Innovation

R&D Investments

As a leading industrial filter supplier and ceramic filter manufacturer, Foundry Max stands at the forefront of filtration technology, continuously advancing breakthroughs in filter innovation and research. With over two decades of expertise in metal filtration, we’ve become a trusted partner for foundries worldwide seeking reliable filtration solutions.

Cutting-Edge R&D Investments

We reinvest approximately 8% of our annual revenue into advancing filter research and development – one of the highest ratios in the industrial filtration industry. This substantial commitment fuels progress across three critical domains:

Filter materials – Making stronger, longer-lasting industrial filters

Filter design – Creating better-performing filters

Application engineering – Custom filtration solutions for different casting process needs

20+

Years Of Experience

Breakthroughs in Filter Materials Technology

Foundry Max tests new ceramic filter formulas to make filters that handle higher heat, resist chemicals, and last longer. These innovations have redefined performance standards for foundry filtration applications.

Zirconia-based filters – Stand up to harsh steel casting conditions

Nano-coated ceramic filters – Work in air purification systems for cleaner environments

Revolutionary Filter Design Approaches

We continue to improve filter manufacturing methods to improve the performance and consistency:

Studying gradient pore structures to optimize strength and permeability

Novel coating filtration technology to improve metal wettability and flow characteristics

Sustainable manufacturing technologies to reduce energy consumption and promote sustainable development

Application Engineering Excellence

Our engineers specialize in integrating filtration systems seamlessly into existing foundry operations, custom filtration solutions for iron, steel, aluminum, and specialty alloy casting.

These innovations have redefined performance standards for foundry filtration applications.

Best placement and angle for smooth metal flow

Complete industrial filtration system design services

Filter Research & Patents

Foundry Max partners with top university engineering programs, leading materials science research institutions, and global foundry technology consortia to solve tough metal filtration problems. Our team uses high-tech tools and fresh ideas to advance foundry filtration.

This collaborative approach has yielded an impressive intellectual property portfolio, including 8 granted patents and 5 pending applications covering core filtration technology.

Why trust FoundryMax?

As the industrial filtration landscape evolves, Foundry Max remains committed to pushing the boundaries of ceramic foundry filter technology – delivering measurable improvements in casting quality, yield, and operational efficiency for our global customer base.

Proven performance in the most demanding casting environments

Continuous filter innovation driven by substantial R&D investment

Complete filtration solutions from a single trusted supplier

Technical expertise spanning materials, design, and application engineering

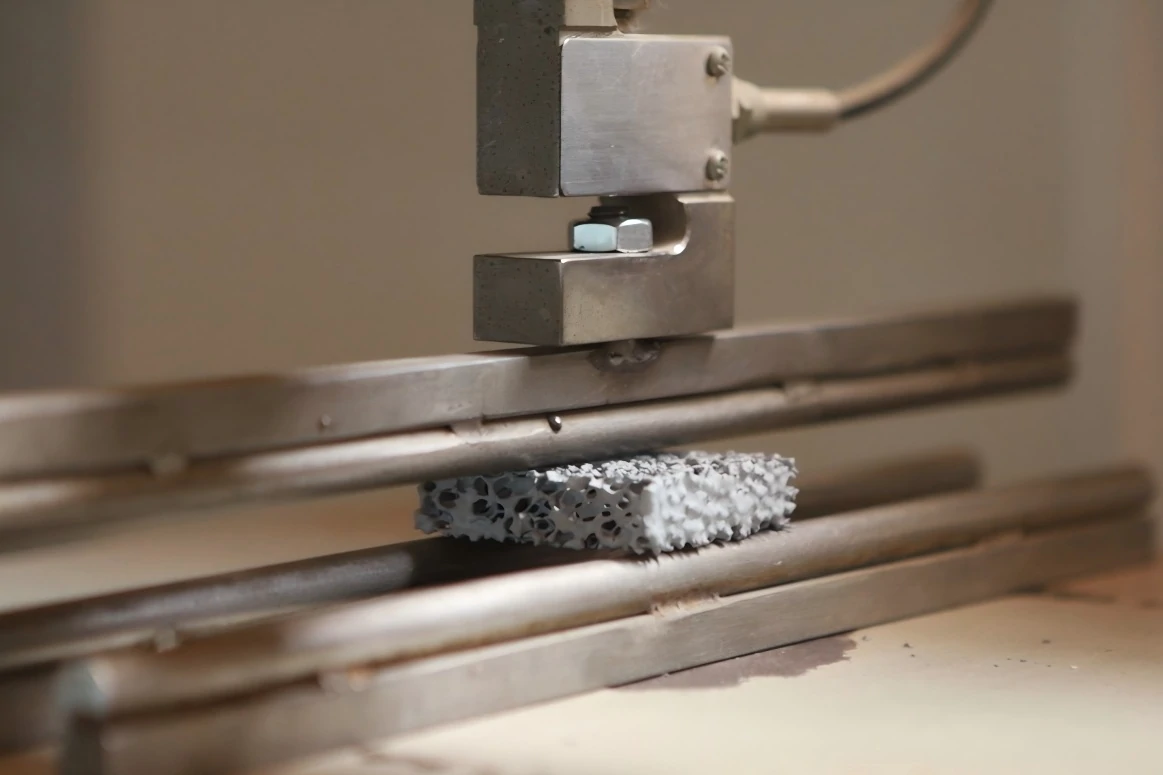

Validated Through Rigorous Testing

Every ceramic filter innovation undergoes extensive evaluation:

Laboratory simulations under extreme conditions

Production-scale trials at partner foundries

Computational fluid dynamics modeling for performance prediction

Filter Innovation Process

Foundry Max’s innovation approach combines a structured development methodology with close customer collaboration.

Analyze the Situation

Our foundry innovation process begins with problem identification and captures information from multiple sources, including customer feedback, field performance data, and proactive market research.

Our technical team analyzes this information to identify high-impact opportunities where advances in filtration technology can deliver significant value to customers.

Research and Development

Once target areas are identified, we implement a phase-gate development process to take potential innovations from concept to validation to commercialization. Cross-functional teams including filter material scientists, process engineers, and application experts work together throughout the process to ensure that technology innovations are transformed into practical products that can be reliably manufactured and easily implemented by customers.

Customer Engagement Trials

Customer engagement is an integral part of our innovation process. We frequently work with select customers to conduct field trials of prototype industrial filters in actual production environments. This approach not only provides valuable real-world performance data, but also gives customers early access to potentially superior filtration technologies.

Filter Performance Prediction

We have also pioneered advanced computational fluid dynamics modeling techniques that can predict filter performance in specific gating systems, allowing for more precise filtration solutions.

Our innovation process focuses not only on filter technology advancement but also on practical application, ensuring that new technologies can be quickly adopted and bring immediate value to customers.

Contact us today for a no-obligation consultation that includes an initial analysis of your current casting process and identification of potential improvement opportunities. Our team ensures a timely response, wherever you are in the world.