Advanced Foundry Filtration Systems for Superior Metal Casting Quality

Evolutionary Filtration Technology for Superior Metal Casting Quality

Temperature Resistance

For high temperature molten metals from 700°C to 1760°C

Filter Materials

Fiberglass, Honeycomb Ceramic, SiC/ZrO2/Al2O3 Foam Ceramic

Applicable Metals

Steel, Iron, Aluminum, Copper and Alloys

Contact our filtration experts today to discuss your specific application and learn how our filter technology can reduce defects, increase yields, and enhance your bottom line. We will analyze your current process and recommend the best filtration solution.

Metal Filtration Technology Development Process

Foundries and metal casting operations face persistent challenges from non-metallic inclusions, oxides, and slag that compromise final product quality, increase rejection rates, and limit production efficiency. Traditional foundry practices have struggled to effectively address these contaminants, especially as manufacturing standards continue to rise.

Metal filtration technology has made significant progress over the past few decades. Each generation of metal filtration systems has significantly improved metal purity, casting quality, and production efficiency, representing one of the most significant technological advancements in the foundry industry.

From the initial fiberglass mesh filters to honeycomb ceramics and now to advanced ceramic foam filters, each generation has brought new improvements in temperature resistance, filtration efficiency, and mechanical strength.

Today’s ceramic foam filters – available in silicon carbide, zirconia, and alumina filters – offer unprecedented levels of inclusion removal, with filtration efficiency rates reaching 95%. This translates directly to measurable business outcomes: scrap rates reduced by up to 35%, improved surface finish, enhanced mechanical properties, and simplified gating systems.

Our comprehensive range covers all three generations, ensuring you have the right solution regardless of your specific metal casting application, from aluminum automotive components to high-temperature steel castings.

Metal Filtration Types

Different metals, casting methods, and quality requirements demand specialized filtration approaches. A one-size-fits-all strategy fails to address the unique characteristics of various molten metals and their specific inclusion types. Our comprehensive filtration portfolio spans three generations, each offering specific advantages for different casting applications:

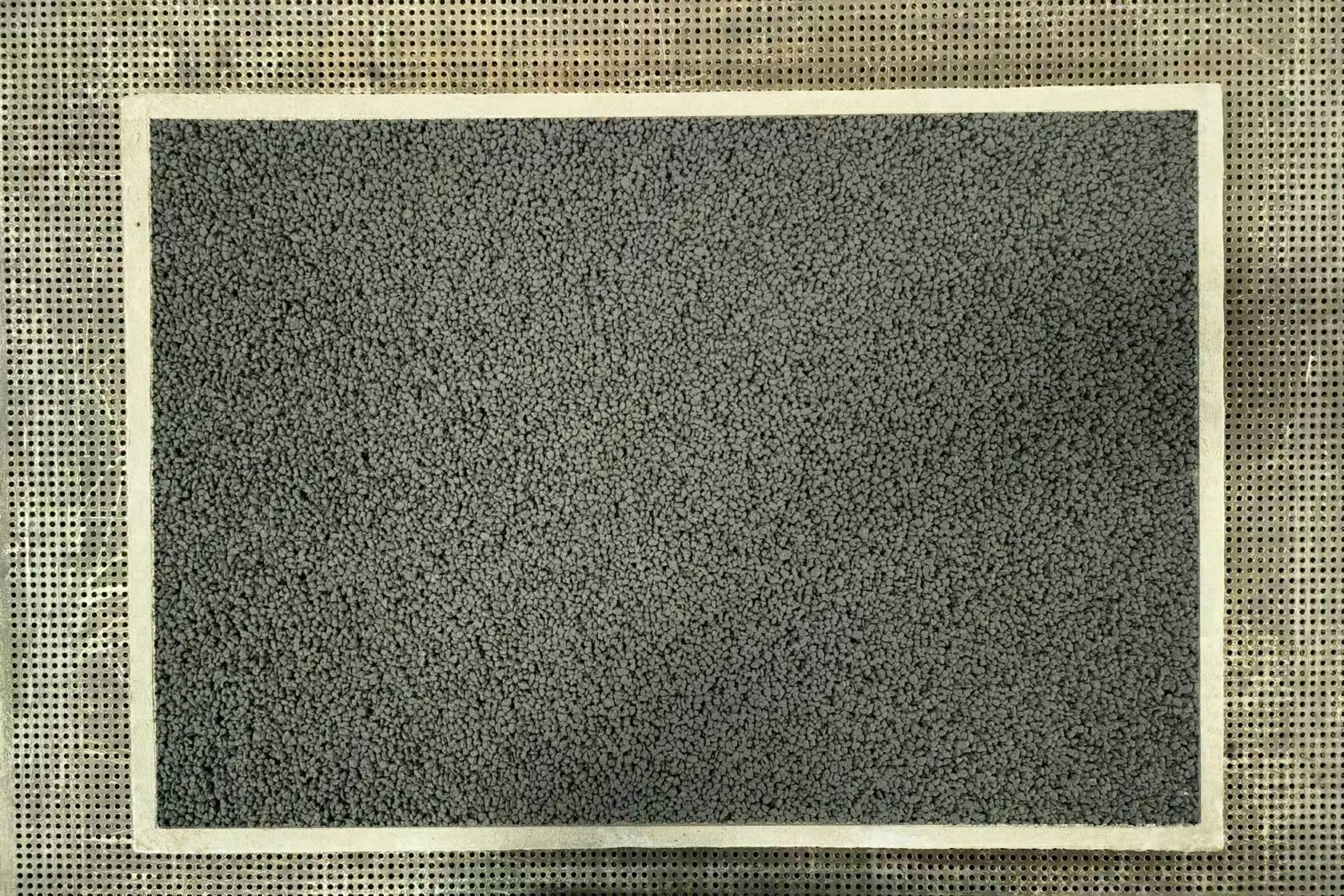

First-Generation Fiberglass Mesh Filters

Economical Solution for Basic Foundry Filtration Needs

Withstands temperatures of 700°C to 1700°C

Available in mesh sizes from 0.8×0.8mm to 2.5×2.5mm

Configurable as flat sheets, or cap-style filter designs

Ideal for aluminum, iron, steel, and copper casting applications

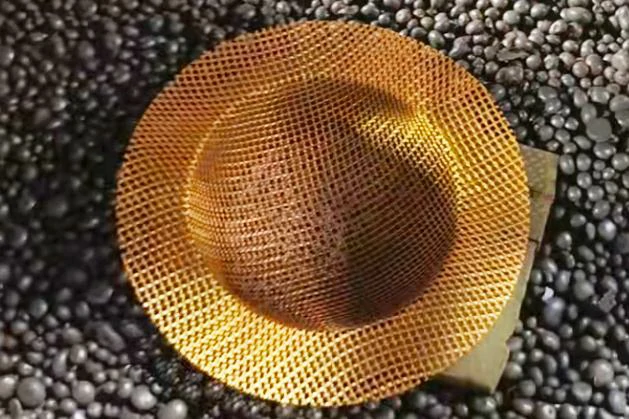

Second-Generation Honeycomb Ceramic Filters

Enhanced Structural Integrity with Improved Flow

Cordierite and mullite compositions

Temperature resistance up to 1390°C

Cell densities of 100-300 cells per square inch

Excellent for copper alloys and iron castings

Superior mechanical strength against metal impact

Third-Generation Ceramic Foam Filters

State-of-the-art filtration performance

Available in SiC (1560°C), ZrO2 (1760°C), and Al2O3 (1250°C) filter materials

Pore sizes from coarse 10 PPI to ultra-fine 60 PPI

Three-dimensional tortuous path for superior inclusion capture

Optimized for all metal types including high-temperature steel applications

This comprehensive range ensures every foundry can implement the ideal filtration solution for their specific metal, temperature range, and quality requirements, delivering measurable improvements in final product quality.

Technical Specifications

|

Specification |

First-Generation Fiberglass Mesh |

Second-Generation Honeycomb Ceramic |

Third-Generation SiC Foam |

Third-Generation ZrO2 Foam |

Third-Generation Al2O3 Foam |

|

Max Temperature |

700°C-1700°C |

1390°C |

1560°C |

1760°C |

1250°C |

|

Primary Materials |

High-silica glass fiber, Alkali-free glass fiber |

Cordierite, Mullite |

Silicon Carbide |

Zirconia |

Alumina |

|

Structure |

Woven mesh |

Parallel channels |

3D reticulated foam |

||

|

Porosity |

0.8×0.8mm to 2.5×2.5mm mesh |

100-300 CPSI |

10-40 PPI |

10-40 PPI |

10-60 PPI |

|

Flow Control |

Limited |

Good |

Excellent |

||

|

Metal Applications |

Aluminum, Copper, Iron, Steel Casting |

Copper, Iron, Aluminum Casting |

Iron, Copper Casting |

Steel, High-temp alloys |

Aluminum |

FoundryMax’s complete foundry filtration range delivers unmatched metal quality improvement across all casting operations. By offering all three generations of filter technology with industry-leading material formulations, we provide solutions precisely matched to your technical requirements and budget constraints.

Our filters not only remove inclusions, but also optimize metal flow, simplify gating systems, and ultimately deliver higher-quality castings at lower total production costs.

For All Casting Processes

Compatible with all common metal castings: steel, iron, aluminum, copper, and their alloys

Compatible with all casting processes: sand casting, investment casting, die casting, lost foam casting, and more

Integrates with common gating system designs: including direct pour, offset pour, and horizontal pour configurations

Works with standard and specialized filter molds and retainers, and is compatible with both horizontal and vertical parting line mold designs

Other Foundry Filter Types

Different metals, casting methods, and quality requirements demand specialized filtration approaches. A one-size-fits-all strategy fails to address the unique characteristics of various molten metals and their specific inclusion types. Our comprehensive filtration portfolio spans three generations, each offering specific advantages for different casting applications:

FM-09 SIC Filter

The high-performance ceramic filter designed for the aluminum alloy casting industry is made of silicon carbide (SiC) high-temperature resistant material sintered through a special process. It can efficiently filter non-metallic inclusions in aluminum alloy molten metal.

FM-02 Reinforced SiC Filter

FM-02 filter has higher strength and higher temperature resistance than ordinary ceramic foam filter, and can withstand heavier casting and higher temperature casting. It is mainly suitable for harsh environments such as filter plates placed at the bottom of the sprue or casting with heavy weight.

Filter Applications

Through continuous innovation in material technology, our filtration solutions have expanded from the foundry industry to the environmental protection field, and are committed to providing more efficient and sustainable product support for industrial manufacturing and green life.

Iron Filtration

Steel Casting Purification

Aluminum Filtration

Copper Filtration

Magnesium Casting Filtration

Air and Water Filtration

Improve your casting quality today with our advanced ceramic filtration technology. Our technical team will analyze your specific casting challenges and recommend the best filtration solution to significantly reduce defects and increase your profitability. Contact us for personalized consultation and filtration recommendations.

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China