Ever wonder why industrial filters are made from such a wide variety of materials? Choosing the right one is a critical decision that directly impacts your operational efficiency, production costs, and even safety protocols. Whether you’re considering cellulose, metal, or synthetic options, the choice goes far beyond just initial price or particle size rating. In fact, there is often one overlooked detail in material selection that can make or break a filter’s performance and ultimately affect your bottom line.

Understanding the Core Industrial Filter Materials

Selecting the ideal filter material depends entirely on its intended application and the specific performance you need. Each material has a unique profile of strengths and weaknesses, making it suitable for different industrial environments. Let’s explore the most common materials used in industrial filtration and what makes each one distinct.

Cellulose: The Economical, Natural Choice

Cellulose, derived from natural plant fibers, stands out as a highly cost-effective option for general-purpose filtration. It excels at capturing larger particles in applications where temperatures are moderate and the chemical environment is not aggressive. One of its significant advantages is that it’s biodegradable, which can be a factor in sustainability initiatives. However, its primary limitation is its vulnerability to chemical attack and breakdown, making it unsuitable for processes involving harsh solvents, acids, or bases.

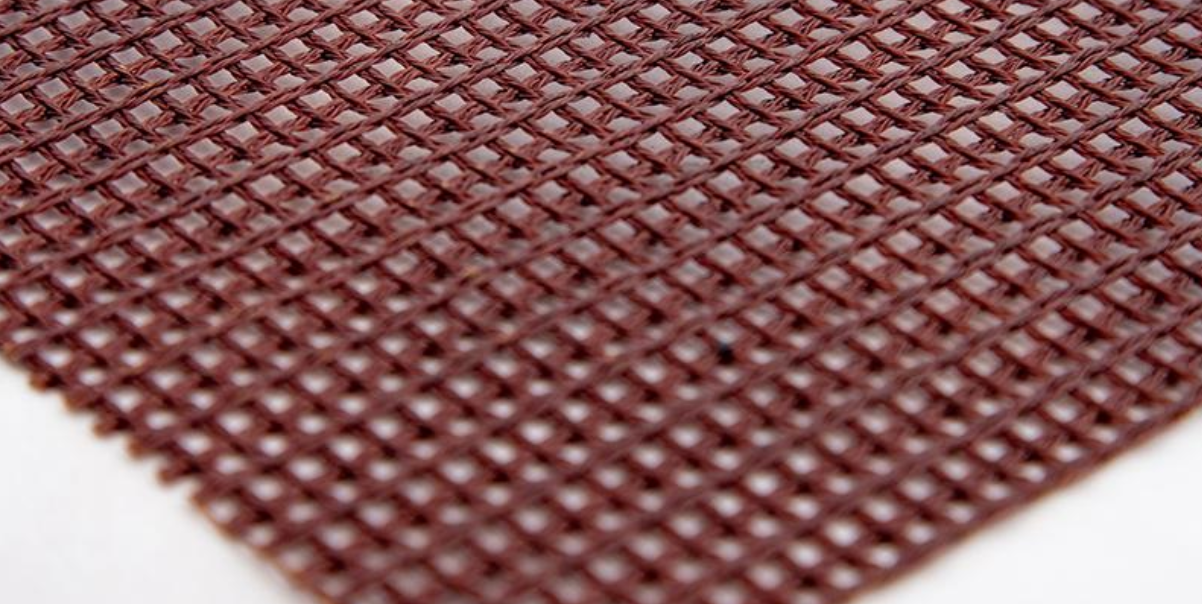

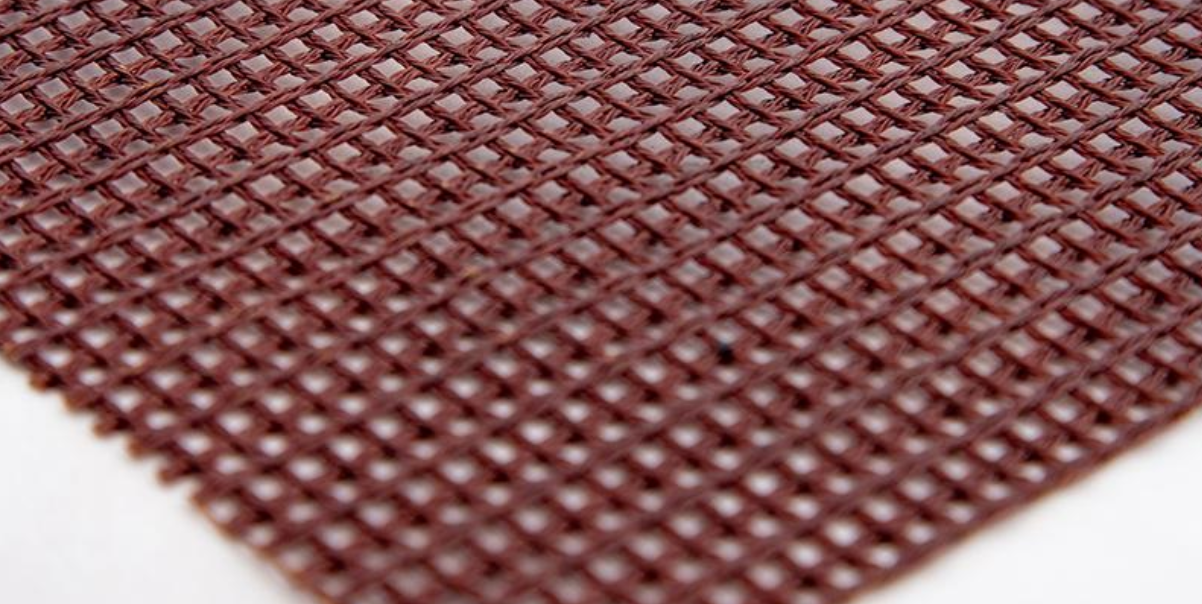

Synthetic Fibers: Versatility and Resilience

