You’re at a commercial equipment supplier looking at rows of kitchen exhaust filters. This choice affects your kitchen’s efficiency, maintenance costs, and fire safety compliance for years.

Honeycomb filter vs baffle filter – it’s more than just price. You need to know how each one handles greasy air, manages airflow, and works in real commercial kitchens.

Setting up a new restaurant? Upgrading your current system? Want to cut cleaning costs? Pick the wrong filter and you’ll face poor ventilation, higher utility bills, or compliance problems.

This comparison shows you the engineering differences and real-world performance of both filter types. You’ll see total ownership costs too. These insights help you choose the right filter for your operations and budget.

Detailed Analysis of Honeycomb Filters

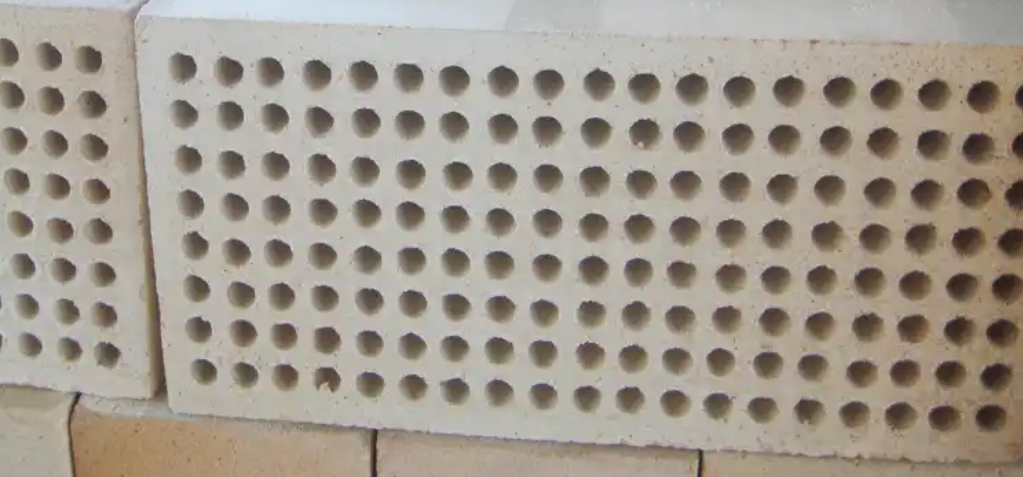

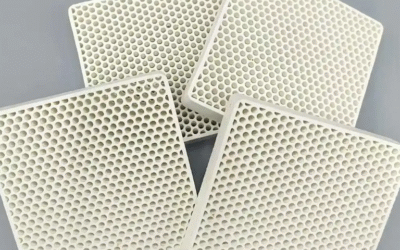

Traditional honeycomb filters use a hexagonal cell structure. This mimics natural honeycomb patterns. Each cell creates multiple contact points. Grease-laden air passes through this maze-like design. The geometric arrangement makes airflow change direction many times. Oil droplets separate from the air stream through centrifugal force.

Structure & Operating Principle

The hexagonal cells measure between 8-12mm in diameter. Manufacturers stack multiple layers at specific angles. This maximizes grease interception. Cooking vapors enter the filter. The honeycomb structure creates turbulent airflow patterns. Heavier grease particles can’t follow the sharp directional changes. They collect on cell walls instead.

Key structural advantages:

– Larger surface area compared to flat designs

– Self-draining channels guide captured grease downward

– Uniform air distribution prevents channeling effects

– Lightweight construction reduces hood strain

Grease Capture Performance

Best honeycomb filters achieve 70-80% grease capture efficiency under normal cooking conditions. Performance varies based on cooking methods. High-heat wok stations produce finer oil mist. Some honeycomb designs struggle to trap this fine mist well. Deep frying operations have heavier grease loads. These match well with honeycomb filtration.

The capture rate decreases as grease builds up within cells. A saturated honeycomb filter can lose 20-30% efficiency. Regular cleaning schedules are essential for maintaining performance.

