Picking a filter for your industrial liquid process seems easy. From my experience, it’s more than just grabbing one from a shelf. I have seen people spend hours fixing clogs or worn-out pumps. They later discover the filter was never the correct fit. Understanding your process requirements saves you time, money, and a lot of headaches.

Define Filtration Objectives

In my experience, you must first define your filtration goals. This is the most important first step before you design a filtration process. This initial stage guides everything that follows. It helps you choose the right filter, size the system properly, and ensure you meet all compliance rules.

Core Filtration Objectives

Contaminant Removal

- The main goal is usually to get rid of unwanted things. This includes solids, germs, or anything affecting color, taste, or odor.

- For making medicines, I recommend filtering down to 0.2 microns to make sure products are sterile.

- In food production, you might just need to remove particles you can see.

Quality Control

You need to make sure your liquid meets product rules or official standards. For example, I suggest keeping particles under 5 microns for clear beverages. For high-purity water, you must remove more than 99.99% of bacteria.

Equipment Protection

You should protect your pumps, valves, and other sensitive parts from dirt and debris. For instance, I’ve seen a 50-micron filter in cooling water increase a pump’s lifespan by over 30%. This is a huge improvement compared to a system with no filter.

Environmental & Regulatory Compliance

You must meet strict discharge limits, such as keeping solids in wastewater under 10 mg/L. I advise you to address the specific rules for food-grade and pharmaceutical work. This includes the limits on contaminants that are allowed.

Key Factors in Defining Filtration Objectives

Contaminant Characterization

First, I recommend you understand your contaminants. Are they particles, germs, or chemicals? You need to figure out their sizes and how much contamination you have at the start. If you need very clear liquid, like getting turbidity below 1 NTU, you will probably need more than one filtration step.

Throughput and Flow Rate

You have to decide how much liquid the system needs to handle. For a large plant, this could be 100 m³/hr.

Chemical Compatibility

I suggest checking that your filter materials can handle your liquid’s chemistry. This prevents the filter from breaking down or leaking bad stuff into your liquid.

Target Discharge Quality

You must set a quality target for your final liquid. Some examples I’ve worked with include: wastewater with less than 30 mg/L TSS, ultrapure water with no particles over 0.1 microns, and dairy products with bacteria below 10 CFU/mL.

Decision-Making Data and Insights

From what I have seen, over 70% of filtration failures happen because the goals were not clear from the start. Or, the contaminant analysis was missed. I often find that using multiple filtration stages is a good approach. It helps you balance cost with the performance you need. I recommend you review your filtration goals regularly. This helps your system stay efficient if your process or the regulations change.

Based on my experience, setting clear filtration goals is the key. It helps you choose the right filter, run efficiently for a long time, and stay compliant with regulations.

Understanding Your Liquid and Process

From my experience, choosing the right industrial liquid filter means you first have to understand your liquid and the process. I believe this analysis is the most important step. It helps your filtration system work well and without problems.

Key Parameters I Recommend You Check

Flow Rate

You should always match the filter’s capacity to your maximum flow. For example, if you use a 200 GPM filter in a 500 GPM system, the system will fail. I suggest you calculate your process’s peak and average flows from the start to avoid picking a filter that’s too small.

Pressure Drop

I recommend you monitor the pressure drop across the liquid filter. A high pressure drop tells you the filter is clogged or you chose the wrong one. In many operations, I see that filtration stops when pressure hits a certain point. This approach makes the most of the filter’s life and prevents surprise flow interruptions.

Particle Characteristics

You need to know the particle size, density, and shape in your liquid. Large or uneven particles clog filters much faster. I have seen irregular particle shapes block a filter’s pores. This reduces how well and how consistently your filter works.

Liquid Viscosity and Density

A thick liquid creates more resistance. This means you will need more pressure for filtration. Heavier liquids affect how contaminants move. This makes a process called inertial impaction more important in your filter choice.

Solids Concentration

High amounts of solids in the liquid will add resistance. This also makes the industrial filter get dirty faster. For batch processes, I suggest you estimate the cake resistance if you don’t have exact data. It’s common to use general numbers in the early planning stages.