Synthetic fibers are engineered for superior performance and are known for their exceptional strength and chemical resistance across a broad range of temperatures. Polyester is a popular all-rounder, offering great durability at a reasonable cost. For applications involving strong acids or other harsh chemicals, polypropylene is often the go-to material due to its robust inertness. When you need to capture extremely fine particles, nylon provides excellent resistance to abrasion and wear, ensuring longevity in demanding filtration tasks. For the most extreme chemical environments, PTFE (Teflon) offers nearly universal chemical resistance, making it an essential choice in sensitive industries like pharmaceuticals and semiconductors, though it comes at a premium price.

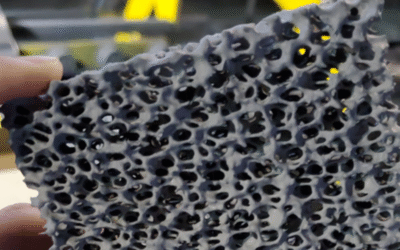

Activated Carbon: The Adsorption Specialist

Unlike materials that physically block particles, activated carbon works through adsorption. Its primary function is to trap odors, volatile organic compounds (VOCs), and other chemical contaminants from air and liquid streams. The material is treated to create an immense internal surface area covered in microscopic pores, making it incredibly effective at capturing molecular-level impurities. This is why activated carbon filters are indispensable for air purification systems, water treatment plants, and other processes where removing gaseous pollutants or dissolved contaminants is the main goal.

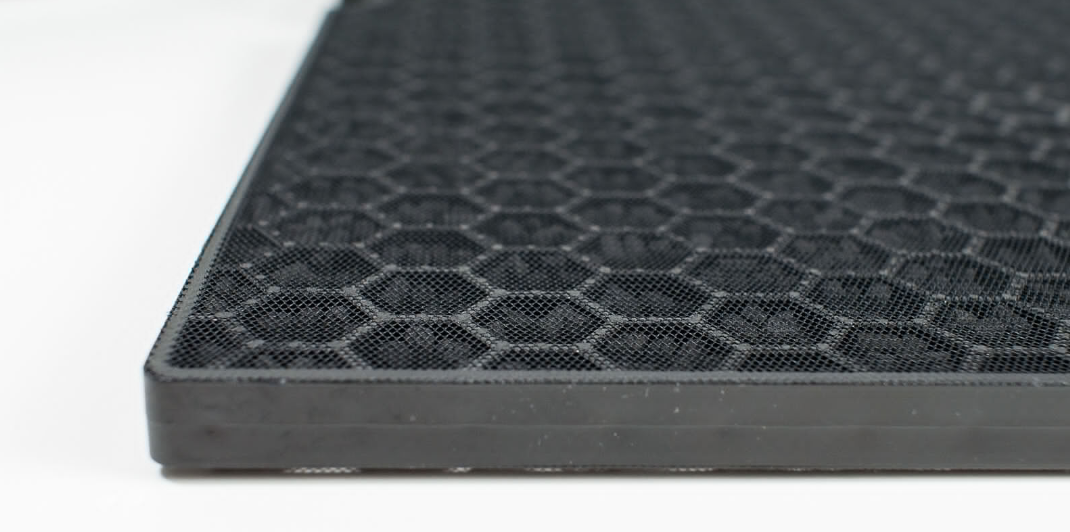

Metal: For Strength and High Temperatures

When durability, longevity, and high-temperature performance are paramount, metal filters are a leading choice. They can be cleaned and reused multiple times, offering a great long-term value. Stainless steel is widely used for its excellent corrosion resistance, making it a staple in food-grade applications and chemical processes where contamination must be avoided. Other metals like aluminum or copper are selected for specialized applications that might require specific chemical compatibility or electrical conductivity, providing tailored solutions for unique industrial challenges.