Airflow & Ventilation Efficiency

These filters generate moderate airflow resistance. This measures at 0.3-0.5 inches of water column when clean. The open cell design allows better airflow compared to dense Mesh filters. But it creates more resistance than baffle systems.

Airflow characteristics:

– CFM (cubic feet per minute) reduction: 15-25% compared to unfiltered hoods

– Noise levels remain moderate at 55-65 dB during operation

– Pressure drop increases a lot when grease-loaded

Cleaning & Maintenance Requirements

Recommended cleaning frequency: Every 1-2 weeks for moderate use. High-volume kitchens need cleaning every week.

Most Honeycomb structure filters are dishwasher-safe. This makes cleaning straightforward. Soak dirty filters in degreasing solution for 30-45 minutes before washing. The honeycomb cells can trap debris. You need thorough rinsing to remove all residue.

Detailed Analysis of Baffle Filters

Baffle filters work best in commercial kitchens with heavy grease. Their strong build and high separation power make them ideal for high-volume cooking. These filters work differently than honeycomb designs.

Structure & Operating Principle

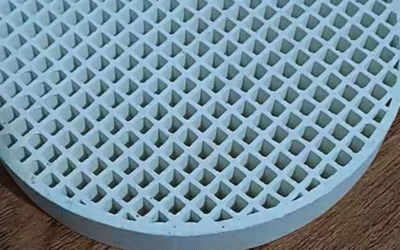

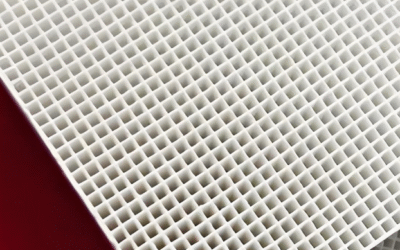

Curved deflector plates mix with perforated panels in a back-and-forth pattern. Two pieces make one unit. This unit fits into the flange opening. The inlet and outlet sit at different positions. Airflow must follow a Z-shaped pathway.

Grease-filled air enters the filter. It hits the first baffle plate right away. The sharp turn creates momentum loss. Large oil drops and particles can’t make the tight turns. Their inertia pushes them into the plate surface. They stick and build up there. Smaller particles move through perforated panels for a second round of filtering.

Key operating mechanics:

– Air changes direction 90 degrees multiple times

– Particles over 0.3μm hit baffle surfaces through inertial collision

– Swirling airflow creates forces that separate oil droplets

– Captured grease drains to the lower collection zone

Grease Capture Performance

Baffle filters do great with inertial separation. They work best with particles over 0.3μm across. Bigger grease particles get caught at higher rates.

The Z-path design makes a swirling effect. This centrifugal separation pulls oil droplets down into collection areas. The lower chamber collects less debris than other filter types. This stops the upper mesh section from clogging fast.

Material Options & Durability

Material comparison for baffle filters:

|

Material |

Advantages |

Best Applications |

|---|---|---|

|

Lightweight, lower cost |

Low-corrosion environments |

|

|

Stainless Steel |

High strength, corrosion-resistant |

Heavy grease kitchens |

Stainless steel baffle filters use high-strength wedge-wire construction. This design holds up against constant grease and cleaning cycles. How long the filter lasts depends on how often you clean it and how much particle load it handles.

Cleaning & Maintenance Systems

advanced baffle systems come with automatic cleaning mechanisms. They work through pressure differential or timed controls.

Automated cleaning process:

1. Pressure sensors detect when pressure drop goes past the set limit

2. An electromagnetic valve switches compressed air to reverse-flush the filter element gaps

3. Debris exits through baffle plate holes

4. Clean air flows through the upper chamber outlet

This automatic cleaning makes the filter last longer. Plus, it cuts fire risks from grease buildup.

Fire Safety Features

The baffle structure blocks flame spread paths. Grease deposits here are harder to ignite than in mesh-style filters. Commercial kitchens need anti-clogging designs to meet code. Automatic cleaning systems cut fire hazards by stopping dangerous grease buildup.