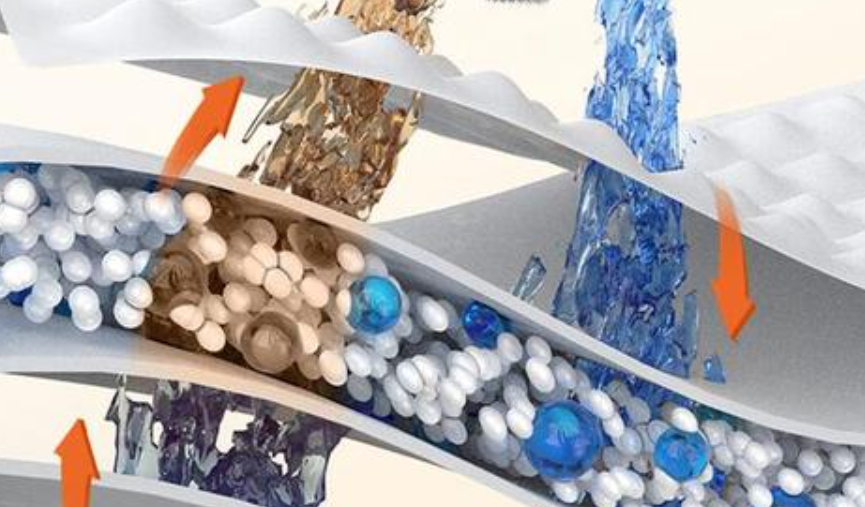

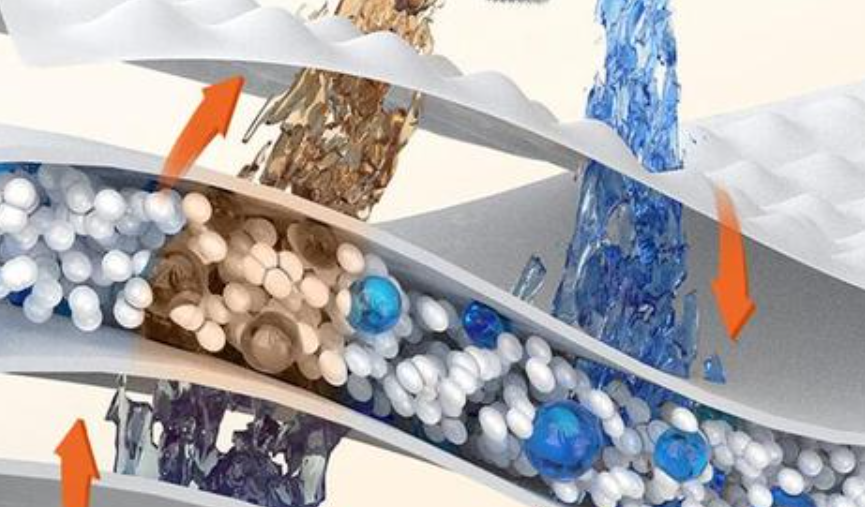

Key Ways Industrial Liquid Filters Work

- Direct Interception: This is for filtering out particles that are bigger than the filter’s pores.

- Inertial Impaction: This is a bigger factor with high flow or dense liquids. Particles can’t follow the liquid’s path and get stuck.

- Adsorption: This method targets tiny dissolved impurities like endotoxins. In my work, I see this is vital for pharmaceutical production.

Based on my experience, if you understand and document these details, you can make better choices. You can pick the right filter type, whether it’s a membrane, depth, or adsorptive filter. You can also set the best parameters for flow rate, pressure, and cleaning cycles. This will give you consistent, high-quality filtration.

Identify Filtration System Requirements

To choose the right industrial liquid filter, you must first know your system’s exact needs. In my experience, getting this step right affects filter performance and the long-run health of your process.

Essential System Parameters To Evaluate

Particle Size Range

You need to know the size of the smallest and largest particles you want to remove. Some filters can catch particles as small as 0.2 microns. Others can handle particles up to 1000 microns. For comparison, a sheet of copy paper is about 100 microns thick.

Required Filter Efficiency

You must choose between nominal (75–80% capture) and absolute filtration (≥99% removal). If your work demands that almost all contaminants are removed, like in pharmaceuticals or making ultrapure water, I always recommend absolute-rated filters.

Flow Rate Demands

Define the minimum and maximum flow rates for your process. I find that oversizing filters a little bit can handle flow surges. This helps prevent production shutdowns. For high-volume needs, I suggest using filter bags or cartridges with a large surface area to avoid clogs.

System Pressure Profile

Make sure your filters can handle the system’s maximum pressure. I advise choosing filters rated about one-third higher than your system’s peak. This accounts for pressure spikes and blockages.