Fiberglass: Resisting Heat and Chemicals

Fiberglass is another excellent choice for high-heat environments and applications involving aggressive chemicals. These fiberglass filters are highly efficient at capturing very fine particles and are valued for their structural stability. Unlike some other materials, fiberglass maintains its shape and integrity even under the harsh conditions common in foundries, chemical plants, and power generation facilities, ensuring consistent and reliable filtration performance where other materials might fail.

Ceramic: Precision Under Extreme Conditions

Ceramic filters are designed for tasks requiring exceptional thermal resistance and highly precise filtration. They are capable of withstanding extreme temperatures while filtering out incredibly small particles, often at a sub-micron level. This capability makes them vital for specialized processes such as sterile water treatment, hot gas filtration, and the recovery of valuable catalysts in the chemical industry. Their rigidity and inertness ensure that they perform reliably in some of the most demanding industrial applications imaginable.

Making the Right Choice: Performance vs. Cost

Choosing an industrial filter material requires a careful balance between performance requirements and budget constraints. This balance is fundamental to designing an efficient and sustainable filtration system. Understanding how different material properties drive performance and influence both upfront and long-term costs is key to making a strategic decision.

To simplify the selection process, here’s a look at how these materials stack up against key performance indicators:

| Material | Key Strengths | Temperature Resistance | Chemical Resistance | Relative Cost |

|---|---|---|---|---|

| Cellulose | Low cost, biodegradable | Low | Poor | Low |

| Synthetics | Durable, versatile, good chemical resistance | Moderate to High | Good to Excellent | Low to Medium |

| Activated Carbon | Adsorbs odors and chemicals | Moderate | Good | Medium |

| Metals | Very durable, reusable, high heat tolerance | Very High | Good to Excellent | High |

| Fiberglass | High heat and chemical resistance | High | Very Good | Medium |

| Ceramic | Extreme heat resistance, precision filtration | Extremely High | Excellent | Very High |

The True Cost of a Filter: An Investment in Reliability

When budgets are tight, a cellulose filter can seem like an attractive choice due to its low initial price. However, this simple, low-cost option has clear weaknesses, often failing when exposed to the harsh chemicals common in industrial settings. This is why more robust materials like metal or ceramic filters, despite their higher upfront cost, can save companies from expensive shutdowns. For example, stainless steel filters can easily handle steamy, corrosive environments, while ceramic filters are tough enough for white-hot furnace fumes. Analysis shows that a majority of maintenance teams now opt for these stronger materials, prioritizing long-term reliability over short-term savings. That extra expense is not just a cost—it’s an insurance policy against catastrophic failure.

Why Chemical Compatibility is Non-Negotiable

The filter material you choose must withstand the fluids and fumes it encounters. If the material breaks down or starts shedding its own particles, you get more than just poor filtration—you get product contamination, expensive shutdowns, and a cascade of operational problems. In fact, an estimated 65% of filter failures could have been prevented if proper attention was paid to chemical compatibility from the start. This single factor is arguably the most important consideration for ensuring the safety and integrity of your entire process.

Matching Filtration Efficiency to Your Goal

You must consider the size of the particles you need to catch. Materials like nylon or ceramic are engineered for much finer filtration than standard cellulose. Capturing microscopic dust—particles you can’t even see—is a significant challenge where the right material choice changes everything. The goal is to select a filter that acts as the perfect shield for your specific process, protecting downstream equipment and ensuring final product quality. Choosing a filter with inadequate efficiency can lead to product defects, equipment damage, and wasted resources.

Summary

Picking the right industrial filter material is a major decision that extends far beyond a simple technical choice; it is a strategic investment in the reliability and efficiency of your future operations. By taking the time to thoroughly understand your specific operational needs—from chemical exposure and temperature extremes to efficiency targets and maintenance cycles—you can select a material that not only works, but elevates your system’s performance beyond expectations.