Filter Materials for Iron Castings

Iron casting is a traditional process in which molten iron is poured into a pre-prepared mold and then cooled and solidified to produce a casting with the desired shape and properties. This process offers advantages such as low cost, wide adaptability, and the ability to produce complex parts. It is widely used in the automotive, machinery, and piping industries.

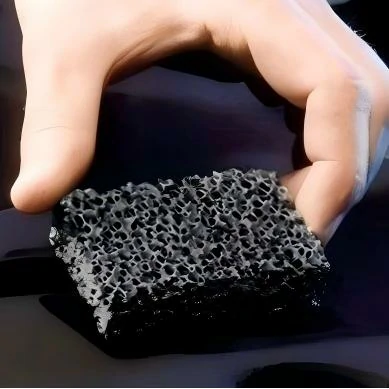

During the casting process, the purity of the molten metal directly affects the quality of the casting. The presence of inclusions (such as slag and oxides) can lead to defects such as porosity and shrinkage. Therefore, filtration and purification technologies are often used in industry to improve the quality of molten iron. Ceramic foam filters and glass fiber filters are two typical high-efficiency filter media.

Cast Iron Filter Function

Silicon carbide ceramic foam filters and fiberglass mesh filters are common molten metal filtration materials used to filter molten iron in casting processes, whether ductile iron, vermicular graphite iron, or gray iron. They are often used in combination in iron casting: the glass fiber mesh provides initial filtration of the molten iron, while the ceramic foam provides further purification, forming a staged filtration system.

This combination not only significantly reduces casting scrap rates but also improves molten iron filling capacity, reducing cold shuts and under-pouring defects caused by unstable flow. Furthermore, the use of filters reduces the need for subsequent shot blasting and improves the surface finish of castings. Practice has shown that the appropriate selection of filter media can improve the mechanical properties of castings by 10%-15%, while also extending mold life, resulting in significant overall benefits.

Impurity removal and purification, intercepting impurities, and reducing defects such as porosity.

Optimizing stable flow, improving mold filling, and reducing secondary oxidation.

Improving performance and reducing scrap rates,efficiently purifying molten iron.

Filter Applications in Iron Casting

As key process equipment in cast iron, ceramic foam and glass fiber filtration technologies can effectively remove inclusions from molten iron, significantly improving the density and mechanical properties of castings. Our filtration solutions are widely used in the production and manufacturing of various iron castings.

Automotive Manufacturing

Mainly used in the production of key components such as engine blocks, cylinder heads, brake discs, and transmission housings, this filter effectively filters impurities from molten iron, significantly reducing porosity and inclusion defects, ensuring higher strength and reliability in castings, meeting the stringent performance requirements of automotive parts.

Machinery Manufacturing Industry

These filters are widely used in the casting process of components such as hydraulic valve bodies, pump casings, gearboxes, and machine tool beds. They not only optimize molten iron fluidity but also reduce casting defects, thereby improving the wear resistance and overall mechanical properties of the castings and ensuring long-term stable operation of the equipment.

Pipe and Valve Industry

These filters are used to produce high-standard cast iron pipes, valves, and flanges. By removing slag and oxides from the molten iron, they significantly improve the pressure resistance and sealing performance of the castings, effectively reducing the risk of leakage caused by casting defects.

Power and Energy Industry

They are used in the production of large castings such as wind turbine hubs and gas turbine casings. They ensure smooth metal filling and reduce internal defects, thereby improving the fatigue resistance and long-term service reliability of the castings.

Rail Transit Industry

Rail Transit IndustryThese filters are used in the manufacture of critical safety components such as train brake discs and bogie components. By stabilizing the molten iron flow and efficiently filtering impurities, they ensure the surface quality and internal density of castings, effectively safeguarding train operation safety.

Construction Machinery Industry

They are used in the casting of heavy components such as excavator counterweights, track shoes, and bearing seats. By improving the purity and fluidity of the molten iron, they enhance the toughness and impact resistance of the castings, while reducing scrap rates and extending service life.

Specific Filter Application Cases in Iron Casting Process

FM-01 Silicon Carbide Filter Application in Automobile Cylinder Head Manufacturing

A leading automotive foundry in Malaysia, producing cast iron cylinder heads, was experiencing a 12% scrap rate due to inclusion-related defects detected during machining and pressure testing. After adopting our FM-01SiC ceramic foam filter, they reduced inclusion-related defects by 78% within the first month of production.