Operating Temperature

Note the temperatures your system reaches. High temperatures can ruin filter materials. For hot processes, I suggest using stainless steel or high-temperature polymers. For instance, seals made from Teflon or Viton are effective well above the standard 38°C (100°F) in hydraulics.

Fluid Viscosity

Thicker liquids require larger filter surfaces or coarser micron ratings. This helps keep pressure drops low and prevents the filter from clogging too fast.

Chemical Compatibility Confirm that all Filter Media, gaskets, and O-rings can handle your liquid’s pH and chemicals. I have seen standard rubber fail quickly in strong acids. For work with corrosive liquids, I always use polypropylene or stainless steel housings.

Dirt Load (Contaminant Concentration)

If your fluid has a lot of solids, I recommend multi-stage filtration. You start with a coarse filter, then use a finer one. This approach helps filters last longer and keeps flow rates stable.

Process Type (Continuous vs. Batch)

For a continuous process, you need durable filters that last a long time. In batch operations, you should plan to change or clean filters after each cycle.

Filter Fit and Maintenance

The filter size, end cap type, and gasket style must match your housing. Problems with fit can lead to leaks, more maintenance work, or even let unfiltered liquid pass through.

Gathering all these requirements at the start helps you select a filter that works for your operation. It will run well and make maintenance predictable. This lets you avoid extra costs and surprises during your process.

How I Choose an Industrial Filter and Setup

To choose the right filter for your industrial process, I suggest matching its features to your daily operations and any regulations. Here are the main choices and things I consider:

Common Filter Types and Their Features

Nominal String Wound Filters

These are made with a core wrapped in polypropylene string. This structure provides depth filtration. I find they work best for removing larger particles from 5–50 microns. They are great for coarse filtering or for liquids with sticky, gel-like gunk.

Meltblown/Spunbonded Filters

These filters use extruded polypropylene fibers. They offer a mix of depth and surface filtering. They capture smaller particles than string wound filters. From my experience, they are excellent for pre-filtration, especially for water. They are useful for targeting particles in the 1–10 micron range.

Pleated Absolute Filters

These have layered, pleated polypropylene. This design gives you more surface area and less pressure drop. They offer up to 99.98% removal efficiency for specific particle sizes, down to 0.2 microns. I recommend these for final filtration steps that need very high purity.

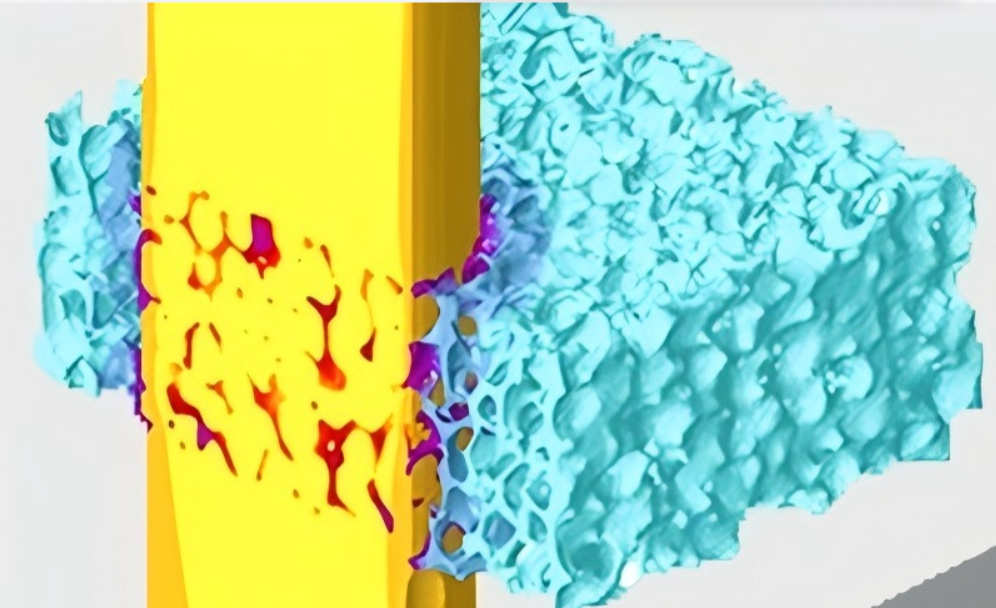

Membrane Filter Cartridges

These are built from pleated synthetic membranes like PES, nylon, or PVDF. I use them to get absolute filtration down to 0.01 microns. This removes the smallest contaminants, including endotoxins. They also keep flow rates high (e.g., >2.0 L/min at a 0.2 micron rating). I see them used often in processes for deionized water, wine, pharmaceuticals, and fermentation.

