Application

In today’s competitive foundry industry, metal quality is the decisive factor between premium castings and costly rejects. Metal filtration, as a critical technology in the casting process, plays an indispensable role in ensuring product quality by effectively removing non-metallic inclusions, oxides, and other harmful impurities from molten metal through physical interception or chemical adsorption.

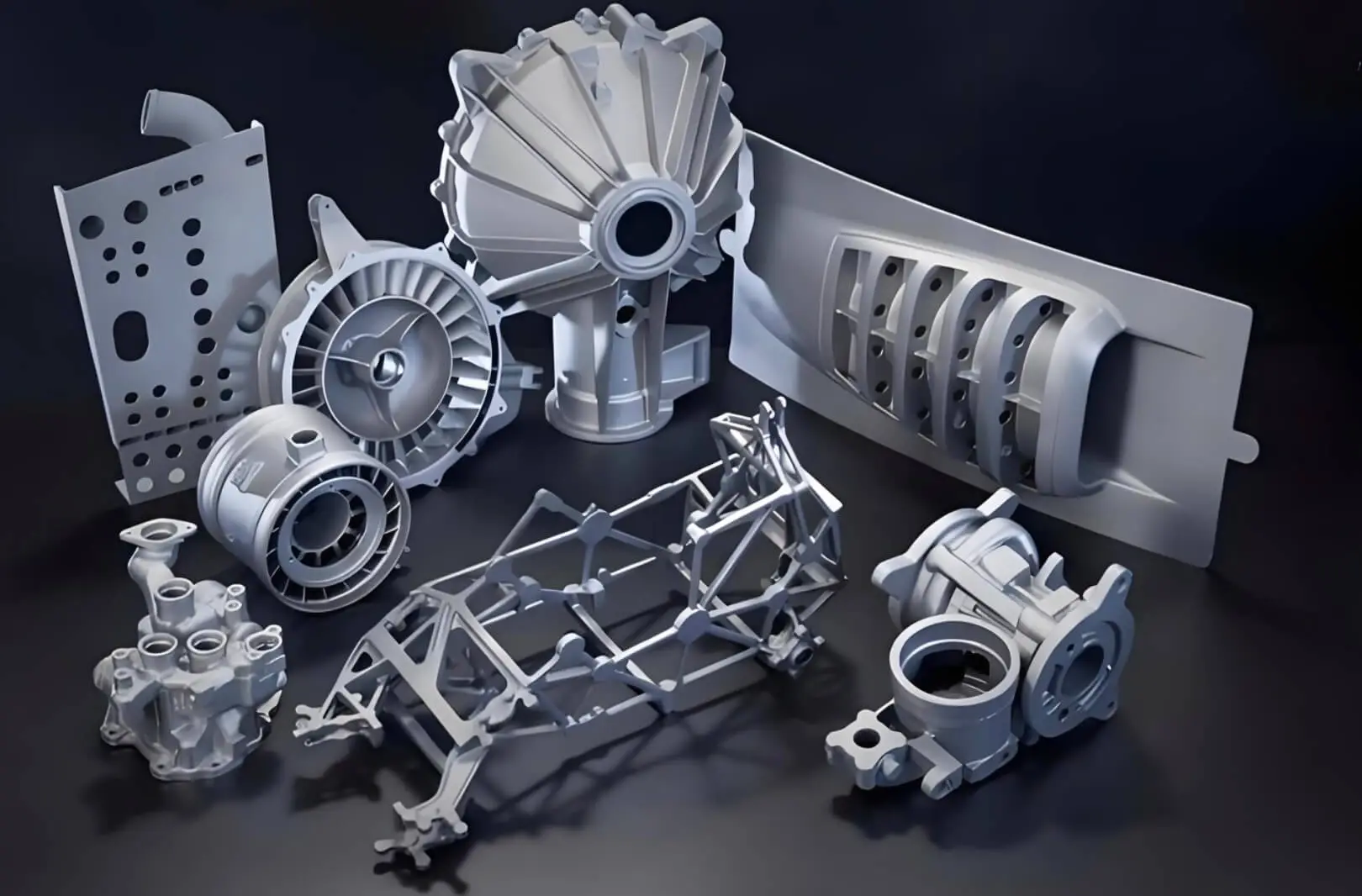

This metal filtration technology significantly improves the internal quality and mechanical properties of castings, making it widely applicable across various metals, including aluminum alloys, magnesium alloys, cast iron, steel, and superalloys. Its importance is particularly evident in the production of high-precision castings, thin-walled components, and high-performance alloy castings.

Beyond impurity removal, filter materials delivers multiple benefits: it reduces casting defects such as porosity and slag inclusions, enhances molten metal fluidity, and optimizes microstructure. These improvements collectively boost product reliability and service life, making filtration a vital process in modern foundry operations.

Aluminum Alloy Casting

Our advanced filtration solutions are widely implemented in aluminum alloy production for critical automotive engine components, precision aerospace parts, and high-quality consumer electronics housings. Through optimized process control and material refinement, these aluminum casting applications consistently achieve a 15% reduction in typical defects such as porosity and inclusions, while significantly improving production yield.