Core Performance Comparison: Airflow Efficiency vs. Grease Capture

Two key numbers matter for commercial kitchen filters. Airflow efficiency shows how much power your exhaust needs. Grease capture rate controls fire risk and duct cleanliness. These two factors often clash.

Airflow Resistance Impact

Honeycomb filters create 30-40% less airflow resistance than baffle types. This cuts your energy bills. Your exhaust fans work less to move air through the system. A 1000 CFM hood with honeycomb filters uses 15-20% less power than one with baffle filters.

Baffle filters use a maze design with many deflection plates. This builds higher resistance at first. But here’s the payoff: baffle filters hold suction strength better once dirty. The multi-stage separation keeps working as grease piles up. Performance holds above 92% efficiency in the 1000-1200 CFM range under heavy grease loads.

Performance Under Different Cooking Loads

Light cooking settings (gas flow <30 Nm³/h, liquid phase 2.9 m³/h):

– Both filter types hit >90% separation efficiency

– Honeycomb filters win here with better airflow

– Energy savings show up most clearly

Medium-intensity cooking (gas flow 35-50 Nm³/h, liquid phase 2-2.5 m³/h):

– Liquid phase separation runs 70-95% across both types

– High moisture content (60-70%) boosts capture rates by 10-20%

– Baffle filters deliver more stable results in this range

Heavy-duty frying (gas flow >50 Nm³/h, liquid phase >2.5 m³/h):

– Separation efficiency falls to <70% for honeycomb designs

– Baffle systems hold 70-95% capture even at extreme loads

– Liquid phase flow affects performance most

Performance Degradation When Dirty

Baffle designs with vortex core tubes keep energy moving at wall surfaces and perforated zones. This stops gas-liquid crossover. At position z=-160mm with 100-150 m³/h flow rate, efficiency holds >92%.

CCV filter tech with oil-repellent coating stays stable. At 0.4 kPa pressure gap, oil removal hits >96.4%. Oil particles flow back to the system instead of blocking the filter. Performance drops less than 4% even with heavy buildup.

Capture Jet dual-nozzle ring designs cut exhaust flow by 30-40% while keeping capture efficiency high. The system avoids the typical drop that happens with grease buildup.

Key Performance Decision Factors

Choose honeycomb filters:

– Energy efficiency ranks first for you

– Cooking loads stay light to medium most days

– You clean filters each week like clockwork

– Airflow volume beats maximum capture in importance

Choose baffle filters:

– Heavy grease comes from frying or wok cooking

– You need steady performance between cleanings

– Fire safety rules demand maximum grease capture

– Kitchen runs at high CFM nonstop (1000+ CFM)

Gas phase flow rate affects separation efficiency in a curve. Efficiency drops at first as flow grows, then climbs again. The best zone sits below 30 Nm³/h. Liquid phase flow jumps create a 20-25% efficiency drop going from 2 to 2.5 m³/h flow rates.

Usage Scenarios and Selection Recommendations

Your cooking method determines which filter works best. Heavy-duty operations need different solutions than light cooking environments.

Heavy-Duty Cooking Applications

Chinese stir-fry restaurants, Indian kitchens, and high-volume frying operations create grease particles larger than 5μm. Baffle filters capture 85-95% of these particles. Honeycomb designs reach 70-80% in the same conditions.

Baffle systems use multi-layer deflection plates. These plates separate grease through centrifugal force. They handle temperatures above 200°C without losing performance. Clean them each week to restore 90% of original efficiency. They work great for kitchens producing over 10m³/h of cooking fumes each day.

Real-world example: A commercial Chinese restaurant runs 50+ stir-fry sessions per day. They installed baffle filters. Fire risk dropped 30% compared to their previous honeycomb system. The reason? Less grease builds up in the collection zones.

Light to Medium Cooking Optimization

Western-style kitchens focus on steaming and light sautéing. They produce fine smoke particles under 5μm. Honeycomb aluminum filters capture 75-90% of these particles. Plus, they keep airflow resistance low under 50Pa.

