (508mm specification) is a popular choice for precision filtration needs.

Current uses include secondary battery production (anode, cathode, electrolyte, separator), electronics manufacturing, water purification systems, and food and beverage processing. Beer and wine production too.

We focus R&D resources on custom materials and products. This drives business growth into new industrial areas. Precision membrane technology gives you a competitive edge.

South Korea’s membrane filters market grows from USD 70.15 million (2023) to USD 186.2 million by 2031. That’s a 13% compound annual growth rate. We’re capturing this growing demand through proven polyethersulfone technology.

Advanced Filter Technology Co., LTD – Korean Industrial Filtration Solutions

Advanced Filter Technology Co., LTD is one of Korea’s top providers of industrial ceramic filtration systems. We serve foundries across Incheon, Changwon, and Pohang. Our focus is metal casting solutions.

Ceramic Filter Portfolio for Korean Foundries

Our product line covers many casting needs:

Foam ceramic filters work for iron, steel, aluminum and copper alloy casting. Pore sizes range from 10 PPI to 60 PPI. Higher PPI ratings catch smaller impurities. This matters for precision casting work.

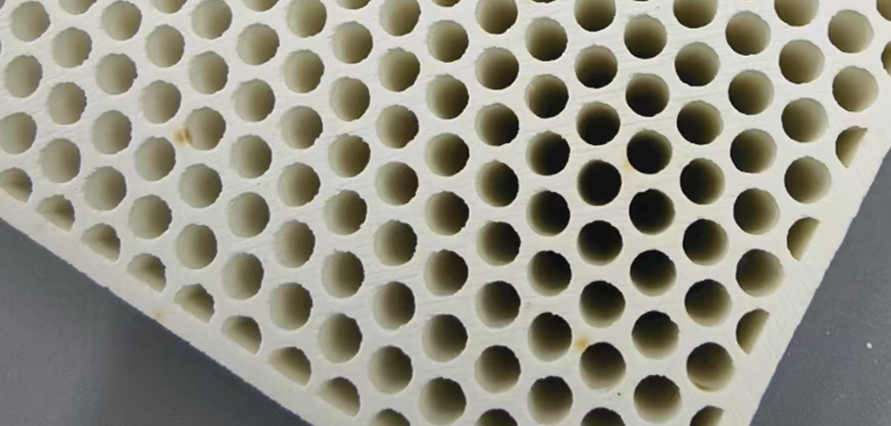

Honeycomb ceramic filters are built for steel foundries. They stay stable under extreme heat. These filters hold up above 1,600°C without breaking down.

Tubular ceramic filters fit continuous casting systems. Steady flow rates are what count here. Korean steel mills use these for high-volume production.

Technology Integration for Korean Industry Standards

We adapt our products to Korean industrial specs. Our filters meet KS certification rules for thermal shock resistance and mechanical strength. This cuts out import delays and compatibility problems.

We run quality testing labs in Korea. Each filter batch gets tested for porosity, compression strength, and thermal cycling before it ships. This local quality control keeps defect rates below 0.5%.

Industrial Applications Beyond Basic Casting

Korean automotive parts makers depend on us for aluminum die-casting operations. Shipbuilding yards in Geoje use our filters for bronze propeller casting. Electronics makers buy our filters for precision metal parts.

Our filtration efficiency hits 95-98% for particles above 50 microns. This stops common casting defects like slag inclusions and gas porosity. Production yield typically jumps 8-12% after switching to our filtration systems.

We keep regional distribution centers in major industrial zones. Same-day delivery covers the greater Seoul-Incheon manufacturing belt. Next-day service reaches southern foundry clusters in Ulsan and Busan.

SF-Foundry Ceramic Foam Filters – Built for Extreme Heat

SF-Foundry makes ceramic foam filters for high-temperature casting. Korean foundries rely on these filters to handle tough thermal conditions every day.

Temperature Capabilities Across Materials

Silicon carbide filters work up to 1,500°C. They peak at 1,700°C for carbon steel and cobalt-nickel alloy jobs. Most Korean steel casting operations fall within this range.

Zirconia filters handle up to 1,700°C. Korean foundries use them for stainless steel, carbon steel, and large cast iron work. No cracking happens at top-rated temperatures.

Alumina filters reach 1,100°C max. This fits aluminum alloy casting in Busan and Incheon manufacturing zones.