Their overall scrap rate dropped to less than 3%, saving approximately $450,000 annually through reduced scrap and rework. Furthermore, the improved metal cleanliness enabled them to reduce wall thickness by 0.5 mm while maintaining structural integrity, resulting in a 4% weight reduction, giving them a competitive advantage in the increasingly weight-conscious automotive market.

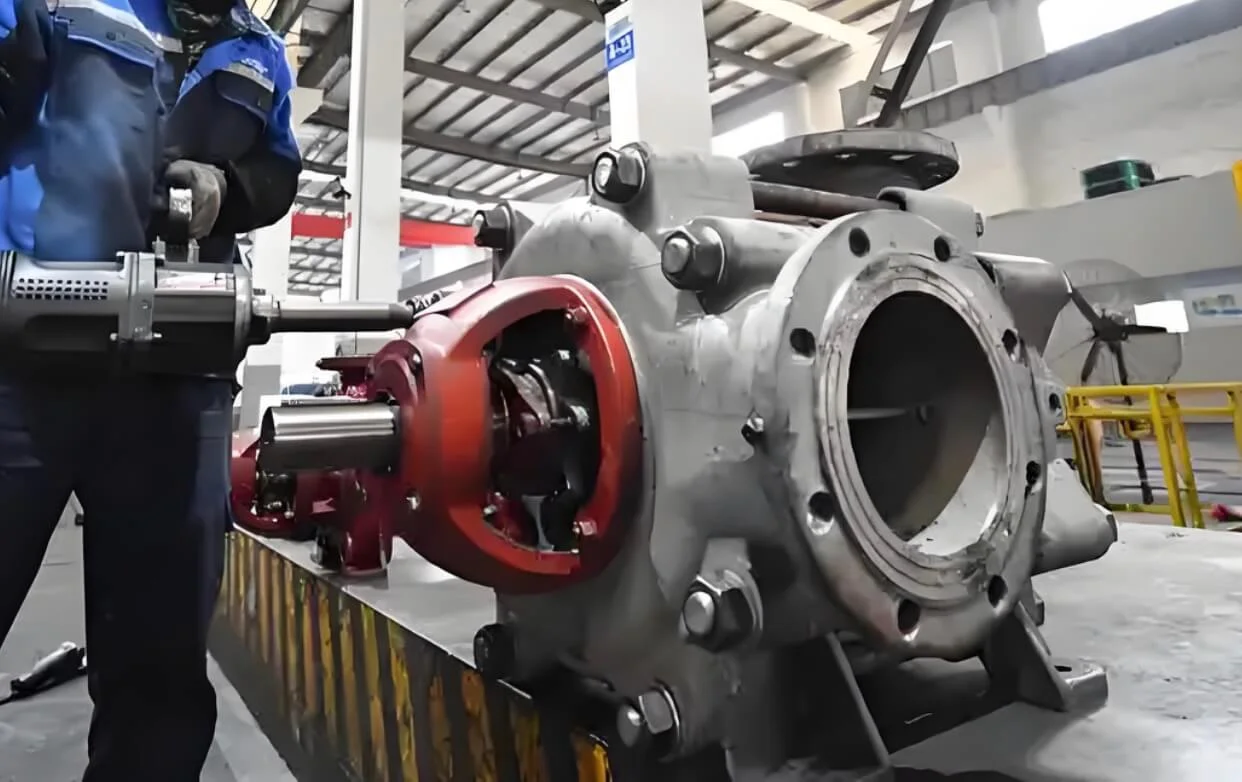

FM-07 Fiberglass Mesh Filter Application in the Production of Industrial Pump Casing

An Indian manufacturer specializing in large industrial cast iron pump casings was struggling with inconsistent mechanical properties and pressure test failures due to oxide inclusions and poor metal distribution. Implementing our FM-07 fiberglass filter in the pouring system significantly improved quality. Inspections revealed an 85% reduction in inclusion-related defects and a 90% reduction in pressure test failures.

The customer reported a 30% improvement in machinability due to the more consistent metal structure, and within the first year, they experienced a 65% reduction in warranty claims for in-service failures. The resulting improved reputation helped them secure three major new contracts valued at $2.8 million annually.

Contact us today for a no-obligation consultation that help you solve your cast iron problems and learn how our filters can help you improve the quality and output of casting and save production costs for your iron plant!