Steam cooking creates less than 2m³/h of cooking vapors. The honeycomb pore structure traps these fine particles through static electricity. Clean them each month to keep efficiency loss below 10%.

Practical case: A residential Western-style kitchen does 20+ steaming sessions per week. They switched to honeycomb filters. Energy use decreased 15% because of better airflow.

Commercial vs Residential Selection

|

Factor |

Commercial Kitchens |

Residential Kitchens |

Data Comparison |

|---|---|---|---|

|

Compliance |

GB 18883 standard, >90% efficiency, annual inspection required |

No requirement, >70% acceptable |

Commercial violation penalties 5x higher |

|

Usage Intensity |

8-12 hours per day, 50m³/h peak fume volume |

2-4 hours per day, 5m³/h peak volume |

Commercial lifespan requirement: 2 years vs residential: 5 years |

|

Maintenance Cost |

Baffle cleaning: ¥2,000/year, replacement: ¥5,000/year |

Honeycomb: ¥500/year, replacement: ¥1,000/5 years |

Commercial total cost 4x residential |

Commercial kitchen selection (baffle filters):

– Strong structure handles Indian/Chinese frying loads

– Needs cleaning each week

– ROI under 1 year through 20% energy savings

– Covers 70% of commercial kitchen market

Residential kitchen selection (honeycomb filters):

– Lower upfront and maintenance costs

– Clean them each month for light cooking

– 5dB quieter compared to baffle systems

– Meets <5mg/m³ residential emission limits

Commercial emission standards require <2.5mg/m³ discharge levels. Baffle filters meet this threshold under heavy loads. Residential kitchens operate under relaxed <5mg/m³ limits. Honeycomb filters work well for these requirements.

Comparison of Cleaning and Maintenance Costs

Labor costs eat up most of your filter maintenance budget. Baffle filters need pros to clean them every 1-2 weeks in busy kitchens. You’ll pay $150-$300 per month for commercial operations. Honeycomb filters cost 30-40% less. Your kitchen staff can clean them in-house with standard dishwashers.

Annual Maintenance Cost Calculation

Baffle filter annual costs:

– Professional cleaning services: $1,800-$3,600/year (every two weeks)

– Filter replacement every 2-3 years: $400-$800 per unit

– Heavy-duty degreasing chemicals: $200-$400/year

– Total first-year cost: $2,400-$4,800

Honeycomb filter annual costs:- In-house cleaning supplies: $150-$300/year- Filter replacement every 12-18 months: $150-$250 per unit- Standard dishwasher detergent: $100-$200/year- Total first-year cost: $550-$900

The gap grows bigger with multiple hoods. Got 4 exhaust hoods? You save $7,400-$15,600 per year with honeycomb filters instead of baffle systems.

Analysis of Labor Cost Proportion

Labor makes up 65-70% of total filter costs for baffle systems. Professional cleaning takes 2-3 hours per hood. Techs charge $50-$75/hour in most markets. Honeycomb maintenance? Just 30-45 minutes per filter. Your current kitchen staff can do this during slow hours at their regular pay.

Heavy-duty cooking changes things. Baffle filters stay at 90%+ efficiency between cleanings under grease loads over 10m³/h. Honeycomb filters drop to 60-70% efficiency in the same setup. This performance drop means more frequent cleaning. You’ll spend an extra $600-$1,200 each year on honeycomb maintenance in high-volume kitchens.

ROI breakeven point: Honeycomb filters pay for themselves in 3-4 months for light to medium cooking. Baffle filters pay back through better energy efficiency and fewer hood motor replacements in heavy-duty setups – usually within 18-24 months.

Initial Investment and Long-Term Economic Analysis

Baffle filters cost 2-3x more upfront than honeycomb designs. A standard commercial baffle filter runs $300-$600 per unit. Honeycomb filters? Just $120-$250 for the same hood size. This price gap scares many buyers away from baffle systems.

But initial cost tells half the story.