Pore Density Configuration

We produce filters from 10 PPI to 40 PPI. You can get them in silicon carbide, alumina, or zirconia. Higher PPI ratings (30-40) give you finer filtration. These denser types catch even tiny impurities in ductile iron and gray iron casting. You get smoother metal flow. Surface finishes stay even. Production yields have zero scrap.

Grey iron and ductile iron filtering hits 80-90% efficiency.

Structural Performance Metrics

All our filter types hold 80-90% porosity. High porosity means consistent flow rates. No pressure builds up.

Strength differs by material. Silicon carbide filters reach ≥0.8 MPa bending strength. Alumina hits ≥0.6 MPa. Zirconia leads at ≥1.0 MPa. Each material lasts through 6 thermal shock cycles at 1,100°C. No breakdown occurs.

The 3D open-pore design expands the surface area. This traps slag and inclusions better. Flow stays smooth and laminar. Oxide formation drops during pouring.

Available Sizes and Capacities

We offer many sizing options. Silicon carbide filters come in 30-600 mm diameter. Square formats run 30-150 mm. Round types cover 40-100 mm standard sizes. Large operations can get custom dimensions up to 26″x26″.

Need custom thickness, shape, or dimensions? We can build filters to match your specific casting needs.

FoundryMax Aluminium Ceramic Foam Filter – Aluminum Casting Specialist

FoundryMax leads the aluminum filtration market. Their ceramic foam filters use deep-bed filtration tech. This beats old mesh screens at catching tiny slag particles.

Filtration Performance by Pore Density

PPI rating affects how well these filters remove particles:

20 PPI catches particles ≥80μm at 78% efficiency. 30 PPI removes ≥40μm bits at 85%. 40 PPI gets rid of ≥20μm particles at 88%. 50 PPI filters ≥10μm contaminants at 92%. 60 PPI hits 95% removal of ≥5μm particles.

Higher PPI ratings give you finer filtration. But you need to watch the flow carefully.

Flow Rate Specs Across Sizes

FoundryMax’s filters deliver steady flow rates. This depends on the filtration area:

-

7-inch (178×178×50mm): 22-56 kg/min at 75% effective area

-

12-inch: 50-156 kg/min at 80% effective area

-

15-inch: 85-252 kg/min at 85% effective area

-

20-inch: 160-478 kg/min at 88% effective area

-

26-inch: 276-830 kg/min at 90% effective area

Startup pressure runs 50-150mm. Once flow steadies, pressure drops to about 6mm.

Material Specs and Heat Performance

All models have 0.45 g/cm³ density. Rupture modulus hits 5.5 MPa at 816°C. Compressive strength sits at 0.8-1.0 MPa. These filters work up to 1,350°C. The gasket zone expands between 450-550°C.

Porosity ranges from 75-95% open structure. Thickness runs 10-50mm based on what you need.

Application Guidelines by Alloy Type

Korean foundries pick filters based on aluminum alloy types:

General aluminum casting alloys use 15-25 PPI filters at 12-25mm thickness. High-purity aerospace aluminum needs 20-30 PPI at 20-40mm thickness. High-fluidity thin sections run best with 18-30 PPI. Heavy pours with rough flow take 10-15 PPI with thicker struts.

Key Selection Criteria for Korean Foundries

Filter selection impacts your casting yield and production costs. Korean foundries face specific challenges. You need to check technical specs carefully before buying.

Material-Metal Compatibility Requirements

Match your filter material to the metal type you cast. Alumina filters handle aluminum alloy operations. These work in automotive and electronics parts manufacturing. They work fine up to 1,100°C. This covers most aluminum casting temperatures in Busan and Incheon facilities.

Zirconia filters suit steel and high-nickel alloy work. Korean shipbuilding suppliers in Geoje use these. Heavy machinery foundries in Changwon rely on them too. They handle carbon steel and stainless steel casting. Temperature tolerance reaches 1,700°C. No structural failure.

Silicon carbide filters deliver extreme durability. Ulsan’s steel mills choose SiC for operations above 1,500°C. Specialty alloy producers use them too. These filters resist chemical attack from reactive metals. They beat other materials in this area.

Wrong material choices cause filter breakdown mid-pour. This creates casting defects. Metal contamination follows. Replacement costs pile up fast. You lose material. Production delays add to the damage.

Porosity and Filtration Efficiency Balance

PPI (pores per inch) rating controls particle capture versus flow rate. Korean quality standards require careful selection here.