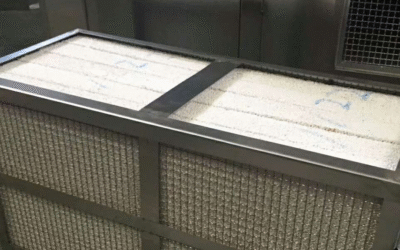

Bag Filters

These are made from woven or felted fabrics. I use them for high-flow, batch processing. You can get them in 1–200 micron ratings. I find them very effective for cutting down waste in batch operations.

Here’s a great benefit: They make 10–15 times less solid waste than cartridge filters. You can often reuse or recycle them.

Key Factors for Filter Setup

Filter Media Compatibility: I’ve learned Polyester media handles more chemicals than polypropylene. This is a key point if you filter harsh or corrosive liquids.

Pressure Drop: Pleated and membrane filters cause less pressure loss. This helps keep your flow rates high for longer periods.

Micron Rating & Dirt Holding Capacity: Pleated filters have a larger surface area. In my experience, this means they last longer and can hold more dirt.

Cost and Operation: For batch jobs, I find bag filters save money, above all if reducing waste is your goal. For continuous, high-volume work, Clean-in-place (CIP) systems can lower your labor costs and waste.

Regulatory Compliance: If you’re in food and beverage, your filters must meet FDA standards. For pharma jobs, you often need certification for <0.2 micron filtration and proof of cleanliness.

My final recommendation is this: Match the filter’s build, efficiency, and features to your industry’s needs. Also, consider your operational demands and regulations. This is how I ensure a filtration process performs well and is cost-effective.

Choosing Industrial Liquid Filters: A Practical and Regulatory Guide

From my experience, choosing the right industrial liquid filter means looking at both practical needs and rules. These factors guide your system’s performance and safety. They also make sure you follow industry and environmental rules.

Chemical Compatibility and Material Selection

- I always start by matching the filter material to the process chemicals.

- For most acids and alkalis, I find Polypropylene works well.

- For very acidic waste, like battery plant runoff (pH < 2), you will need special materials. I suggest PVDF or stainless steel in these cases.

- You need to know what’s in your liquid. Things like oils, greases, or solvents can damage parts or cut a filter’s life short.

- I often suggest pre-treatment, like an oil-water separator. This helps if oils could clog your filters or if solvents might degrade the filter materials.

Temperature and Environmental Conditions

Standard polypropylene systems are safe up to 80°C (176°F). If your process is hotter, I recommend using high-temperature polymers, better polypropylene, or all-metal filters. Think about where the filter will be. An indoor setup is different from an outdoor one. Harsh weather can reduce a filter’s life and impact safety.

Operational and Process Requirements

I need to know if your system runs all the time (continuous) or in cycles (batch). What are the highest and lowest flow rates you expect? Some of my clients at large plants need filters that handle tens to hundreds of cubic meters per hour. Your filters must be rated for your plant’s specific operating and design pressures.

The operating environment also matters. Will the filter be stationary, mobile, or exposed to harsh conditions?

Contaminant Load and Purity Demands

For large particles, I recommend using depth filters or bag filters. For fine particles and high-purity needs, like in pharma or food industries, I use membrane or pleated filters. In my experience with wastewater, the goal is often to remove 1–10 micron particles. For sterile processes, you need filters that can remove particles smaller than 0.2 microns.

Regulatory Compliance and Documentation

You must make sure all filters and materials meet current industry and environmental rules.

Pharmaceutical, food, and beverage plants usually need absolute-rated filters. These must have full certification and a clear supply history. For wastewater treatment, your system has to meet local standards for contaminants. I also check that your maintenance plan fits with compliance rules. Your replacement schedule should also align with your budget for operating costs.

A Checklist for Choosing Your Industrial Liquid Filter

From my experience, choosing the right filter is critical. I’ve created this step-by-step checklist to help you make the best choice for your process.

1. Know Your Goals and What ‘Clean’ Means to You

First, identify what you need to remove. Are they particles, suspended solids, bacteria, or colloids?