Comparison of Total Cost of Ownership over 5 Years

Baffle filter 5-year ownership:

– Initial investment (4 filters): $1,200-$2,400

– Annual maintenance: $2,400-$4,800 × 5 = $12,000-$24,000

– Replacement costs (year 3): $1,200-$2,400

– Energy savings: -$2,000-$3,500 (20% fan efficiency gain)

– Total 5-year cost: $12,600-$23,300

Honeycomb filter 5-year ownership:

– Initial investment (4 filters): $480-$1,000

– Annual maintenance: $550-$900 × 5 = $2,750-$4,500

– Replacement costs (years 2, 4): $960-$2,000

– Energy baseline: $0

– Total 5-year cost: $4,190-$7,500

You save $8,410-$15,800 over five years with honeycomb systems for light to medium cooking.

The Turning Point for Return on Investment in Intensive Cooking

Heavy-duty kitchens change this math. Grease loads above 10m³/h per day force honeycomb filters into frequent cleanings. You’re cleaning them each week. This doubles labor costs to $1,200-$1,800 per year. Performance drops. Reduced airflow causes 15-25% higher energy use. That adds $800-$1,500 to your annual utility bills.

The baffle filter advantage shows up at 18-24 months. Better grease capture means:

– 30% fewer hood motor replacements (saving $600-$1,200 per motor)

– 40% less ductwork cleaning (cutting $800-$1,500 from annual service costs)

– Lower fire insurance premiums in some markets (2-5% reduction on kitchen coverage)

Chinese stir-fry restaurants and Indian kitchens see baffle filter ROI in 14-18 months. The break-even point hits at 8m³/h grease production per day.

The Law of Diminishing Returns on Long-Term Assets

Both filter types lose value over time. Honeycomb filters drop to 60-70% efficiency after 12-15 months under moderate use. Baffle systems keep 85-90% performance through 24-30 months. This helps protect your exhaust system. Fan motors, ductwork, and hood surfaces stay cleaner for longer.

Calculate your kitchen’s grease load. Take cooking hours per day. Multiply by estimated fume volume. Loads under 6m³/h favor honeycomb economics. Loads over 8m³/h make baffle filters the smarter long-term choice despite higher upfront costs.

Fire Safety and Compliance Requirements

Your commercial kitchen filter choice affects fire code compliance. Regulatory bodies classify kitchen exhaust systems as critical fire prevention infrastructure. The filter you pick sets inspection schedules, insurance costs, and legal risks.

Mandatory Requirements for Filtration Systems under Chinese Fire Safety Regulations

China tightened fire safety standards for 2026. The GB standard “Fire Safety Management for Personnel-Dense Places” is now mandatory. Public comments ran through February 3rd. The regulation covers:

-

Shopping malls over 3,000㎡

-

Hotels with 100+ rooms

-

Hospitals with 300+ beds

-

Care facilities for the elderly with 100+ beds

Key compliance rule: Fire safety managers at these sites need Registered Fire Protection Engineer credentials. This applies to 14 high-risk types, including restaurant kitchens, markets, and production workshops.

GB 46034-2025 starts February 1, 2026. The National Fire and Rescue Administration created this inspection standard. It sets protocols for public spaces.

Filter Configuration Standards for Childcare Facilities and High-Risk Environments

Childcare centers have strict fire equipment rules:

-

Install ≥2 units of 3kg ABC dry powder or 3L water-based extinguishers per 50㎡

-

Give staff filter-type self-rescue respirators at 1:1.2 ratio

-

Clean kitchen exhaust systems on set schedules

-

No bottled liquefied gas in high-rise buildings

Energy storage sites must follow Qinghai Province Electrochemical Energy Storage Station Fire Safety Management Measures from February 1, 2026. They need fire brigades, regular drills, and auto suppression systems.

Direct Correlation Between Filter Type and Compliance

Baffle filters meet tougher standards for heavy-duty commercial kitchens. They capture 85-95% of grease, hitting emission limits under <2.5mg/m³. Honeycomb filters catch 70-80%. That works for homes (<5mg/m³) but barely passes for commercial use.