The casting materials enhances the mechanical properties and surface finish of aluminum castings, ensuring superior performance in lightweight structural applications where strength-to-weight ratio and dimensional accuracy are paramount.

Iron Casting

Our specialized filter materials significantly enhance the quality of iron alloy castings, particularly for pipe fittings, automotive parts, machine bases, and structural components. By effectively capturing impurities and regulating metal flow during the casting process, these filters dramatically reduce common defects including porosity, slag inclusions, and oxide formations in cast iron products.

This results in improved metallurgical integrity, enhanced mechanical properties, and superior metal quality – ultimately increasing the tensile strength, impact toughness, and fatigue resistance of ductile iron, gray iron, and other iron-based castings for demanding industrial applications.

Steel Alloy Casting

Our advanced filtration solutions deliver critical filter performance for steel alloy castings used in turbine blades, industrial furnace components, and aerospace parts. Specifically engineered for high-performance steel alloys, these filter materials effectively remove impurities during the casting process to ensure structural integrity and stable operation under extreme high-temperature conditions (700-1700°C).

By maintaining consistent material purity, they enhance the thermal stability, mechanical strength, and fatigue resistance of cast steel components – enabling reliable performance in demanding power generation, industrial processing, and aerospace applications.

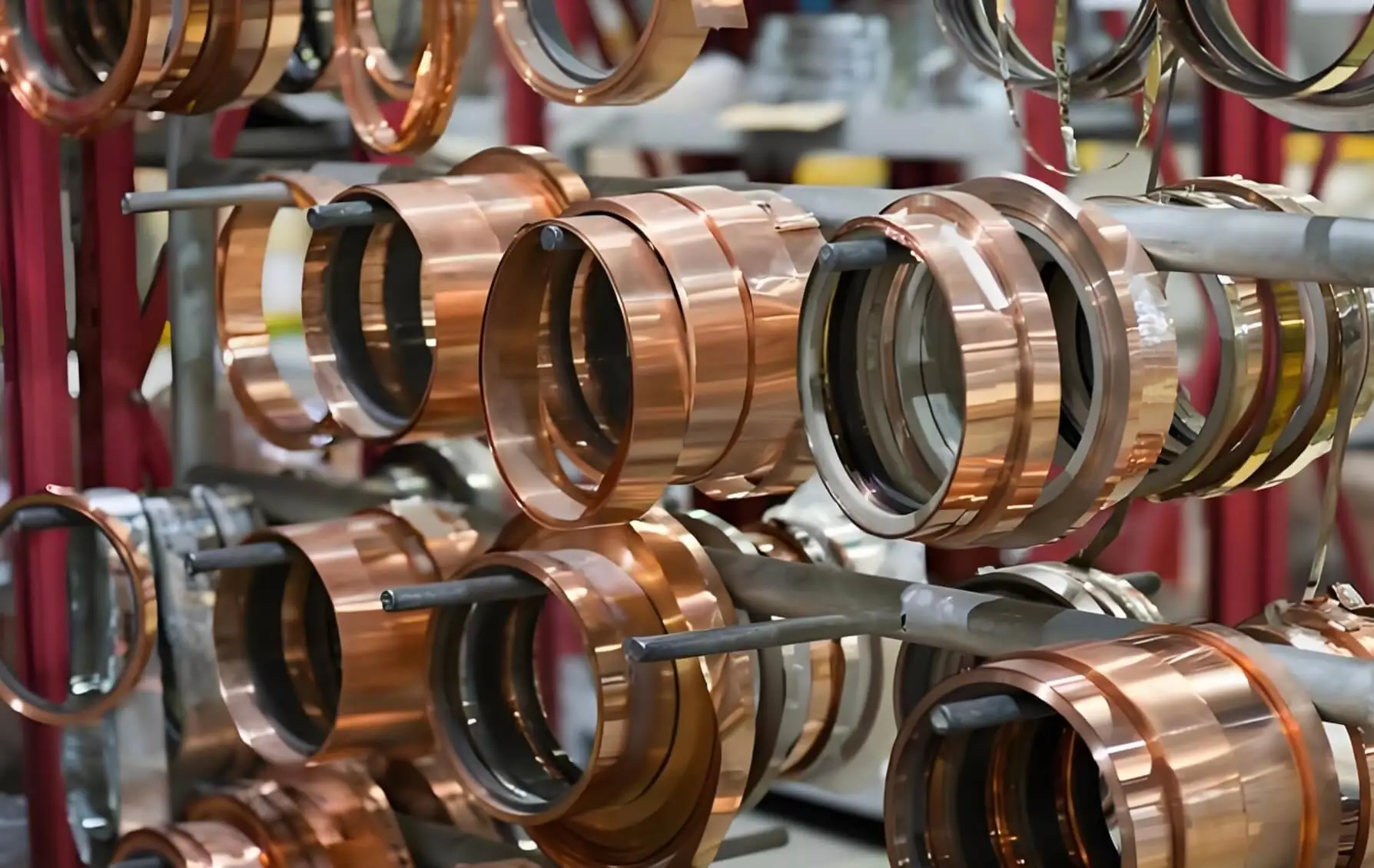

Copper Alloy Casting

Our metal filtration solutions are extensively utilized in manufacturing critical components for electrical components, marine hardware, and decorative fixtures. By leveraging the inherent properties of copper alloys, we ensure superior electrical conductivity and exceptional corrosion resistance in the final products.