You need to decide between absolute filtration (which I recommend for purity, as it removes ≥99.99% of particles at a certain size) and nominal filtration (which is good for removing most larger particles).

Be clear about your final product’s quality. Does it need to be sterile, clear, or just free of particles?

2. Check Your Liquid and System’s Conditions

- Viscosity: For thick or viscous liquids, I suggest you select larger, stronger filters.

- Operating Temperature: Choose a filter material that can handle your system’s temperature range.

- Chemical Compatibility: Your filter material must handle your chemicals. In my work, I find PTFE and polypropylene work for many uses. For harsh acids or bases, I always suggest stainless steel.

- Flow Rate: Sizing is key. I suggest getting a filter a little larger than you need. This helps manage sudden increases in flow.

- System Pressure: Pick filters rated at least 33% higher than the highest pressure you expect.

- Dirt Load: If you have a lot of solids, my advice is to plan for multi-stage filtration. Start with a coarse filter and finish with a fine one.

- Process Mode: Think about your process type. Is it a batch process where you’ll change filters often? Or is it continuous, where the filter needs to last a long time?

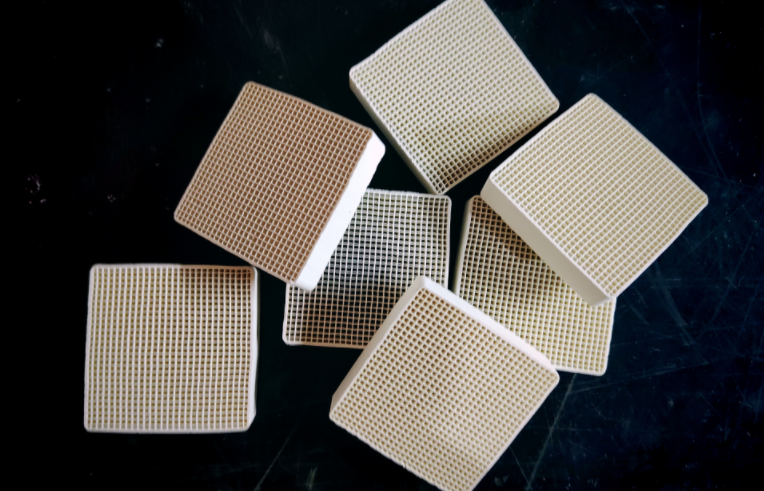

3. Pick the Right Filter Type and Material

You can use depth filters for high amounts of solids and suspended sediments. I’d choose screen or bag filters to remove large particles in jobs like mining. I recommend membrane filters for ultra-fine jobs, like in pharma or sterile settings. These usually filter down to 0.1 or 0.2 microns. You can add Activated Carbon or specialty media to remove chemicals through absorption.

Example: I’ve seen pharmaceutical plants depend on these tiny membrane filters to ensure product safety. In contrast, a mining operation I worked with used simple, tough bag filters to get rid of large grit.

4. Meet All Rules and Quality Standards

Check that your filters meet all necessary rules, such as those from the FDA, EPA, ISO, or your local government.

You have to be extra careful in regulated fields. I always double-check everything for food, beverage, pharma, and medical applications. Ask for paperwork and traceability for every part of the filter.

5. Check for Proper Fit and Installation

Make sure the filter size and housing will fit your system. I recommend checking all the key measurements yourself. Be sure you have enough space to remove old filters and install new ones. I suggest you plan for the future. Can you easily upgrade your system if your needs grow?

6. Final Checklist for Your Filter Choice

- Have you stated your filtration goals and target contaminant size?

- Do you know your liquid’s key properties, like viscosity, temperature, and chemicals?

- Have you written down your flow, pressure, and process mode needs?

- Is the filter type and material right for your needs?

- Did you calculate all operating and maintenance costs?

- Have you covered all compliance and paperwork needs?

- Will the filter fit your system? Is it flexible for future growth?

I designed this checklist so you can cover every important point before buying your filter. Following this will help you get the best performance, efficiency, and safety while meeting all rules.

Summary

Based on my experience helping clients with filtration, I’ve learned success comes from preparation and patience. I suggest you take time to study your process. Document your specific needs. Then, choose filters based on data, not assumptions.

In my opinion, this upfront work saves you from troubleshooting later. A good filter does more than remove contaminants. It also protects your entire system. This ensures you get steady, quality results for years.