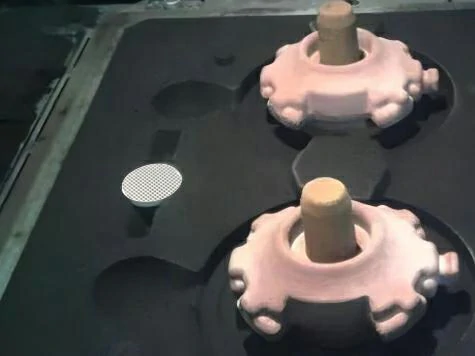

FM-06 Ceramic Honeycomb Filter for Metal Casting

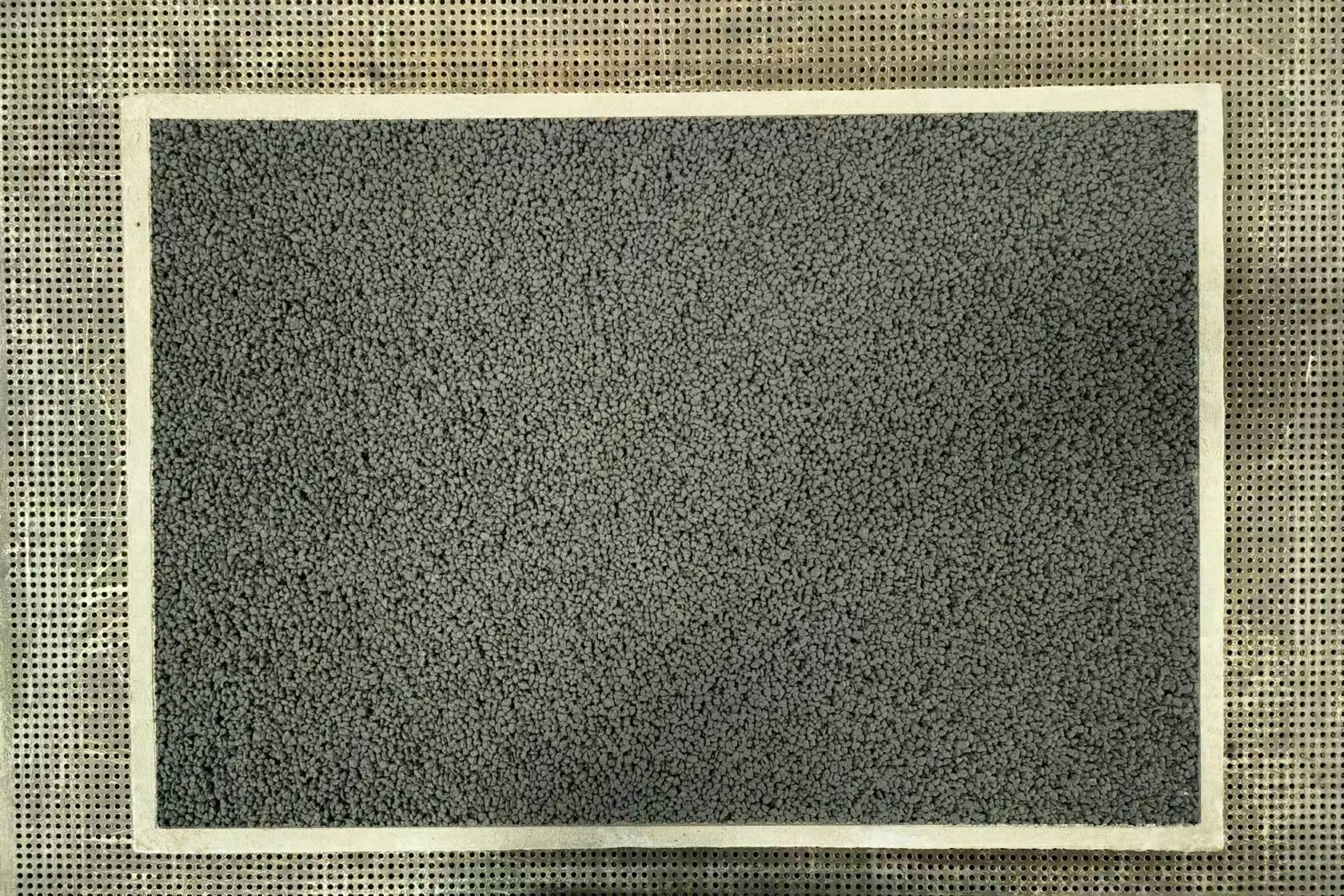

Our FM-06 honeycomb ceramic filter is manufactured using advanced ceramic processing technology and features a precisely engineered parallel honeycomb channel structure, providing optimal flow dynamics and exceptional filtration efficiency.

The FM-06 ceramic honeycomb filter improves metal casting quality with high-temperature resistance