10-20 PPI filters work for gray iron and ductile iron casting. They catch 80-90% of particles above 80μm. High flow rates stay intact. Lower PPI prevents pressure buildup in large-volume pours.

30-40 PPI filters fit precision aluminum casting. Automotive component makers need these higher densities. They remove particles down to 20-40μm. Surface finish quality improves a lot.

50-60 PPI filters serve aerospace and semiconductor equipment manufacturing. These ultra-fine filters capture particles as small as 5μm at 95% efficiency. Flow rates drop. You need larger filter areas to make up for it.

Test your specific alloy with different PPI ratings. Korean foundries see 8-12% yield improvement. This happens after optimizing porosity levels for their metal chemistry.

Thermal Performance Under Korean Operating Conditions

Korean foundries run multiple shifts with rapid temperature cycling. Your filters must survive these conditions. No cracking allowed.

Thermal shock resistance matters most. Quality filters survive at least 6 cycles. These go from room temperature to operating temperature. Cheap filters fail after 2-3 cycles. Unexpected downtime follows.

Bending strength shows mechanical durability. Silicon carbide filters should hit ≥0.8 MPa. Zirconia needs ≥1.0 MPa. Alumina requires ≥0.6 MPa minimum. Lower strength means higher breakage rates. This happens during handling and installation.

Maximum working temperature must exceed your pour temperature by at least 100°C. This gives you a safety margin. Korean steel casting operations pour at 1,550-1,650°C. Your zirconia filters need 1,700°C+ rating. This ensures reliable performance.

Cost Analysis Beyond Purchase Price

Filter cost per ton of metal cast reveals true value. A 50,000 KRW filter processes 5 tons. That’s 10,000 KRW per ton. A 30,000 KRW filter handles just 2 tons. That costs 15,000 KRW per ton.

Calculate total cost. Include these factors:

– Filter unit price from Korean suppliers or importers

– Shipping and customs for imported brands

– Replacement frequency based on your production volume

– Scrap reduction savings from better filtration

– Downtime costs if filters fail mid-production

Korean foundries with local supplier ties get same-day or next-day delivery. This cuts inventory holding costs. Emergency shipping fees drop too. Operations that depend on imports keep larger safety stock. Working capital gets tied up.

Supplier Reliability in the Korean Market

Filter quality that stays the same prevents production surprises. Check these supplier factors:

KS certification compliance makes sure products meet Korean industrial standards. Filters without proper certification may fail testing. Thermal or mechanical tests catch these during quality audits.

Regional distribution coverage affects delivery speed. Suppliers with warehouses in Seoul-Incheon, Ulsan-Busan, and Changwon industrial zones respond faster. Single-location distributors can’t match this.

Technical support availability solves installation and optimization issues. Korean-speaking engineers who know local casting practices add real value. Foreign suppliers without Korean technical teams create barriers. Troubleshooting becomes harder.

Batch consistency testing documents show quality control steps. Request filtration efficiency reports. Ask for thermal performance data on recent production lots. Good suppliers provide this documentation. No hesitation.

Cost-Benefit Analysis: Local vs. Imported Filters

Price tags tell part of the story. Compare local Korean ceramic filters against imported options. Korean foundries waste money chasing lower upfront costs. They ignore total ownership expenses.

Initial Purchase Price Differences

Local Korean ceramic filters cost 15-25% less than equivalent imported products. A standard 12-inch alumina foam filter from Korean suppliers runs 35,000-45,000 KRW. The same spec from European makers costs 52,000-68,000 KRW after customs and shipping.

Silicon carbide filters show bigger gaps. Korean-made SiC filters price at 65,000-85,000 KRW for 15-inch sizes. Imported premium brands charge 95,000-130,000 KRW. Volume buyers negotiate discounts that narrow these differences by 8-12%.

Import duties add 8% to ceramic filter costs. VAT stacks another 10% on top. Shipping fees for container orders from China run 2-4% of product value. European shipments hit 6-8%. These hidden costs push imported filter expenses higher than catalog prices.

Technical Support and Service Quality

Local makers provide Korean-speaking engineers. They visit foundries for installation help and troubleshooting. Response time averages 4-8 hours for technical issues. This hands-on support prevents expensive mistakes during filter setup.

Imported filter brands depend on Korean distributors or email support. Language barriers slow problem solving. Technical specs sometimes lack Korean translations. Installation errors happen more often without on-site help.