Labor-heavy businesses got digital upgrades through 2025-2026. Fire equipment operator certification is now required. Your filter system needs to work with these compliance frameworks.

Shandong Province Fire Regulations (starts January 1, 2026) make new public and residential buildings add electric bicycle parking and charging zones. This cuts kitchen fire risks from other ignition sources.

Commercial violations cost 5x more than residential ones. Annual checks confirm your filter keeps its rated efficiency. Baffle systems maintain >90% performance longer between cleanings. This cuts compliance risks during surprise inspections.

Final Decision Matrix

Numbers beat guesswork. A decision matrix scores each filter type against weighted criteria. This stops emotional buying. It shows which system matches your operational needs.

Build Your Filter Scoring System

Four-step matrix process:

-

List your evaluation criteria – Budget, grease capture rate, airflow efficiency, cleaning frequency, fire safety compliance

-

Assign weights – Total must equal 100%. Example: Grease capture 30%, maintenance cost 25%, airflow 20%, initial price 15%, fire safety 10%

-

Score each option – Use 1-10 scale for honeycomb vs baffle performance in each category

-

Calculate weighted totals – Take scores, multiply by weights, then add them up

Heavy-Duty Frying Kitchen Example

|

Filter Type |

Grease Capture (30%) |

Maintenance Cost (25%) |

Airflow (20%) |

Initial Price (15%) |

Fire Safety (10%) |

Total Score |

|---|---|---|---|---|---|---|

|

Honeycomb |

7 (2.1) |

8 (2.0) |

9 (1.8) |

9 (1.35) |

6 (0.6) |

7.85 |

|

Baffle |

9 (2.7) |

6 (1.5) |

7 (1.4) |

5 (0.75) |

9 (0.9) |

8.25 |

Baffle filters win for high-grease operations. They score highest in your critical 30% weighted category. That’s grease capture performance.

Western Light-Cooking Restaurant

|

Filter Type |

Energy Efficiency (35%) |

Initial Cost (30%) |

Noise Level (20%) |

Cleaning Labor (15%) |

Total Score |

|---|---|---|---|---|---|

|

Honeycomb |

9 (3.15) |

9 (2.7) |

8 (1.6) |

8 (1.2) |

8.65 |

|

Baffle |

7 (2.45) |

5 (1.5) |

6 (1.2) |

6 (0.9) |

6.05 |

Honeycomb filters take the lead here. Lower airflow resistance cuts your energy bills by 15-20% each year. This works great with light steam and sauté cooking methods.

Quick Decision Reference

Choose baffle filters:

– Grease capture scores above 30% in your priority weights

– Your kitchen produces more than 8m³/h of cooking fumes each day

– Fire safety compliance ranks in your top 3 criteria

– You run Chinese stir-fry, Indian, or high-volume frying operations

Choose honeycomb filters:

– Energy efficiency and initial cost combine for 50%+ of your weights

– Your kitchen produces less than 6m³/h of fumes each day

– You want quiet operation (residential kitchens, open-plan restaurants)

– Western-style cooking makes up most of your menu

Your kitchen’s specific conditions matter more than general advice. Use this matrix with your actual operational data before you buy.

Conclusion

Honeycomb or baffle filters? There’s no universal winner here. You need to match the right tech to your kitchen setup.

Running a busy commercial kitchen? Oil builds up fast, and fire safety can’t be ignored. Baffle filters give you strong grease capture and last longer under heavy use.

Got a home kitchen or lighter commercial space? Budget and easy cleaning matter more. Honeycomb filters balance efficiency with simple maintenance.

The smart move? Check your cooking volume, cleaning ability, and long-term costs. Use the decision matrix we provided.

The honeycomb filter vs baffle filter choice boils down to three things:

– How hard your kitchen works

– Your maintenance resources

– Local fire safety rules

Talk to a ventilation specialist before you buy. They can check your specific setup.

Pick the right filter now. You get better air quality, less maintenance trouble, and could save thousands over the years. Your kitchen needs equipment that works as hard as you do—make the right choice.