and efficient filtration. It replaces traditional fiberglass filters, offering better heat stability and cleaner metal flow.

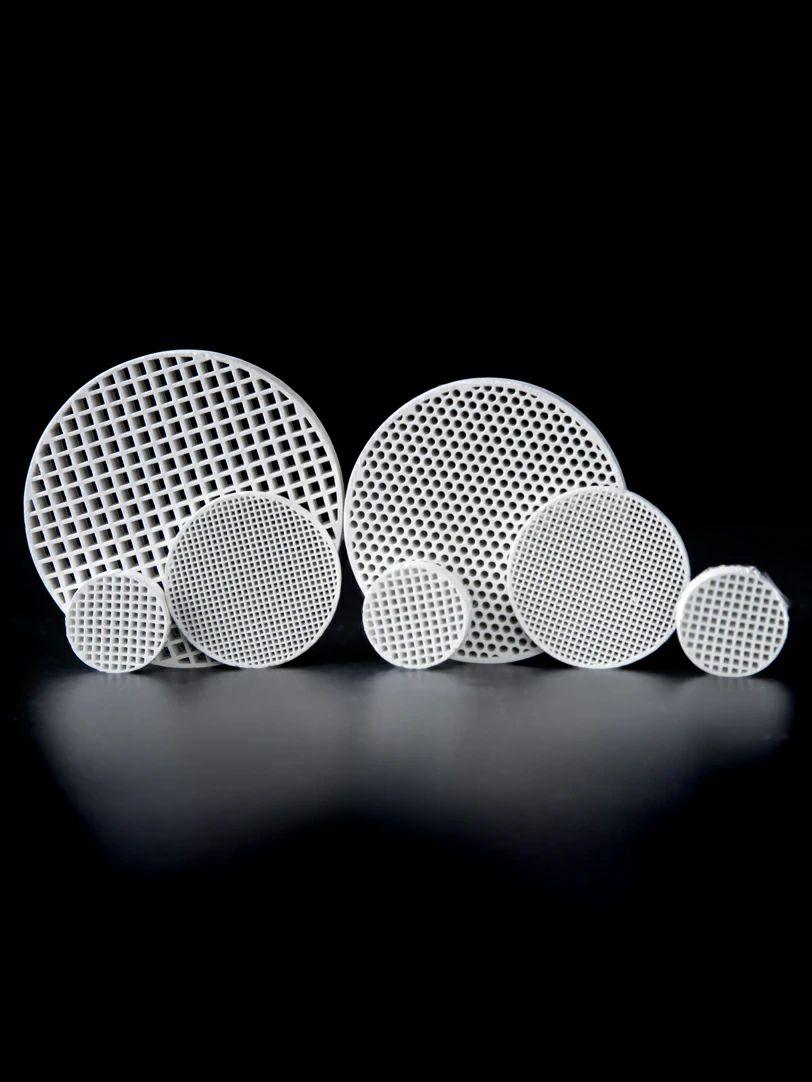

Available in square, rectangular, and round configurations, with custom sizes available to fit your existing gating system.

High-temperature resistance – Works up to 1390°C, perfect for cast iron and non-ferrous metals.

Optimized flow design – Honeycomb channels reduce turbulence and improve metal quality.