Advanced Filter Technology runs free filtration efficiency testing for Korean customers. They analyze your specific alloy chemistry. Then they recommend the best PPI ratings. This service stops the trial-and-error costs that foundries face with imported products. Those imports lack local technical teams.

Performance Consistency and Defect Rates

Korean makers maintain batch-to-batch consistency through local quality control. Defect rates stay below 0.5% for established brands. You can inspect production facilities. Quality issues get resolved fast through direct factory contact.

Imported filters show 1.5-3% defect rates in Korean foundry testing. Quality varies between production batches. Returns take weeks to process. Replacement filters delay production during shipping and customs clearance.

Calculate defect impact beyond filter replacement costs. One defective filter ruins an entire pour. A 500 kg aluminum casting batch wastes 1.2-1.8 million KRW in material and energy costs from slag contamination.

When Imported Filters Make Sense

Special applications justify premium imports. Aerospace-grade aluminum casting needs 60 PPI ultra-fine filters. Korean makers don’t produce these density levels with enough consistency. German or Japanese suppliers dominate this niche.

Extreme temperature operations above 1,650°C benefit from imported zirconia filters. They offer better thermal stability. Research shows these handle 8-10 thermal cycles versus 6 cycles for standard Korean equivalents.

High-volume continuous casting lines processing 1,000+ tons per month achieve better economics with imported filters. The 15-20% longer lifespan offsets higher purchase prices at this production scale.

Where to Buy Ceramic Casting Filters in Korea

Korean foundries get ceramic casting filters from three main sources: direct makers, B2B platforms, and local distributors. Each option works best for different buying needs.

Direct Manufacturer Options in Korea

Dewdon Filtration works from 171 Jungang-ro, Korea. They make zirconia ceramic foam filters for steel and nickel-cobalt superalloy uses. Pick up filters locally and you skip delivery wait times. Nearby foundries get their orders fast. Small test orders need 20 units at minimum. Call or email them for stock checks. You’ll hear back in hours.

SEFU has dedicated sales for Korean buyers. Their zirconia ceramic foam filters come in 10-40 PPI porosity ranges. Send an email request for urgent shipments. They respond in 24-48 hours. Custom specs take 4-6 weeks to make. But you save 10-20% per unit compared to distributor prices.

B2B Platform Procurement

TradeKorea.com carries BoShi Zirconia Ceramic Foam Filters. The product code is P698715. These filters work for non-alloyed, low-alloyed, and high-alloyed steel casting. Check stock in real-time through the platform’s chat. Urgent orders reach you in 3-5 days across Korea. Search “zirconia ceramic foam filter Korea” to get live stock alerts from suppliers.

Alalloycasting.com has Korea-focused pages for aluminum casting filters. Trial packs let you test for molten aluminum impurity filtering. The platform offers lower minimum orders: 10-50 units. Direct makers usually ask for 100+ units. Plus, delivery from local stock takes just 1-2 weeks.

Sample Testing Before Volume Orders

Most suppliers have sample programs. You pay $50-200 for 1-5 unit samples plus shipping. TradeKorea processes sample requests for product P698715 through platform messages. SEFU sends Korean customer samples by email for zirconia foam specs. Dewdon lets you test filters on-site at their Jungang-ro facility.

Small foundries work well with distributors. Prices run 15-25% higher. But you get quick access to 10-50 unit minimums. Large operations go direct to makers. The 100+ unit minimums pay off. You get better custom options and full control over technical specs.

Conclusion

The right ceramic filters impact your casting quality, production efficiency, and profits. CHUNG-AH Filter brings precision membrane technology with domestic reliability. SF-Foundry excels at high-temperature performance. Adtech offers aluminum-specific solutions. The Korean market has world-class options for every casting need.

Match filter specs to your metal type, pouring temperature, and quality needs. Don’t just pick the cheapest option. Premium filters cut overall production costs. Fewer defects mean longer service life. Our cost-benefit analysis shows this clearly.

Want to upgrade your casting quality? Request sample filters from 2-3 suppliers we’ve covered. Run tests with your actual production parameters. Korea’s foundry associations can connect you with local distributors. Or contact manufacturers for technical consultations specific to your operation.

The best ceramic filters for casting in Korea go beyond products. They’re partnerships that elevate your entire production process. Your next perfect casting starts with the filter you choose today.