Filter Materials for Aluminum Alloy Castings

Aluminum alloy casting is a common metal forming process in which molten aluminum alloy is poured into a pre-prepared mold cavity and, upon cooling and solidification, a casting of the desired shape and size is obtained.

This process is particularly suitable for producing complex, lightweight components and is widely used in applications such as automotive engine blocks, wheels, aerospace components, and electronic equipment housings.

Aluminum alloy casting primarily includes several processes, such as gravity casting, low-pressure casting, and die casting. Each method has its own unique characteristics, and the appropriate process can be selected based on product requirements.

Aluminum Alloy Casting Filter Function

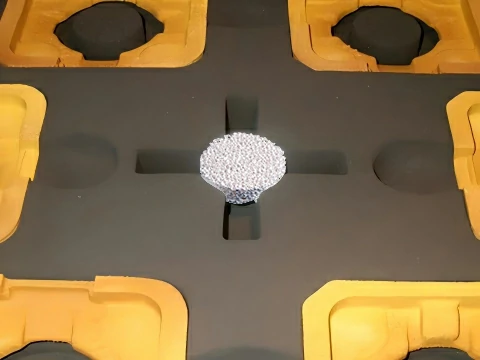

Filters play a vital role in the aluminum alloy casting process. These porous, mesh-like products, such as alumina ceramic filters and glass fiber filters, are installed at appropriate locations in the casting system, typically at the bottom of the runner or sprue.

As the molten aluminum flows through the filter, its complex pore structure effectively intercepts and absorbs various suspended inclusions in the melt, including alumina film, slag generated during the smelting process, residual unmelted additives, and other non-metallic impurities. If these impurities enter the mold cavity, they often form slag inclusions within the casting. In severe cases, this can lead to a decrease in mechanical properties or even outright scrapping.

Removing non-metallic inclusions and reducing porosity and improving casting density

Improving metal fluidity for smoother mold filling

Improving casting mechanical properties

Filter Applications in Aluminum Alloy Casting

As a core component of the casting process, aluminum filtration technology effectively removes impurities from molten aluminum, significantly improving the material’s density and mechanical properties. Our filters are used in aluminum casting production across a variety of industries

Automotive Manufacturing

Engine Components: Used to filter molten aluminum for key castings such as cylinder blocks, cylinder heads, and pistons to prevent inclusions from causing insufficient strength or seal failure.

Gearbox Housings: Ensure internal purity of thin-walled, complex structures and reduce tool wear during machining.

Wheel Hub Casting: Filter oxide films and slag from molten aluminum to improve fatigue life and surface quality.

Aerospace Industry

Aircraft Structural Parts: Load-bearing components such as door frames and brackets require extremely high purity to meet impact and fatigue resistance requirements. Engine parts: Turbine housings, fuel system components, etc., to prevent impurities from causing cracks in high-temperature environments.

Electronics and Communications Equipment

5G base station heat sink housings: Filtering molten aluminum ensures uniform thermal conductivity and prevents localized overheating caused by impurities.

Smartphone/laptop casings: Improving surface treatment yield and reducing pitting defects.

Power and Energy Sector

New Energy Vehicle Battery Trays: Preventing impurities from reducing welding performance and ensuring the sealing of battery packs.

Photovoltaic Inverter Housings: Filtering molten aluminum improves weather resistance and heat dissipation efficiency.

General Machinery and Industrial Components

Hydraulic Valve Bodies: Preventing impurities from clogging precision flow passages.

Pump Casings and Impellers: Reducing the risk of flow corrosion and extending service life.

Specific Filter Application Cases in the Aluminum Alloy Casting Process

FM-04 Alumina Filter Application in Automotive Aluminum Casting Production

In automotive aluminum casting production, our FM-04 alumina ceramic foam filters are widely used in the casting process of key components such as engine blocks, cylinder heads, pistons, and wheel hubs. These components typically require extremely high internal casting quality.

Using our FM-04 filter, a globally renowned automotive parts manufacturer achieved a significant improvement in cylinder block defect rates at its German plant, from 3.2% to 0.8%. The filter’s uniform pore structure ensures smooth aluminum flow, reducing turbulence and gas entrainment during the pouring process. It also effectively removes oxides and non-metallic inclusions from the molten aluminum, significantly improving the mechanical properties and density of the casting.

FM-07 Fiberglass Mesh Filter Application in High-precision Aluminum Die-Casting Production

In the production of high-precision aluminum die-castings, such as communications equipment housings and precision instrument components, our FM-07 glass fiber filter significantly improves product surface quality and dimensional accuracy. A manufacturer of smartphone metal casings saw a 78% reduction in surface defect rates and approximately 25% lower post-processing costs after adopting our FM-07 filter.

By removing microscopic inclusions from the molten aluminum, the filter reduces deposit accumulation within the mold cavity and extends mold life by nearly 40%. In addition, the improved fluidity of molten aluminum makes the filling of complex thin-walled structures more uniform, reduces cold shut and flow mark defects, and increases the first-time pass rate of finished products from 88% to over 97%, greatly improving production efficiency and material utilization.

Contact us today for a no-obligation consultation that help you solve your aluminum alloy casting problems and learn how our filters can help you improve the quality and output of aluminum alloy casting and save production costs for your aluminum plant!