Strong thermal shock resistance – Stays crack-free during pouring

Reduces oxidation – Smooth flow minimizes air contact, keeping metal clean.

Stronger castings – Lowers defects and improves final product strength.

Fits automation – Works with automated systems for faster production.

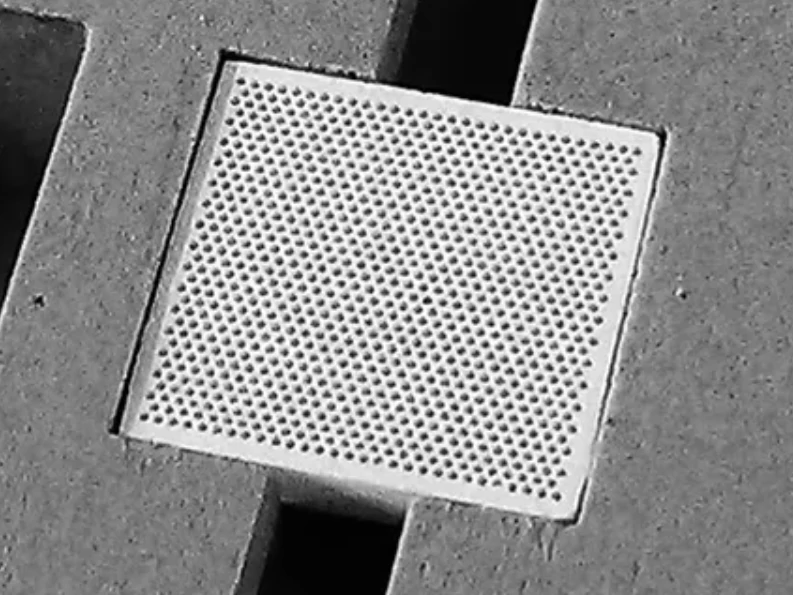

Square Ceramic Filter with Round Pore Size

Square Ceramic Filter with Square Pore Size

Round Ceramic Filter with Square Pore Size

Round Ceramic Filter with Round Pore Size

Ceramic Honeycomb Filters for Metal Casting and Foundry Applications

Made of cordierite and mullite materials, our ceramic honeycomb filters offer excellent performance at temperatures up to 1390°C, effectively removing oxides and slag while preventing metal splashing in cast iron, ductile iron, and aluminum castings.

Technical Specifications

|

Size(mm) |

Hole(mesh) |

Max filtration weight(kg) |

Flow rate(kg/sec) |

||||

|

Grey iron |

Ductile iron |

Aluminum |

Grey iron |

Ductile iron |

Aluminum |

||

|

37×37 |

100,300 |

35 |

25 |

15 |

3 |

2 |

2 |

|

40×40 |

100,300 |

40 |

30 |

20 |

4 |

2 |

2 |

|

43×43 |

100,300 |

55 |

50 |

30 |

4 |

2 |

2 |

|

50×50 |

100,200 |

70 |

58 |

40 |

6 |

4 |

3 |

|

55×55 |

100,200 |

80 |

67 |

47 |

9 |

5 |

4 |

|

60×60 |

100,200 |

85 |

75 |

55 |

10 |

6 |

5 |

|

66×66 |

100,200,300 |

95 |

90 |

62 |

12 |

8 |

6 |

|

75×75 |

100,300 |

150 |

119 |

85 |

14 |

9 |

7 |

|

81×81 |

100,300 |

200 |

174 |

122 |

18 |

12 |

9 |

|

Φ30 |

100,200,300 |

35 |

25 |

16 |

3 |

2 |

1 |

|

Φ34 |

200,300 |

40 |

29 |

20 |

3 |

2 |

2 |

|

Φ40 |

100,200,300,400 |

43 |

32 |

28 |

4 |

2 |

2 |

|

Φ50 |

100,200 |

50 |

40 |

30 |

5 |

3 |

2 |

|

Φ60 |

100 |

60 |

58 |

40 |

9 |

4 |

3 |

|

Φ70 |

100 |

70 |

65 |

52 |

12 |

5 |

4 |

|

Φ80 |

100,300 |

85 |

78 |

63 |

15 |

8 |

5 |

|

Φ90 |

100,200 |

100 |

90 |

78 |

18 |

10 |

7 |

Filtration Efficiency

Removes over 90% of inclusions larger than 30μm, 25% higher than traditional fiber filters