Magnesium Alloy Casting

This filter materials significantly enhance the casting of magnesium alloys, facilitating the production of lightweight, high-performance components for the automotive and aerospace industries. By effectively removing impurities and optimizing the microstructure, it improves material purity, refines grain structure, and enhances key mechanical properties—such as strength, ductility, and fatigue resistance—while maintaining the alloy’s inherent weight advantages. The result is higher-quality cast parts that meet stringent industry standards for durability and safety.

Environmental Protection

Our advanced ceramic filter materials offer versatile solutions for critical environmental protection applications, including industrial emission control, water treatment, and air purification systems. By effectively capturing harmful pollutants, heavy metals, and particulate matter, they help industries comply with stringent environmental regulations while reducing their ecological footprint. These high-performance filters contribute to cleaner air, safer water resources, and sustainable industrial practices—supporting global efforts toward a greener, healthier planet

Refractory Casting Filters for Various Casting Processes

Foundry Solutions for Improving Metal Casting Quality

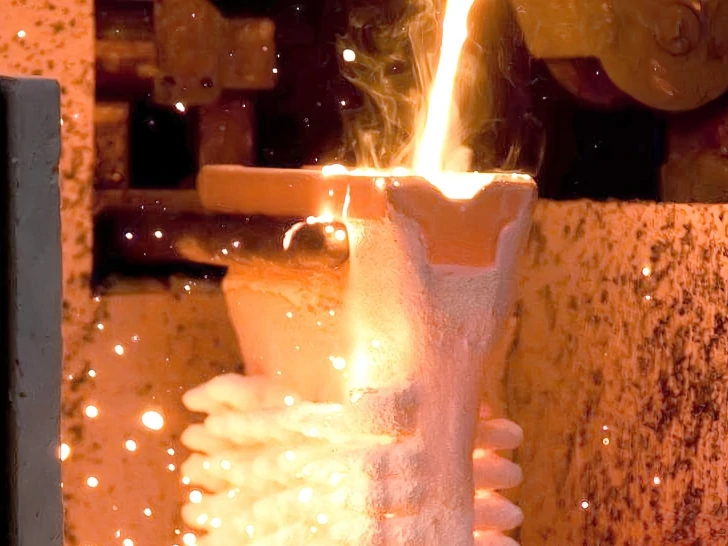

During the casting process, impurities, slag, and oxides in the molten metal directly affect the strength, surface finish, and yield of the casting. As a professional supplier of refractory casting materials, we provide high-performance casting filters that help optimize molten metal flow, effectively intercept impurities, and significantly improve casting quality. They are suitable for a variety of casting processes.

Sand Casting

Ceramic filters effectively intercept slag, oxides, and impurities, reducing defects such as porosity and slag inclusions, and are particularly suitable for complex and large castings.

Metal Mold Casting

(gravity casting, low-pressure casting)

Stabilizes molten metal flow, reduces turbulence and oxidation, and improves casting density and surface finish.

Investment Casting

(lost wax casting)

Filters minute impurities from precision castings such as high-temperature alloys and stainless steel, ensuring dimensional accuracy and internal quality.

Die Casting

Use in the gating system or riser sleeve to reduce molten metal flow rate, minimize air entrapment, and improve the mechanical properties of castings.

Lost Foam Casting

Prevents residue from entering the mold cavity, reducing the risk of porosity and slag inclusions. Improves pouring stability and increases casting yield.

PRODUCT

Among various filtration materials, foam ceramic filters stand out as one of the most widely used filtration media in the industry due to their unique three-dimensional interconnected porous structure, excellent high-temperature stability, and chemical inertness. They efficiently capture fine particles in molten metal while ensuring smooth metal flow, minimizing turbulence-induced reoxidation. As a result, they are extensively utilized in critical applications such as automotive engine components, aerospace precision castings, and high-end equipment manufacturing.

ADVANTAGE

By implementing our filtration solutions, manufacturers achieve significant reductions in defect rates, minimized material wastage, and enhanced consistency in final castings—key factors in improving production efficiency and product quality.

The foundry industry involves diverse metal casting processes, each with specific filtration demands based on alloy type, pouring temperature, and casting design. Our products are engineered to meet these precise technical requirements, delivering reliable performance across aluminum, iron, copper, high-temperature alloys, and magnesium casting applications.

WHY CHOOSE US

With over 20 years of experience in advanced ceramic technology, we provide customized filtration systems for aluminum, iron, copper, high-temperature alloys, and magnesium casting, which not only remove harmful inclusions but also optimize metal flow dynamics, comprehensively improving your casting quality and production efficiency.