Improve Metal Yield

Reduced turbulence and splashing typically increase effective metal yield by 2-5%

Reduced Defects

Average 60% reduction in inclusion-related defects after implementation

Thermal Stability

Less than 0.2% dimensional change at maximum operating temperature

What Can We Offer?

Our honeycomb ceramic filters utilize advanced ceramic technology to remove more impurities while improving metal flow characteristics, resulting in superior casting quality. Our filters integrate seamlessly with modern production systems, simplifying pouring designs and delivering consistent performance, ultimately reducing overall production costs while improving end-product quality.

Our honeycomb ceramic filters are designed to integrate seamlessly with a variety of casting systems and processes. This technology is compatible with a wide range of molds, including green sand, no-bake sand, and shell casting systems. The filter’s predictable flow characteristics often simplify pouring designs, potentially reducing overall metal usage and improving yield.

The filters integrate effectively with both manual and automated pouring systems. Our filters maintain dimensional stability during preheating and casting, ensuring consistent positioning and performance in high-volume production environments.

Advanced Ceramic Filtration Technology for Superior Metal Casting Quality

Experience the difference for yourself. Request a trial sample package to test our honeycomb ceramic filters in your production environment and measure the improvement in casting quality.

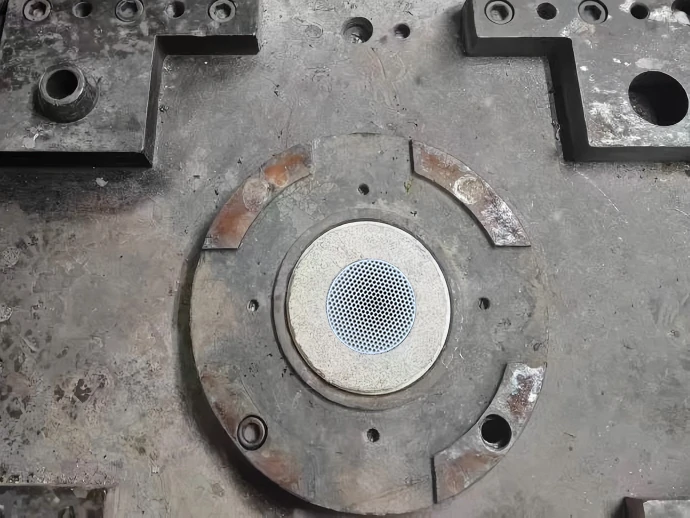

Filter Application

Our filters are designed for seamless integration into your existing foundry operations. They are compatible with all standard foundry equipment and gating systems, supporting both manual and automated processes. Whether you work with gray iron, ductile iron, carbon steel, or aluminum alloys, our filters deliver consistent performance. They easily adapt to standard and custom filter elements/holders across various gating systems and are suitable for both horizontal and vertical mold orientations, ensuring flexibility and efficiency in your production.

Industry-Specific Applications:

Automotive: Engine blocks, cylinder heads, transmissions

Heavy Equipment: Hydraulic components, structural parts, drivetrain components

Pumps and Valves: Complex housings, impellers, valve bodies

Energy: Turbine components, power distribution equipment

Aerospace: Structural components, engine parts, specialized hardware

Industrial Machinery: Machine tool bases, frames, high-stress components

More Foundry Filters

Dedicated to excellence in foundry filtration, we provide high-quality molten metal filters to enhance your casting processes.

Request your honeycomb ceramic filter sample now and experience significant improvements in casting quality. Our technical team will help you determine the optimal filter specifications for your specific application and provide personalized implementation guidance.

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China